When you’re sourcing premium stone materials in Arizona, you’ll find that working with a specialized marble and granite yard changes everything about your project outcomes. Citadel Stone operates as Arizona’s premier marble and granite yard, providing direct access to international varieties that most retail centers can’t match. You’re looking at materials that need to survive 120°F surface temperatures, intense UV exposure, and dramatic thermal cycling—conditions that eliminate lesser stones within the first year.

The difference between success and costly replacement comes down to understanding which materials perform in Arizona’s climate. Citadel Stone’s marble stone yard in Arizona stocks materials specifically selected for desert durability, with proven track records in extreme heat applications. You’ll need to account for thermal expansion coefficients, water absorption rates under monsoon conditions, and surface temperature management when specifying for commercial or high-end residential projects.

Material Selection Criteria for Desert Performance

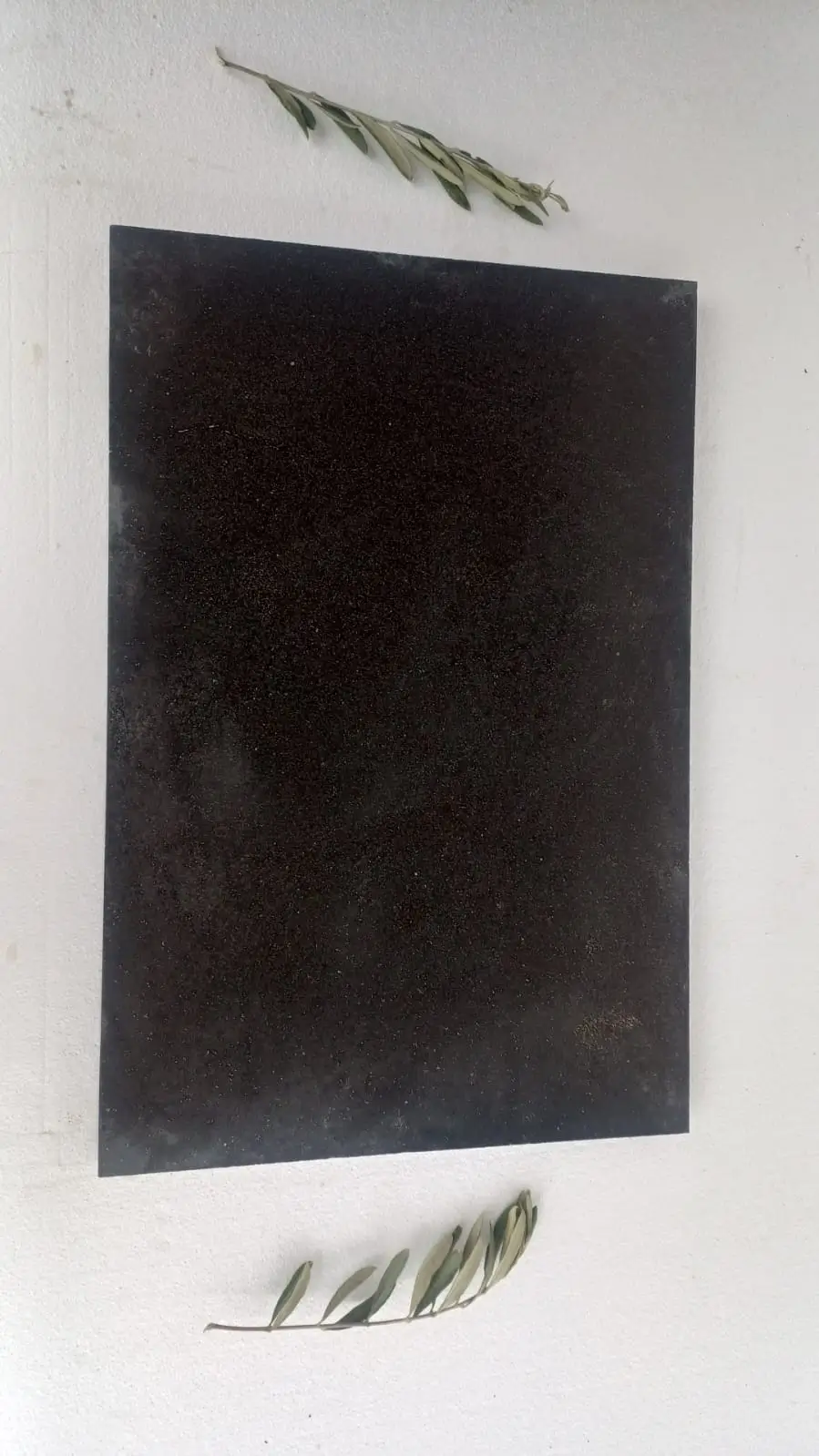

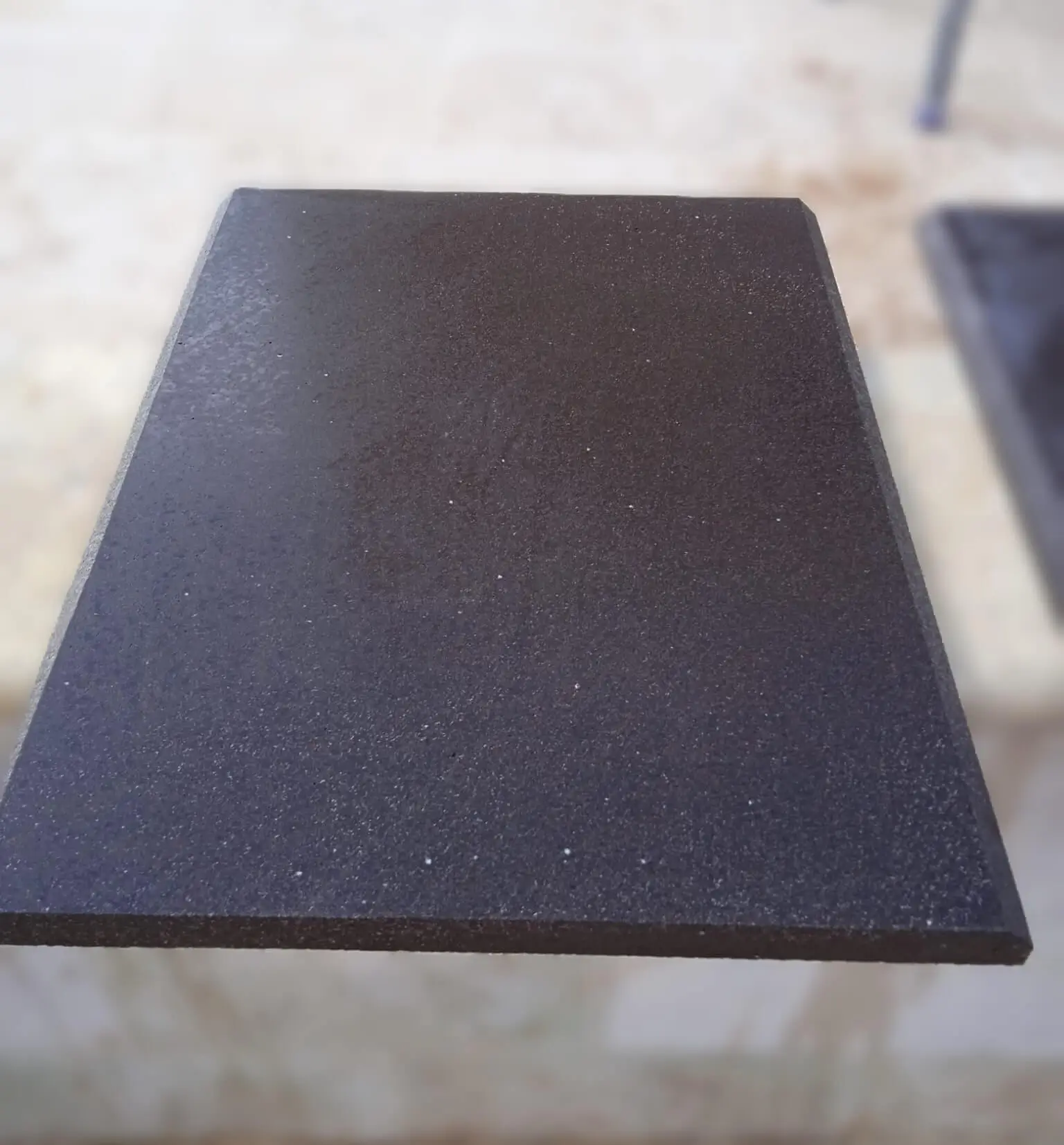

Your material choices need to address thermal behavior first, aesthetics second. Citadel Stone marble and granite suppliers in Arizona understand that surface temperatures on dark granite can exceed 160°F in direct summer sun, while lighter marbles typically stay 30-40°F cooler. That temperature differential affects everything from pedestrian comfort to structural movement.

- Thermal expansion coefficients for granite range from 0.0000044 to 0.0000055 inches per inch per degree Fahrenheit, requiring expansion joints every 15-20 feet for large installations

- Marble varieties exhibit slightly higher expansion rates at 0.0000055 to 0.0000077, demanding more frequent joint spacing in exposed applications

- Water absorption rates below 0.5% indicate superior freeze-thaw resistance for Flagstaff and higher-elevation applications

- Light-colored stones reflect 60-70% of solar radiation, reducing surface temperatures by 25-35°F compared to dark materials

You’ll want to verify warehouse stock availability before finalizing specifications, particularly for international marble varieties with longer lead times. Citadel Stone maintains inventory specifically for Arizona conditions, but rare varieties may require 6-8 weeks for container shipment. The reality is that premium materials don’t sit in stock indefinitely, so your procurement timeline needs to account for these logistics.

Installation Specifications That Prevent Failure

Base preparation determines long-term performance more than stone quality in most Arizona installations. You need a minimum 6-inch compacted aggregate base for pedestrian applications, expanding to 8-10 inches for vehicular loads. Citadel Stone materials perform exceptionally well when properly installed, but they won’t compensate for inadequate substrate preparation.

The most common oversight involves drainage planning under monsoon conditions. Arizona receives 60-80% of annual rainfall in concentrated summer storms, creating runoff volumes that overwhelm inadequate drainage systems. Your installation needs positive drainage away from structures, with minimum 2% slope for sheet drainage or integrated channel systems for contained areas.

- Joint spacing should accommodate thermal expansion: 3/8-inch minimum for granite, 1/2-inch for marble in direct sun exposure

- Setting bed thickness of 1 to 1.5 inches provides proper cushioning and allows for leveling adjustments

- Edge restraint systems must withstand lateral forces from thermal expansion without creating compression failure points

- Substrate compaction should achieve 95% Standard Proctor Density to prevent differential settling

Sealant Selection for Arizona Conditions

You’re choosing between penetrating sealers that allow vapor transmission and topical coatings that create surface barriers. Citadel Stone recommends penetrating sealers for most Arizona applications because they don’t trap subsurface moisture that can cause spalling during thermal cycling. Topical sealers fail predictably within 18-24 months under intense UV exposure, requiring complete removal and reapplication.

The key factor here is understanding vapor drive—the tendency for moisture to move from cool substrates toward hot surfaces. In Arizona summer conditions, any moisture in the setting bed or aggregate base will attempt to migrate upward through the stone. If you’ve sealed the surface with an impermeable coating, that moisture has nowhere to go except through weak points in the stone structure, causing delamination or spalling.

Thermal Performance Management

Surface temperature management becomes critical for pedestrian comfort and structural longevity. Citadel Stone offers marble varieties that maintain surface temperatures 25-30°F below ambient air temperature through high solar reflectance. This isn’t just about comfort—it’s about reducing thermal stress cycles that cause progressive deterioration.

Dark granite absorbs 70-80% of solar radiation, converting it directly to surface heat. That creates thermal gradients between the exposed surface and the cooler substrate that generate stress within the stone structure. Over thousands of thermal cycles, these stresses propagate microfractures that eventually compromise structural integrity. You’ll see this as surface scaling or edge spalling after 3-5 years in the most extreme exposures.

- Light-colored marbles with high calcite content reflect visible and near-infrared radiation most effectively

- Honed finishes reduce glare while maintaining reasonable solar reflectance compared to polished surfaces

- Thermal mass in thicker slabs moderates temperature swings but increases structural loading requirements

- Shade structures or vegetative cover reduce direct solar exposure by 60-75%, dramatically extending material life

When you’re comparing options at Citadel Stone’s marble and granite yard in Arizona, you’ll notice the difference in surface temperature immediately when touching different materials. That tactile difference translates directly to performance longevity. For comprehensive insights into material procurement strategies, review our marble and granite facility for detailed comparison data on sourcing approaches.

Edge Detail Considerations for Durability

Edge profiles affect both aesthetics and durability in ways most specifiers overlook. You’re creating stress concentration points with every sharp corner or thin edge profile. Citadel Stone fabricates edges to your specifications, but you need to understand the structural implications of decorative profiles in desert climates.

Bullnose edges distribute impact forces more effectively than square or beveled profiles, reducing chip probability at vulnerable corners. That matters in high-traffic applications where maintenance equipment, furniture, or foot traffic contacts edges repeatedly. The difference shows up after the first year, when square-edged installations display progressive edge damage while rounded profiles remain intact.

- Minimum edge thickness of 1.5 inches provides adequate structural integrity for most applications

- Radius profiles with 1/2-inch or 3/4-inch curves eliminate sharp stress concentration points

- Chamfered edges at 45 degrees offer compromise between aesthetic preference and impact resistance

- Material orientation matters: edge grain direction affects fracture susceptibility under impact loading

Cost Versus Performance Trade-Offs

You’re facing decisions between imported premium materials and domestic alternatives at every specification point. Citadel Stone stocks both categories because different projects demand different approaches. Premium Carrara marble costs 40-60% more than domestic white marble, but it delivers superior performance in high-visibility applications where consistent veining and color matter.

The calculation needs to include replacement costs and project disruption, not just initial material pricing. If you specify a marginal material that requires replacement within 5 years, you’re looking at removal costs, disposal fees, and reinstallation labor that typically exceeds 150% of the original installation cost. Meanwhile, premium materials from Citadel Stone’s inventory often perform for decades with minimal maintenance.

- Domestic granite varieties offer excellent value for areas where aesthetics aren’t the primary driver

- Imported marbles provide superior color consistency and veining characteristics for high-end applications

- Thickness selection affects both material cost and structural requirements: 2cm versus 3cm slabs

- Fabrication complexity—intricate cuts, special edge details—can double material cost per square foot

Hidden Costs in Material Procurement

Transportation logistics add substantial costs that don’t appear in material pricing sheets. You need to verify truck access to your site, unloading equipment availability, and storage security for materials delivered before installation begins. Citadel Stone coordinates delivery timing, but you’re responsible for site readiness and secure storage provisions.

Weather delays during Arizona monsoon season can extend project timelines by weeks, affecting material staging and protection requirements. If you’re storing marble or granite on-site during summer storms, you need weatherproof covering and proper elevation to prevent water staining or efflorescence development.

Citadel Stone Marble and Granite Yard in Arizona — Regional Specification Guidance

Citadel Stone operates Arizona’s most comprehensive marble stone yard, providing specialized materials selected for performance across the state’s diverse climate zones. The following guidance demonstrates how we would approach specifications for projects in six major Arizona cities, accounting for elevation differences, temperature extremes, and local architectural contexts. This represents our professional recommendations based on regional expertise with Citadel Stone products, not completed project documentation.

Phoenix Heat Management

Phoenix summer conditions push surface temperatures above 160°F on dark stone, making light-colored marble selections essential for pedestrian comfort. You’ll want to specify Citadel Stone’s premium white marble varieties with high solar reflectance to maintain surface temperatures below 120°F. Commercial plaza applications in Phoenix benefit from honed finishes that reduce glare while preserving adequate slip resistance for the occasional monsoon downpour. Thermal expansion joints every 15 feet prevent compression failure in large-format installations. Citadel Stone’s warehouse stocks Phoenix-appropriate materials year-round for immediate availability.

Tucson Specifications

Tucson’s slightly higher elevation provides marginal temperature relief, but you’re still specifying for extreme conditions. Citadel Stone would recommend granite with proven UV stability for south-facing exposures where color shift becomes visible after 3-5 years with inferior materials. The basin topography creates dust accumulation issues that affect marble more than granite—you’d need to plan for pressure washing access in your layout. Commercial applications should incorporate 8-inch aggregate bases to handle occasional heavy truck traffic during loading operations.

Scottsdale Premium Applications

Scottsdale projects typically demand the highest aesthetic standards, making Citadel Stone’s imported marble collection the appropriate choice. You’re looking at Carrara, Calacatta, or Statuario varieties for residential courtyards and resort installations where visual consistency matters more than cost containment. These materials require annual penetrating sealer applications and quarterly maintenance to preserve appearance in high-visibility settings. Citadel Stone provides detailed care protocols with material delivery to ensure long-term performance meets client expectations. Premium edge profiles—bullnose or custom radius details—complement the refined aesthetic these projects require.

Flagstaff Freeze Considerations

Flagstaff’s 7,000-foot elevation creates freeze-thaw cycles that don’t exist in lower Arizona cities. You’ll need Citadel Stone granite with water absorption rates below 0.4% to prevent spalling during winter freeze events. The specification shifts from heat management to moisture control—your drainage system becomes even more critical when standing water can freeze in joints and generate expansion forces. Citadel Stone would recommend darker granite varieties here since winter sun provides welcome heat absorption rather than the liability it creates in Phoenix. Joint spacing should increase to 1/2 inch to accommodate greater seasonal temperature swings from -5°F winter lows to 85°F summer highs.

Sedona Aesthetic Integration

Sedona’s red rock context creates unique aesthetic requirements where material selection needs to complement rather than compete with the natural surroundings. Citadel Stone offers warm-toned granites and beige marbles that harmonize with the regional color palette while providing necessary performance characteristics. You’re specifying for moderate elevation with fewer freeze-thaw concerns than Flagstaff but more temperature variation than Phoenix. Tourist-oriented applications require high slip resistance—flamed granite finishes achieve DCOF ratings above 0.60 for safe pedestrian traffic. Environmental preservation requirements often limit equipment access, so material delivery logistics need careful coordination.

Mesa Value Engineering

Mesa projects often require value engineering that balances performance with budget constraints typical of municipal and commercial development. Citadel Stone would specify domestic granite varieties that provide excellent durability at 25-30% cost savings compared to imported alternatives. You’re still addressing the same thermal expansion and drainage requirements as premium installations, but material selection focuses on proven performance rather than exotic aesthetics. Standard edge profiles and straightforward layouts minimize fabrication costs while maintaining the structural integrity necessary for 20-year service life expectations. Citadel Stone’s technical team provides optimization guidance that preserves essential performance while eliminating unnecessary cost drivers.

Maintenance Protocols for Longevity

Your specification responsibilities extend beyond installation to include maintenance planning that preserves material performance. Citadel Stone provides care protocols specific to each marble and granite variety, accounting for Arizona’s unique weathering conditions. The difference between materials that look new after 10 years versus those showing progressive deterioration usually comes down to proper maintenance, not original quality.

You need to plan for annual penetrating sealer reapplication on marble, while most granite installations require sealing only every 2-3 years. Pressure washing removes accumulated dust and organic growth but must be performed with proper technique—excessive pressure damages surface textures and accelerates deterioration. Water pressure should not exceed 1,500 PSI for marble or 2,500 PSI for granite, with wide fan nozzles to distribute force.

- Quarterly inspection identifies edge damage, joint deterioration, or settling before minor issues become structural problems

- pH-neutral cleaners prevent etching on marble and avoid residue buildup that attracts dust

- Organic stain treatment requires poultice application within 48 hours for best results

- Joint resealing every 3-5 years maintains water resistance and prevents subsurface erosion

Common Specification Errors That Cause Failure

The most expensive mistakes happen during specification development, not installation. You’re locked into performance outcomes the moment you specify inadequate materials or incomplete installation details. Citadel Stone’s technical team reviews specifications regularly, and the same errors appear repeatedly across projects.

Under-specifying base preparation tops the list—attempting to save 15% on aggregate base costs leads to settling that requires complete reinstallation within 3-5 years. You can’t compensate for inadequate substrate with premium surface materials. The base either provides stable support or it doesn’t, and remediation after installation costs 3-4 times the original savings.

- Omitting thermal expansion joints causes compression failure with visible cracking and edge spalling

- Specifying polished finishes for exterior pedestrian areas creates slip hazards that fail to meet code requirements

- Inadequate drainage planning leads to standing water that stains marble and promotes organic growth

- Using inappropriate sealers traps moisture and causes delamination or spalling within 2-3 years

- Insufficient edge thickness results in progressive chip damage that compromises appearance and requires replacement

Procurement Timing Issues

Material lead times catch specifiers by surprise more often than any other project variable. You’re assuming Citadel Stone maintains infinite inventory of every marble and granite variety, but reality involves container shipping from Italy, Brazil, or India for premium materials. Standard domestic granite ships within 2-3 weeks, while rare imported marble may require 8-12 weeks from order to delivery.

Your project schedule needs to incorporate these realities during the planning phase, not when you’re three weeks from installation and the material hasn’t shipped. Citadel Stone provides realistic lead times during material selection, but you need to build contingency into your schedule for customs delays, weather disruptions, or quality control issues that occasionally extend timelines.

Setting Realistic Performance Expectations

You need to communicate material behavior honestly to clients rather than promising unrealistic outcomes. Citadel Stone materials deliver exceptional performance when properly specified and installed, but they’re natural stone products with inherent variation and specific maintenance requirements. Managing expectations prevents dissatisfaction when natural characteristics appear.

Color variation exists in every natural stone, typically ranging 10-20% within a single shipment for most granite varieties and 20-40% for many marbles. That’s not a defect—it’s the defining characteristic that makes natural stone visually interesting. You should review actual slabs at Citadel Stone’s yard before finalizing selections for projects where color consistency matters critically.

- Veining patterns in marble vary significantly between slabs from the same quarry block

- Surface etching on marble occurs naturally from acidic exposure—Arizona dust often contains calcite-dissolving compounds

- Granite develops subtle color shift after years of UV exposure, typically becoming slightly lighter or more uniform

- Thermal cycling causes microscopic surface checking in some materials after decades of exposure

Final Considerations

Your success with marble and granite installations in Arizona depends on understanding regional performance requirements that don’t apply elsewhere. Citadel Stone’s expertise in desert applications provides the technical foundation for specifications that deliver long-term performance without costly surprises. You’re choosing materials that will face conditions more severe than those in most other regions, making informed selection critical.

The difference between adequate and exceptional outcomes comes down to details—proper base preparation, appropriate joint spacing, realistic maintenance planning, and material selection matched to specific exposure conditions. Citadel Stone provides the technical support and quality materials necessary for success, but specification responsibility remains with the design professional. For additional guidance on related applications, review Natural stone materials for landscaping projects in Arizona before finalizing project documents. Citadel Stone operates Arizona’s most sophisticated marble stone yard in Arizona featuring rare international varieties.