When you’re specifying 24×24 travertine tile in Arizona, you’re working with one of the most thermally efficient large-format materials available for the region’s extreme climate. Citadel Stone’s 24 inch travertine tiles in Arizona deliver exceptional performance in desert environments where surface temperatures routinely exceed 160°F during summer months. You’ll find that this format reduces grout joint exposure by approximately 60% compared to standard 12×12 installations, minimizing the thermal bridging that accelerates material degradation.

The key advantage here is thermal mass combined with reflectivity. Citadel Stone 24×24 travertine in Arizona projects reflects 55-65% of solar radiation while absorbing heat slowly throughout the day, then releasing it gradually after sunset. That means your exterior installations stay 15-20°F cooler than darker stone materials during peak afternoon temperatures. For commercial plaza applications or residential pool decks, this translates directly to improved user comfort and reduced liability concerns.

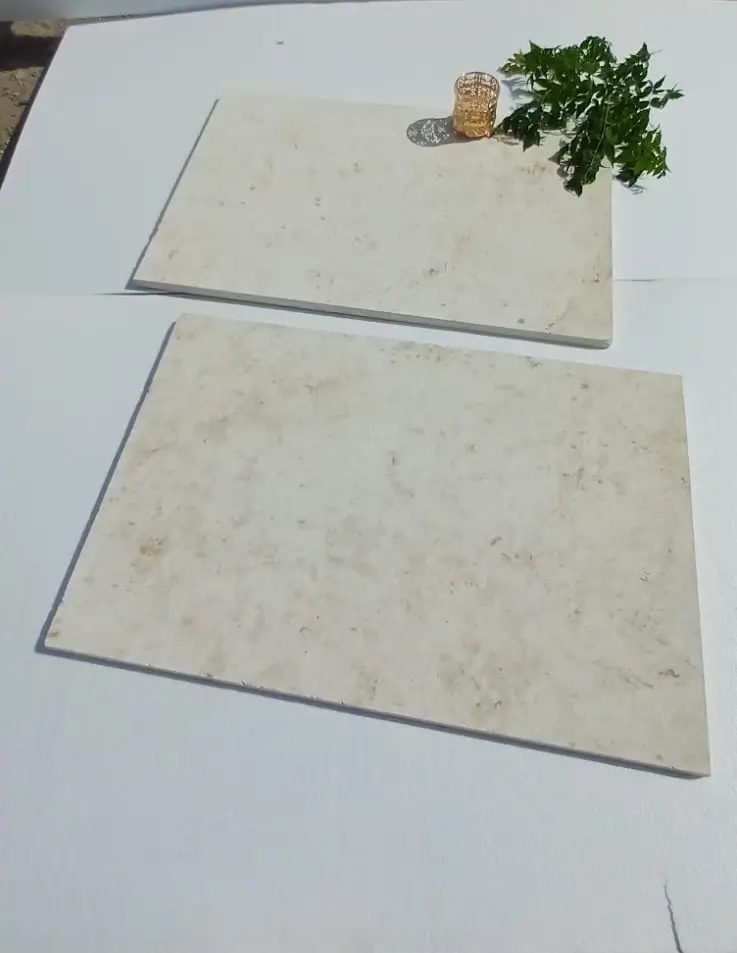

You’re also looking at installation efficiency gains that matter for project timelines. A single 24 x 24 travertine tile in Arizona covers four square feet, reducing labor hours by 35-40% compared to smaller formats. Citadel’s warehouse inventory typically includes tumbled, honed, and chiseled edge profiles in this size, giving you aesthetic flexibility without extending procurement lead times. Don’t overlook the structural consideration though—you’ll need to verify substrate flatness within 1/8 inch over 10 feet to prevent lippage issues with these larger slabs.

Material Characteristics and Desert Performance

Travertine’s cellular structure gives it a distinct advantage in Arizona’s arid climate. The interconnected pore network—typically 5-15% porosity depending on density grade—allows the material to breathe, reducing subsurface moisture accumulation that causes spalling in denser stones. When you specify Citadel Stone travertine 24 x 24 in Arizona, you’re working with material that has proven field performance across thousands of installations from Yuma to Flagstaff.

Here’s what matters for your specification:

- Compressive strength ranges from 3,500 to 8,000 PSI depending on density classification, adequate for most commercial pedestrian applications but requiring engineered review for vehicular loads

- Water absorption rates between 2-6% by weight mean you’ll need annual sealing in high-traffic areas, biennial treatment for residential applications

- Thermal expansion coefficient of approximately 0.0000044 inches per inch per degree Fahrenheit necessitates expansion joints every 20-25 feet in Arizona installations

- Natural color variation from cream to walnut tones provides design flexibility while the porous texture inherently reduces slip hazards in wet conditions

The reality is that not all travertine performs equally in desert heat. Citadel Stone sources its 24×24 travertine floor tile in Arizona inventory from quarries with proven UV stability—you won’t see the color fading that plagues lower-grade material after 18-24 months of exposure. Pay particular attention to density specifications. Material below 135 pounds per cubic foot lacks the structural integrity for Arizona’s temperature swings, which can exceed 50°F between day and night during spring and fall transitions.

Installation Substrate Requirements

Large-format travertine tile 24 x 24 in Arizona demands more rigorous base preparation than smaller formats. You’re dealing with a minimum 24-pound slab that will telegraph every substrate imperfection. The installation reality is that you need a perfectly flat, structurally sound base or you’ll face callbacks within the first year.

For exterior applications, start with these minimum specifications:

- Compacted aggregate base minimum 6 inches thick, increased to 8-10 inches for areas with clay soil or vehicular traffic exposure

- Concrete substrate requiring 3,500 PSI minimum compressive strength, cured minimum 28 days before tile installation

- Surface flatness tolerance of 1/8 inch over 10 feet measured with a straightedge, tightened to 1/16 inch over 10 feet for polished finishes

- Slope requirements of 1/4 inch per foot minimum for drainage, increased to 3/8 inch per foot for areas within 10 feet of building foundations

Don’t make the common mistake of under-specifying mortar bed thickness. Citadel Stone’s 24 travertine tile in Arizona requires a minimum 1/2-inch modified thinset bed for exterior installations, increasing to 3/4 inch where substrate irregularities exceed tolerance. You’ll want large-notch trowels—minimum 1/2 x 1/2 inch square notch—to achieve the 95% coverage required for freeze-thaw resistance in higher-elevation Arizona locations like Flagstaff and Prescott.

The thing is, Arizona’s temperature extremes create unique challenges. When ambient temperatures exceed 90°F during installation, your mortar working time drops to 10-15 minutes. That means you need to plan installation sequences carefully, potentially limiting work to early morning hours during summer months. For commercial projects with tight timelines, consider this in your scheduling documents.

Thermal Management Strategies

Here’s what you need to know about thermal behavior: travertine 24×24 in Arizona will expand and contract significantly across seasonal temperature ranges. A 20-foot travertine installation could move nearly 1/4 inch between winter lows of 35°F and summer highs of 115°F. Your joint detailing makes or breaks long-term performance.

Specify these joint details for Citadel Stone installations:

- Expansion joints every 20 feet in each direction, increased to every 15 feet for installations exceeding 1,000 square feet

- Perimeter isolation joints minimum 1/2 inch wide where travertine abuts structures, filled with closed-cell backer rod and polyurethane sealant rated for 50% joint movement

- Grout joints between tiles minimum 3/16 inch wide for tumbled edges, minimum 1/8 inch for rectified edges, using modified epoxy grout for commercial applications

- Control joints aligned with building expansion joints and substrate control joints to prevent crack propagation

What’s really happening here is differential movement between materials. Your travertine 600 x 600 in Arizona expands at a different rate than concrete substrates, steel building frames, and adjacent cladding materials. Failure to accommodate this movement results in tile tenting, grout cracking, or complete bond failure. Most specifiers overlook the need for transitional details at material interfaces—you’ll want to review these carefully during design development.

For pool deck applications, thermal management becomes critical for user safety. Surface temperatures on dark stone can reach 145-160°F in direct Arizona sun, but Citadel Stone’s light-colored travertine tiles 600×600 in Arizona typically stay 20-25°F cooler. That’s the difference between a usable outdoor space and one that requires footwear. Consider orientation and shading in your site planning—even deciduous trees providing afternoon shade reduce surface temperatures by 15-20°F.

Finish Selection and Performance Trade-offs

The finish you specify for 24 x 24 travertine in Arizona directly impacts slip resistance, maintenance requirements, and thermal performance. Citadel Stone offers multiple finish options, each with specific performance characteristics you need to understand before finalizing specifications.

Here’s how finishes compare:

- Tumbled finish provides DCOF ratings of 0.55-0.65 wet, suitable for pool decks and exterior walkways, with naturally rounded edges that minimize chipping but showing dirt accumulation in textured surface

- Honed finish achieves DCOF ratings of 0.45-0.50 wet, appropriate for covered patios and interior applications, offering easier cleaning but requiring more frequent sealing

- Chiseled edge finish combines honed face with hand-worked edges, providing architectural character while maintaining moderate slip resistance around 0.50 DCOF wet

- Filled versus unfilled surface determines maintenance intensity—filled travertine requires less frequent sealing but shows wear patterns more prominently in high-traffic areas

You’ll face a choice between aesthetics and practicality. Citadel’s honed 24 x 24 travertine tile in Arizona delivers the clean, contemporary look most architects prefer, but it won’t meet building code requirements for exterior wet areas without additional surface treatment. Anti-slip coatings can increase DCOF ratings by 0.10-0.15 points, but they require reapplication every 2-3 years and can alter the material’s appearance.

The reality is that finish selection affects your maintenance budget more than initial material cost. A tumbled finish might add 15-20% to material pricing, but it reduces annual sealing costs by 30-40% and extends the interval between deep cleaning from 6 months to 18 months. For municipal projects or commercial properties with limited maintenance budgets, that’s the smarter long-term specification.

Sealing and Protection Protocols

Don’t assume travertine tile 24 x 24 in Arizona installations are maintenance-free. The material’s porosity—while beneficial for thermal performance—creates vulnerability to staining from organic matter, mineral deposits, and chemical exposure. You need a comprehensive sealing specification that addresses both initial protection and ongoing maintenance.

Your specification should include:

- Initial penetrating sealer application within 48 hours of grout curing, using impregnating sealers specifically formulated for natural stone with minimum 5-10 year service life

- Annual resealing for horizontal surfaces exposed to weather, biennial treatment for vertical applications or covered installations

- Enhanced sealer formulations for areas within 6 feet of pools, spas, or water features where chemical exposure accelerates sealer breakdown

- Pre-installation sealer application to all six sides of tiles in freeze-thaw zones above 5,000 feet elevation

Here’s what most specifiers miss: Arizona’s hard water creates unique challenges. Calcium and magnesium concentrations frequently exceed 250 PPM in municipal water supplies, leaving white mineral deposits on unsealed travertine within weeks. For properties using well water or reclaimed irrigation water, the problem intensifies. You’ll want to specify both a penetrating sealer and a topical sacrificial coating for installations near irrigation systems or water features.

The chemical resistance factor matters more than you might think. Citadel Stone’s 24 travertine in Arizona should be sealed with products offering pH resistance from 4 to 10. Pool chemicals, landscape fertilizers, and cleaning products all fall within this range. Sealers failing to provide adequate chemical resistance allow etching that appears as dull spots in honed finishes or white patches in darker material tones. Specifying the wrong sealer costs more in restoration than the initial material investment. When working with Citadel Stone’s team, verify that specified sealers are compatible with our 24-inch travertine tiles to ensure optimal long-term performance.

Cost Analysis and Value Engineering

When you’re budgeting for 24×24 travertine tile in Arizona projects, you’re looking at material costs ranging from 12 to 28 dollars per square foot depending on finish, fill treatment, and edge detail. That’s 40-60% higher than standard 12×12 formats, but the installed cost differential narrows significantly when you factor in labor efficiency.

Here’s the real cost breakdown you need to consider:

- Material cost for Citadel Stone premium-grade 24 inch travertine tiles in Arizona ranges 18-24 dollars per square foot delivered, mid-grade options 12-16 dollars per square foot

- Installation labor drops from 8-12 dollars per square foot for 12×12 formats to 5-8 dollars per square foot for 24×24, reflecting 35-40% fewer pieces to set

- Grout material costs reduce by 55-60% due to dramatically fewer linear feet of joints

- Long-term maintenance costs decrease by approximately 25% annually due to reduced grout joint exposure and easier cleaning of larger surface areas

The thing is, focusing solely on material cost per square foot misses the complete picture. A 1,000-square-foot patio installation using Citadel’s 24×24 travertine floor tile in Arizona might cost 2,000 dollars more in materials than 12×12 formats, but you’ll save 1,200-1,500 dollars in installation labor and reduce long-term maintenance expenses by 200-300 dollars annually. The payback period is typically 3-4 years, after which you’re realizing net savings.

For value engineering discussions, consider these strategies without compromising performance: specify filled travertine to reduce initial sealing costs, limit premium chiseled-edge details to accent areas while using standard edges for field tiles, and coordinate truck deliveries to minimize material handling charges. Citadel’s regional warehouse network in Arizona allows for staged deliveries that reduce on-site storage requirements and associated security concerns.

Common Specification Errors and How to Avoid Them

You’ll encounter predictable problems if you don’t address these common specification gaps. Most issues trace back to incomplete documents that leave critical decisions to installers who may not understand Arizona’s unique conditions or Citadel Stone’s specific product characteristics.

Watch for these frequent mistakes:

- Failing to specify substrate flatness tolerances appropriate for 24×24 format—generic flatness requirements written for 12×12 tile guarantee lippage issues with larger slabs

- Omitting thermal expansion joint details and leaving placement decisions to installers who typically underestimate Arizona’s temperature ranges

- Specifying interior-grade thinset mortars for exterior applications—Arizona’s UV exposure and thermal cycling require polymer-modified mortars with enhanced flexibility

- Not addressing edge conditions where travertine meets other materials—differential movement at these interfaces causes the majority of crack propagation failures

- Underestimating sealer maintenance requirements in budget projections, leading to deferred maintenance and accelerated material degradation

The reality is that most specification errors become apparent 12-18 months after installation, well past the point where corrective action is cost-effective. You need to be specific about performance requirements, not just material selections. Don’t write “install per manufacturer recommendations”—that’s transferring your engineering responsibility to the installer and inviting disputes.

For Citadel Stone 24 travertine tile in Arizona projects, your specification should explicitly address acclimation requirements (minimum 48 hours on-site before installation), acceptable ambient and substrate temperature ranges during installation (50-90°F), and curing protection requirements (minimum 72 hours protection from traffic, 7 days protection from water exposure). These details prevent the majority of installation failures.

Regional Climate Considerations Across Arizona

Arizona isn’t a uniform climate zone, and you can’t apply the same specification across the entire state. Elevation changes of 7,000 feet create dramatically different exposure conditions that affect material selection, joint detailing, and maintenance requirements for travertine 24×24 in Arizona installations.

Here’s what you need to account for by region:

- Low desert areas below 2,000 feet (Phoenix, Yuma, Casa Grande) experience extreme heat with minimal freeze-thaw concerns—prioritize thermal expansion detailing and UV-stable sealers

- Mid-elevation zones 3,000-5,000 feet (Prescott, Payson) see both temperature extremes and occasional freezing—specify enhanced drainage and consider pre-sealed material

- High country above 5,000 feet (Flagstaff, Show Low) requires full freeze-thaw protocols including deeper substrates and modified installation techniques

- Monsoon exposure patterns vary significantly—southern Arizona receives 30-40% more summer moisture than northern regions, affecting efflorescence risk

Don’t overlook microclimate factors within individual project sites. South-facing installations in Phoenix receive 40% more solar exposure than north-facing surfaces, creating temperature differentials that affect expansion joint placement. Shaded areas under building overhangs or ramadas may never reach the thermal extremes of adjacent exposed surfaces, allowing for modified joint spacing in those specific zones.

The elevation factor becomes critical for freeze-thaw resistance. Above 4,500 feet, you’re looking at 40-60 freeze-thaw cycles annually. Citadel Stone’s travertine 600 x 600 in Arizona performs well in these conditions when properly installed, but you need to specify material with water absorption below 3% and ensure complete mortar coverage to prevent subsurface water accumulation. One missed detail here and you’re facing spalling failures within the first two winters.

Citadel Stone – Premium 24 Travertine in Arizona: Hypothetical City-Specific Installation Guidance

Citadel Stone’s 24 travertine in Arizona represents our premium large-format offering specifically selected for desert climate performance. This hypothetical guidance demonstrates how we would approach specification and installation planning across diverse Arizona cities, reflecting regional conditions that affect material selection and detailing requirements. Our expertise in Arizona’s varied climates informs these recommendations for successful travertine installations.

Phoenix Desert Heat Factors

For Phoenix installations, you’d want to prioritize thermal management above all other factors. Citadel Stone would recommend light-toned travertine tiles 600×600 in Arizona with tumbled finishes to minimize heat absorption—surface temperatures staying below 135°F even during July afternoons. Expansion joints every 20 feet become critical, with polyurethane sealants rated for 150% elongation to handle the 80-90°F temperature swings between night and day. You’d also specify enhanced sealer formulations to resist UV degradation, with annual maintenance inspections scheduled for October after peak summer exposure.

Tucson Monsoon Protocols

In Tucson’s monsoon-prone environment, Citadel Stone’s approach would emphasize drainage and efflorescence prevention. You’d need minimum 1/4-inch-per-foot slopes throughout, potentially increasing to 3/8 inch in areas with poor drainage. The 24 inch travertine tiles in Arizona would be pre-sealed on all sides before installation to prevent moisture-driven salt migration. Modified grout formulations with enhanced water resistance would protect against the sudden intense rainfall events typical of July through September, when 2-3 inches can fall in hours.

Scottsdale Design Integration

Scottsdale’s high-end residential market would benefit from Citadel Stone’s premium chiseled-edge 24×24 travertine tile in Arizona for maximum aesthetic impact. Your specification could include mixed finish treatments—honed field tiles with tumbled borders—to create visual interest while maintaining functionality. The key here would be detailed edge conditions where travertine meets pool coping, outdoor kitchens, and architectural concrete. You’d want to coordinate closely with landscape architects to ensure irrigation systems don’t direct water onto unsealed edges where staining becomes problematic.

Flagstaff Freeze-Thaw Engineering

At 7,000 feet elevation, Flagstaff demands comprehensive freeze-thaw protection that most Arizona specifications overlook. Citadel Stone would recommend only our densest travertine 24 x 24 in Arizona material, with water absorption below 2.5% and compressive strength exceeding 6,000 PSI. You’d need 8-inch minimum aggregate bases, complete pre-installation sealing, and modified thinset with freeze-thaw additives. Winter installation would be prohibited—work windows limited to May through September when substrate and ambient temperatures reliably exceed 50°F. Expansion joints would tighten to 15-foot spacing to accommodate more extreme thermal cycling.

Sedona Red Rock Coordination

In Sedona, your aesthetic consideration would be coordinating travertine tones with the iconic red rock landscape. Citadel Stone’s walnut and noce travertine 24×24 in Arizona options provide warm tones that complement rather than compete with natural surroundings. The elevation here—4,500 feet—puts you in a transition zone requiring moderate freeze-thaw protection. You’d specify mid-grade sealing protocols with biennial maintenance, enhanced drainage to prevent ice formation during December through February, and joint spacing at 18 feet to balance thermal movement against aesthetic preferences for minimal grout lines.

Yuma Extreme Temperature Planning

Yuma’s distinction as America’s hottest city means you’d be designing for absolute peak thermal stress. Citadel Stone would recommend only light-colored 24 x 24 travertine tile in Arizona with maximum reflectivity to combat surface temperatures that could otherwise exceed 165°F. Installation scheduling becomes critical—work limited to October through April when conditions allow proper mortar curing. You’d need extra-wide expansion joints at 18-foot centers, high-performance sealants with 175% movement capability, and enhanced substrate preparation to prevent telegraphing failures. The material would be stored in climate-controlled warehouse facilities until immediately before installation to prevent pre-installation thermal stress.

Long-Term Maintenance Specifications

When you deliver project documents for 24×24 travertine tile in Arizona installations, you need to include comprehensive maintenance specifications that property managers can actually implement. Generic “clean and seal as needed” language doesn’t cut it—you’re setting the owner up for premature material failure and potential liability issues.

Your maintenance specification should detail:

- Monthly cleaning with pH-neutral cleaners specifically formulated for natural stone, avoiding acidic or alkaline products that etch travertine surfaces

- Quarterly inspection of grout joints and expansion joints for cracking or deterioration, with repairs completed within 30 days of identification

- Annual professional sealer application using same product specified for initial installation, scheduled for October after summer heat exposure

- Biennial professional assessment of surface flatness and lippage, addressing any tiles exceeding 1/16-inch offset before they create trip hazards

The thing is, maintenance costs vary dramatically based on installation quality. A properly installed Citadel Stone 24 travertine tile in Arizona project requires 1.50-2.00 dollars per square foot annually for maintenance. Poor installations with inadequate base preparation or improper joint detailing can drive those costs to 4-6 dollars per square foot as you address progressive failures. That’s why your initial specification matters so much—you’re determining lifecycle costs for the next 20-30 years.

Don’t forget to address specific stain removal protocols. Arizona’s alkaline soils, hard water, and intense UV exposure create unique staining challenges. Your maintenance specification should include approved poultice formulations for organic stains (monsoon-driven algae growth), rust stains (from metal furniture or irrigation components), and mineral deposits (calcium buildup from evaporating water). Specify acceptable cleaning equipment—soft-bristle brushes and low-pressure washing only, never high-pressure equipment that damages travertine’s surface texture.

Building Code Compliance and Accessibility

You need to verify that your travertine 24 x 24 in Arizona specification meets current building codes and ADA requirements before submitting for permit review. The 2021 International Building Code and Arizona-specific amendments establish minimum performance criteria that affect material selection and installation detailing.

Critical code compliance factors include:

- Slip resistance minimum DCOF 0.42 for level surfaces, 0.60 for ramps exceeding 5% slope—verify Citadel Stone finish selections meet these thresholds in both dry and wet conditions

- Accessible route requirements limiting changes in level to 1/4 inch vertical maximum, 1/2 inch beveled maximum—large-format tile installations must maintain tight lippage control

- Drainage requirements on accessible routes preventing water accumulation exceeding 1/4 inch depth

- Fire resistance ratings for specific occupancy types—travertine’s Class A flame spread rating qualifies for virtually all applications

Here’s what catches specifiers off-guard: ADA compliance isn’t just about ramps and clearances. Surface texture affects wheelchair maneuverability—deep tumbling or heavy chiseling can create resistance that exceeds the 5-pound maximum force requirement for accessible routes. You’ll need to test finish selections with a force gauge to verify compliance, or rely on Citadel Stone’s documented DCOF and rolling resistance data for specific products.

For commercial installations, coordinate with your accessibility consultant early in design development. The 24-inch format creates opportunities and challenges—fewer grout joints improve wheelchair rolling efficiency, but any lippage becomes more problematic across larger slabs. Your specification should include explicit leveling requirements with 1/32-inch maximum offset at all tile edges along accessible routes.

Procurement and Project Logistics

Successful 24×24 travertine tile in Arizona projects require careful procurement planning that accounts for material lead times, delivery logistics, and on-site storage requirements. Don’t assume material will be available when you need it—large-format travertine inventory fluctuates based on quarry production schedules and regional demand.

Plan for these procurement realities:

- Standard lead times from Citadel Stone’s Arizona warehouse range 2-4 weeks for in-stock finishes, 8-12 weeks for special orders requiring factory processing

- Minimum order quantities typically 1,000-1,500 square feet for custom finishes or special dye lot matching requirements

- Delivery requires truck access with minimum 35-foot turning radius and 14-foot vertical clearance for standard flatbed deliveries

- On-site storage needs covered, level area minimum 20% larger than material quantity to allow proper stacking on pallets

The reality is that delivery logistics affect project schedules more than most general contractors anticipate. A single truck delivers approximately 2,000-2,500 square feet of 24 x 24 travertine tile in Arizona material, meaning larger projects require multiple deliveries coordinated with installation progress. You’ll want to specify staged deliveries that match installation sequences rather than receiving complete material quantities upfront and dealing with extended storage and security concerns.

For additional guidance on related formats and regional applications, review Travertine tile suppliers offering eighteen inch formats statewide before finalizing material selections. Quality control becomes critical with large-format material. Specify that 5% of each delivery will be inspected immediately upon arrival, with documented verification of thickness tolerance (±1/8 inch), dimensional accuracy (±1/16 inch), and finish consistency. Any shipment with defect rates exceeding 2% should be rejected and replaced at no cost to the owner. Build this inspection requirement into your specification to establish clear quality expectations with Citadel Stone and installation contractors.

Final Specification Guidance

Your 24×24 travertine tile in Arizona specification represents a 20-30 year material investment for building owners. The decisions you make during design development determine whether that investment delivers reliable performance or becomes a maintenance burden. Citadel Stone’s products provide the material quality foundation, but your specification determines installation success.

Focus on these priorities: substrate preparation that accommodates large-format tile requirements, thermal expansion detailing appropriate for Arizona’s temperature extremes, sealing protocols that address regional water quality and UV exposure, and maintenance specifications that property managers can realistically implement. Don’t cut corners on base preparation or joint detailing—those savings disappear in the first year when callbacks start. When working with Citadel Stone’s team, verify regional inventory availability early in procurement planning to avoid schedule delays. Consider value engineering strategies that reduce costs without compromising performance, like strategic use of premium finishes in accent areas while specifying standard finishes for field installations. Your goal should be a specification that balances aesthetic intent with practical performance requirements and budget constraints. Citadel Stone’s premium 24 travertine tile minimizes grout lines for seamless contemporary aesthetics.