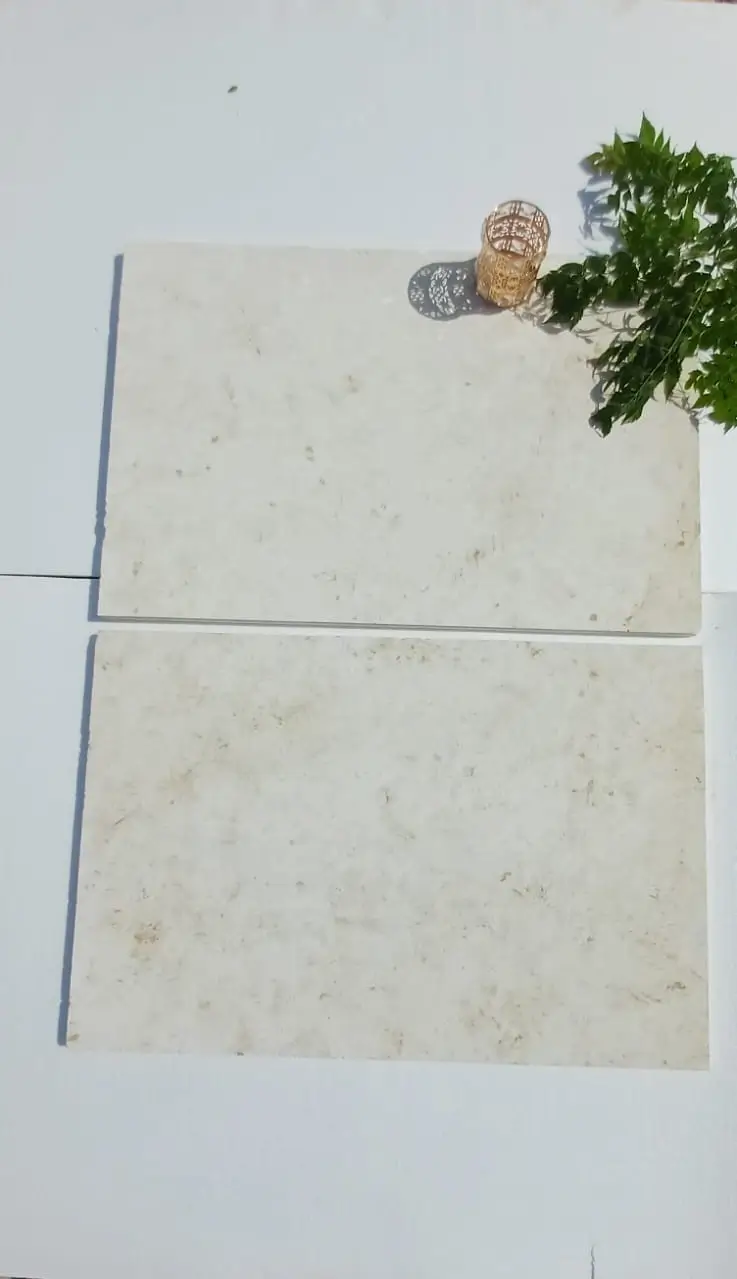

When you’re selecting tile for Arizona applications, 6×12 travertine tile in Arizona delivers the versatility you need for both residential and commercial projects. You’ll find this rectangular format works exceptionally well for shower walls, kitchen backsplashes, and feature walls where you want visual interest beyond standard square formats. Citadel Stone’s 6×12 travertine tile in Arizona comes in multiple finishes and color ranges, giving you the design flexibility to match regional aesthetics while meeting the thermal and durability demands of the Southwest climate.

The 6×12 dimension creates a subtle linear pattern that elongates wall surfaces without the pronounced directionality of larger planks. You’re looking at a format that’s substantial enough to reduce grout joint visibility but manageable enough for detailed installations around fixtures and transitions. Citadel Stone inventory includes filled and unfilled options, honed and tumbled finishes, and color selections ranging from classic ivory to rich walnut tones.

Material Characteristics for Arizona Climates

Travertine’s cellular structure behaves differently than dense stone in Arizona’s extreme heat cycles. You’ll need to understand how this sedimentary carbonate rock responds to thermal stress, moisture fluctuation, and UV exposure common across Phoenix, Tucson, and surrounding desert communities. Citadel Stone’s 6×12 travertine tile in Arizona performs reliably when you account for these environmental factors during specification and installation.

The material exhibits interconnected porosity that affects both water absorption and thermal conductivity. Here’s what matters for your Arizona projects:

- Water absorption rates typically range from 2% to 5% by weight, requiring proper sealing for wet applications

- Thermal expansion coefficient approximates 5.3 × 10⁻⁶ per degree Fahrenheit, moderate compared to denser stone types

- Compressive strength generally exceeds 6,000 PSI for quality grades, adequate for wall applications with proper substrate

- Mohs hardness of 3 to 4 means travertine scratches more easily than granite but remains durable for vertical surfaces

- Natural color variation within individual tiles and between production lots requires careful selection and layout planning

You should verify ASTM C1526 compliance for physical properties when specifying Citadel Stone materials. The standard establishes minimum thresholds for density, absorption, and strength that separate quality travertine 6×12 in Arizona from substandard imports.

Format Advantages in Design Applications

The 6×12 format gives you installation flexibility that square tiles can’t match. You’ll create different visual effects depending on orientation—horizontal installation elongates spaces, while vertical stacking adds height perception. Citadel Stone’s travertine 6×12 in Arizona works particularly well in shower enclosures where you want to minimize horizontal grout lines that collect soap residue and mineral deposits.

Pattern options include running bond, stack bond, herringbone, and vertical brick patterns. Running bond at one-third offset provides the most forgiving layout for managing natural color variation across Citadel Stone tiles. You’re less likely to create noticeable color banding compared to stack bond installations where alignment issues become more obvious.

The rectangular format also simplifies transitions around niches, windows, and fixture penetrations. You can often adjust tile placement by rotating pieces 90 degrees rather than making custom cuts. This flexibility reduces installation time and material waste, particularly important when you’re working with premium Citadel Stone inventory where minimizing offcuts directly affects project economics.

Finish Selection for Function and Aesthetics

Finish choice dramatically affects both appearance and maintenance requirements for 16×24 travertine tile in Arizona. Citadel Stone offers honed, tumbled, brushed, and filled finishes, each creating distinct visual and tactile characteristics. You’ll need to balance aesthetic preferences against practical considerations like cleaning difficulty and long-term wear patterns.

Honed finishes provide a smooth, matte surface that works well in contemporary designs. You’re looking at easier cleaning compared to heavily textured options, but the smooth surface shows water spots more readily in hard-water areas common throughout Arizona. Citadel’s honed 3×6 travertine in Arizona requires consistent sealing to prevent staining from cosmetic products in bathroom applications.

Tumbled finishes create an aged, Old-World appearance with rounded edges and surface texture. This treatment effectively disguises the natural pitting characteristic of travertine, making filled holes less noticeable. The textured surface provides better slip resistance if you’re using 3×6 tumbled travertine tile in Arizona for shower floors, though the format isn’t ideal for that application due to excessive grout joints.

- Filled travertine uses resin or cement to close natural voids, creating a smoother surface that’s easier to clean

- Unfilled travertine retains visible holes that create authentic character but trap debris and require more maintenance

- Brushed finishes combine texture with relative smoothness, offering a middle ground for slip resistance and cleanability

- Polished travertine works for accent walls but isn’t recommended for wet areas due to low DCOF ratings

Don’t overlook how Arizona’s hard water interacts with different finishes. You’ll see mineral deposits more prominently on smooth honed surfaces, while textured tumbled finishes tend to hide light scale buildup. Citadel Stone’s 3×6 tumbled travertine in Arizona performs particularly well in areas with mineral-heavy water supplies common in Phoenix and surrounding communities.

Color Range and Regional Design Preferences

Arizona’s architectural palette favors warm earth tones that complement desert landscapes and Southwestern design traditions. You’ll find that Citadel Stone’s ivory, beige, and walnut travertine colors align naturally with regional preferences for warm neutrals. The 8 x 16 travertine tile in Arizona inventory emphasizes these color families because they work across both traditional and contemporary design applications.

Ivory and light beige travertine reflects light effectively, helping interior spaces feel larger and brighter—a practical advantage in Arizona where outdoor brightness creates strong contrast with interior lighting. You should note that lighter colors also show mineral deposits and soap scum more readily, requiring more frequent cleaning in hard-water areas. Citadel’s premium grades maintain more consistent coloration across production runs, reducing the visible patchwork effect that can occur with lower-quality imports.

Mid-tone beige and noce (walnut) colors provide better tolerance for Arizona’s dusty conditions. You won’t see surface dust as obviously on these tones compared to white or ivory options. The natural color variation within walnut travertine also helps disguise minor staining or etching that can occur despite proper sealing. When you specify 4×8 travertine tile in Arizona for high-traffic commercial applications, these darker tones reduce apparent soiling between cleaning cycles.

Substrate Preparation for Vertical Applications

Your substrate preparation determines whether Citadel Stone’s 6×12 travertine tile in Arizona performs as specified or develops problems within the first year. Travertine’s weight and porosity create specific requirements that differ from lighter ceramic tiles. You’re dealing with approximately 12 to 14 pounds per square foot for standard thickness material, requiring adequate backing support and appropriate thin-set selection.

Cement board remains the most reliable substrate for wet applications. You’ll want minimum ½-inch thickness, properly fastened at 8-inch centers to studs rated for the combined weight of substrate, tile, and thin-set. Waterproof membranes should extend at least 3 inches beyond the tile field on all sides. Don’t assume standard construction waterproofing is adequate—you need ANSI A118.10 compliant membranes that bond properly with your thin-set mortar system.

Surface preparation affects thin-set bond strength directly. Here’s what you need to verify before installation begins:

- Substrate flatness within 1/8 inch over 10 feet, measured with straightedge in multiple directions

- No deflection exceeding L/360 under live load—travertine’s rigidity won’t tolerate substrate flex without cracking

- Surface must be clean, dry, and free from oils, paint, or other bond-breaking contaminants

- Joints and seams properly taped and finished with thin-set before membrane application

- All penetrations sealed and waterproofed before tile installation begins

You should also consider thermal movement in Arizona applications. Interior temperatures can fluctuate 30°F or more between air-conditioned comfort and non-conditioned spaces. Movement joints at perimeter transitions and changes in plane prevent stress concentration that leads to cracking. Citadel Stone recommends soft joints at all inside corners and where tile meets dissimilar materials.

Thin-Set Selection and Application Techniques

Standard thin-set mortars don’t provide adequate performance for travertine in Arizona conditions. You need medium-bed or large-and-heavy-tile mortars that accommodate the format size and provide extended working time in low-humidity desert air. Citadel Stone installations perform best with polymer-modified mortars rated for the tile size and application type you’re specifying.

Back-buttering individual tiles ensures complete coverage under the tile. You can’t rely on wall-applied thin-set alone when working with natural stone that may have slight back-surface irregularities. This technique also helps you manage Arizona’s rapid thin-set skinning—you’re often working with 10 to 15 minute open times before the mortar surface becomes unworkable. For guidance on related installation approaches, see our 8×16 travertine tile inventory for comprehensive technical specifications.

Trowel size matters more than most installers realize. You’ll need at least ½-inch square-notch trowels for 6×12 format tiles, potentially larger for heavily textured backs. The notch size should create ridges that collapse to 80% coverage or better when tiles are set. Insufficient coverage creates voids where moisture can accumulate, leading to efflorescence or bond failure in wet applications.

Grout Selection and Joint Sizing Considerations

Joint width affects both aesthetics and long-term performance when you install Citadel Stone’s travertine tiles 600 x 400 in Arizona. Minimum joint width should be 3/16 inch for rectified edges, increasing to ¼ inch or more for tumbled or non-rectified materials. Don’t attempt tight joints with natural stone—you need space to accommodate dimensional variations and provide stress relief during thermal cycling.

Sanded grout works for joints 1/8 inch and wider, which covers most 6×12 travertine installations. You’re looking for grout that matches or coordinates with the tile color variation rather than creating strong contrast. High-contrast grout emphasizes every layout imperfection and makes natural stone’s dimensional variability more obvious. Citadel Stone typically recommends neutral grout tones that blend with the overall tile color range.

Epoxy grout provides superior stain resistance but comes with application challenges in Arizona’s heat. Working time decreases significantly when ambient temperatures exceed 85°F, common in non-conditioned spaces during installation. If you choose epoxy for 2×4 travertine tile in Arizona applications, schedule installation during cooler morning hours and ensure adequate ventilation to manage fumes.

- Standard cement-based grout requires sealing after curing, adding a maintenance step that’s often overlooked

- Polymer-modified grouts provide better stain resistance than standard types without epoxy’s application challenges

- Grout color should be selected from samples grouted on actual tile, not from color charts that don’t account for tile absorption

- Joint depth should be consistent at two-thirds of tile thickness minimum to prevent bond failure

Sealing Requirements and Maintenance Protocols

Every travertine installation requires sealing—the question is when and with what product. You’ll get different recommendations depending on finish type and application location. Citadel Stone’s travertine 600 x 400 in Arizona needs initial sealing after grout has fully cured, typically 72 hours after grouting in low-humidity desert conditions.

Penetrating sealers work better than topical coatings for most applications. You want products that protect below the surface without creating a film that can peel or wear unevenly. Impregnating sealers fill the stone’s porous structure with water-repellent compounds while allowing vapor transmission—critical for preventing moisture-related problems in Arizona’s climate.

Application frequency depends on exposure conditions. Shower walls need resealing every 12 to 18 months under normal residential use. Kitchen backsplashes might extend to 24 months between treatments if you’re not dealing with heavy grease exposure. You can test sealer effectiveness with water droplets—if water beads persist for 5 minutes or longer, protection remains adequate. When water absorbs quickly, it’s time to reseal the Citadel Stone surface.

Don’t use acidic cleaners on travertine. The calcium carbonate composition reacts with acids, causing etching that appears as dull spots on honed finishes. Arizona’s hard water creates cleaning challenges that tempt homeowners to use stronger products, but acid-based cleaners cause permanent damage. You should specify pH-neutral stone cleaners and include this guidance in owner’s manuals for projects involving travertine tiles 60 x 40 in Arizona.

Thermal Performance in Arizona Conditions

Arizona’s temperature extremes test material performance in ways that milder climates don’t. You’re dealing with surface temperatures that can exceed 150°F on sun-exposed exterior walls and dramatic cooling from air conditioning in interior spaces. Citadel Stone’s travertine 6×12 in Arizona handles these conditions better than many alternatives when properly installed with appropriate expansion provisions.

Travertine’s moderate thermal expansion coefficient means less movement stress compared to denser stones like granite. You’re still looking at measurable expansion—a 10-foot wall section could expand nearly 1/16 inch with a 50°F temperature swing. This is why soft joints at perimeter transitions matter so much. Rigid connections to dissimilar materials create stress points where cracks initiate during heating and cooling cycles.

Interior installations face less extreme conditions but still require attention to thermal movement. The temperature difference between exterior walls and interior partition walls creates differential expansion. When you install 1×2 travertine tile in Arizona on both exterior and interior surfaces within the same space, make sure your movement joints accommodate these differences. Citadel Stone recommends movement joints at room corners and where tile fields transition to other finishes.

Common Specification Errors to Avoid

Most travertine problems result from specification oversights rather than material defects. You’ll avoid the majority of issues by addressing these common mistakes during the design phase. Citadel Stone’s technical team regularly sees the same errors repeated across Arizona projects, despite straightforward solutions being available.

- Specifying travertine for high-impact areas without acknowledging the material’s moderate hardness—it’s not granite

- Failing to require mock-ups that show actual color variation and finish characteristics before full installation

- Not detailing movement joints at material transitions, particularly where tile meets metal or glass elements

- Inadequate waterproofing details at shower niches, shampoo ledges, and bench tops where water pools

- Omitting sealing requirements from specifications, leaving it to installer discretion or owner responsibility

- Under-specifying substrate requirements, particularly deflection limits that prevent cracking under normal use

- Choosing bright white grout with warm-toned travertine, creating visual discord that cheapens the overall appearance

You should also address shade variation explicitly in your specifications. Natural stone comes with inherent color range that varies between quarry runs. Specifying “substantial variation” or “V3” according to industry standards sets appropriate expectations. Citadel Stone maintains inventory of multiple production lots, but even controlled selection shows more variation than manufactured ceramic products.

Don’t forget to specify proper curing times between installation phases. Thin-set needs adequate cure before grouting, typically 24 to 48 hours in Arizona’s dry climate. Grout needs full cure before sealing. Rushing these steps compromises long-term performance regardless of material quality. When you’re working with premium Citadel Stone products, protect your investment by enforcing proper installation timing.

Citadel Stone – Premium Travertine Tiles 600 x 300 in Arizona — Regional Specification Guide

Citadel Stone’s travertine tiles 600 x 300 in Arizona represent our commitment to quality materials that perform reliably in Southwest conditions. This section provides hypothetical specification guidance for Arizona communities where our expertise in desert climate applications would inform material selection and installation approaches. You’ll find conditional recommendations based on regional factors that affect travertine performance across the state’s diverse climate zones.

Arizona’s climate varies dramatically from low desert to high plateau regions. When you’re specifying Citadel Stone travertine for Arizona projects, you need to account for temperature ranges, humidity variations, and water quality differences that affect both initial installation and long-term maintenance. Our regional knowledge helps you avoid common pitfalls that emerge when applying generic specifications to Southwest conditions.

Phoenix Installation Factors

Phoenix’s extreme summer heat and hard water create specific challenges for travertine applications. You’d want to emphasize sealing protocols that protect against mineral deposit accumulation from the city’s heavily treated water supply. Citadel Stone would recommend penetrating sealers with enhanced stain resistance for shower installations where Phoenix’s water chemistry accelerates surface buildup. Interior temperature stability from consistent air conditioning actually creates favorable conditions for installation timing—you could work year-round with proper climate control during cure periods. Movement joint spacing might be more conservative in Phoenix applications where air-conditioned interiors meet superheated exterior walls.

Tucson Climate Considerations

Tucson’s slightly higher elevation and monsoon moisture patterns would influence Citadel Stone specification approaches differently than Phoenix. You’re dealing with more pronounced seasonal humidity swings that affect sealer selection and reapplication intervals. Summer monsoon conditions could extend thin-set and grout curing times compared to drier Phoenix installations. Tucson’s water quality varies by neighborhood, so you’d want to test specific conditions before finalizing sealer recommendations. The city’s strong Southwestern design traditions align well with travertine’s natural warmth, making our walnut and noce color ranges particularly appropriate for regional aesthetics.

Scottsdale Design Applications

Scottsdale’s luxury residential market would benefit from Citadel Stone’s premium-grade travertine with tight color sorting and superior finish quality. You’d specify first-choice materials with minimal fill and consistent veining patterns that align with high-end design expectations. Scottsdale projects often incorporate spa-like bathrooms where travertine’s natural aesthetic supports wellness-focused design. Our tumbled finishes would work particularly well for creating Old-World elegance in Mediterranean-inspired homes common throughout Scottsdale neighborhoods. Water quality remains similar to Phoenix, requiring the same attention to sealing and maintenance protocols.

Flagstaff Temperature Extremes

Flagstaff’s high-altitude climate presents unique considerations that would shape Citadel Stone specifications differently than lower-elevation Arizona cities. You’re working with genuine freeze-thaw potential that doesn’t exist in Phoenix or Tucson. While travertine performs well in Flagstaff’s interior applications, you’d need to account for heating system effects on humidity and temperature cycling. The extended heating season creates drier interior conditions than lower elevations, potentially requiring more frequent sealer reapplication. Flagstaff’s mountain aesthetic aligns naturally with travertine’s organic character, particularly our textured and tumbled finishes that complement rustic mountain design traditions. Movement joints would need careful attention where tile meets exterior walls subject to snow loads.

Sedona Aesthetic Integration

Sedona’s distinctive red rock landscape would influence Citadel Stone color recommendations toward warmer beige and walnut tones that harmonize with regional geology. You’d avoid cool gray travertines that clash with Sedona’s warm earth palette. The community’s resort-focused market creates opportunities for spa and hospitality applications where travertine’s natural elegance enhances wellness environments. Sedona’s building codes emphasize environmental integration, making natural stone an appropriate material choice. Water quality varies between Oak Creek corridor properties and upland developments, requiring site-specific sealer selection. Sedona’s tourism economy means commercial installations would need durable finishes that maintain appearance under heavy use.

Yuma Desert Performance

Yuma’s position as Arizona’s hottest city and its agricultural economy create unique conditions for Citadel Stone applications. You’d face the most extreme thermal stress of any Arizona location, requiring careful attention to expansion provisions and substrate preparation. Yuma’s Colorado River water source provides better quality than groundwater-dependent Phoenix, potentially reducing mineral deposit issues. The agricultural community’s practical focus would favor our durable honed finishes over delicate polished options. Yuma’s heating-dominated climate creates stable interior conditions much of the year, but summer cooling loads match Phoenix levels. Commercial agricultural-related facilities might choose travertine for office and hospitality spaces where the natural material provides welcome contrast to industrial surroundings.

Budget Planning and Long-Term Value

Citadel Stone’s 6×12 travertine tile in Arizona carries premium pricing compared to ceramic alternatives, but you’re investing in natural material with distinct aesthetic qualities that manufactured products can’t replicate. Material costs typically range from $8 to $18 per square foot depending on grade, finish, and color selection. You’ll pay more for first-choice materials with tight color sorting and less fill, but the visual consistency often justifies the premium in high-visibility applications.

Installation costs exceed standard ceramic tile due to the material’s weight and the specialized techniques required for natural stone. You should budget $12 to $20 per square foot for professional installation including substrate preparation, waterproofing, and sealing. Total project costs for 6×12 travertine range from $20 to $38 per square foot installed, positioning it in the upper-middle range of wall finish options.

The long-term value proposition depends on maintenance commitment and application appropriateness. Travertine in well-suited applications maintains appearance and functionality for decades with proper care. You’re looking at resealing costs every 12 to 24 months plus routine cleaning with appropriate products. Total lifecycle cost over 20 years remains competitive with premium ceramic options when you factor in travertine’s timeless aesthetic that doesn’t date as quickly as trend-driven manufactured tiles.

Professional Specification Guidance

When you’re ready to specify Citadel Stone’s 6×12 travertine tile in Arizona, start with clear project requirements that address both functional needs and aesthetic goals. You’ll make better decisions by establishing priorities early—whether you’re optimizing for budget, durability, appearance, or maintenance ease. Each priority leads to different product selections within the travertine category.

Work directly with Citadel Stone’s technical team to review substrate conditions, water quality, and climate factors specific to your project location. We provide samples from current inventory so you can evaluate actual color variation and finish characteristics rather than relying on photographs that don’t capture natural stone’s complexity. Mock-ups remain the most effective way to set accurate expectations before committing to full installation.

Don’t overlook the importance of qualified installers with natural stone experience. Citadel Stone can recommend installation professionals familiar with travertine’s specific requirements. You’re protecting your material investment by ensuring proper techniques throughout the installation process. For additional resources on Arizona travertine applications, review Premium travertine tile suppliers and installation services in Arizona before finalizing your project specifications. Citadel Stone’s popular travertine 6×12 provides rectangular elegance for wall applications.