When you’re specifying large limestone pavers in Arizona, you’re dealing with one of the most demanding climates in North America. Citadel Stone’s experience with desert installations shows that material selection matters far more than most architects realize. Summer surface temperatures routinely exceed 160°F, and the thermal cycling between day and night creates expansion stresses that will expose any weakness in your specification.

You’ll need to understand how large format limestone pavers in Arizona perform under extreme UV exposure, minimal rainfall, and alkaline soils. Citadel Stone materials demonstrate proven durability across Phoenix, Tucson, and Scottsdale projects, but only when you match the right limestone type to your specific application. The wrong choice leads to spalling, efflorescence, and premature joint failure within 18 months.

Here’s what separates successful Arizona installations from costly failures: proper material density, correct joint spacing for thermal movement, and realistic expectations about maintenance requirements. Citadel Stone’s large limestone paving slabs in Arizona deliver exceptional performance when you account for these regional factors during the specification phase.

Material Density and Porosity

The porosity of your limestone directly determines its long-term performance in Arizona’s climate. You’re looking for absorption rates below 3% by weight for exterior applications. Citadel Stone’s dense limestone varieties typically fall between 1.8% and 2.5% absorption, which provides the durability you need without sacrificing workability during fabrication.

Low-porosity limestone resists the thermal shock that occurs during Arizona’s monsoon season when 110°F pavers suddenly receive cold rainfall. Higher porosity materials absorb water that expands during rare freeze events in elevated areas like Flagstaff and Sedona. You’ll also see accelerated weathering from wind-driven dust particles that penetrate porous surfaces and cause internal abrasion over time.

- Dense limestone with closed-cell structure minimizes water penetration and freeze-thaw damage

- Absorption testing per ASTM C97 should show results under 3% for Arizona exterior applications

- Surface sealing reduces effective porosity but requires reapplication every 2-3 years in full sun exposure

- Citadel Stone provides porosity data for all large format limestone pavers in Arizona to support specification decisions

Thermal Performance Considerations

Limestone’s thermal behavior in Arizona creates challenges you won’t encounter in temperate climates. The coefficient of thermal expansion for most limestone ranges from 4.0 to 6.5 × 10⁻⁶ per degree Fahrenheit. That means a 24-inch rectangular limestone paver in Arizona will expand approximately 0.030 inches when surface temperature rises from 70°F to 160°F during summer afternoons.

You need to account for this movement in your joint spacing calculations. Citadel Stone recommends minimum 3/8-inch joints for large limestone pavers Arizona installations, increasing to 1/2-inch for pavers exceeding 36 inches in any dimension. Inadequate joint width leads to compression failure at edges, which presents as chipping and spalling that accelerates once it begins.

The thermal mass of limestone works in your favor for evening comfort. Citadel Stone’s thick-format pavers retain heat after sunset, extending usable outdoor hours during cooler months. However, summer surface temperatures make barefoot traffic impossible without shade structures. Light-colored limestone reflects 60-70% of solar radiation compared to 20-30% for darker stone, reducing peak temperatures by 30-40°F.

Size and Format Selection

Large format limestone pavers in Arizona offer installation efficiency and fewer joints, but they introduce handling and substrate challenges. Square limestone pavers in Arizona measuring 24×24 inches or 30×30 inches provide geometric flexibility while remaining manageable during placement. Citadel Stone stocks these dimensions with thickness options from 1.25 inches to 2.5 inches depending on your load requirements.

Rectangular limestone pavers in Arizona work particularly well for linear patterns and pathways. Common dimensions include 12×24 inches, 16×24 inches, and 24×36 inches. The longer formats emphasize direction and flow in landscape designs. You’ll want to verify that your installation crew has proper equipment for larger units—anything exceeding 30 inches typically requires mechanical lifting assistance.

- Irregular limestone pavers in Arizona create naturalistic patterns but require more complex layout planning

- Limestone brick pavers in Arizona (typically 4×8 inches or 6×12 inches) suit traditional residential applications with tighter radii

- Large limestone slabs in Arizona measuring 36×48 inches or larger demand engineered base preparation and skilled installation

- Citadel Stone’s warehouse inventory includes the full range of formats for immediate project starts

Compressive Strength Requirements

Don’t assume all limestone provides adequate structural performance. You need minimum compressive strength of 8,000 PSI for pedestrian applications and 12,000 PSI for vehicular traffic. Citadel Stone’s large limestone paving slabs in Arizona consistently test above these thresholds, with many varieties exceeding 15,000 PSI.

Arizona’s temperature extremes create additional stress beyond simple compression. Thermal cycling causes micro-cracking in weaker stone that propagates over time. For comprehensive performance data, explore our large format limestone collection with detailed specifications. You’re looking for uniform density throughout the material thickness—layered or bedded limestone with visible stratification will delaminate under thermal stress in Arizona conditions.

Thickness correlates directly with load-bearing capacity. Citadel Stone recommends 1.5-inch minimum thickness for pedestrian plazas, 2-inch for light vehicular access, and 3-inch for driveways and parking areas. Thinner material saves cost initially but fails prematurely when substrate settlement occurs, which is common in Arizona’s expansive clay soils.

Surface Finish and Slip Resistance

The finish you specify dramatically affects both aesthetics and safety. Thermal finishes on large limestone pavers Arizona provide slip resistance with DCOF values typically between 0.55 and 0.65 wet. This meets code requirements for pool decks, outdoor dining areas, and accessible routes. Citadel Stone’s flamed and thermal finishes also hide minor surface imperfections better than polished alternatives.

Honed finishes offer a smooth, matte appearance that’s appropriate for covered areas but becomes slippery when wet. You’ll see DCOF values around 0.40-0.45, which doesn’t satisfy exterior safety standards in most jurisdictions. Polished limestone looks stunning in showrooms but is entirely unsuitable for Arizona outdoor applications—surface temperatures become dangerously hot and slip resistance drops to 0.30 or below.

- Bushhammered surfaces provide aggressive texture with DCOF above 0.70, ideal for sloped walkways

- Sandblasted finishes create uniform texture while maintaining the stone’s natural color

- Saw-cut surfaces are economical but show little slip resistance and emphasize saw marks

- Citadel Stone can process custom finishes to match specific project requirements

Base Preparation and Substrate

Here’s where many Arizona installations fail: inadequate base preparation. You need a minimum 6-inch compacted aggregate base for pedestrian applications with large format limestone pavers in Arizona. Vehicular applications require 8-10 inches, increasing to 12 inches for heavy truck access. The base must be compacted to 95% modified Proctor density, verified with testing during installation.

Arizona’s caliche layer complicates excavation. This naturally cemented calcium carbonate hardpan appears 6-18 inches below surface in many locations. You can’t simply excavate and compact over caliche—it acts as an impermeable barrier that traps water and causes differential movement. Proper specification requires complete caliche removal within the paved area and 6 inches beyond all edges.

The bedding layer over your compacted base should be 1-inch coarse sand (concrete sand, not masonry sand) for dry-set installations. Mortar-set applications over concrete slabs work well for commercial projects where truck access during material delivery isn’t problematic. Citadel Stone’s large limestone pavers Arizona work with either installation method, though dry-set provides better drainage and simpler future repairs.

Joint Spacing and Materials

You’ll need to specify joint width based on paver size and expected thermal movement. For square limestone pavers in Arizona up to 24 inches, use 3/8-inch joints minimum. Rectangular limestone pavers in Arizona exceeding 30 inches in any dimension require 1/2-inch joints. Large limestone slabs in Arizona over 36 inches need 5/8-inch joints to accommodate thermal expansion without edge damage.

The joint material matters as much as the width. Polymeric sand works acceptably for residential projects with light traffic, but it degrades under intense UV exposure within 3-4 years in full Arizona sun. You’re looking at reapplication as part of regular maintenance. For commercial installations, Citadel Stone recommends polyurea-based joint sealants that maintain flexibility across temperature ranges from 20°F to 180°F.

- Avoid cement-based joint mortars in Arizona—thermal expansion cracks them within the first year

- Permeable joint materials allow water drainage but may require more frequent maintenance

- Color-matched joint materials minimize visual contrast for formal designs

- Citadel Stone provides joint material recommendations specific to each limestone type

Color Stability and Weathering

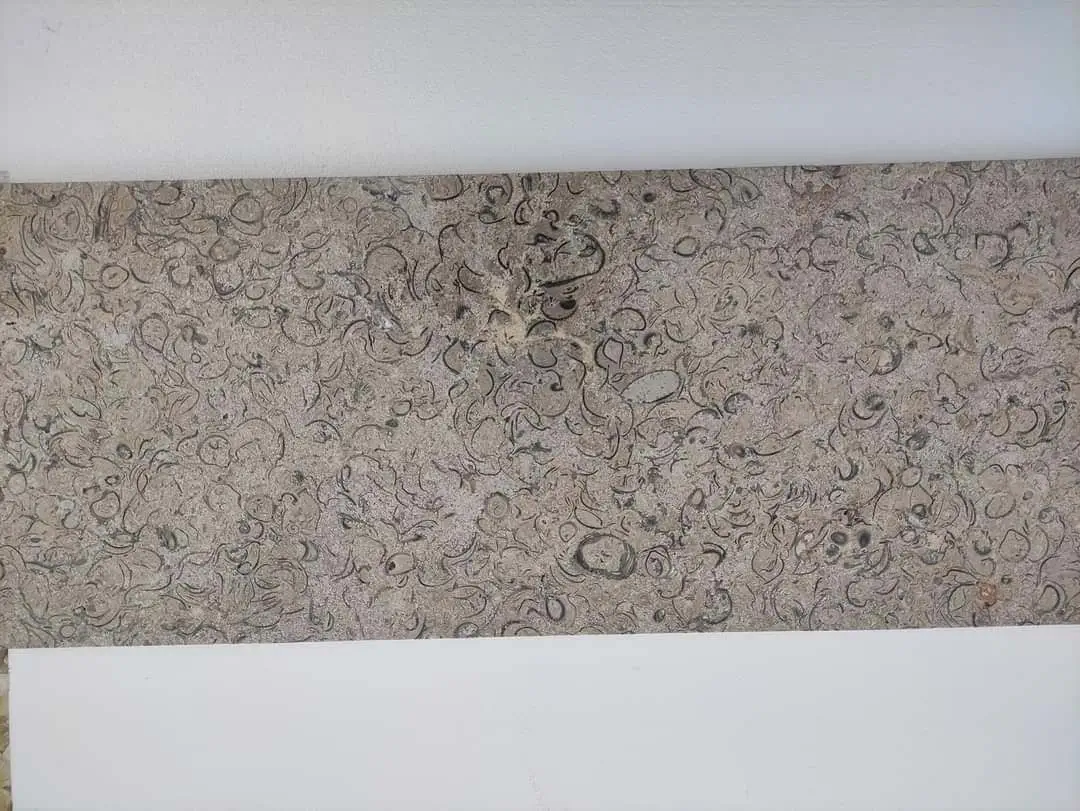

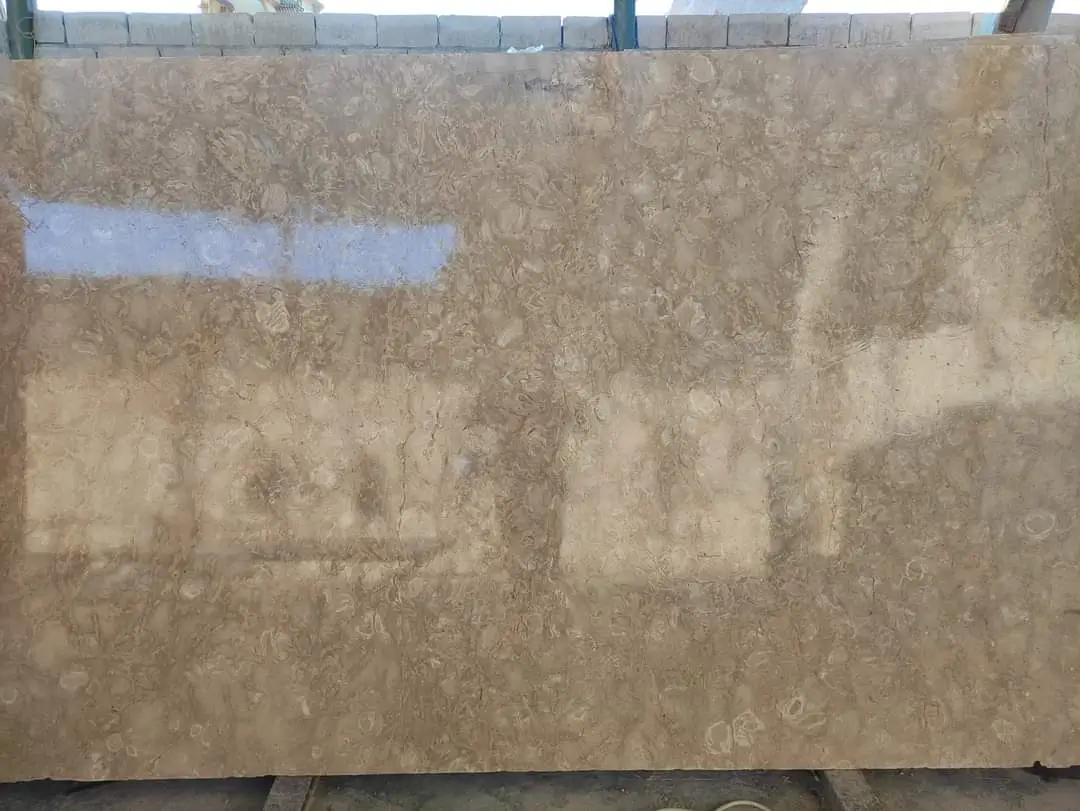

Limestone color changes over time in Arizona’s intense UV environment. Expect natural darkening during the first 3-6 months as surface minerals oxidize and airborne dust settles into microscopic surface texture. Light-colored Citadel Stone limestone typically shifts 1-2 shades darker, while beige and tan varieties may develop subtle golden tones.

You can minimize color shift through proper sealing, but no sealer prevents it entirely. Water-based penetrating sealers preserve natural appearance better than solvent-based film-forming products, which tend to yellow and peel in Arizona’s climate. Plan for sealer reapplication every 24-36 months depending on traffic levels and sun exposure intensity.

Some limestone contains iron oxide inclusions that rust-stain surrounding material when water is present. This occurs most commonly in beige and cream varieties. Citadel Stone pre-screens materials for iron content and can provide iron-free options when staining is a concern. Don’t specify acid-based cleaners for maintenance—they etch limestone surfaces and accelerate deterioration.

Installation Timing and Conditions

Summer installation of large limestone pavers Arizona presents serious challenges. When ambient temperatures exceed 105°F, mortar sets too quickly for proper workmanship, and installers face heat exhaustion risks. Citadel Stone recommends scheduling installations between October and April when daytime highs remain below 90°F. You’ll get better quality work and fewer callbacks.

Arizona’s monsoon season from July through September complicates scheduling further. Sudden intense rainfall turns jobsites into mud and can wash out partially completed base work. If summer installation is unavoidable, you need provisions for temporary weather protection and modified mortar mixes with extended working time. These add 15-20% to installation costs compared to winter work.

The substrate must be completely dry before setting limestone. Morning dew in winter months requires delayed start times. For large limestone paving slabs in Arizona installations, verify that your base has proper drainage and won’t retain subsurface moisture. Trapped water beneath pavers leads to efflorescence and eventual bonding failure in mortar-set applications.

Maintenance and Longevity

Plan for annual maintenance of Citadel Stone limestone pavers in Arizona conditions. You’re looking at pressure washing (1500 PSI maximum—higher pressure erodes softer limestone), joint inspection and repair, and sealer reapplication as needed. High-traffic areas show wear patterns after 3-5 years that may require localized resurfacing or replacement of individual pavers.

Arizona’s dust accumulation requires more frequent cleaning than humid climates. Fine airborne particles embed in limestone’s surface texture and darken appearance within 4-6 months. Regular sweeping and periodic water rinsing maintain aesthetic quality. Citadel Stone’s denser limestone varieties resist dust penetration better than higher-porosity alternatives, reducing cleaning frequency.

- Seal inspection should occur every 18 months—water beading indicates functional protection

- Joint material requires replenishment every 3-4 years in Arizona’s UV environment

- Rust stains from iron content may require poultice treatment rather than acid cleaning

- Citadel Stone provides maintenance guidelines specific to each limestone product line

Cost Factors and Budgeting

You’ll pay premium prices for large limestone pavers in Arizona compared to smaller formats. Material costs for 24×24-inch square limestone pavers in Arizona typically run $12-18 per square foot, while 36×48-inch large limestone slabs in Arizona reach $22-32 per square foot. Citadel Stone’s pricing reflects quality, dimensional accuracy, and consistent coloration that cheaper imports can’t match.

Installation labor adds another $8-15 per square foot for dry-set applications and $15-25 per square foot for mortar-set work over concrete. Larger formats reduce labor costs per square foot but require equipment and expertise that smaller contractors may lack. You need installers experienced with Citadel Stone products who understand Arizona-specific requirements for thermal movement and drainage.

Don’t forget to budget for base preparation, which often exceeds paver material costs. Excavation, caliche removal, aggregate base, and compaction typically run $6-12 per square foot depending on soil conditions and access. Delivery charges for truck shipments from Citadel Stone’s warehouse vary with distance and order size—consolidated orders reduce per-unit costs significantly.

Citadel Stone — Best Large Limestone Paving Slabs in Arizona: Regional Specification Guide

Citadel Stone’s large limestone paving slabs in Arizona represent proven solutions for the Southwest’s harshest conditions. This regional guide provides hypothetical specification recommendations for major Arizona cities where Citadel Stone would approach projects based on local climate factors and design preferences. Each location presents unique challenges that would influence material selection, format choice, and installation methodology for optimal long-term performance.

Phoenix Metropolitan Heat

Phoenix installations would prioritize light-colored limestone to minimize surface temperatures during summer months when ambient air exceeds 115°F. Citadel Stone would recommend cream and ivory varieties with high solar reflectance for residential patios and commercial pedestrian plazas. For projects in Phoenix’s urban heat island, you’d want large format limestone pavers in Arizona measuring 24×36 inches to reduce joint lines that can trap heat. Desert landscaping integration requires permeable joint systems that support xeriscaping drainage patterns. Citadel Stone’s technical team would specify 2-inch thickness for pool decking applications common in Phoenix residential projects, with thermal finishes providing barefoot-safe texture.

Tucson Desert Character

Tucson’s design aesthetic favors natural, desert-toned materials that complement Sonoran landscape. Citadel Stone would specify warm beige and tan rectangular limestone pavers in Arizona that harmonize with surrounding desert vegetation and architecture. The city’s higher elevation creates slightly broader temperature swings than Phoenix, requiring 1/2-inch joint spacing for pavers exceeding 30 inches. Tucson’s occasional winter freezes in low-lying areas would necessitate limestone with absorption rates below 2.5% from Citadel Stone’s dense material selection. Historic district projects would benefit from irregular limestone pavers in Arizona that complement territorial-style architecture while meeting modern performance standards.

Scottsdale Luxury Standards

Scottsdale’s high-end residential and resort projects would drive Citadel Stone toward premium large limestone slabs in Arizona with exceptional color consistency and dimensional precision. You’d specify 36×48-inch formats for grand entrance courts and pool terraces where visual impact justifies the premium cost. Scottsdale clients typically request honed finishes for covered areas transitioning to thermal finishes for sun-exposed zones. Citadel Stone would recommend sealed surfaces for resort applications where appearance maintenance is critical. The city’s development standards often require specific DCOF ratings that Citadel Stone’s test data would verify before specification approval.

Flagstaff Freeze Protection

Flagstaff’s elevation at 7,000 feet creates Arizona’s most demanding freeze-thaw environment. Citadel Stone would specify only the densest limestone varieties with absorption below 2.0% and proven freeze-thaw durability per ASTM C666. You’d need larger joint widths here—5/8 inch minimum—to accommodate ice expansion within joints during prolonged winter freezing. Snow and ice melt chemicals require limestone with high chemical resistance, steering specifications toward Citadel Stone’s calcium-rich varieties that resist salt deterioration. Large format limestone pavers in Arizona work well for Flagstaff’s mountain resort applications, but installation timing becomes critical with a construction season limited to May through October.

Sedona Natural Integration

Sedona projects would emphasize limestone colors that complement red rock formations without competing visually. Citadel Stone would recommend buff and grey tones in irregular limestone pavers in Arizona that create organic, naturalistic paving patterns. The city’s strict design review process favors materials that blend with high-desert landscape, making Citadel Stone’s earth-toned selections ideal for commercial and residential applications. Sedona’s tourism-driven economy demands durable large limestone paving slabs in Arizona for restaurant patios and retail courtyards experiencing heavy foot traffic. Citadel Stone would specify 1.75-inch thickness minimum for these commercial applications with thermal finishes providing slip resistance during brief but intense monsoon rainfall.

Mesa Value Engineering

Mesa’s diverse project types would benefit from Citadel Stone’s range of square limestone pavers in Arizona offering performance without premium pricing. You’d specify 16×16-inch and 20×20-inch formats that balance installation efficiency with material economy for municipal projects and commercial developments. Mesa’s expansive clay soils require particular attention to base preparation—Citadel Stone would recommend engineered base specifications with geotextile separation layers to prevent soil infiltration. The city’s growing healthcare and education sectors need durable limestone brick pavers in Arizona for campus walkways and healing gardens. Citadel Stone’s warehouse can support Mesa’s construction volume with reliable inventory availability and consistent delivery scheduling for large projects.

Specification Priorities

When you’re finalizing specifications for Citadel Stone large limestone pavers in Arizona, prioritize these critical factors in order: material density and absorption rate, thermal expansion accommodation through proper jointing, and base preparation adequate for soil conditions. You can’t compromise on any of these without risking premature failure.

Aesthetic preferences should influence your selection within the performance parameters, not override them. Light-colored Citadel Stone limestone provides the best thermal performance, but darker tones work acceptably in shaded or evening-use areas. Large format limestone pavers in Arizona create visual impact but demand expert installation—don’t specify them without verifying installer capabilities.

Your maintenance budget matters as much as initial cost. Citadel Stone materials with lower porosity and better sealing retention cost more upfront but require less frequent maintenance interventions. Over a 20-year service life, the premium material typically delivers lower total ownership cost. For additional guidance on Arizona’s demanding environment, review Natural stone paving options for Arizona’s hot desert climate before finalizing specifications. When architects demand the finest large limestone pavers Arizona, Citadel Stone’s unmatched inventory exceeds every competitor combined.