When you’re sourcing natural stone for Arizona projects, you’ll quickly discover that working with a stone slab yard in Arizona offers advantages that go far beyond simple material availability. Citadel Stone’s extensive inventory includes bluestone, limestone, granite, and marble slabs sized for everything from residential pool decks to commercial plaza installations. The selection process requires more than browsing—you need to understand how Arizona’s extreme heat cycles, UV exposure, and occasional freeze-thaw events in higher elevations affect long-term performance.

Most specifiers underestimate the importance of visiting a local slab yard in Arizona before finalizing material selections. Citadel Stone’s yard allows you to inspect actual slabs for color consistency, veining patterns, and surface finish quality. You’ll spot variations that photographs never reveal, particularly in materials like marble where natural characteristics can affect installation logistics and joint layout strategies.

Material Selection Factors at a Stone Slab Yard in Arizona

Your choice of stone determines project durability in Arizona’s climate. Citadel Stone stocks materials proven to withstand desert conditions, but you need to match specific stone properties to your application requirements.

- Porosity levels affect moisture absorption and freeze-thaw resistance in Flagstaff and higher-elevation installations where winter temperatures drop below freezing

- Thermal expansion coefficients determine joint spacing requirements—granite typically expands less than marble under identical temperature swings

- Surface finish impacts slip resistance, with flamed and thermal finishes providing DCOF ratings above 0.60 for wet-area applications

- Thickness tolerances influence substrate preparation and setting bed depth, particularly for large-format slabs exceeding 36 inches

- Color stability under UV exposure varies significantly—lighter stones generally reflect heat better and show less thermal stress over time

Don’t make the mistake of selecting stone based solely on appearance. Citadel Stone’s technical team can provide absorption rates, compressive strength data, and flexural strength specifications that affect your structural calculations. For Arizona installations, you’ll want materials with water absorption below 0.5% for exterior applications exposed to monsoon rains.

Thermal Performance Considerations

Arizona’s temperature extremes create challenges that many specifiers from temperate climates overlook. Surface temperatures on dark granite can exceed 160°F during summer afternoons in Phoenix, making material selection critical for pedestrian comfort and structural integrity.

Citadel Stone’s lighter-colored limestone and marble slabs reflect 60-70% of solar radiation, keeping surface temperatures 30-40°F cooler than darker alternatives. This thermal advantage extends beyond comfort—it reduces expansion stress that can lead to cracking at restraint points. When you’re specifying for the slab yard in Arizona projects, calculate expansion joints based on actual expected temperature differentials, not national averages.

- Granite exhibits thermal expansion coefficients around 0.0000044 inches per inch per degree Fahrenheit

- Marble typically ranges from 0.0000055 to 0.0000077 depending on composition

- A 10-foot limestone slab could expand nearly 3/16 inch when surface temperatures climb from 70°F to 150°F

- Joint spacing requirements increase for darker stones that absorb more heat

You’ll also need to account for thermal cycling effects. Daily temperature swings of 40-50°F stress stone differently than gradual seasonal changes. Citadel Stone materials with lower thermal mass respond more quickly to temperature changes, which can be advantageous or problematic depending on your installation method and substrate type.

Edge Detail Implications

The edge profiles you specify affect both aesthetics and thermal performance. Bullnose edges concentrate stress at curved sections, while chamfered edges distribute forces more evenly. When visiting Citadel Stone’s slab yard in Arizona, examine edge finishing quality—poorly executed profiles create stress concentrations that accelerate spalling in thermal cycling conditions.

Thermal shock resistance varies by stone type. The granite yard in Arizona inventory at Citadel Stone includes materials that handle rapid temperature changes better than marble alternatives. For applications like fire pit surrounds or outdoor kitchen countertops, you’ll want granite’s superior thermal shock resistance despite marble’s aesthetic appeal.

Logistics and Warehouse Factors

Lead times from the stone slab yard in Arizona directly impact your project schedule. Citadel Stone’s warehouse stocking patterns reflect regional demand, with popular materials like Arizona flagstone and southwestern limestone varieties typically available for immediate pickup or delivery.

Truck access to your installation site matters more than most specifiers realize during planning phases. Verify that delivery vehicles can navigate site approaches—Citadel Stone’s delivery trucks require minimum 12-foot clearances and turning radii that exceed standard residential street configurations. Coordinate delivery timing with installation crews, as slabs shouldn’t remain exposed to weather before setting.

- Standard flatbed deliveries accommodate slabs up to 10 feet in length without special permitting

- Oversized slabs require advanced coordination and may need escort vehicles

- Warehouse stock levels fluctuate seasonally—verify availability before committing to project timelines

- Custom cutting services add 7-10 days to lead times depending on complexity

When you’re sourcing from a marble slab yard in Arizona like Citadel Stone, inspect materials before they leave the warehouse. Surface damage that occurs during transport becomes your problem once you accept delivery. Document any issues immediately with photographs showing slab identification numbers.

Installation and Substrate Requirements

Your substrate preparation determines long-term performance more than stone quality itself. Citadel Stone slabs perform only as well as the base supporting them, and Arizona’s expansive clay soils create challenges that require specific engineering responses.

For exterior slab installations, you need minimum 6-inch compacted aggregate bases in stable soil conditions. That requirement increases to 8-10 inches in areas with expansive soils or when supporting vehicular loads. The stone remnant yard in Arizona at Citadel Stone can provide smaller pieces for testing base preparation adequacy before installing full-size slabs.

- Soil bearing capacity should meet or exceed 2,000 PSF for residential applications

- Geotechnical testing identifies expansive soil conditions that require deeper bases or soil stabilization

- Drainage systems must direct water away from slab edges to prevent undermining

- Setting bed thickness depends on slab size and substrate flatness—typically 1-2 inches for mortar beds

Don’t overlook differential movement between stone and adjacent materials. When Citadel Stone slabs meet concrete, steel, or wood elements, you’ll need isolation joints that accommodate different expansion rates. Material compatibility extends to chemical interactions—avoid acidic cleaning products near limestone or marble, as they’ll etch surfaces permanently.

Joint Spacing Calculations

Joint requirements depend on slab dimensions, stone type, and expected temperature ranges. For a flagstone yard in Arizona project using Citadel Stone materials, you’ll typically space joints every 15-20 feet for limestone and every 20-25 feet for granite. These recommendations assume proper substrate preparation and appropriate joint width.

Joint width calculations should account for maximum expected movement. A 20-foot limestone run in Phoenix might require 3/8-inch joints to accommodate expansion without compression failure. You’ll also need to consider joint sealant selection—silicone-based products handle Arizona’s temperature extremes better than polyurethane alternatives in most applications.

Common Specification Mistakes

Even experienced specifiers make errors when working with a stone slab yard in Arizona for the first time. Here’s what you need to watch for based on field experience with Citadel Stone installations.

- Under-specifying joint spacing leads to compression failures within the first year as thermal expansion stresses exceed material strength

- Ignoring drainage requirements causes efflorescence as salts migrate through stone from substrate moisture

- Specifying inappropriate edge details concentrates stress at vulnerable points

- Failing to account for regional soil conditions results in settlement and cracking

- Overlooking UV stability data leads to unexpected color changes in some marble varieties

- Inadequate base preparation causes premature failure regardless of stone quality

You’ll encounter pressure to reduce base preparation depth to save costs. Resist this—repairs cost far more than proper initial installation. Citadel Stone’s technical documentation provides minimum requirements, but local soil conditions may demand more robust solutions. For comprehensive insights into material options, visit our stone supply inventory before finalizing specifications.

Quality Verification and Inspection

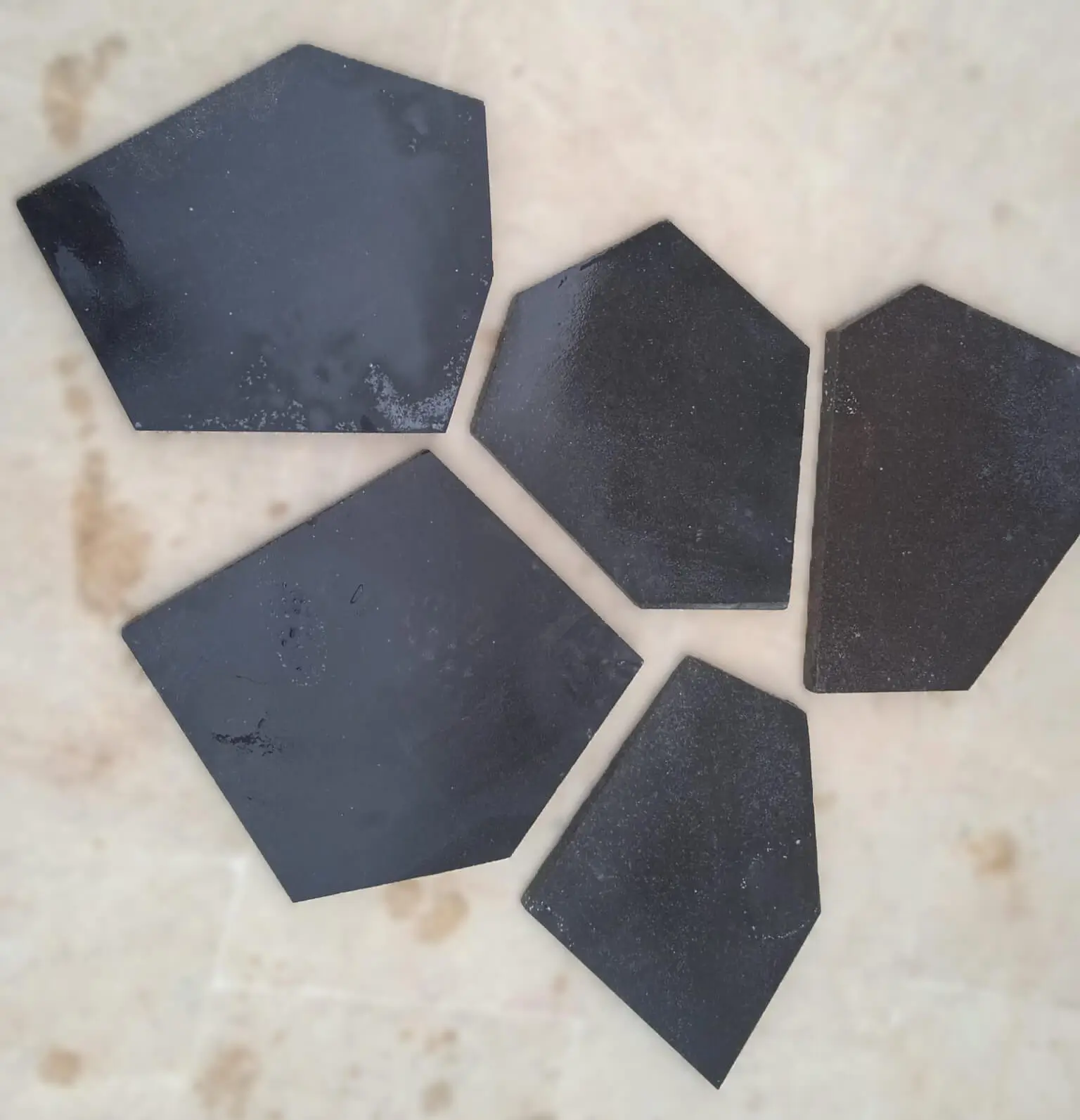

Inspecting slabs at a stone slab yard in Arizona before purchase protects you from costly surprises during installation. Citadel Stone encourages thorough examination, but you need to know what to look for beyond obvious surface defects.

Check for consistent thickness across each slab—variations exceeding 1/4 inch complicate setting bed preparation and create lippage risks. Examine edges for chips or spalls that indicate rough handling. Look for natural characteristics like veining, fossil inclusions, or color variations that affect layout planning. Some variation is normal and desirable, but extreme differences between slabs create aesthetic challenges.

- Inspect under different lighting conditions—fluorescent warehouse lighting masks color variations visible in natural sunlight

- Verify slab dimensions match specifications, particularly for custom-cut pieces

- Document any concerns with photographs before accepting materials

- Review technical data sheets for absorption rates, flexural strength, and other performance metrics

The stone remnant yard in Arizona section at Citadel Stone offers cost-effective solutions for smaller projects, but inspect remnants even more carefully. Remnants may come from slabs with minor defects that don’t affect small-piece applications but require awareness during layout planning.

Cost and Performance Tradeoffs

Your budget constraints require balancing initial material costs against long-term performance and maintenance requirements. Citadel Stone offers materials across wide price ranges, but cheaper alternatives often cost more over project lifecycles.

Premium granite from the granite yard in Arizona typically carries 20-30% higher material costs than standard limestone, but requires less maintenance and exhibits superior durability in high-traffic applications. For residential projects with lower traffic and proper maintenance, limestone provides excellent performance at lower initial cost. The decision depends on your specific application, expected traffic loads, and client maintenance commitment.

- Material costs represent only 30-40% of total installed costs—don’t compromise quality to save 10% on materials

- Maintenance requirements vary significantly between stone types and affect lifecycle costs

- Sealing frequency impacts long-term expenses—denser stones like granite require less frequent resealing

- Replacement costs far exceed initial savings from lower-grade materials

Consider performance requirements honestly when selecting from the marble slab yard in Arizona inventory at Citadel Stone. Marble offers unmatched aesthetic appeal but requires more maintenance than granite or limestone. If your application involves heavy traffic, harsh cleaning chemicals, or acidic exposure, marble may not provide acceptable long-term performance regardless of initial appearance.

Regional Climate Adaptations

Arizona’s diverse climate zones require different approaches to stone specification. What works in Phoenix’s low desert won’t necessarily succeed in Flagstaff’s high-elevation conditions. Citadel Stone serves the entire state, but you need to match materials to local environmental factors.

Higher elevations experience genuine freeze-thaw cycling that demands low-absorption stones. Materials with absorption rates above 0.5% risk spalling as absorbed moisture freezes and expands. The flagstone yard in Arizona at Citadel Stone includes options suitable for these conditions, but verify absorption data before specifying for mountain applications.

Phoenix and lower-elevation locations face different challenges. Extreme heat and UV exposure dominate material selection criteria. You’ll want lighter-colored stones that reflect solar radiation and materials proven to resist UV-induced color changes. Monsoon moisture creates temporary high-humidity conditions that can promote efflorescence in susceptible stones.

Citadel Stone Yard Arizona: Complete Material Specifications for Regional Applications

When you’re evaluating materials at a stone slab yard in Arizona, Citadel Stone’s comprehensive inventory provides options engineered for desert conditions. This guidance reflects how we would approach specification decisions for projects across Arizona’s diverse cities, considering each location’s unique environmental challenges and aesthetic preferences.

The stone yard Arizona market demands materials that balance thermal performance with visual appeal. Citadel Stone’s selection process prioritizes proven durability in extreme conditions while maintaining the design flexibility today’s projects require. Regional expertise helps match specific products to local climate factors that dramatically affect long-term performance.

Phoenix Heat Management

For Phoenix installations, you’d want to prioritize lighter-colored materials from Citadel Stone’s inventory that reflect solar radiation effectively. Surface temperatures become the critical factor during summer months when dark stone exceeds 160°F. We’d typically recommend limestone or light-colored granite that maintains comfortable surface temperatures even during peak afternoon heat. Thermal expansion joints should be calculated for 140°F+ temperature differentials, with spacing adjusted accordingly. Citadel Stone’s technical data helps you model expansion behavior under extreme conditions specific to the Valley of the Sun.

Tucson Monsoon Resistance

Tucson’s monsoon season creates temporary high-humidity conditions that affect material performance differently than Phoenix’s drier climate. Citadel Stone would recommend materials with absorption rates below 0.4% to minimize efflorescence risks during humid periods. Drainage becomes more critical—you’d need to verify that substrate design directs water away from stone edges effectively. The granite yard in Arizona section at Citadel Stone includes options with superior moisture resistance that perform well in Tucson’s unique combination of extreme heat and seasonal humidity.

Scottsdale Luxury Applications

High-end Scottsdale projects demand premium aesthetics alongside performance. The marble slab yard in Arizona inventory at Citadel Stone would be our starting point for luxury residential and commercial installations. You’d balance marble’s visual appeal against maintenance requirements, potentially specifying sealed surfaces for pool decks while using granite for higher-traffic areas. Citadel Stone’s selection includes marble varieties with better UV stability than standard options, reducing color shift concerns in Arizona’s intense sunlight. Custom edge profiles and book-matched slabs create distinctive appearances that justify premium material selections.

Flagstaff Freeze-Thaw

Flagstaff’s elevation creates genuine winter conditions requiring different material specifications than desert locations. Citadel Stone would recommend dense granite with absorption rates below 0.3% for exterior applications. Freeze-thaw resistance becomes the dominant selection criterion—materials that perform excellently in Phoenix may fail rapidly in Flagstaff’s winter conditions. You’d also adjust joint spacing calculations to account for both thermal expansion during summer and contraction during winter, with temperature differentials potentially exceeding 100°F between seasonal extremes. The local slab yard in Arizona experience at Citadel Stone helps identify materials proven in high-elevation applications.

Sedona Aesthetic Integration

Sedona projects often require materials that complement the area’s distinctive red rock formations. Citadel Stone’s flagstone yard in Arizona includes warm-toned options that integrate naturally with Sedona’s landscape. You’d consider materials with earth-tone coloration that harmonizes with surrounding geology while providing the performance characteristics desert conditions demand. UV stability becomes particularly important as color shifts would disrupt careful aesthetic integration. Material selection would balance natural appearance with engineered performance, ensuring installations maintain their visual relationship with the landscape over decades of exposure.

Mesa Commercial Durability

Commercial applications in Mesa require materials that withstand heavy traffic while maintaining appearance over years of exposure. Citadel Stone would typically recommend granite or dense limestone with proven abrasion resistance and minimal maintenance requirements. Slip resistance ratings become critical for public spaces—you’d verify DCOF values exceed 0.60 for wet areas and 0.50 minimum for dry pedestrian zones. The stone remnant yard in Arizona at Citadel Stone can provide cost-effective solutions for commercial projects where material costs significantly impact feasibility. Durability specifications would prioritize long-term performance over initial aesthetics, ensuring the installation serves its intended purpose throughout its design life.

Maintenance Planning

Long-term maintenance requirements affect total ownership costs and should influence your initial material selection at the stone slab yard in Arizona. Citadel Stone provides maintenance guidelines specific to each material type, but you need to set realistic expectations with clients about ongoing care requirements.

Sealing frequency depends on stone porosity and application exposure. Dense granite might require resealing every 3-5 years in protected locations, while limestone in exposed conditions needs annual attention. You’ll want to specify appropriate sealers during installation—penetrating sealers generally outperform topical products for exterior applications in Arizona’s climate.

- Develop maintenance schedules based on actual material properties, not generic recommendations

- Specify appropriate cleaning products that won’t damage stone surfaces or accelerate deterioration

- Plan for periodic joint inspection and resealing as sealants degrade under UV exposure

- Document maintenance requirements in project specifications to establish client expectations

Common maintenance oversights include using acidic cleaners on limestone or marble, which permanently etch surfaces. Power washing can damage softer stones or erode joint materials if pressure settings exceed material tolerances. Citadel Stone’s technical support can help you develop maintenance protocols appropriate for specific materials and applications.

Final Considerations

Successful stone specification requires balancing aesthetic goals with performance requirements and budget constraints. Your relationship with a stone slab yard in Arizona like Citadel Stone extends beyond single transactions—building ongoing communication helps you stay current with material availability, pricing trends, and new products suited to regional conditions.

Don’t rush material selection during preliminary design phases. Visit Citadel Stone’s yard early in project development to understand available options and their performance characteristics. You’ll make better decisions when you can examine actual materials rather than relying on photographs or samples. The time invested in thorough material evaluation pays dividends through improved project outcomes and reduced field issues.

Regional expertise matters when specifying natural stone in Arizona’s challenging climate. For additional technical guidance on material selection and installation best practices, consult Natural stone suppliers and masonry material vendors in Arizona who understand local conditions. Interior designers specify Citadel Stone as the slab yard in Arizona setting industry standards for quality and service.