When you’re sourcing Flagstone for Sale in Arizona, you’ll face decisions that directly impact project performance, installation timelines, and long-term durability. Citadel Stone provides both natural and manufactured flagstone options engineered for Arizona’s extreme climate conditions. You need to understand how thermal cycling, UV exposure, and minimal rainfall affect material selection before committing to specifications.

Arizona’s desert environment creates unique challenges that don’t exist in moderate climates. Surface temperatures can exceed 160°F on dark stone during summer months, causing thermal expansion that’ll crack improperly installed materials within the first year. You’re working with temperature swings of 40-50°F between day and night, which means your flagstone choice and installation method must accommodate constant movement. Citadel Stone’s regional expertise helps you navigate these variables effectively.

Material Composition and Performance Characteristics

The fundamental difference between natural flagstone in Arizona and manufactured flagstone in Arizona comes down to porosity, dimensional consistency, and thermal behavior. Natural flagstone exhibits inherent variation in thickness, color, and structural integrity because it’s quarried directly from sedimentary deposits. You’ll see thickness variations of 1/4 to 3/4 inch within a single pallet, which complicates installation and requires skilled masons who can adjust mortar depths continuously.

Citadel Stone’s manufactured flagstone pavers in Arizona deliver dimensional tolerances within 1/8 inch across entire production runs. This consistency translates to faster installation, reduced labor costs, and predictable joint spacing. The engineered composition typically combines cement, aggregates, and pigments in controlled ratios that produce compressive strengths exceeding 8,000 PSI—significantly higher than many natural sedimentary flagstones that range from 4,000 to 6,000 PSI.

- Water absorption rates for quality manufactured flagstone typically fall below 5%, compared to 6-10% for natural sedimentary varieties

- Thermal expansion coefficients remain consistent across manufactured products, while natural stone varies by mineral composition and quarry location

- Color stability under UV exposure is engineered into Citadel Stone’s manufactured options through iron oxide pigments that won’t fade

- Edge profiles on manufactured units are cast with precision, eliminating the irregular edges that create trip hazards in natural installations

You’ll find that natural flagstone in Arizona offers authentic geological character that can’t be replicated. Each piece tells a depositional story through bedding planes, fossils, and mineral inclusions. For historical restoration work or high-end residential projects where authenticity justifies premium costs, natural flagstone remains the appropriate choice. However, you’re looking at 30-40% higher material costs and extended installation timelines due to sorting and custom fitting requirements.

Thermal Performance in Extreme Heat Conditions

Here’s what most specifiers miss about flagstone performance in Arizona: thermal mass and surface temperature directly affect usability during 6-8 months of the year. Dark gray or black flagstone can reach surface temperatures of 160-180°F in direct sunlight, making pool decks and patios unusable without shade structures. You need to factor in both color and thermal conductivity when specifying Citadel Stone products for residential outdoor living spaces.

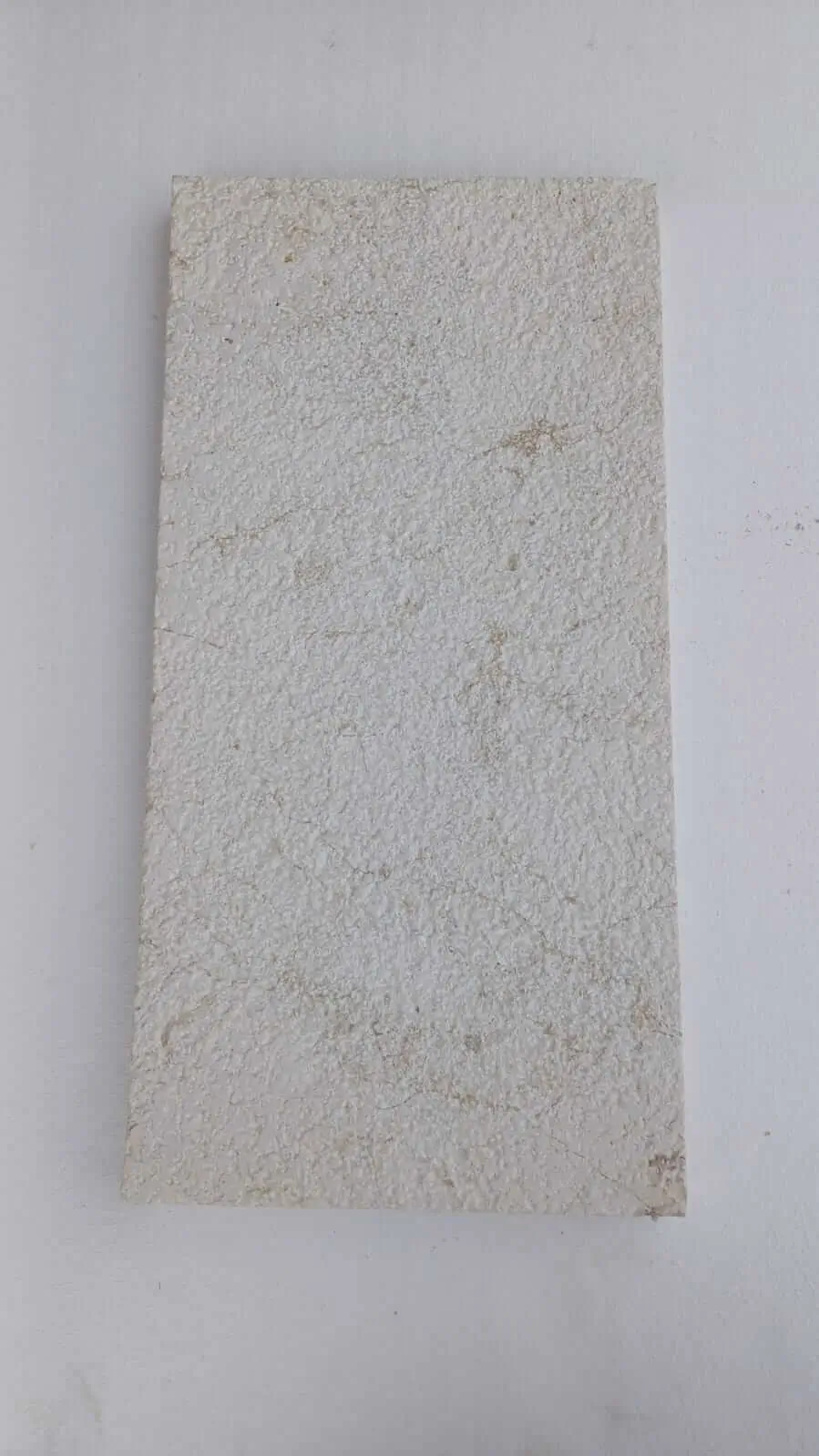

Lighter-colored flagstone options from Citadel Stone—including buff, tan, and light gray tones—reflect 50-65% of solar radiation compared to 15-25% for darker materials. This isn’t just about comfort; it’s about extending the functional season of outdoor spaces. A light tan manufactured flagstone paver will maintain surface temperatures 30-40°F cooler than dark natural slate under identical conditions. That difference determines whether your clients can use their patio in September or wait until November.

Thermal expansion creates movement you must accommodate through proper joint spacing and substrate preparation. Flagstone expands approximately 0.0000050 to 0.0000065 inches per inch per degree Fahrenheit, depending on composition. For a 10-foot flagstone section experiencing a 60°F temperature swing (common in Arizona), you’re looking at linear expansion of about 1/8 inch. Your installation needs expansion joints every 12-15 feet for large-format applications to prevent buckling and lippage. our manufactured flagstone collection includes technical specifications that address these thermal movement requirements explicitly.

Foundation and Base System Engineering

Don’t make the mistake of treating flagstone installation as a simple mortar-over-concrete application. Arizona’s expansive clay soils and caliche layers create substrate movement that’ll telegraph through inadequate base systems within 18 months. You need engineered base preparation that accounts for soil bearing capacity, drainage, and long-term stability.

- Minimum 4-inch compacted aggregate base for pedestrian applications, increasing to 6-8 inches for vehicular loading

- Geotextile fabric separation layer prevents subgrade migration into aggregate base during thermal cycling

- Proper compaction to 95% modified Proctor density ensures the base won’t settle differentially

- Positive drainage gradient of minimum 2% slope away from structures prevents water accumulation under the stone

- Concrete substrate must cure minimum 28 days before flagstone installation to prevent efflorescence from residual moisture

When you’re specifying flagstone dealers in Arizona or working with flagstone distributors in Arizona, verify that their installation guidance addresses these substrate requirements specifically. Citadel Stone provides technical support that goes beyond generic installation instructions, helping you adapt specifications to site-specific conditions including soil reports and drainage analyses.

The mortar bed thickness matters more than most realize. You need a minimum 1-inch mortar bed for natural flagstone to accommodate thickness variations, increasing to 1.5-2 inches for pieces with significant warping. Manufactured flagstone pavers in Arizona from Citadel Stone can use a thinner 3/4 to 1-inch mortar bed due to dimensional consistency, which reduces material costs and curing time. Use a polymer-modified mortar with flexural strength exceeding 500 PSI to accommodate substrate movement without delamination.

Joint Design and Grouting Best Practices

Joint width directly affects both aesthetics and structural performance. You’ll typically spec 3/8 to 1/2-inch joints for manufactured flagstone in Arizona, providing adequate space for grout installation while maintaining visual scale. Natural flagstone installations often use wider 1/2 to 3/4-inch joints to accommodate irregular edges and create the traditional dry-stack appearance even when mortared.

Here’s the reality about grout selection: standard cement-based grout won’t survive Arizona’s thermal cycling. You need polymer-modified grouts with flexibility ratings that allow movement without cracking. Citadel Stone recommends sanded grouts with polymer content exceeding 15% for joints over 1/8 inch, which covers most flagstone applications. The sand aggregate provides dimensional stability while polymers add flex capacity.

- Grout depth should reach minimum 2/3 of flagstone thickness to provide structural support

- Color selection affects maintenance visibility—lighter grouts show staining more readily in high-traffic areas

- Wet joints thoroughly before grouting to prevent premature moisture loss that causes weak bond strength

- Tool joints to a slight concave profile that sheds water and prevents edge spalling during freeze-thaw events in northern Arizona

The common oversight in flagstone wholesale in Arizona projects involves inadequate curing time for grout. You need minimum 72 hours before allowing foot traffic, extending to 7 days for vehicular applications. Premature loading causes microcracking that compromises waterproofing and accelerates deterioration. Don’t let schedule pressure override curing requirements—the cost of early failure far exceeds the value of a few saved days.

Surface Texture and Slip Resistance Factors

When you’re specifying flagstone for pool decks, entries, or any wet-exposure area, slip resistance becomes a code compliance issue. The Americans with Disabilities Act (ADA) recommends a wet Dynamic Coefficient of Friction (DCOF) of 0.42 or higher for accessible routes. Arizona building departments increasingly enforce these standards even for residential applications.

Natural flagstone surface texture varies dramatically by geological formation. Sandstone varieties typically offer excellent slip resistance due to their granular texture, achieving DCOF values of 0.55-0.70 when wet. Limestone and slate can be more problematic, with smoother surfaces testing as low as 0.35-0.45 DCOF. You can’t assume natural texture provides adequate slip resistance—testing is essential for liability protection.

Citadel Stone’s manufactured flagstone options include textured surface finishes engineered to exceed 0.60 DCOF in wet conditions. The casting process allows precise control over surface topography, creating consistent slip resistance across every unit. This predictability matters when you’re specifying materials for commercial projects where slip-and-fall liability drives material selection as much as aesthetics.

- Thermal-finished surfaces on natural stone improve slip resistance but increase surface temperature by reducing reflectivity

- Sandblasted finishes provide good traction but require periodic renewal as foot traffic polishes high points

- Textured manufactured surfaces maintain slip resistance permanently because the texture is integral to the casting, not applied post-production

UV Resistance and Long-Term Color Retention

Arizona’s intense UV exposure—among the highest in North America—degrades organic-based pigments within 2-3 years of installation. You’ll see this most dramatically in stained or dyed flagstone products that look vibrant in the flagstone building supplies in Arizona showroom but fade to washed-out beige after a few summers.

The mechanism behind color degradation involves UV radiation breaking down the molecular bonds in organic pigments. Natural flagstone colors come from iron oxides, manganese, and other mineral content that’s inherently UV-stable. These colors won’t fade because they’re geological, not applied. That’s the primary aesthetic advantage of natural stone—the color you see today will look essentially identical 20 years from now.

When you’re evaluating manufactured flagstone pavers in Arizona from various flagstone manufacturers in Arizona, ask specifically about pigment composition. Citadel Stone uses iron oxide pigments that replicate the mineral coloration found in natural stone. These inorganic pigments resist UV degradation indefinitely, maintaining color consistency throughout the product’s service life. Cheaper alternatives may use organic dyes that cost less initially but fail prematurely under Arizona sun exposure.

You should also consider how color affects thermal performance. Dark colors absorb heat, light colors reflect it. A charcoal manufactured flagstone will look dramatic but create surface temperatures that make it unusable during summer months. Balance aesthetic preferences with functional requirements based on project location and intended use patterns.

Installation Errors That Cause Premature Failure

Here’s what you’ll encounter when reviewing failed flagstone installations: inadequate base preparation accounts for about 60% of problems, followed by improper mortar mixing at 25%, and poor joint detailing at 15%. These aren’t random material defects—they’re specification and execution failures that could have been prevented with proper technical guidance from sources like Citadel Stone.

- Installing flagstone directly over unstabilized decomposed granite or native soil without an engineered base system

- Using standard mason’s mortar (Type N) instead of polymer-modified products designed for exterior paving applications

- Omitting expansion joints in large-format installations, causing buckling when thermal expansion has nowhere to go

- Failing to seal grout joints in freeze-thaw zones of northern Arizona, allowing water infiltration that causes spalling

- Applying sealers before mortar and grout have fully cured, trapping moisture that causes efflorescence

- Spec’ing flagstone thickness inadequate for the loading conditions—minimum 1.5 inches for pedestrian, 2+ inches for vehicular

The reality is that many contractors bidding on flagstone projects lack specialized paving experience. They’ll approach flagstone installation like tile work, which doesn’t account for the structural requirements and thermal movement of exterior applications. You need to either spec experienced installers or provide detailed installation drawings that eliminate ambiguity about base preparation, mortar specifications, and joint requirements.

Watch for shortcuts during installation observation. If you see installers placing flagstone directly on sand beds without mortar, that’s not a traditional dry-set installation—it’s a shortcut that’ll result in settlement, weed growth, and instability within one season. Proper dry-set installations require precise edge restraints, geotextile fabric, 4+ inch aggregate bases, and bedding sand that’s been properly screened and compacted. Most flagstone paving and building supplies in Arizona applications benefit from full mortar-set installation over concrete substrate for long-term performance.

Sealing Requirements and Maintenance Protocols

You’ll get conflicting advice about sealing flagstone in Arizona—some sources claim it’s essential, others say it’s optional. The truth depends on flagstone type, installation location, and expected exposure conditions. Natural flagstone in high-traffic areas or around pools benefits from penetrating sealers that reduce staining without creating slippery film-forming surfaces.

Penetrating sealers work by filling the pore structure with hydrophobic compounds that repel water and oil-based stains. You’re not creating a surface coating—you’re modifying the stone’s absorption characteristics. Quality penetrating sealers for Citadel Stone products should meet these criteria: VOC content below 250 g/L for environmental compliance, penetration depth exceeding 3mm, and expected service life of 3-5 years before reapplication becomes necessary.

Manufactured flagstone in Arizona typically exhibits lower porosity than natural sedimentary stones, which means sealing may be optional depending on use patterns. Citadel Stone’s engineered products achieve water absorption rates below 5%, comparable to many granite and quartzite materials that don’t require sealing. For residential patios with normal use, you can often skip sealing entirely and simply clean periodically with pH-neutral detergent.

- Test sealer on sample pieces before full application to verify it doesn’t darken the stone beyond acceptable limits

- Apply sealers only after mortar and grout have cured completely—minimum 30 days for cementitious products

- Reapply sealers when water no longer beads on the surface, typically every 2-4 years depending on traffic and exposure

- Avoid film-forming acrylic sealers on exterior flagstone—they create slippery surfaces and peel under UV exposure

Maintenance requirements for Flagstone for Sale in Arizona include periodic cleaning to remove organic growth, particularly in shaded areas where moisture persists. Use oxygen bleach solutions rather than chlorine products, which can discolor natural stone and degrade mortar joints. Power washing works effectively but keep pressure below 1,500 PSI and use wide fan tips to avoid eroding grout joints.

Cost Comparison and Project Budgeting

When you’re analyzing costs for flagstone projects, you need to look beyond material price per square foot. Natural flagstone in Arizona from wholesale flagstone pavers in Arizona suppliers typically ranges from $8-15 per square foot for material alone, while manufactured options from Citadel Stone fall in the $6-11 range. That 20-30% material cost difference seems significant until you factor in installation labor.

Natural flagstone requires sorting, custom fitting, and thickness compensation that adds 40-60% more labor hours compared to manufactured products with consistent dimensions. An experienced mason can install approximately 60-80 square feet of manufactured flagstone per day, dropping to 40-50 square feet for natural material. At labor rates of $40-60 per hour, that difference translates to $3-5 per square foot in additional installation costs for natural stone.

You’re looking at total installed costs (material + labor + substrate) of approximately $18-28 per square foot for quality flagstone installations in Arizona. Projects requiring extensive substrate preparation, difficult access, or complex patterning can push costs to $30-35 per square foot. Compare these numbers to stamped concrete ($12-18 installed) or pavers ($15-22 installed) when presenting options to clients.

- Freight costs from flagstone distributors in Arizona affect project budgets significantly—verify delivery charges before finalizing material selection

- Premium natural stone varieties like Pennsylvania bluestone or Colorado sandstone can exceed $20 per square foot for material alone when shipped to Arizona

- Locally-sourced flagstone from Arizona quarries reduces freight costs but limits color and texture options compared to Citadel Stone’s broader inventory

The economic advantage of manufactured flagstone in Arizona becomes more pronounced on larger projects where dimensional consistency accelerates installation. A 2,000-square-foot commercial plaza using Citadel Stone manufactured products might save $8,000-12,000 in labor costs compared to natural stone, partially offsetting any material cost premiums for higher-end products.

Citadel Stone — Premium Flagstone for Sale in Arizona Performance

Citadel Stone brings specialized expertise in matching flagstone products to Arizona’s diverse climate zones and project requirements. You’re working with professionals who understand the difference between specifying materials for Flagstaff’s 7,000-foot elevation with freeze-thaw cycles versus Phoenix’s extreme heat and minimal moisture. This regional knowledge translates into product recommendations that perform reliably rather than requiring premature replacement.

When you’re sourcing from Citadel Stone warehouse locations, you’ll find inventory levels that support project timelines without extended lead times. Many flagstone dealers in Arizona operate primarily as order-takers, requiring 6-8 week lead times for material delivery from out-of-state quarries or manufacturers. Citadel maintains regional stock that allows project starts within days rather than months—critical when you’re managing construction schedules with weather-dependent activities.

The technical support Citadel Stone provides goes beyond product sales. You’ll receive installation guidance specific to your project conditions, including substrate recommendations, mortar specifications, and joint detailing appropriate for your location and exposure. This consultative approach helps prevent the common specification errors that plague flagstone projects and lead to callbacks, warranty claims, and reputation damage.

How Citadel Stone Would Approach Flagstone for Sale in Arizona Projects

When recommending Flagstone for Sale in Arizona for diverse municipal and commercial applications, Citadel Stone’s approach centers on matching material characteristics to performance requirements and regional climate factors. Arizona’s eleven cities present distinct environmental conditions that influence material selection—from high-elevation freeze-thaw considerations to low-desert thermal extremes. You’ll find that successful specifications account for these variables proactively rather than treating Arizona as a monolithic climate zone.

Citadel Stone would emphasize manufactured flagstone options for projects requiring dimensional consistency and accelerated installation timelines. The engineered products deliver predictable performance across Arizona’s temperature extremes while maintaining the authentic appearance that clients expect from natural stone. You’re getting material that looks like quarried flagstone but installs with the efficiency and reliability of manufactured pavers.

Phoenix Thermal Performance

For Phoenix applications where surface temperatures exceed 150°F on dark materials, Citadel Stone would recommend light-colored manufactured flagstone in tan, buff, or light gray tones. These colors reflect 50-60% of solar radiation, maintaining surface temperatures 30-40°F cooler than darker alternatives. You’d spec polymer-modified mortars with flexural strength exceeding 500 PSI to accommodate the 50-60°F daily temperature swings common during transitional seasons. Base preparation needs minimum 6-inch compacted aggregate over properly graded subsoil, with positive drainage to prevent water accumulation during monsoon season. Expansion joints every 12-15 feet accommodate thermal movement in large-format installations typical of commercial plazas and municipal hardscaping projects around the metro area.

Tucson UV Stability

Tucson’s intense UV exposure—among the highest in North America—requires iron oxide pigmented manufactured flagstone that won’t fade under prolonged sun exposure. Citadel Stone’s engineered products use inorganic pigments that maintain color stability indefinitely, unlike organic dyes that degrade within 2-3 years. You’d specify penetrating sealers for high-traffic areas while leaving residential patios unsealed to reduce maintenance requirements. The slightly higher elevation compared to Phoenix means you’ll occasionally see overnight temperatures approach freezing in winter, so your grout specification should include polymer content exceeding 15% for flexibility during thermal cycling. Joint widths of 3/8 to 1/2 inch provide adequate grouting space while maintaining the traditional flagstone aesthetic that works well in Tucson’s desert contemporary and Spanish colonial architectural contexts.

Scottsdale Resort Applications

High-end resort and residential projects in Scottsdale demand premium aesthetics combined with commercial-grade durability. Citadel Stone would recommend manufactured flagstone in varied sizes—12×12, 12×24, and 24×24 inch units—creating random patterns that replicate natural stone installations. You’d specify textured surfaces with DCOF ratings exceeding 0.60 for pool deck and spa surround applications where wet slip resistance meets ADA and local code requirements. Color blends mixing three to four complementary tones create visual interest while maintaining the refined appearance luxury projects require. Installation over structural concrete substrate with 1-inch polymer-modified mortar beds ensures long-term stability in areas with heavy furniture loads and wheeled traffic from resort maintenance equipment. Sealed joints prevent staining from organic debris and pool chemicals common in these high-maintenance environments.

Flagstaff Freeze-Thaw Resistance

At 7,000 feet elevation, Flagstaff experiences 100+ freeze-thaw cycles annually—conditions that don’t exist elsewhere in Arizona. Citadel Stone would specify manufactured flagstone with water absorption below 4% to minimize freeze-thaw damage potential. You’d require closed-cell joint backing rod beneath polymer-modified grout in all joints, preventing water infiltration that causes spalling during freeze events. Base systems need to extend below the frost line at 30 inches depth, incorporating well-draining aggregate that won’t retain water during spring thaw. Surface drainage becomes critical—minimum 2% slope prevents standing water that freezes and creates slip hazards. Installation timing matters here too; you’d schedule flagstone work between May and September when substrate and mortar can cure properly before cold weather returns. Citadel’s technical guidance for northern Arizona projects addresses these unique requirements explicitly.

Sedona Aesthetic Integration

Sedona’s iconic red rock landscape creates aesthetic expectations that influence material selection for both commercial and residential projects. Citadel Stone would recommend manufactured flagstone in earth tones—terra cotta, buff, and light brown—that complement rather than compete with the natural environment. You’d specify larger format units (18×18, 24×24 inches) that reduce joint visibility and create clean contemporary lines appropriate for modern desert architecture. The moderate elevation (4,500 feet) means you’ll see occasional light freezes but not the sustained cold that drives Flagstaff specifications. You can use slightly more aggressive joint designs with 1/4 to 3/8 inch spacing that emphasizes the flagstone geometry. Tourist-oriented commercial projects need enhanced durability specifications including sealed surfaces to resist staining from heavy foot traffic and outdoor dining applications.

Yuma Extreme Heat

Yuma’s position as one of the hottest cities in the United States demands careful material selection for year-round usability. Citadel Stone would strongly recommend light-colored manufactured flagstone—cream, light tan, or pale gray—to minimize heat absorption. You’d spec minimum 2-inch thickness for vehicular applications common in municipal parking and commercial loading areas where thermal stress combines with mechanical loading. The extremely low annual rainfall (3 inches) means drainage requirements are minimal, but dust control becomes important. Sealed surfaces prevent fine desert dust from staining porous stone. You’d specify wider joints (1/2 to 3/4 inch) filled with polymer-modified grout that flexes during the 40-50°F temperature swings between winter lows around 45°F and summer highs exceeding 110°F. For additional installation considerations, see Wholesale bluestone pavers and bulk paver stone suppliers for technical guidance on base preparation and substrate requirements specific to low-desert conditions. Contemporary projects feature Citadel Stone’s innovative manufactured flagstone options for consistent sizing.