When you’re sourcing natural stone for Arizona projects, you’ll quickly discover that material selection makes or breaks long-term performance. The extreme desert climate—with temperature swings exceeding 40°F in a single day and relentless UV exposure—demands stone that can handle thermal cycling without spalling or fading. Citadel Stone specializes in Arizona-proven materials that deliver the durability your specifications require, backed by warehouse inventory that keeps projects on schedule.

You need a stone yard Arizona professionals trust for consistent quality and technical support. Here’s what actually matters when you’re specifying materials for this challenging environment.

Material Performance in Arizona Climate

Arizona’s desert conditions create performance challenges most stone suppliers don’t adequately address. You’re dealing with summer surface temperatures that routinely hit 150-160°F on dark pavers, combined with winter freezes in northern regions. Citadel Stone’s product selection focuses on low-porosity materials that resist the thermal stress inherent to these extremes.

The key factor here is thermal expansion coefficient. Natural stone expands approximately 0.0000044 to 0.0000072 inches per inch per degree Fahrenheit, depending on mineral composition. For a 10-foot bluestone slab experiencing a 100°F temperature swing, you’re looking at nearly 3/16 inch of movement. Your joint spacing needs to accommodate this reality, or you’ll see edge spalling within the first seasonal cycle.

- Citadel Stone bluestone from Pennsylvania quarries exhibits compressive strength exceeding 19,000 PSI, making it suitable for vehicular applications

- White limestone options reflect 60-70% of solar radiation, reducing surface temperatures by 15-20°F compared to darker materials

- River stone selections demonstrate interconnected pore structures below 3% water absorption, critical for freeze-thaw resistance in Flagstaff elevations

- Thermal finish options on Citadel products provide slip resistance ratings above DCOF 0.60 for pool deck applications

Don’t assume that generic stone specifications translate directly to Arizona performance. The state’s combination of intense UV degradation and minimal moisture creates unique weathering patterns that accelerate surface deterioration in certain materials. Citadel Stone’s Arizona-focused inventory accounts for these regional demands.

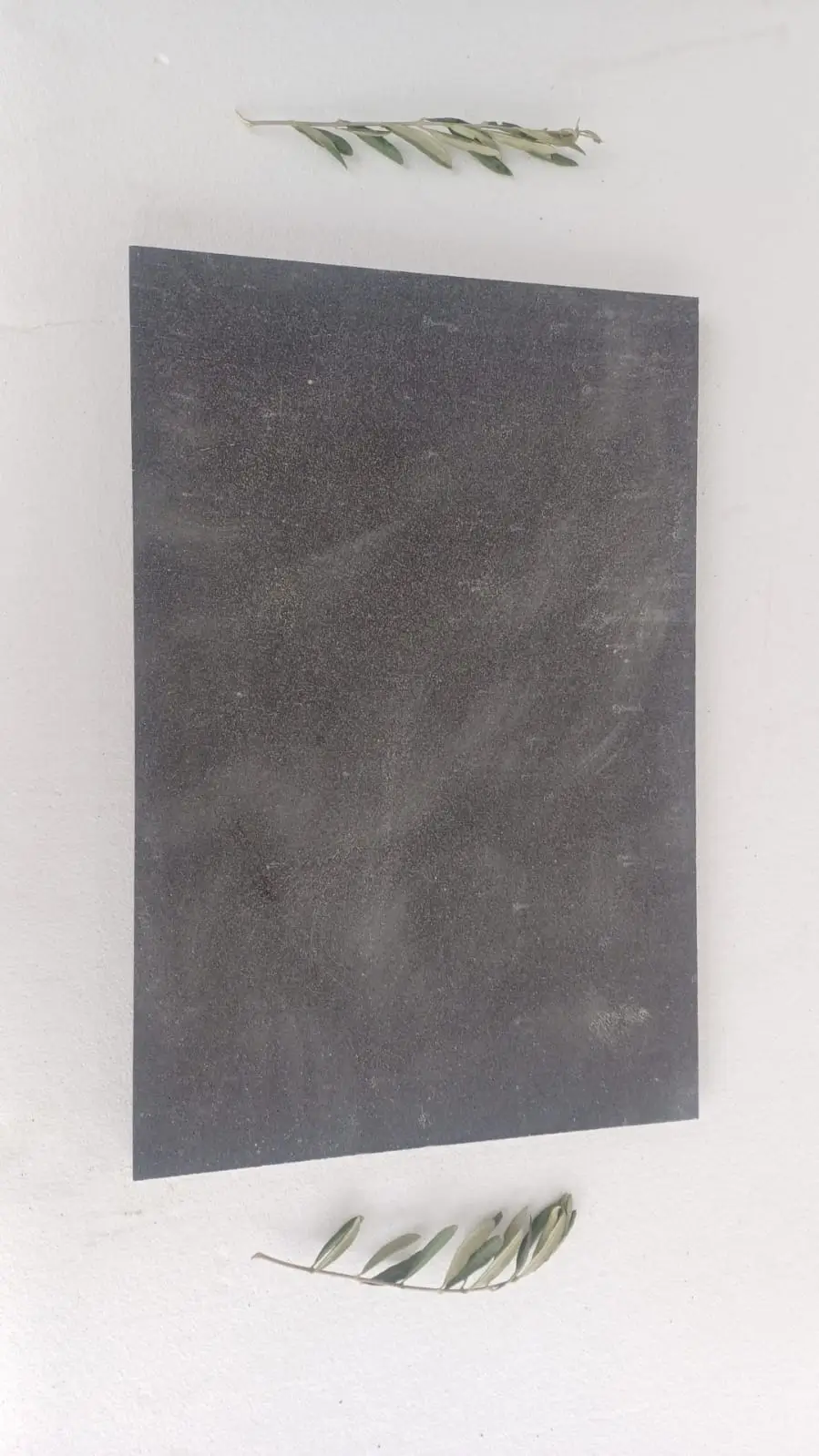

Selecting Stone Yard Pavers for Arizona Projects

When you’re specifying stone yard pavers in Arizona, thermal mass becomes a critical consideration most specifiers overlook. Dark granite or basalt pavers can retain heat well into evening hours, creating uncomfortable outdoor spaces that defeat the purpose of the installation. You’ll want to balance aesthetic preferences with functional thermal performance based on the project’s actual use patterns.

Citadel Stone’s paver inventory includes materials specifically suited to Arizona’s demands. Bluestone pavers offer superior dimensional stability compared to sandstone alternatives, with thickness tolerances typically within 1/8 inch across production runs. This consistency matters when you’re installing large format pavers—anything over 24 inches square—where lippage becomes visually problematic with even minor thickness variations.

Your base preparation requirements escalate in Arizona’s expansive clay soils. Standard 6-inch compacted aggregate bases work for pedestrian applications, but you need 8-10 inches minimum for vehicular loads, with geotextile separation layers to prevent clay migration. Citadel’s technical team can walk you through proper substrate specifications that prevent the premature settling issues common in Phoenix-area installations.

Edge detail selection affects both aesthetics and structural performance. Bullnose edges reduce chip risk during handling and installation, while thermal or natural cleft edges provide more slip resistance. For commercial pool decks, you’ll typically specify a thermal finish with eased edges—this combination delivers DCOF values above 0.60 while minimizing sharp edges that create liability concerns.

Bluestone Stone Yard Applications in the Desert Southwest

Bluestone stone yard in Arizona projects benefit from the material’s exceptional hardness and low porosity. Genuine Pennsylvania bluestone—which Citadel Stone imports directly from quarries—contains dense feldspar and quartz crystals that resist abrasion far better than the sedimentary sandstones common to southwestern landscapes. You’re looking at a Mohs hardness of 6-7, compared to 3-4 for most sandstones.

The color stability factor matters more in Arizona than most regions. Bluestone’s iron content can oxidize over time, but the dense crystalline structure limits this color shift to subtle warming rather than the dramatic fading you’ll see with porous materials. In full desert sun exposure, properly sealed Citadel Stone bluestone maintains color integrity for 8-12 years before requiring attention, versus 3-5 years for lesser-quality alternatives.

- Thickness specifications of 1.5-2 inches work for residential pedestrian applications with proper base preparation

- Increase to 2.5-3 inches for driveways and commercial vehicular loads exceeding 6,000 pounds

- Joint spacing of 3/8 to 1/2 inch accommodates thermal expansion in Arizona temperature ranges

- Polymeric sand jointing materials must be UV-stabilized formulations rated for desert environments

Watch for suppliers who misrepresent Chinese bluestone as Pennsylvania material—the performance difference is substantial. Pennsylvania bluestone from Citadel’s sources demonstrates water absorption rates below 1.5%, while imported alternatives often exceed 4%, making them unsuitable for freeze-thaw zones in northern Arizona.

River Stone Considerations for Arizona Landscapes

River stone yard materials serve multiple functions in Arizona projects, from decorative groundcover to erosion control in desert xeriscaping. You’ll find that river stone from Citadel Stone inventory includes size ranges from 1-inch cobbles to 8-inch boulders, with rounded profiles that create visual interest while facilitating water drainage during monsoon events.

The reality is that river stone selection affects long-term maintenance more than initial aesthetics suggest. Rounded river stones shift under foot traffic far more than angular crushed materials, making them poor choices for walking paths or high-traffic areas. You’ll want to specify them for decorative beds, dry stream installations, or low-traffic landscape accent zones where their natural appearance enhances the design intent.

For erosion control applications, river stone functions best in the 3-6 inch diameter range. Smaller materials migrate during heavy rain events, while oversized stones create voids that allow soil washout underneath. Citadel Stone can provide gradation analysis that ensures proper sizing for your specific slope and drainage conditions. For comprehensive guidance on related paving options, see Citadel Stone paver materials yard for comparison data across material types.

Don’t overlook the heat retention characteristics of river stone in Arizona installations. Dark basalt river stones can reach surface temperatures exceeding 170°F in direct summer sun, making them uncomfortable for areas adjacent to pools or patios. Lighter-colored quartzite river stones reflect more solar radiation and maintain temperatures 20-30°F cooler—a factor worth considering in your material specifications.

White Stone for Solar Reflectivity and Heat Management

White stone yard Arizona specifications increasingly focus on solar reflectivity as property owners seek to reduce heat island effects. Citadel Stone’s white limestone and marble options can reflect 60-75% of incident solar radiation, compared to 15-25% for dark granite or basalt. This translates to surface temperature differences of 30-40°F during peak afternoon hours—a dramatic improvement in outdoor comfort.

You need to understand the trade-offs with white stone materials. While thermal performance excels, white limestone typically exhibits higher porosity than denser bluestone or granite. Water absorption rates of 3-5% are common, which means you’re looking at more frequent sealing intervals—typically annual applications in Arizona’s intense UV environment. Citadel’s sealers formulated for desert conditions extend this to 18-24 months with proper application.

Hardness considerations matter for white stone applications. Marble delivers stunning aesthetics but rates only 3-4 on the Mohs scale, making it susceptible to scratching and etching. You’ll want to reserve marble for vertical applications or low-traffic decorative installations. For functional paving, Citadel Stone’s dense white limestone options provide better durability while maintaining the light color benefits.

- White travertine offers natural slip resistance with its porous surface texture, suitable for pool decks without additional finishing

- Polished white marble requires honed or flamed finishes to achieve DCOF values above 0.50 for exterior use

- White limestone pavers need UV-stable sealers reapplied every 12-18 months to prevent surface degradation from Arizona sun exposure

- Light-colored stones reduce ambient temperatures in outdoor living spaces by 8-12°F compared to dark materials

Arizona Rock and Indigenous Material Considerations

Arizona rock materials sourced from local quarries offer certain logistical advantages, but you’ll find that performance characteristics often fall short of imported alternatives from Citadel Stone’s national network. Indigenous flagstone and sandstone exhibit the warm earth tones clients often request, yet their high porosity—frequently 6-8% water absorption—creates durability concerns in freeze-thaw applications above 5,000 feet elevation.

The thing is, local Arizona rock often demonstrates inconsistent dimensional tolerances. Flagstone thickness can vary 1/2 inch or more within a single pallet, complicating installation and creating lippage issues that require extensive grinding. Citadel Stone’s curated selections maintain tighter tolerances—typically within 1/4 inch—because we source from quarries with modern processing capabilities rather than small-scale operations with limited equipment.

Transportation costs favor local materials, but that advantage disappears when you factor in replacement expenses for premature failures. A local sandstone patio that spalls after three winters costs far more in total lifecycle expense than properly specified bluestone from Citadel’s inventory that performs for decades. Your client conversations should emphasize long-term value rather than initial material savings.

Indigenous materials work well for specific applications where their characteristics align with performance requirements. Arizona flagstone excels in vertical veneer installations where freeze-thaw isn’t a concern, and its natural color variations complement southwestern architecture. Citadel Stone can provide both imported and regional materials, allowing you to specify the right product for each application rather than forcing regional materials into unsuitable roles.

Warehouse Inventory and Project Lead Times

Truck delivery schedules often become the constraint that delays Arizona stone projects, especially during peak construction seasons from October through April. Citadel Stone maintains regional warehouse stock specifically to address this bottleneck. You can typically secure material delivery within 5-7 business days for standard products, versus 3-6 weeks when sourcing directly from distant quarries.

Project phasing requires coordination between material availability and installation schedules. When you’re specifying Citadel Stone products for large commercial projects, you’ll want to confirm warehouse quantities early in the design process. For quantities exceeding 10,000 square feet, lead times extend to 2-3 weeks as materials are consolidated from multiple quarry sources to ensure consistent color and texture across the installation.

The reality of stone specification is that color variation exists within every natural material. Citadel Stone’s warehouse staff can provide photos of current inventory lots, allowing you to specify actual material rather than relying solely on small samples that may not represent the full range of variation. This preview capability prevents the costly surprises that occur when large quantities arrive on site looking substantially different than the architect’s approved sample.

Stone Yard Masonry Considerations for Arizona

Stone yard masonry in Arizona demands attention to mortar formulation and joint design that accounts for thermal expansion. You’re dealing with thermal differentials between stone and mortar that create stress at the interface, especially with full-bed mortar applications. Citadel Stone recommends Type S mortar with latex modifiers for improved flexibility, along with 3/8-inch minimum joint widths to accommodate movement.

Vertical stone veneer installations require proper anchoring systems that allow independent movement between the stone facing and backup wall. Rigid attachments transfer thermal stress into the stone, creating fracture risks at anchor points. You’ll want to specify adjustable tie systems that permit 1/8 inch of movement while maintaining structural connection—these systems cost 15-20% more than rigid ties but eliminate the callback issues that destroy project profitability.

- Weep holes at 32-inch horizontal spacing ensure drainage behind stone veneer, preventing efflorescence and freeze damage

- Flashing installation at all horizontal ledges protects structural elements from water infiltration during monsoon events

- Joint sealant specifications must include products rated for 50% joint movement and continuous UV exposure in Arizona conditions

- Citadel Stone thin veneer products in the 1-1.5 inch thickness range reduce structural loading compared to full-thickness materials

Don’t specify stone masonry without addressing efflorescence potential. Arizona’s water contains high mineral content that migrates through porous stone and mortar, depositing white crystalline deposits on surfaces. Using low-alkali mortars and applying penetrating sealers to Citadel Stone materials before grouting substantially reduces this common defect.

Common Stone Yard Arizona Specification Mistakes

Most specification errors stem from copying boilerplate language without adapting to Arizona’s unique conditions. Generic stone specs that work in temperate climates fail here because they don’t address thermal cycling or UV degradation. You need Arizona-specific language that references appropriate ASTM standards and includes regional performance criteria.

One critical factor that often surprises less experienced specifiers is the interaction between stone selection and irrigation systems. Reclaimed water—common in Arizona landscapes—contains elevated salt levels that accelerate surface deterioration on certain stone types. Citadel Stone materials with absorption rates below 2% resist this degradation, while porous sandstones show visible damage within 2-3 years of reclaimed water exposure.

Under-specifying base preparation remains the most expensive mistake in stone yard Arizona projects. You’ll see settlement issues within the first year when bases don’t account for expansive soils or lack proper compaction. Citadel’s installation guidelines specify 95% modified Proctor density for aggregate bases—this isn’t optional, it’s the minimum standard that prevents callbacks.

- Failing to specify thermal expansion joints at 15-20 foot intervals in large paver installations leads to buckling and edge damage

- Omitting UV-stable sealers from specifications results in accelerated color fading and surface degradation in Arizona sun

- Inadequate substrate drainage specifications cause efflorescence and premature mortar joint failure

- Specifying polished finishes for exterior horizontal surfaces creates dangerous slip conditions when wet

Watch for the tendency to prioritize aesthetics over performance. That stunning polished white marble looks incredible in samples, but you’ll be explaining its rapid deterioration to an unhappy client within 18 months if you specify it for Arizona patio paving. Citadel Stone’s product specialists can guide you toward materials that deliver both visual impact and long-term durability appropriate to the specific application and exposure.

Rock and Stone Yard Material Comparison Criteria

When you’re evaluating rock and stone yard in Arizona suppliers, product quality varies dramatically based on quarry sources and processing standards. Citadel Stone’s advantage comes from direct quarry relationships that ensure consistent grading and quality control. You’re not getting third-hand materials that have passed through multiple distributors, each taking their markup while adding handling damage.

The comparison factors that actually matter extend beyond price per square foot. You need to evaluate total installed cost, which includes waste factors, installation labor efficiency, and expected service life. A cheaper sandstone that requires replacement in 5-7 years costs far more in lifecycle terms than properly specified Citadel Stone bluestone that performs for 25-30 years with minimal maintenance.

Technical support capabilities separate professional stone yards from commodity material suppliers. Citadel Stone provides specification assistance, installation best practices documentation, and field support that prevents the costly errors common with inexperienced suppliers. When you’re working with materials that represent 30-40% of total hardscape budgets, this expertise directly impacts project profitability.

Citadel Stone Arizona: Proven Material Performance in Southwestern Conditions

After years of Arizona project experience, you’ll recognize that certain material selections consistently outperform alternatives in this climate. Citadel Stone has refined inventory based on actual field performance data rather than theoretical specifications. The products we stock for Arizona markets have demonstrated durability in completed installations, not just laboratory testing.

Our Pennsylvania bluestone inventory specifically addresses the thermal cycling challenges inherent to desert installations. These materials have performed successfully in Phoenix projects where summer hardscape temperatures routinely exceed 150°F, followed by winter nights that occasionally drop below freezing in elevated areas. The dense crystalline structure resists the thermal stress that causes spalling in lesser materials.

Citadel Stone’s warehouse logistics ensure that Arizona contractors can maintain project schedules without the extended lead times that plague competitors relying on just-in-time delivery from distant quarries. When you’re coordinating installations around Arizona’s weather windows—avoiding both extreme summer heat and winter cold snaps—material availability becomes as important as material quality. We maintain inventory depth that supports projects from single residential patios to multi-acre commercial hardscape developments.

Citadel Stone Yard Arizona: How We’d Specify Stone Yard Materials Across Arizona Cities

When specifying stone yard Arizona materials for projects throughout the state, Citadel Stone products offer proven performance in the diverse climate zones from Yuma’s low desert to Flagstaff’s high elevation forests. This hypothetical guidance demonstrates how we’d approach material selection for different Arizona municipalities, accounting for their unique environmental conditions and typical project requirements. Our expertise in Arizona applications comes from years of supporting installations across the state with materials specifically suited to southwestern demands.

Phoenix Applications

For Phoenix projects, you’d want Citadel Stone bluestone pavers in thermal finishes that maintain slip resistance despite the region’s intense heat and occasional monsoon downpours. The metropolitan area’s alkaline soils and reclaimed irrigation water would call for low-porosity materials—our Pennsylvania bluestone with absorption rates below 1.5% would resist the efflorescence and salt damage common to lesser materials. In typical residential pool deck installations, you’d specify 2-inch thick pavers with 1/2-inch joints filled with UV-stable polymeric sand, accounting for the 100°F+ temperature swings between day and night during summer months. Commercial plaza applications in downtown Phoenix would benefit from Citadel’s white limestone options, reducing surface temperatures by 30-40°F compared to dark granite while delivering the thermal mass that extends evening use of outdoor spaces.

Tucson Considerations

Tucson’s slightly higher elevation and biseasonal rainfall pattern would influence your Citadel Stone material specifications toward enhanced drainage capabilities. You’d likely recommend our river stone selections in 3-5 inch diameters for erosion control in desert landscaping, combined with bluestone steppers for pedestrian circulation through xeriscape installations. The city’s commitment to water conservation and native landscaping makes Citadel’s natural cleft flagstone ideal for patio applications that complement Sonoran Desert aesthetics. In typical foothill residential projects, you’d specify permeable paver systems using our 2.5-inch thick bluestone with 3/8-inch aggregate-filled joints, allowing monsoon runoff infiltration while providing stable vehicular surfaces for driveways that see daily thermal cycling exceeding 80°F from morning to afternoon.

Scottsdale Specifications

High-end Scottsdale projects would call for premium Citadel Stone selections that balance luxury aesthetics with desert performance. You’d specify our white limestone pavers for resort-style pool decks and outdoor living areas, knowing that the material’s solar reflectivity keeps surfaces comfortable even in June heat while the UV-stable sealers we recommend prevent the rapid deterioration that destroys lesser limestone products. Typical specifications for Scottsdale desert contemporary architecture would include Citadel’s honed bluestone in large format 24×36-inch slabs, creating the clean minimalist lines clients expect while delivering compressive strength above 19,000 PSI for vehicular porte-cochère applications. Stone yard masonry veneers using our 1.5-inch thin-cut materials would provide the substantial appearance luxury clients demand while reducing structural loading and installation costs compared to full-thickness applications.

Flagstaff Requirements

Flagstaff’s 7,000-foot elevation and genuine four-season climate would shift your Citadel Stone specifications toward freeze-thaw resistance as the primary performance criterion. You’d recommend our Pennsylvania bluestone exclusively for this market, as its sub-1% absorption rate and dense crystalline structure handles the 100+ annual freeze-thaw cycles without the spalling that destroys porous sandstones within 3-5 winters. Typical mountain residence applications would specify 2.5-3 inch thick Citadel bluestone pavers for entry courts and walkways, with thermal finishes providing slip resistance when wet or snow-covered. The proper installation approach would include 8-10 inch compacted aggregate bases to prevent frost heave, along with 1/2-inch expansion joints at 12-15 foot intervals to accommodate the seasonal ground movement common to high-elevation sites.

Sedona Projects

Sedona’s red rock landscape would guide your Citadel Stone selections toward materials that complement rather than compete with the dramatic natural surroundings. You’d likely specify our natural cleft bluestone in warm gray tones for residential patios and pathways, as the material’s subtle coloration provides visual contrast against red sandstone geology while maintaining the organic character clients expect in this setting. Stone yard Arizona river stone in earth tones would work well for dry stream beds and decorative landscape features that echo the area’s natural arroyos. For commercial hospitality projects, you’d recommend Citadel’s thermal bluestone pavers in areas surrounding pools and spas, knowing the material handles both the freeze potential of 4,500-foot elevation winters and the intense summer sun that draws visitors year-round.

Mesa Installations

Mesa’s suburban residential market would benefit from Citadel Stone products that deliver long-term value without premium pricing. You’d typically specify our bluestone pavers in standard rectangular formats for backyard patio installations, with 1.5-2 inch thicknesses providing adequate performance for pedestrian use at price points residential clients can accommodate. The city’s expansive clay soils would require your specifications to emphasize proper base preparation—you’d call for geotextile fabric separation layers beneath 6-8 inch compacted aggregate bases to prevent the substrate migration that causes premature settling in Mesa neighborhoods. For driveway applications, Citadel’s 3-inch thick bluestone pavers would handle residential vehicle loads while maintaining the natural stone aesthetics that increase property values in established Mesa communities. Additional installation insights for related applications can be found through Natural stone fabrication and installation services for residential projects before finalizing your specifications. Citadel Stone stocks authentic bluestone stone yard in Arizona selections imported directly from Pennsylvania quarries.

Realistic Performance Expectations

Setting accurate client expectations prevents the disappointment that damages professional reputations. You need to explain that natural stone weathers and develops patina over time—this isn’t defective performance, it’s the material behaving as natural stone should. Citadel Stone products will show some color evolution, particularly in the first 12-24 months of exposure as surface minerals oxidize and stabilize.

The maintenance requirements for stone vary substantially based on material selection and application. You’ll need to communicate that sealed stone requires resealing every 18-36 months in Arizona conditions, while unsealed materials may develop surface staining that becomes permanent. Citadel Stone provides maintenance guidelines specific to each product, giving you documentation that sets appropriate expectations from project outset.

Your professional role includes educating clients about the performance trade-offs inherent in material selection. That gorgeous white marble delivers stunning initial aesthetics but demands higher maintenance and accepts more wear than denser alternatives. When you explain these realities upfront using Citadel Stone’s technical specifications as supporting evidence, clients make informed decisions rather than experiencing buyer’s remorse.