When you’re selecting stone veneer suppliers in Arizona for your next architectural project, you’ll quickly discover that material performance varies dramatically based on climate adaptation and product sourcing. Citadel Stone specializes in natural stone veneer solutions engineered for Arizona’s extreme thermal conditions, offering stone veneer suppliers Arizona architects and builders trust for commercial facades and high-end residential applications. You’ll need suppliers who understand how desert heat cycles, UV exposure, and minimal precipitation affect veneer adhesion systems and long-term substrate performance.

Arizona’s construction environment demands more than standard stone veneer products. You’re dealing with summer surface temperatures exceeding 160°F on south-facing walls, daily temperature swings of 40-50°F, and winter freeze events in elevated regions like Flagstaff. Citadel Stone’s veneer stone suppliers in Arizona inventory includes materials proven to handle these extremes without delamination or efflorescence issues that plague inferior products within the first 18 months.

Material Selection Criteria for Stone Veneer Suppliers in Arizona

Your veneer specification starts with understanding absorption rates and thermal expansion coefficients. Citadel Stone’s natural stone veneer suppliers in Arizona stock materials with absorption rates below 0.5%, critical for preventing moisture-related failures in Arizona’s monsoon season. You’ll want to verify compressive strength exceeds 8,000 PSI for commercial applications, particularly on high-rise projects where wind loads and seismic factors come into play.

Here’s what you need to evaluate when comparing stone veneer dealers in Arizona:

- Water absorption percentage affects freeze-thaw durability in northern Arizona elevations and monsoon performance statewide

- Thermal expansion coefficient determines joint spacing requirements for large facade areas exposed to direct solar gain

- Substrate compatibility with common Arizona construction materials including concrete masonry units, metal stud framing, and EIFS systems

- UV stability and color retention over 10-15 year exposure cycles under intense desert sunlight

- Attachment system compatibility with both mechanical anchoring and thin-set mortar applications

- Thickness consistency across production runs to maintain uniform reveal lines and shadow patterns on contemporary facades

The reality is that most thin stone veneer suppliers in Arizona import materials without regional performance testing. Citadel Stone maintains documentation on thermal cycling, salt spray resistance, and adhesion testing specific to Arizona installation conditions. You’ll find this data essential when responding to architect requests for product data sheets and when defending specifications during value engineering.

Installation Considerations with Natural Thin Stone Veneer Suppliers in Arizona

Your installation approach needs to account for Arizona’s extreme substrate temperatures during application. When surface temperatures exceed 110°F, standard thin-set mortars lose workability within 15-20 minutes, and you’ll face adhesion failures within the first year. Citadel Stone technical teams recommend modified polymer mortars specifically formulated for hot-weather applications, with extended open times that maintain bond strength even when applied to substrates at 130°F.

Pay particular attention to these installation variables:

- Application timing should avoid midday heat during June through August when substrate temperatures peak

- Joint spacing requirements increase by approximately 30% compared to temperate climate installations due to thermal expansion

- Mechanical anchoring becomes mandatory for veneer installations above 30 feet in elevation where wind loads exceed 25 PSF

- Weep screeds and drainage planes require careful detailing to handle concentrated monsoon rainfall events that can deliver 2-3 inches in under an hour

- Substrate preparation standards must address Arizona’s prevalent stucco and EIFS existing wall assemblies when retrofitting older buildings

Don’t overlook the impact of Arizona’s low humidity on mortar curing. You’re working in conditions where relative humidity frequently drops below 15%, causing rapid moisture loss from thin-set applications. For comprehensive material performance data, review our stone veneer materials to understand how Citadel Stone products maintain adhesion under these challenging conditions. Proper curing protocols require misting installations twice daily for the first 72 hours, adding labor costs that contractors unfamiliar with desert construction often underestimate.

Regional Climate Factors Affecting Stone Veneer Performance

Arizona’s climate zones create dramatically different performance requirements across the state. You’ll specify differently for Phoenix projects at 1,100 feet elevation versus Flagstaff installations at 7,000 feet where winter freeze-thaw cycles become the dominant failure mechanism. Citadel Stone’s cladding stone suppliers in Arizona maintain inventory appropriate for both environments, understanding that one-size-fits-all specifications lead to premature failures.

Desert Heat Considerations

Southern Arizona’s sustained high temperatures create thermal stress that causes differential movement between veneer and substrate. When you’re working on projects in Phoenix, Tucson, or Yuma, you’ll need expansion joints every 12-15 feet horizontally and at every floor line vertically for buildings exceeding two stories. Stone cladding suppliers in Arizona sometimes recommend tighter spacing, but field experience shows this interval prevents the stress concentration that leads to corner cracking and bond line failures.

Surface temperatures on dark-colored stone veneer can reach 180°F during peak summer months. This thermal load causes dimensional changes that weaker attachment systems can’t accommodate. Citadel Stone’s mechanical anchoring solutions allow for controlled movement while maintaining structural integrity, unlike rigid adhesive-only systems that fracture under thermal stress.

Monsoon Moisture Management

Arizona’s monsoon season delivers intense rainfall between July and September, creating moisture management challenges that differ significantly from conventional rain screen applications. You’re dealing with wind-driven rain that can penetrate improperly detailed joints and weep systems. Citadel Stone installation protocols include continuous drainage planes with minimum 3/8-inch air gaps behind veneer, sized to handle the concentrated water volumes Arizona storms produce.

Watch for these moisture-related issues specific to Arizona construction:

- Efflorescence appears more aggressively due to rapid evaporation rates pulling salts to the surface during drying cycles

- Substrate moisture content requires verification before veneer application since Arizona’s dry air can mask underlying moisture issues

- Flashing integration with parapet walls and roof terminations needs careful attention where sudden storms overwhelm inadequate drainage capacity

- Salt deposits from dust storms can accumulate at horizontal surfaces and penetrate stone porosity if absorption rates exceed 0.5%

Sourcing and Availability Through Stone Veneer Manufacturers in Arizona

When you’re planning project timelines, you need to understand that natural stone veneer suppliers in Arizona typically maintain limited local inventory due to warehouse space costs and the capital requirements of stocking diverse material profiles. Citadel Stone operates differently, keeping substantial stock of proven performers for Arizona applications in our warehouse facilities, reducing lead times from the industry standard of 8-12 weeks down to 2-3 weeks for most specifications.

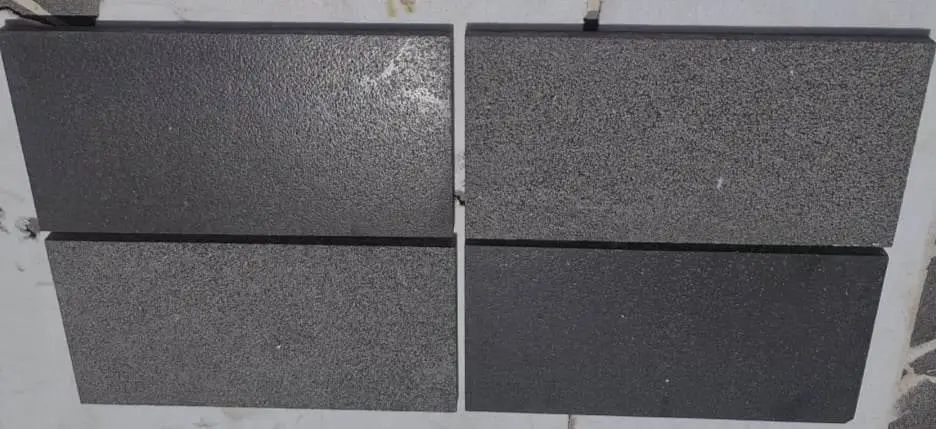

The sourcing challenge becomes critical when you’re specifying natural materials with inherent color variation. You’ll want to review full-range samples representing the expected variation rather than single pieces that don’t reflect production reality. Citadel Stone provides large-format sample boards showing the complete color range within each stone type, preventing the specification surprises that occur when contractors install material that technically meets spec but visually disappoints the design team.

Lead Time Planning

Your procurement schedule needs to account for quarry production cycles and international shipping when specifying imported stone veneer. Domestic materials generally ship within 4-6 weeks, while European limestone and Asian granite products require 10-14 weeks from order to delivery. Plan accordingly when bidding projects with compressed schedules, and verify Citadel Stone warehouse stock levels before committing to aggressive timelines in your proposals.

Truck delivery logistics matter more than most specifiers realize. Arizona job sites often have access restrictions, particularly in established urban areas with narrow streets or gated communities with weight limits. Confirm delivery vehicle requirements during preconstruction planning to avoid the delays and additional costs associated with transloading materials to smaller trucks at off-site locations.

Cost Factors and Value Engineering

You’ll encounter significant price variation among stone veneer suppliers Arizona contractors typically use, with costs ranging from $8-$15 per square foot for basic natural thin stone veneer to $25-$40 per square foot for premium materials with custom fabrication. Citadel Stone pricing reflects the quality differential that comes from rigorous material selection and Arizona-specific performance testing, positioning our products in the $12-$28 range depending on stone type and thickness specifications.

The upfront cost difference becomes less significant when you factor in lifecycle performance. Inferior veneer products that fail within 5-7 years due to delamination or thermal stress create replacement costs exceeding $35-$50 per square foot when you account for removal, substrate repair, and reinstallation. You’re better served specifying proven materials from the start rather than facing warranty claims and client dissatisfaction down the road.

Consider these cost variables during specification development:

- Material thickness affects both unit pricing and installation labor, with full-bed applications requiring 40-50% more mortar than thin-set methods

- Custom color matching or selection from specific quarry blocks adds 25-35% to base material costs but may be necessary for historic preservation or high-visibility projects

- Mechanical anchoring systems increase installed cost by $4-$7 per square foot but provide essential performance for applications above 30 feet

- Sealer application adds $1.50-$2.50 per square foot but extends service life and reduces maintenance requirements in Arizona’s harsh environment

- Corner pieces and trim components typically cost 2-3 times the field stone rate due to fabrication complexity

Common Specification Mistakes to Avoid

Most specification problems with veneer stone suppliers in Arizona stem from adapting standard details developed for temperate climates without accounting for desert conditions. You can’t simply reference generic stone veneer installation standards and expect Arizona-appropriate performance. Citadel Stone has documented the failures that occur when specifiers overlook regional factors, and these issues appear repeatedly across projects.

Here’s what goes wrong when specifications don’t address Arizona-specific requirements:

- Inadequate expansion joint spacing causes corner cracking and bond line failures within 18-24 months as thermal cycling stresses accumulate

- Standard mortar specifications without hot-weather admixtures lead to adhesion failures when application occurs during summer months

- Insufficient drainage plane depth results in moisture accumulation during monsoon season, causing efflorescence and potential freeze damage in elevated locations

- Omitting UV stability requirements allows color fading that becomes visually apparent within 3-5 years on south and west-facing installations

- Failure to specify substrate temperature limits for application permits installation during conditions that compromise bond strength

- Underspecified base preparation on retrofit applications where existing wall assemblies have inadequate structural capacity for stone veneer loads

The most expensive mistake involves selecting stone veneer dealers in Arizona based solely on initial pricing without verifying material performance documentation. You’ll find that cheap veneer often comes from suppliers who can’t provide absorption testing, compressive strength data, or thermal cycling results. When problems appear 18 months into a project’s service life, you’re facing liability issues that far exceed any initial cost savings.

Technical Support and Documentation

Your specification needs backing from suppliers who provide engineering support beyond basic product data sheets. Citadel Stone maintains technical staff with Arizona-specific installation experience who can review project details and identify potential performance issues during the design phase. You’ll need this level of support when responding to architect RFIs, addressing contractor questions, or defending specifications during plan review.

Verify that your selected natural thin stone veneer suppliers in Arizona can provide:

- ASTM C1780 compliance documentation for thin veneer products including adhesion testing per ASTM C482

- Thermal cycling test results showing performance through 50 freeze-thaw cycles without deterioration

- Water absorption data per ASTM C97 demonstrating absorption rates appropriate for intended applications

- Load testing results for mechanical anchoring systems under simulated wind loads

- Installation details adapted for Arizona climate conditions rather than generic manufacturer recommendations

- Sample project references with verified Arizona installations exceeding 5 years in service

Substrate Compatibility Issues

Arizona construction uses substrate materials that create unique compatibility challenges for stone veneer applications. You’re frequently working with concrete masonry units, metal stud framing with exterior gypsum sheathing, and existing stucco assemblies on retrofit projects. Each substrate type requires different attachment approaches and preparation standards that generic stone veneer specifications often overlook.

When specifying over CMU construction, you’ll need to address the dimensional variation inherent in concrete block. Standard tolerance of ±1/4 inch in 10 feet creates an irregular surface that requires either furring to establish a plane or thick-bed mortar application that increases material costs and adds structural load. Citadel Stone’s stone cladding suppliers in Arizona inventory includes thickness-calibrated materials that minimize the mortar bed depth required to achieve acceptable finished tolerances.

Metal Stud Considerations

Light-gauge metal framing assemblies require careful load calculation since stone veneer adds 12-15 PSF to the wall assembly. Your structural engineer needs to verify that stud spacing, gauge, and deflection characteristics can support the additional load without exceeding L/360 deflection limits. Mechanical anchoring becomes essential on metal stud assemblies, with fasteners penetrating through sheathing into studs at maximum 16-inch spacing vertically and 24-inch spacing horizontally.

The reality is that many metal stud buildings in Arizona weren’t originally designed for stone veneer retrofit applications. You’ll need structural evaluation before specifying veneer on existing buildings, and you may discover that stud reinforcement or supplemental framing becomes necessary. Budget for these conditions when pricing retrofit projects rather than assuming existing assemblies have adequate capacity.

Citadel Stone—Premier Stone Veneer Suppliers Across Arizona: Regional Specification Guidance

Citadel Stone serves as the trusted source for natural stone veneer suppliers in Arizona, offering regionally adapted materials and technical expertise for projects across diverse climate zones. This section provides hypothetical specification guidance demonstrating how Citadel Stone would approach veneer selection and installation planning for major Arizona markets. The recommendations reflect our understanding of regional conditions, typical architectural requirements, and the performance characteristics of our stone veneer product lines.

Phoenix Commercial Applications

For Phoenix commercial facades, you’d specify Citadel Stone’s low-absorption limestone veneer with mechanical anchoring for projects exceeding three stories. The valley’s extreme heat and intense UV exposure require materials with proven thermal stability and color retention. Citadel would recommend joint spacing at 12-foot intervals with compressible backing rod and polyurethane sealant rated for ±50% movement. Installation scheduling would target October through April to avoid summer substrate temperatures that compromise adhesion, with evening and early morning work windows during unavoidable summer applications. You’d want to verify substrate preparation includes continuous drainage plane with minimum 3/8-inch air gap to manage occasional but intense monsoon events.

Tucson Desert Climate Adaptation

Tucson’s slightly higher elevation and marginally cooler temperatures still demand heat-resistant stone veneer specifications similar to Phoenix requirements. Citadel Stone would provide materials with absorption rates below 0.4% to handle the concentrated rainfall during monsoon season while maintaining thermal performance through summer months exceeding 110°F. You’d specify light-colored stone selections to minimize solar heat gain on south and west exposures, reducing surface temperatures by 20-30°F compared to darker materials. Citadel’s technical team would recommend breathable sealers rather than film-forming products to allow moisture vapor transmission while providing stain resistance for the dust accumulation common in Tucson’s desert environment.

Scottsdale Luxury Residential Standards

Scottsdale’s high-end residential market demands aesthetic excellence alongside performance, requiring Citadel Stone’s premium stone veneer selections with consistent color and tight dimensional tolerances. You’d specify full-range sample review to ensure the natural variation meets client expectations before material procurement. Citadel would recommend mechanical anchoring even on two-story applications to provide the long-term stability luxury homeowners expect, avoiding the adhesion concerns that can develop with thin-set-only installations. Custom corner fabrication and specialty trim pieces would come from Citadel’s warehouse inventory, maintaining the design integrity that Scottsdale projects require. Installation details would emphasize clean weep screed integration and precise joint tooling to achieve the refined appearance these projects demand.

Flagstaff Freeze-Thaw Performance

Flagstaff’s elevation creates freeze-thaw conditions requiring different material selection than southern Arizona projects. Citadel Stone would specify dense, low-porosity stone with documented performance through 50+ freeze-thaw cycles per ASTM C666. You’d need expansion joints at closer spacing—approximately 10-foot intervals—to accommodate the greater thermal range between winter lows and summer highs at 7,000-foot elevation. Citadel’s technical guidance would emphasize robust flashing and drainage details since Flagstaff receives snow accumulation and spring melt conditions absent in desert locations. Mechanical anchoring becomes essential given the structural loads from ice damming and the increased wind exposure at higher elevations. Material selection would prioritize quartzite and granite options from Citadel’s inventory rather than limestone products better suited to warmer regions.

Sedona Aesthetic Integration

Sedona’s distinctive red rock landscape creates aesthetic requirements where stone veneer must complement or contrast thoughtfully with the natural environment. Citadel Stone would guide material selection toward warm earth tones or deliberate contrast colors that respect the visual context. You’d want materials with UV stability verified through accelerated weathering testing since Sedona’s high-altitude sunlight intensity exceeds Phoenix levels despite cooler temperatures. Installation approaches would need to address the sloped terrain and challenging site access common in Sedona’s canyon locations, requiring careful truck delivery planning and potential material staging at off-site locations before final transport to installation areas. Citadel’s experience with custom residential projects would inform recommendations for mechanical anchoring patterns and joint detailing that maintain design intent while providing structural performance.

Yuma Extreme Temperature Conditions

Yuma represents Arizona’s most extreme heat environment, with summer temperatures regularly exceeding 115°F and surface temperatures on south-facing stone veneer reaching 180-190°F. Citadel Stone would specify materials proven in desert testing facilities with thermal cycling through temperature ranges exceeding normal ASTM protocols. You’d need expansion joints at maximum 10-foot spacing and potentially supplemental mechanical anchoring even on single-story applications due to the severe thermal stress. Light-colored stone selection becomes critical to maintain surface temperatures within manageable ranges, and Citadel would recommend avoiding dark granite or slate products entirely. Installation scheduling would be restricted to November through March since summer conditions make proper mortar curing nearly impossible. Citadel’s technical support would emphasize substrate temperature monitoring and application timing to avoid the adhesion failures common when installers attempt summer veneer work in Yuma’s extreme environment.

Final Considerations

Selecting stone veneer suppliers in Arizona requires understanding how extreme climate conditions affect material performance and installation requirements. You’ll need suppliers like Citadel Stone who maintain Arizona-adapted inventory, provide technical support beyond basic product data sheets, and understand the regional factors that cause inferior products to fail within the first few years of service. Don’t compromise on material quality or supplier expertise to achieve minor cost savings that evaporate when premature failures require expensive remediation.

Your successful veneer specification balances aesthetic requirements with performance realities, accounting for thermal expansion, moisture management, and substrate compatibility in ways that generic manufacturer details don’t address. Citadel Stone’s experience with Arizona installations provides the regional knowledge base you need when responding to design challenges and contractor questions throughout project execution. For additional insights on complementary materials, review Natural stone pavers for residential and commercial outdoor spaces before finalizing comprehensive hardscape and facade specifications. Exterior facades trust Citadel Stone, the most architectural stone veneer suppliers Arizona commercial projects.