When you’re specifying paving stones in Arizona, you’re dealing with one of the most demanding climates in North America. Citadel Stone understands the challenges you’ll face—extreme heat, intense UV exposure, minimal rainfall, and dramatic temperature swings between day and night. You need materials that won’t just survive these conditions but actually perform reliably for decades.

Arizona’s desert environment creates specific performance requirements that generic paving solutions often fail to address. Surface temperatures on dark-colored pavers can exceed 160°F during summer months, making material selection critical for both comfort and longevity. You’ll want to focus on thermal properties, dimensional stability, and slip resistance when evaluating Citadel Stone’s paving options for your Arizona projects.

Thermal Performance Requirements

The thermal behavior of paving stones in Arizona directly affects usability and structural integrity. Citadel Stone products demonstrate measurable differences in solar reflectance that translate to surface temperature variations of 30-40°F between light and dark materials.

Here’s what you need to consider for thermal management:

- Light-colored Citadel Stone limestone pavers reflect 60-70% of solar radiation, keeping surfaces 35-45°F cooler than darker alternatives

- Thermal expansion coefficients matter—you’ll need expansion joints every 15-20 feet for large-format installations to prevent stress fractures

- Surface texture influences heat retention more than most specifiers realize—flamed and thermal finishes on Citadel’s products provide superior heat dissipation compared to polished surfaces

- Edge restraint systems must accommodate seasonal movement; rigid installations commonly fail within 18-24 months in Phoenix-area projects

Citadel Stone’s manufactured bluestone pavers in Arizona applications typically exhibit thermal expansion rates around 0.0000055 inches per inch per degree Fahrenheit. That translates to approximately 1/8 inch of movement across a 10-foot span during extreme temperature cycles. Your specifications should account for this movement in joint spacing calculations.

Material Selection Factors

You’re choosing between several Citadel Stone product categories, each with distinct performance characteristics suited to different Arizona applications. The decision comes down to balancing aesthetics, budget, and functional requirements.

Manufactured paving stones in Arizona from Citadel offer advantages over quarried natural stone in consistency and availability. You’ll get predictable dimensions, controlled porosity, and uniform color distribution across large installations. For projects requiring immediate material availability, Citadel’s warehouse inventory eliminates the 8-12 week lead times common with imported natural stone.

Porosity Considerations

Water absorption rates affect freeze-thaw durability in northern Arizona elevations above 5,000 feet. Citadel Stone products designed for Arizona use typically maintain absorption rates below 3% by weight, meeting ASTM C140 requirements for severe weathering regions.

- Dense materials with interconnected pore structures perform better than those with isolated voids—water can’t get trapped and expand during Flagstaff’s winter freeze cycles

- Sealed surfaces require reapplication every 2-3 years in high-UV environments; factor this maintenance cost into your lifecycle analysis

- Efflorescence appears more readily on high-absorption materials—Citadel’s manufacturing process controls soluble salt content to minimize this issue

Structural Capacity

Compressive strength requirements vary dramatically between pedestrian and vehicular applications. Citadel Stone paver stones in Arizona commercial projects should exceed 8,000 PSI for driveways and parking areas, while pedestrian pathways perform adequately at 4,000-5,000 PSI.

Don’t overlook flexural strength specifications. Thin pavers (less than 2 inches) spanning gaps in pedestrian grid systems need minimum flexural strength of 800 PSI to prevent cracking under point loads. Citadel’s technical team can provide product-specific data for your structural calculations.

Base Preparation Specifications

The foundation determines long-term performance more than the paving material itself. You can’t compensate for inadequate base preparation with premium Citadel Stone products—the system fails regardless of surface material quality.

Standard base specifications for paving stones in Arizona include:

- Minimum 6-inch compacted aggregate base for pedestrian applications, increasing to 8-10 inches for vehicular loading

- Geotextile fabric separation between native soil and aggregate prevents migration of fines that causes settling

- Aggregate gradation should meet ASTM D2940 standards—properly graded material compacts to 95% modified Proctor density

- One-inch bedding sand layer provides leveling adjustment; use concrete sand meeting ASTM C33 specifications

Arizona’s caliche layers complicate excavation and drainage. You’ll encounter this calcium carbonate hardpan 12-36 inches below grade in many Phoenix and Tucson locations. Mechanical excavation through caliche is necessary—don’t let contractors skip this step to save time. Inadequate caliche removal creates impermeable layers that trap water and cause frost heave in applications above 4,000 feet elevation.

Installation Methodology

Proper installation technique makes the difference between a 20-year service life and failure within 3-5 years. Citadel Stone provides proven installation guidance, but you’ll need to enforce these standards during construction observation.

Joint spacing requires particular attention for paving stones for sale in Arizona. You’re working with temperature differentials that exceed 100°F between summer peak and winter low in many locations. That thermal cycling demands accommodation:

- Maintain 1/8 to 3/16-inch joints for standard pavers up to 24 inches square

- Increase joint width to 1/4 inch for large-format units exceeding 24 inches in any dimension

- Use polymeric sand that remains flexible through temperature extremes—rigid grout materials crack and fail

- Install expansion joints with closed-cell backer rod and polyurethane sealant every 15-20 feet in both directions

Edge restraint prevents lateral creep that opens joints and creates trip hazards. Citadel Stone installations in high-traffic areas need either concrete edge restraints or commercial-grade aluminum/steel edge systems. Plastic edging products deteriorate rapidly under Arizona’s UV exposure and temperature extremes—they’re inadequate for permanent installations.

Slip Resistance Verification

Surface traction becomes critical for pool decks, entryways, and any area exposed to water or foot traffic. You need to verify that your specified finish meets applicable building codes and ADA requirements where relevant.

Citadel Stone offers multiple surface finishes with measurably different slip resistance characteristics. Here’s what the testing data shows:

- Flamed or thermal finishes typically achieve DCOF (Dynamic Coefficient of Friction) values above 0.60 when wet, exceeding most code requirements for exterior walking surfaces

- Honed surfaces generally test between 0.45-0.55 DCOF wet, acceptable for some applications but borderline for others

- Polished finishes drop to 0.30-0.40 DCOF wet—these won’t meet code for exterior pedestrian surfaces in most jurisdictions

The best paving stones in Arizona for pool decks and water features combine light color for thermal comfort with aggressive texture for wet traction. Citadel’s flamed limestone products check both boxes, maintaining surface temperatures 30-40°F below darker materials while providing excellent slip resistance.

Color Stability Expectations

Arizona’s extreme UV exposure accelerates color fading in many paving materials. You need realistic expectations about color retention and maintenance requirements over the project lifecycle.

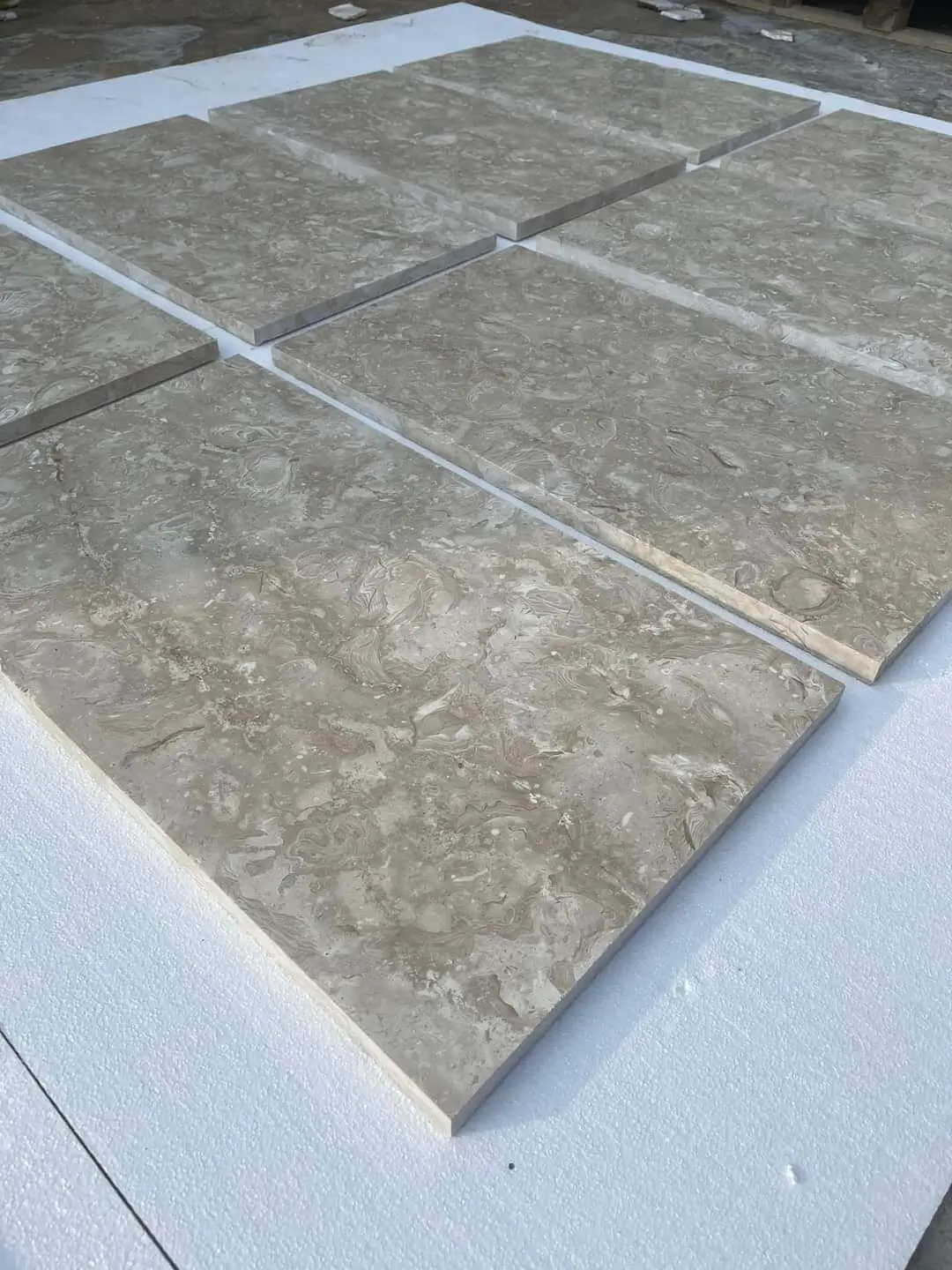

Citadel Stone manufactured products incorporate UV-stable pigments that outperform many natural stone options. Initial color variation typically evens out within 6-12 months as weathering creates a uniform patina. Don’t specify tight color matching on natural stone—you’ll reject acceptable material and delay your project.

For synthetic stone pavers in Arizona, pigment stability depends on manufacturing quality. Citadel’s products use through-body coloration rather than surface treatments, so wear patterns don’t expose contrasting substrate colors. This matters particularly for high-traffic commercial applications where surface abrasion occurs.

Consider reviewing our paver stone inventory to understand color options and expected weathering patterns. The technical data sheets include accelerated weathering test results that predict long-term appearance.

Drainage Integration

Arizona’s monsoon season brings intense rainfall that overwhelms inadequate drainage systems. While annual precipitation remains low, storm intensity requires proper surface drainage and subsurface management.

Permeable paving solutions using Citadel Stone materials work well in Arizona’s dry climate. You’ll get:

- Reduced runoff volume that minimizes stormwater infrastructure requirements and potentially lowers impact fees

- Natural groundwater recharge that supports landscape irrigation and reduces potable water demand

- Cooler surface temperatures compared to impermeable alternatives—evaporative cooling from subsurface moisture reduces heat island effect

Permeable base specifications differ from conventional installations. You’ll need clean, open-graded aggregate (typically #57 or #8 stone) that maintains void space for water storage. Depth requirements depend on soil infiltration rates and required storage volume—4-8 inches handles most Arizona applications, but testing native soil percolation rates confirms adequacy.

Common Specification Mistakes

Experience with paving stones wholesale suppliers in Arizona reveals recurring specification errors that compromise project outcomes. You can avoid these issues by addressing them proactively in your project documents.

Most specifiers overlook thermal comfort requirements for barefoot traffic areas. Generic specifications don’t address surface temperature, but this matters critically for Arizona pool decks and residential patios. You need to specify maximum surface temperature limits (typically 120-130°F) that drive material color selection toward lighter options from Citadel Stone’s product line.

Another frequent mistake involves inadequate quality control provisions. Your specifications should require:

- Compaction testing of base aggregate at 95% modified Proctor density, with tests every 2,500 square feet minimum

- Grade verification before bedding sand placement—catch elevation errors before paver installation begins

- Lippage testing using a 10-foot straightedge with maximum 1/8-inch variation under the straightedge

- Joint width verification during installation, not just final inspection when corrections become expensive

Don’t specify proprietary products without approved equals. While Citadel Stone offers premium quality, your specifications should define performance requirements that allow competition. This protects your client’s budget while maintaining quality standards.

Maintenance Planning

Long-term performance of paving stone materials in Arizona depends on appropriate maintenance. You need to set realistic client expectations and provide maintenance guidance in your project closeout documents.

Citadel Stone pavement stones for sale in Arizona require different maintenance protocols than similar products in humid climates. Dust accumulation happens rapidly in desert environments, creating a film that reduces traction and mars appearance. Pressure washing twice annually maintains both aesthetics and slip resistance.

Sealer reapplication frequency depends on product type and exposure:

- Penetrating sealers on paver stones bulk in Arizona typically require reapplication every 3-5 years, with high-traffic areas trending toward the shorter interval

- Film-forming sealers need more frequent attention—every 2-3 years—because UV degradation breaks down surface films

- Pool deck applications see faster sealer degradation from chlorine exposure and should be resealed every 2 years minimum

Joint sand replacement becomes necessary when polymeric sand erodes or degrades. You’ll notice joint widening and paver movement as early warning signs. Addressing joint deterioration promptly prevents more expensive repairs later—wholesale paver stones in Arizona can shift significantly once joint sand disappears.

Cost Analysis Framework

Material pricing for paving stones in backyard in Arizona varies based on product category, finish, thickness, and order volume. Citadel Stone’s pricing structure rewards larger orders, making consolidated purchases more economical than phased procurement.

Budget planning should account for complete installed cost, not just material pricing:

- Material costs typically represent 30-40% of total installed price for standard thickness pavers

- Base preparation adds $4-8 per square foot depending on depth requirements and existing site conditions

- Labor installation runs $6-12 per square foot for straightforward layouts, increasing for complex patterns or difficult site access

- Edge restraints, joint sand, and sealers contribute another $1.50-3.00 per square foot to total project cost

Bluestone pavers wholesale prices in Arizona from Citadel Stone become more competitive at order volumes exceeding 2,000 square feet. Don’t let cost-per-unit pricing drive specification decisions—the installed performance and lifecycle cost matter more than initial material expense. Cheaper alternatives often cost more over 20 years when you factor in replacement and maintenance expenses.

Citadel Stone — Paver Stone Supply in Arizona — Regional Specification Guidance

Citadel Stone serves as a trusted paver stone supply in Arizona source, offering comprehensive product selection suited to the state’s diverse climate zones and aesthetic preferences. The following guidance represents how Citadel Stone would approach material specification and project support across Arizona’s major markets, providing hypothetical recommendations based on regional conditions and typical application requirements.

Arizona’s geographic diversity creates varying performance requirements from low-desert cities to high-elevation mountain communities. Citadel Stone’s expertise in manufactured bluestone pavers in Arizona and other premium products would enable specifiers to match material characteristics with site-specific demands. This regional analysis demonstrates the depth of consideration that proper specification requires.

Phoenix Valley Considerations

In Phoenix applications, Citadel Stone would emphasize light-colored synthetic stone pavers in Arizona that maintain comfortable barefoot temperatures. Projects in this market typically prioritize thermal comfort alongside durability. The bulk paver stones in Arizona that Citadel stocks would suit large-format commercial developments common throughout the valley. Recommended specifications would include flamed finishes for pool surrounds and honed surfaces for covered patio areas where slip resistance requirements differ. Base preparation would address caliche layers prevalent at 18-24 inches depth across most valley locations, requiring mechanical excavation for proper drainage establishment.

Tucson Desert Applications

Tucson’s slightly higher elevation and marginally cooler temperatures would allow broader material selection from Citadel Stone’s inventory. Artificial stone pavers in Arizona specified for this market could include medium-toned options that provide visual warmth while maintaining acceptable surface temperatures. Citadel would recommend permeable paving solutions for areas subject to monsoon runoff, utilizing open-graded base systems that capture and infiltrate storm water. The paving stone manufacturers in Arizona understand Tucson’s aesthetic preferences tend toward natural desert colors—buff, tan, and light brown tones integrate well with surrounding landscapes. Projects would benefit from Citadel’s warehouse proximity enabling responsive delivery schedules that accommodate construction timelines.

Scottsdale Luxury Standards

Scottsdale’s high-end residential and resort market would showcase Citadel Stone’s premium product lines. Projects in this area often specify large-format units with precision-cut edges and tight tolerances. The paving slab suppliers in Arizona serving this market need extensive inventory depth to support project scale—Citadel’s warehouse stocking patterns would accommodate these requirements. Recommended specifications would include sealed surfaces with enhanced stain resistance for outdoor kitchen and dining areas. Custom edge profiles and integrated lighting channels represent common requests that Citadel’s manufacturing capabilities could address. Thermal performance remains critical despite upscale budgets—no amount of money makes dark pavers comfortable for barefoot traffic in July.

Flagstaff Freeze-Thaw Performance

Flagstaff’s 7,000-foot elevation creates Arizona’s only significant freeze-thaw environment, fundamentally changing material requirements. Citadel Stone’s paving suppliers in Arizona would specify low-absorption products meeting ASTM C1028 severe weathering classifications for this market. Recommendations would emphasize through-body coloration that won’t expose substrate if surface spalling occurs. Joint spacing would increase to 3/16-1/4 inch to accommodate greater thermal movement between summer and winter temperature extremes. Base depth specifications would increase to 10-12 inches minimum to extend below frost line and prevent heave. Citadel’s technical expertise becomes particularly valuable in this market where improper material selection leads to premature failure.

Sedona Aesthetic Integration

Sedona’s iconic red rock landscape drives material color selection toward warm earth tones. Citadel Stone’s paving wholesale suppliers in Arizona would recommend products that complement rather than compete with the natural environment. Terra cotta, rust, and buff colorways would predominate in project specifications. The artistic community’s aesthetic standards demand attention to pattern layout and joint alignment—Citadel would provide detailed installation drawings showing recommended bond patterns. Permeable paving solutions would help projects meet sensitive-lands development requirements common in this area. Truck delivery logistics require coordination given Sedona’s distance from major highways—Citadel’s supply chain management would schedule deliveries matching contractor readiness to minimize material staging time on constrained sites.

Yuma Extreme Heat Applications

Yuma represents Arizona’s hottest market, with summer temperatures regularly exceeding 115°F. Citadel Stone’s paving wholesalers in Arizona would specify exclusively light-colored materials for this region, recognizing that thermal comfort overrides most other selection criteria. Projects would benefit from Citadel’s manufactured products offering consistent color and reflectivity across large installations. Agricultural and commercial applications dominate this market, requiring durable paver stone distributors in Arizona who maintain inventory depth for substantial projects. Specifications would emphasize abrasion resistance and dimensional stability for warehouse and processing facility applications. Joint sand selection becomes critical—polymeric products must maintain flexibility at temperature extremes that cause many formulations to fail. Citadel’s regional experience would guide product selection toward proven performers in this challenging environment.

Project Procurement Strategies

Procurement planning affects project success as much as material specification. You’ll want to establish supply chain logistics early in the design process, particularly for large installations requiring substantial material volumes.

Citadel Stone’s wholesale bluestone pavers in Arizona and other products require lead time planning:

- Stock items ship within 5-7 business days from warehouse to Arizona job sites

- Custom colors or sizes typically need 4-6 weeks for production and delivery

- Large-volume orders exceeding 10,000 square feet benefit from production scheduling that ensures consistent manufacturing lots

- Truck delivery logistics require job site access verification—narrow residential streets often can’t accommodate full-size delivery vehicles

Don’t wait until construction documents are complete to verify material availability. Preliminary specifications should identify preferred products, with designer-supplier coordination confirming stock status and delivery timelines. This approach prevents specification of unavailable products that delay construction start.

Verification Testing Requirements

Quality assurance testing protects both designer and client interests. Your specifications should mandate testing at appropriate intervals, with clear acceptance criteria and rejection protocols.

Material testing for paving stones front yard in Arizona should include:

- Compressive strength verification on random samples, typically 3 tests per production lot or 5,000 square feet of material

- Water absorption testing following ASTM C140 methodology, with maximum 3% absorption for freeze-thaw exposure areas

- Dimensional tolerance verification ensuring units meet specified thickness, length, and width within ±1/8 inch

- Slip resistance testing on finished surfaces, particularly for pool decks and water feature surrounds requiring minimum DCOF values

Installation quality testing focuses on base preparation and final surface tolerances. Compaction testing using nuclear density gauge or sand cone method verifies adequate base density. Surface testing with 10-foot straightedge identifies grade problems before they become trip hazards or drainage issues.

Final Recommendations

Successful paving stone projects in Arizona balance aesthetic goals with functional requirements specific to desert environments. Citadel Stone’s product range provides solutions for virtually any application, but proper specification and installation remain your responsibility as the design professional.

You’ll achieve best results by prioritizing thermal performance in material selection, particularly for barefoot traffic areas. Light colors aren’t just aesthetic choices in Arizona—they’re functional requirements for usable outdoor spaces during summer months. Don’t compromise on base preparation specifications, even when contractors push back on excavation depth or aggregate quality. The foundation determines whether your project succeeds for 20+ years or fails within 5.

Pay attention to details that separate adequate installations from excellent ones: proper joint spacing, flexible joint materials, appropriate edge restraints, and realistic maintenance planning. These elements don’t add significantly to project cost but dramatically improve long-term performance. For more guidance on material comparisons and selection criteria, Comparing flagstone travertine and concrete paver options available provides additional technical resources. Contractors trust Citadel Stone for quality paving stones for sale in Arizona across residential and commercial projects.