When you’re specifying Stone Steps & Treads in Arizona, you’re dealing with one of the most demanding environments in North America. Desert heat, intense UV exposure, and extreme daily temperature swings create conditions that test every aspect of natural stone performance. Citadel Stone products are engineered to meet these challenges, but you’ll need to understand how material selection, thermal behavior, and installation details interact in Arizona’s climate.

The key issue isn’t just aesthetics—it’s long-term structural integrity. You’ll want stone treads that resist thermal shock, maintain slip resistance when dust settles on surfaces, and won’t spall under rapid temperature changes. Citadel Stone’s inventory includes multiple options for Stone Steps & Treads in Arizona projects, each with distinct performance characteristics worth understanding before you finalize specifications.

Thermal Performance in Arizona Climate

Arizona’s surface temperatures regularly exceed 140°F on exposed stone during summer afternoons. That’s not air temperature—that’s the actual material surface temperature your clients will contact. Citadel Stone’s limestone and sandstone treads exhibit thermal expansion coefficients around 0.0000044 inches per inch per degree Fahrenheit, which translates to measurable movement in larger installations.

Here’s what that means for your project: a 48-inch tread can expand nearly 1/4 inch when surface temperature swings from 70°F morning conditions to 140°F afternoon heat. You’ll need expansion joints at regular intervals, and you can’t rely on mortar alone to accommodate this movement. Citadel Stone recommends flexible sealants in joints wider than 3/8 inch for exterior Arizona applications.

- Light-colored limestone from Citadel Stone reflects 60-70% of solar radiation, keeping surface temperatures 15-25°F cooler than darker materials

- Thermal mass properties help moderate temperature swings, but you’ll still need proper joint spacing every 15-20 feet

- Rapid cooling after sunset can create thermal shock—Citadel Stone products with lower porosity handle this stress better

- UV stability matters more than most specifiers realize; some stones fade noticeably within 18 months of Arizona exposure

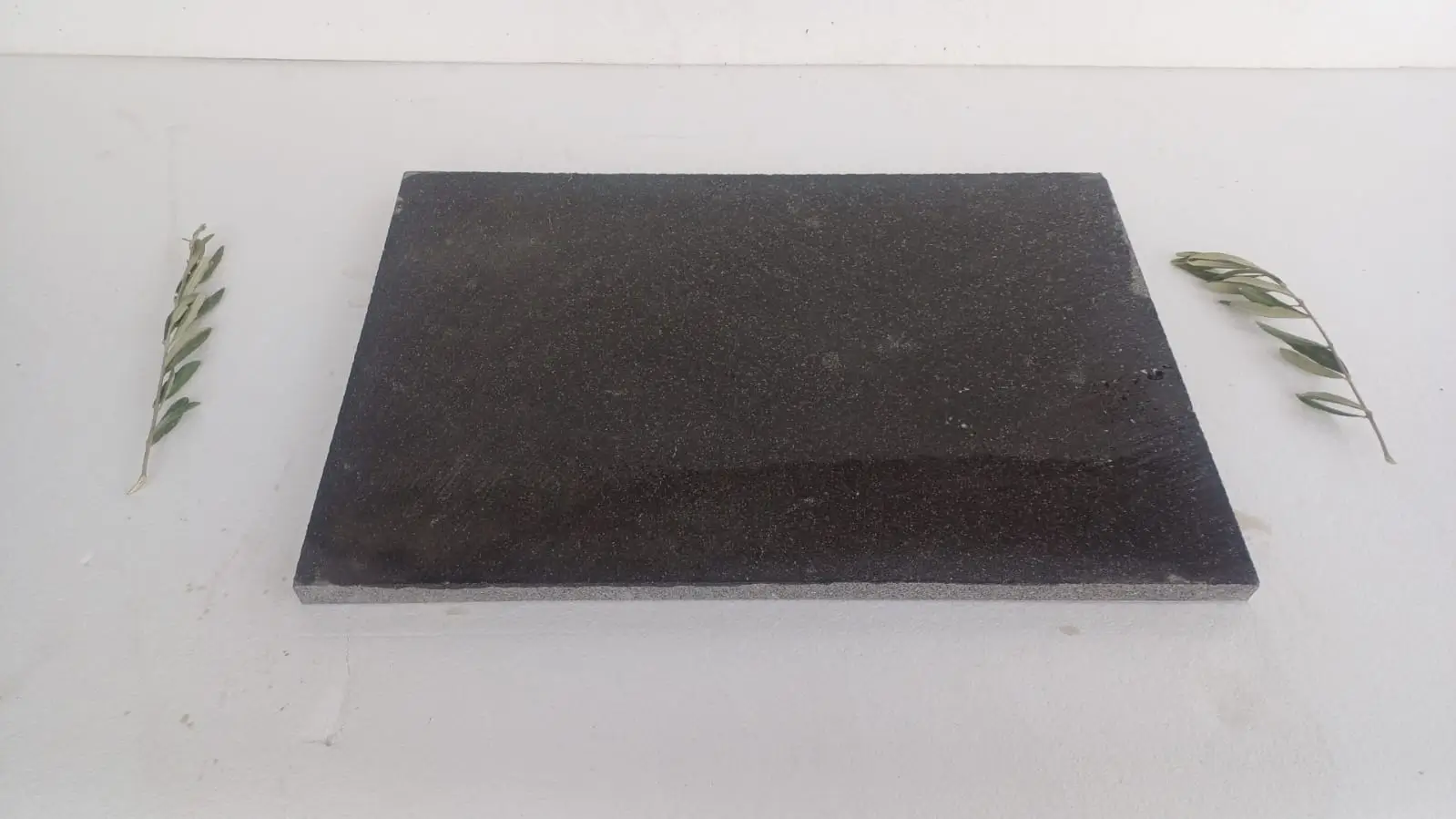

Material Selection Criteria

You’re choosing between several stone types when specifying Stone Steps & Treads in Arizona, and the decision affects maintenance requirements for years. Citadel Stone’s limestone treads offer excellent workability and consistent color, but you’ll need to account for slightly higher porosity compared to granite or quartzite alternatives.

The porosity factor directly impacts water absorption, which matters even in Arizona’s dry climate. Monsoon season brings intense rainfall that can saturate stone rapidly, and if you’ve specified material with interconnected pore structures exceeding 3% absorption by weight, you’re risking freeze damage in higher elevations like Flagstaff. Citadel Stone tests all tread materials to ASTM C97 standards, giving you reliable absorption data.

- Compressive strength should exceed 8,000 PSI for commercial applications—Citadel Stone limestone typically ranges 9,000-12,000 PSI

- Abrasion resistance becomes critical in high-traffic areas; thermal finish provides better traction than honed surfaces

- Edge durability matters for our stone tread materials with bullnose profiles, where chipping can occur during installation or impact

- Color consistency across multiple shipments requires attention to quarry block selection—request samples from Citadel Stone warehouse inventory

Slip Resistance Specifications

Arizona dust settles on everything, and when monsoon rains hit, that dust creates a slippery film on smooth stone surfaces. You need to specify finishes that maintain traction under these conditions. Citadel Stone’s thermal-finished treads achieve DCOF (Dynamic Coefficient of Friction) values above 0.60 when tested per ASTM C1028, meeting ADA requirements and most building codes.

Don’t make the mistake of specifying polished or honed finishes for exterior treads in Arizona. The combination of dust, occasional moisture, and high foot traffic creates liability issues. Citadel Stone’s flamed and thermal finishes provide the texture necessary for safety without sacrificing the premium appearance your clients expect. You’ll find these finishes also hide minor surface scratches better than smooth options.

Finish Options and Performance

The surface finish you specify determines both initial slip resistance and long-term maintenance requirements. Citadel Stone offers multiple finish options for Stone Steps & Treads in Arizona installations, each with distinct characteristics. Thermal finishes create a textured surface through flame treatment, exposing the crystalline structure while maintaining relatively smooth feel underfoot.

- Flamed finishes work well for limestone and granite, providing DCOF values of 0.65-0.75 in dry conditions

- Natural cleft surfaces on sandstone offer inherent texture but can show more variation between pieces

- Brushed finishes provide moderate texture with easier cleaning compared to heavily textured options

- Avoid sandblasted finishes in Arizona—they trap dust and require frequent power washing to maintain appearance

Installation and Substrate Requirements

Your Stone Steps & Treads in Arizona installations will only perform as well as the substrate preparation allows. Citadel Stone products require a stable, well-compacted base that won’t settle under load or shift with thermal cycling. For exterior applications, you’ll want a minimum 6-inch compacted aggregate base, increasing to 8 inches where soil conditions include expansive clays common in Phoenix and Tucson areas.

The mortar bed thickness matters more than most installers realize. You need a minimum 1-inch mortar bed for treads under 2 inches thick, increasing to 1.5 inches for thicker treads. Citadel Stone recommends polymer-modified mortar for Arizona applications—standard portland cement mortars don’t provide sufficient flexibility for thermal movement. Don’t let your installer skimp on this specification; premature cracking typically traces back to inadequate mortar beds.

- Substrate must slope away from structures at minimum 2% grade to ensure proper drainage during monsoons

- Reinforcement with welded wire mesh in the mortar bed prevents cracking on treads exceeding 36 inches in width

- Allow mortar to cure minimum 72 hours before exposing Citadel Stone treads to foot traffic—Arizona heat accelerates curing but don’t rush it

- Truck access to installation sites needs verification during planning; Citadel Stone treads can weigh 150-200 pounds per piece

Edge Detail Considerations

The edge profile you specify affects both aesthetics and durability. Citadel Stone’s bullnose stone steps suppliers in Arizona can provide various edge treatments, but not all profiles perform equally in desert conditions. Full bullnose edges (180-degree radius) provide the most durable option, distributing impact forces across a larger surface area compared to sharp 90-degree edges.

Sharp edges chip easily during installation and use, particularly on limestone and sandstone. You’ll see this damage most commonly at tread nosings where foot traffic concentrates. Citadel Stone fabricates bullnose edges with radii ranging from 1/2 inch to full bullnose, and the choice affects both cost and performance. A 1-inch radius provides good durability at moderate cost, while full bullnose adds approximately 15-20% to material pricing.

Structural Considerations for Edge Profiles

Edge profiles affect more than appearance—they influence how loads transfer through the material. Citadel Stone engineers recognize that concentrated loads near edges can cause fractures in stone with natural bedding planes. When you’re detailing Stone Steps & Treads in Arizona for commercial applications, you need to consider how edge profiles interact with material structure.

- Limestone steps suppliers in Arizona typically recommend minimum 1.5-inch thickness for bullnose treads in commercial settings

- Sandstone with prominent bedding planes requires careful orientation during fabrication to prevent delamination at edges

- Granite allows for thinner profiles due to higher tensile strength, but Citadel Stone still recommends 1.25-inch minimum for durability

- Custom edge profiles require extended lead times—verify Citadel Stone warehouse stock for standard profiles to meet tight schedules

Maintenance and Sealing Protocols

Arizona’s environment demands proactive maintenance approaches. You can’t treat Stone Steps & Treads in Arizona the same way you’d specify for humid climates. Citadel Stone products benefit from penetrating sealers that protect against staining without creating surface films that can trap moisture or degrade under UV exposure.

The sealing schedule depends on stone porosity and traffic levels. High-traffic commercial installations using Citadel Stone limestone treads typically need resealing annually, while residential applications might extend to 18-24 months between treatments. Don’t specify topical sealers for Arizona exteriors—they’ll peel and discolor within 6-12 months under intense UV exposure. Penetrating sealers like fluoropolymer-based products provide better long-term performance.

- Test sealers on sample pieces before full application; some react poorly with specific stone mineralogy in Citadel Stone materials

- Cleaning requires pH-neutral products—alkaline cleaners can etch limestone and cause permanent dulling

- Power washing should use maximum 1,200 PSI pressure to avoid surface erosion on softer stones

- Efflorescence appears more commonly during monsoon season; you’ll need specific cleaning protocols for calcium carbonate deposits

Common Specification Mistakes

You’ll avoid costly change orders by understanding where most specifiers go wrong with Stone Steps & Treads in Arizona. The biggest mistake involves underestimating thermal movement and specifying insufficient joint spacing. Citadel Stone has seen numerous projects require remedial work because expansion joints were omitted or placed too far apart.

Another frequent error is specifying consistent tread thickness without accounting for natural stone variation. Citadel Stone products typically show thickness variation of ±1/8 inch on nominal dimensions, and you need to detail how installers will address this during setting. Shimming might be necessary, or you can specify oversized mortar beds to accommodate variation.

- Don’t specify sealers in purchase orders for Citadel Stone treads—they’re best applied after installation and initial curing

- Avoid setting treads directly on concrete without a mortar bed; differential thermal expansion will cause cracking

- Never specify rigid grout in joints between treads; you need flexible materials that accommodate movement

- Don’t assume all Citadel Stone products have identical installation requirements—verify specifications for each material type

Cost vs Performance Analysis

When you’re balancing budgets against performance requirements, Stone Steps & Treads in Arizona present interesting trade-offs. Citadel Stone’s premium materials cost more upfront but deliver superior longevity in harsh desert conditions. The question isn’t just initial material cost—it’s lifecycle cost including maintenance, replacement, and liability considerations.

Lower-cost alternatives often show premature deterioration in Arizona’s climate. You’ll see spalling, color fading, and surface erosion within 3-5 years on inferior materials, while properly specified Citadel Stone products maintain appearance and performance for decades. The cost difference typically amounts to 15-30% on initial material pricing, but replacement costs can exceed 200% of original installation when you factor in demolition and disposal.

Citadel Stone Steps & Treads in Arizona — Regional Specification Guide

Understanding how Citadel Stone would approach projects across Arizona helps you make informed material selections. This guide provides hypothetical specifications based on regional climate variations, typical project types, and local building practices. Citadel Stone’s experience with Stone Steps & Treads in Arizona encompasses diverse applications from desert resort installations to mountain residential projects.

The recommendations reflect Arizona’s climatic diversity, from low desert heat in Yuma to high-elevation freeze-thaw cycles in Flagstaff. Each location presents distinct challenges that affect material selection, installation details, and maintenance protocols for Citadel Stone products.

Phoenix Specification Approach

Phoenix’s extreme heat and minimal freeze exposure would drive Citadel Stone to recommend lighter-colored limestone treads with thermal finishes for most applications. You’d want to prioritize UV stability and thermal mass properties, specifying joint spacing every 15 feet maximum to accommodate expansion. Citadel Stone’s warehouse stock in lighter tones would suit commercial plaza installations where heat reflection benefits pedestrians. The typical specification would include 2-inch nominal thickness for commercial traffic, with bullnose edges on all exposed nosings. Monsoon drainage becomes critical—Citadel would detail positive drainage away from structures with minimum 2.5% slope on all horizontal surfaces.

Tucson Material Selection

Tucson’s slightly cooler temperatures and higher elevation would allow Citadel Stone to consider a broader material palette including medium-toned sandstones. You’d still need thermal finish for slip resistance, but color fade concerns diminish slightly compared to Phoenix installations. Citadel Stone would recommend verifying water absorption rates carefully for any material specified, targeting maximum 2.5% absorption to handle occasional heavy monsoons. Installation details would emphasize proper substrate preparation given Tucson’s expansive soil conditions in many areas. Citadel’s approach would include polymer-modified setting beds and flexible joint sealants throughout.

Scottsdale Premium Applications

Scottsdale’s upscale residential and resort market would see Citadel Stone recommending premium limestone steps suppliers in Arizona inventory with custom edge details and specialized finishes. You’d specify tighter thickness tolerances and select blocks for color consistency across entire projects. Citadel Stone would likely suggest full bullnose edges with hand-finished details for high-end applications, accepting the 20-25% cost premium for superior aesthetics. The typical Scottsdale specification from Citadel would include annual maintenance programs, professional sealing applications, and detailed cleaning protocols to maintain appearance standards. Design coordination with landscape architects would ensure proper integration of stone treads with surrounding hardscape materials.

Flagstaff Freeze-Thaw Concerns

Flagstaff’s elevation brings freeze-thaw cycles that don’t affect lower Arizona locations. Citadel Stone would recommend only materials with water absorption below 1.5% for Flagstaff applications, favoring denser limestones or considering granite alternatives for critical installations. You’d need to verify that all Citadel Stone treads meet ASTM C1026 requirements for freeze-thaw durability. Installation specifications would emphasize complete mortar coverage to prevent water accumulation beneath treads. Citadel’s warehouse would stock appropriate materials tested specifically for freeze-thaw performance, understanding that standard desert-climate recommendations don’t translate to Flagstaff conditions. Joint sealing becomes even more critical to prevent water infiltration during winter months.

Sedona Aesthetic Integration

Sedona’s red rock landscape creates unique aesthetic expectations that would influence Citadel Stone’s material recommendations. You’d likely specify warm-toned sandstones or select limestone with iron oxide content to complement natural surroundings. Citadel Stone would emphasize natural cleft or thermal finishes that echo the texture of native rock formations. The challenge involves balancing aesthetic integration with performance requirements—some visually appropriate materials require more maintenance than alternatives. Citadel’s approach would include detailed discussions with design teams about acceptable trade-offs between appearance and durability. Tourist-oriented commercial applications would need extra attention to slip resistance given high foot traffic and visitor unfamiliarity with site conditions.

Yuma Extreme Heat Specifications

Yuma represents Arizona’s most extreme desert conditions, with summer temperatures consistently exceeding Phoenix levels. Citadel Stone would recommend the lightest available limestone treads to minimize heat absorption, potentially suggesting supplemental shade structures for south-facing installations. You’d want maximum joint flexibility given extreme thermal cycling, with Citadel specifying polyurethane-based sealants rated for continuous exposure above 150°F. Material selection from Citadel Stone’s inventory would prioritize UV stability above most other factors—color fade becomes visible faster in Yuma’s intense sunlight. Installation timing matters significantly; Citadel would recommend scheduling major tread installations during October through March to avoid summer heat that complicates mortar curing and material handling. Truck deliveries during summer months require special consideration for driver safety and material protection during transport.

Final Specification Guidance

Professional specification of Stone Steps & Treads in Arizona requires understanding how material properties, climate factors, and installation details interact over project lifetimes. Citadel Stone products deliver reliable performance when you match material characteristics to application requirements and detail installations appropriately. The key lies in recognizing that Arizona’s environment isn’t uniform—specifications appropriate for Phoenix won’t necessarily work in Flagstaff.

Your most critical decisions involve material selection, edge details, and joint spacing. Don’t let budget pressures push you toward inadequate specifications—the cost of premature failure far exceeds the savings from cheaper materials. Citadel Stone maintains warehouse inventory across multiple stone types specifically to give specifiers options that balance cost against performance. For comprehensive information about complementary materials, review Premium natural stone coping solutions for Arizona pool installations before finalizing project specifications. Exterior stairway construction trusts Citadel Stone, the most reliable Stone Steps & Treads Arizona outdoor access.