When you’re specifying 12mm travertine tile in Arizona, you’re choosing a material that balances durability with the thermal demands of desert climates. This thickness provides structural integrity for residential and light commercial applications while maintaining the aesthetic warmth travertine brings to interior spaces. You’ll find that Citadel Stone’s 12mm travertine offerings address the unique challenges Arizona projects present, from Phoenix’s intense summer heat to Flagstaff’s occasional freeze cycles.

The 12mm profile sits in a practical middle ground. It’s substantial enough to resist cracking under normal foot traffic yet thin enough to simplify installation over existing substrates in renovation work. Citadel Stone materials in this thickness category demonstrate proven performance across Arizona’s diverse climate zones, making them a reliable choice when you need predictable results without the expense of thicker formats.

Thickness Advantage: Structural Performance

The 12mm dimension isn’t arbitrary. You’re working with a thickness that provides approximately 30-40% more material mass than standard 10mm tiles, translating directly to improved impact resistance and load distribution. When foot traffic concentrates in high-use areas like entryways or kitchen zones, that extra material depth helps prevent the surface fracturing that thinner tiles experience under point loads.

Citadel Stone’s 12mm travertine tiles typically handle distributed loads up to 250-300 PSI without substrate reinforcement beyond standard residential requirements. You’ll want to verify your subfloor meets deflection standards—specifically L/360 for tile installations—but the thickness itself contributes meaningful structural capacity. For comparison, 10mm tiles often require more conservative substrate specifications to achieve similar performance thresholds.

- Reduced telegraphing of minor substrate imperfections due to increased rigidity

- Lower breakage rates during handling and installation compared to thinner formats

- Enhanced dimensional stability across temperature fluctuations common in Arizona homes

- Improved sound dampening characteristics in second-story installations

The material composition matters here. Travertine’s interconnected pore structure means you’re not getting the same density as granite or porcelain in equivalent thickness. Testing shows that 12mm travertine tiles from Citadel Stone exhibit compressive strength in the 4,000-6,000 PSI range, adequate for residential applications but requiring proper substrate preparation to transfer loads effectively.

Arizona Climate Considerations

Arizona’s climate zones span dramatically different conditions. You’re dealing with Phoenix valley floors where summer surface temperatures regularly exceed 180°F, Flagstaff elevations where winter freezes occur 100+ nights annually, and everything in between. The 12mm travertine tile in Arizona performs differently depending on which microclimate you’re specifying for, and understanding those distinctions prevents performance issues down the line.

Thermal expansion becomes critical in desert installations. Travertine exhibits a coefficient of thermal expansion around 0.0000044 inches per inch per degree Fahrenheit. In practice, a 24-inch tile experiencing a 50°F temperature swing—common in Arizona homes with large windows—will expand approximately 0.0053 inches. You’ll need expansion joints at perimeter walls and every 20-25 feet in open floor plans to accommodate this movement without inducing stress cracks.

Moisture absorption presents another consideration. Citadel Stone travertine 12mm in Arizona applications shows water absorption rates typically between 2-5% by weight, categorizing it as moderately porous under ASTM C97 testing protocols. In Arizona’s low-humidity environment, this characteristic rarely causes problems indoors. However, you should still seal the material, particularly in wet areas like bathrooms or near exterior doors where monsoon moisture occasionally intrudes.

Installation and Substrate Requirements

Proper substrate preparation determines long-term performance more than any other single factor. You need a flat, stable surface with deflection not exceeding L/360 under load. For 12mm travertine installations, that means plywood subfloors should be minimum 1-1/8 inch thick over joists spaced 16 inches on center, or you’ll need to add deflection-limiting reinforcement.

Concrete slabs offer the ideal substrate for Citadel Stone’s 12mm travertine products. The thermal mass of concrete moderates temperature swings, reducing expansion and contraction cycles that stress grout joints. You’ll want the concrete fully cured—minimum 28 days—and surface moisture levels below 3 pounds per 1,000 square feet per 24 hours as measured by calcium chloride testing. Arizona’s dry climate accelerates concrete curing, but don’t skip verification testing.

- Bond mortar selection: Use medium-bed mortars (3/16 to 1/2 inch thickness) to accommodate minor substrate variations without voids

- Trowel notch size: 1/2 x 1/2 inch square-notch trowels provide adequate coverage for tiles up to 18 inches; larger formats need 3/4 inch notches

- Back-buttering: Required for tiles exceeding 15 inches in any dimension to ensure 95%+ mortar coverage

- Working time: Arizona’s low humidity extends mortar open time slightly, but you still have 15-20 minutes maximum before skinning occurs

Don’t overlook expansion joint placement. You need soft joints at all perimeter transitions, at doorways, and where tile fields exceed 20-25 feet in either direction. These joints accommodate not just thermal movement but also structural deflection in wood-framed buildings. Sealant selection matters—use polyurethane-based products rated for continuous immersion if you’re working near wet areas.

For projects requiring proven structural specifications, consider reviewing Citadel Stone’s 12mm collection for comparative load-bearing data across different natural stone formats. The technical documentation addresses substrate compatibility and joint spacing calculations specific to thicker tile installations.

Finish Options and Performance Implications

The surface finish you specify for 12mm travertine tiles in Arizona dramatically affects both aesthetics and functionality. Citadel Stone offers multiple finish options, each with distinct performance characteristics you need to match to the application context.

Honed finishes provide a matte, smooth surface that’s become the default choice for interior residential work. You’re getting a DCOF (Dynamic Coefficient of Friction) rating typically in the 0.50-0.60 range when dry, dropping to 0.40-0.50 when wet. That’s adequate for most interior applications but marginal for areas that see water exposure. The smooth surface shows scratches more readily than textured finishes, so high-traffic commercial environments may see visible wear patterns within 3-5 years.

- Tumbled finishes: Rounded edges and weathered appearance conceal minor damage well; DCOF values around 0.55-0.65 wet

- Brushed finishes: Textured surface with visible tool marks; excellent slip resistance (DCOF 0.60-0.70) and better scratch concealment

- Filled versus unfilled: Unfilled travertine retains natural voids; filled versions use resin or cement to create smoother surfaces with reduced porosity

Arizona’s intense UV exposure through windows can cause subtle color shifts in travertine over time. You’ll see the most pronounced changes in lighter tones, where cream and ivory shades may develop slightly warmer undertones after 12-18 months of direct sunlight exposure. Citadel Stone’s travertine tiles 12mm in Arizona installations show relatively stable coloration compared to other natural stones, but setting realistic expectations with clients about natural material evolution prevents misunderstandings.

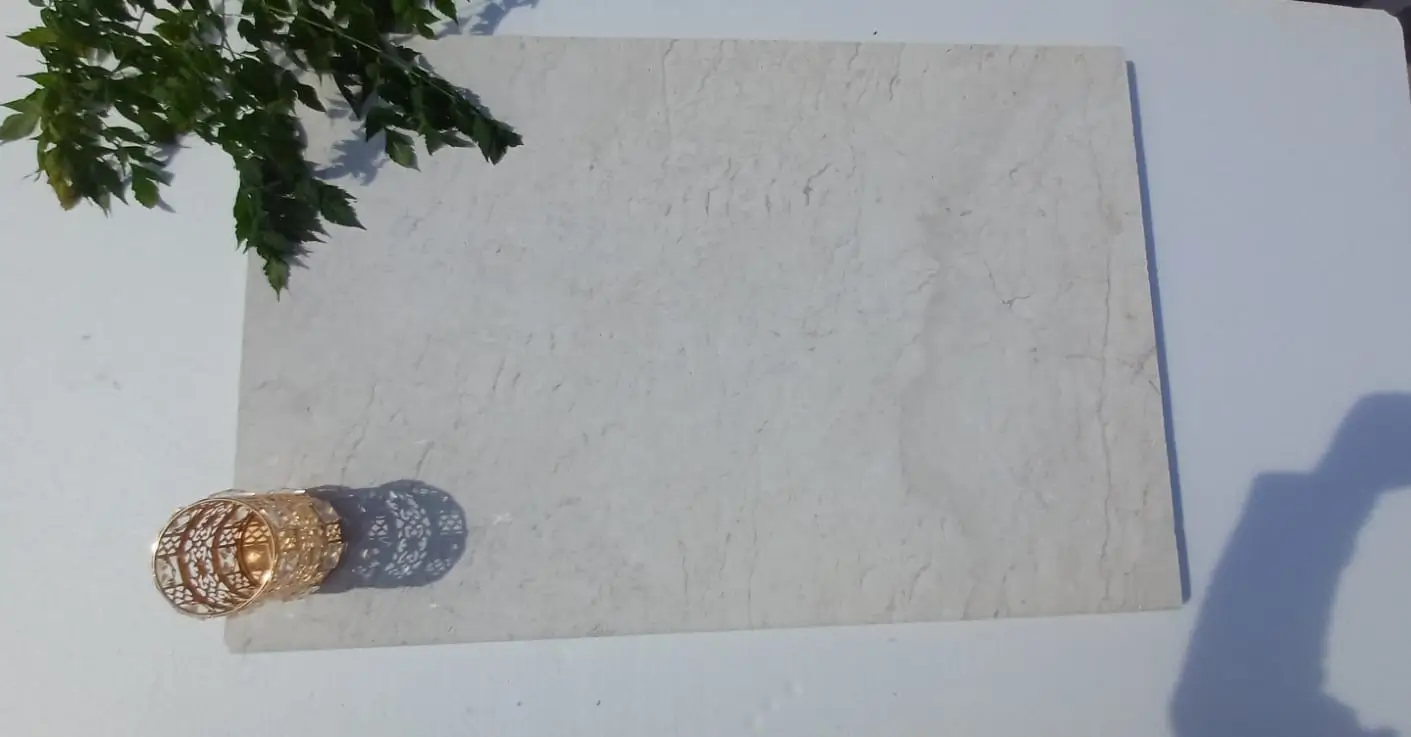

Color Variation and Visual Management

Here’s what most specifiers miss: travertine exhibits significant piece-to-piece color variation within any given lot. You’re not working with a manufactured product where every tile matches precisely. Citadel Stone’s 12mm travertine inventory includes materials ranging from soft ivory to rich walnut tones, and even within a single color designation, you’ll see natural variation spanning several shades.

This variation becomes your design asset when you manage it correctly. Dry-lay the tiles before setting to distribute color across the floor field evenly. You’ll want to pull from multiple boxes simultaneously during installation to blend the natural gradation rather than creating distinct zones of lighter and darker material. Most installers recommend opening 6-8 boxes at once for projects exceeding 500 square feet.

The 12mm thickness helps here because the added mass means less backside color telegraphing through the material. Thinner tiles sometimes show substrate darkness through lighter stones, particularly when wet. That’s rarely an issue with 12mm formats, giving you more flexibility in substrate color without affecting final appearance.

Grout Joint Specifications

Joint width selection affects both aesthetics and performance. You’ll often face pressure to minimize grout lines, but resist the temptation to go too tight with natural stone. Citadel Stone recommends minimum 1/8 inch joints for rectified 12mm travertine and 3/16 inch for standard-edge tiles. This allows for the dimensional variation inherent in natural stone while providing adequate grout volume to absorb minor movements.

Wider joints—3/8 to 1/2 inch—work well when you want to emphasize the individual tiles or create a more rustic appearance. They also simplify installation by reducing the precision required for layout, particularly valuable when working with travertine’s natural edge irregularities. The performance trade-off is that wider joints collect more dirt and require more aggressive cleaning to maintain appearance.

- Sanded versus unsanded: Use sanded grout for joints 1/8 inch and wider; unsanded grout for tighter joints (though you shouldn’t go tighter with travertine)

- Grout color selection: Matching stone tones minimizes grout line visibility; contrasting colors emphasize tile geometry

- Epoxy grout consideration: Provides superior stain resistance but requires expert installation and costs 3-4x more than cementitious grouts

Don’t forget that grout joints serve as stress relief. They’re engineered weak points that allow minor movements without transferring forces into the tile itself. Attempting to create “groutless” installations with 1/16 inch joints compromises this function and typically results in premature cracking, particularly in Arizona where thermal cycling stresses the tile assembly.

Maintenance Requirements and Longevity

Your specification responsibility extends beyond installation to long-term maintenance planning. Citadel Stone’s 12mm travertine requires sealing at installation and periodic resealing to maintain stain resistance and ease of cleaning. In Arizona’s dry climate, you’ll typically need resealing every 18-24 months for floor applications, somewhat less frequently for wall installations that don’t see wear traffic.

Sealer selection depends on desired appearance and usage intensity. Penetrating sealers soak into the stone’s pore structure without creating a surface film, maintaining the natural look while providing stain protection. Topical sealers create a sacrificial surface layer that enhances color depth and provides superior stain resistance but may show wear patterns in high-traffic areas. You should specify penetrating sealers for most residential 12mm travertine installations.

Cleaning protocols matter more than most clients realize. Acidic cleaners—including many common household products like vinegar or citrus-based formulations—etch travertine’s calcium carbonate composition, creating dull spots that require professional restoration to correct. You need pH-neutral cleaners specifically formulated for natural stone. Citadel Stone provides maintenance guidelines with material shipments, but you should incorporate these requirements into project specifications and owner manuals.

- Daily maintenance: Dust mop or vacuum with brush attachment; damp mop with pH-neutral stone cleaner weekly

- Stain response: Blot spills immediately; never allow acidic substances like wine or coffee to sit on unsealed or worn travertine

- Restoration timeline: Professional honing and resealing every 5-7 years maintains optimal appearance in residential applications

Cost Considerations and Value Analysis

The 12mm travertine tile in Arizona costs more than thinner formats but less than premium 20mm pavers. You’re typically looking at $8-15 per square foot for material alone from Citadel Stone’s warehouse inventory, depending on finish, color, and tile size. That positions it in the mid-to-upper range for natural stone flooring, comparable to higher-end porcelain but significantly less than exotic granites or marbles.

Installation labor runs $6-10 per square foot for straightforward layouts, increasing to $12-15 per square foot for complex patterns or small-format mosaics. The 12mm thickness doesn’t meaningfully affect labor costs compared to thinner tiles—installers charge based on square footage and pattern complexity rather than material thickness. You should budget for substrate preparation separately, particularly if existing floors require removal or leveling.

The value proposition comes from longevity and aesthetic appeal. Properly installed and maintained 12mm travertine from Citadel Stone delivers 20-30 years of service in residential applications, far exceeding the 10-15 year lifespan typical of mid-grade porcelain or luxury vinyl products. The natural material warmth and variation provide visual interest that manufactured products struggle to replicate, maintaining design relevance across changing trends.

Common Specification Mistakes

You’ll avoid most problems by recognizing these frequent oversights. First, many specifiers neglect to account for Arizona’s extreme temperature differentials between air-conditioned interiors and sun-exposed surfaces near windows or glass doors. That 40-50°F gradient creates significant stress at transition zones. You need expansion joints at these locations, not just at perimeter walls.

Second, substrate preparation often receives inadequate attention in specifications. Generic language like “prepare substrate per manufacturer recommendations” leaves too much interpretation. You should specify flatness tolerances explicitly: maximum 1/4 inch variation in 10 feet and 1/16 inch variation in 12 inches for large-format tiles exceeding 15 inches. Citadel Stone recommends these standards for all 12mm travertine installations.

- Failing to specify sealer type and application timing, leading to installed tiles that absorb stains before protection is applied

- Inadequate acclimation time: natural stone should be on-site 48-72 hours before installation to reach ambient temperature and moisture conditions

- Omitting expansion joint details at critical locations like doorways, plumbing penetrations, and floor-to-wall transitions

- Not coordinating with other trades: ensure HVAC systems are operational before tile installation to maintain stable temperature and humidity

Third, many specifications fail to address warehousing and logistics. Arizona’s building boom means Citadel Stone inventory turns over quickly during peak seasons. You need to verify material availability before bidding and coordinate delivery schedules with truck access to job sites. Desert construction sites often lack covered storage, so plan for immediate installation or provide protected material staging to prevent sun damage to packaging and labels.

Citadel Stone: Travertine supplier across Arizona — Project Guidance

When you’re evaluating suppliers for 12mm travertine tile in Arizona projects, the relationship between material quality, regional expertise, and logistics support determines project success as much as the stone itself. Citadel Stone’s position as a specialized natural stone supplier across the state means you’re working with teams who understand how desert conditions affect material performance and installation timing.

This section provides hypothetical project guidance for major Arizona markets, demonstrating how Citadel Stone would approach typical residential and commercial installations. The scenarios reflect common challenges and solutions based on regional climate patterns, building practices, and aesthetic preferences across the state’s diverse communities.

Phoenix Volume Projects

In Phoenix’s high-volume residential construction market, you’d find Citadel Stone positioning 12mm travertine as a mid-tier flooring option that balances cost with the luxury appearance buyers expect. The valley’s extreme summer heat—where air temperatures reach 115-120°F and interior surfaces near windows can hit 130-140°F—would drive recommendations for lighter travertine tones that minimize heat absorption. Projects in master-planned communities would typically specify filled and honed finishes in ivory or cream tones for 2,500-4,000 square foot great room installations, with material staged from Citadel’s warehouse inventory to meet compressed construction schedules common in production housing.

Scottsdale Luxury Installations

Scottsdale’s high-end residential market would see Citadel Stone recommending premium travertine 12mm selections with more pronounced color variation and natural character. You’d specify unfilled or lightly filled versions that showcase the stone’s natural voids and surface texture, often in larger format tiles exceeding 18 inches to minimize grout lines in expansive open floor plans. The area’s design-conscious clientele would drive selections toward silver, gold, and walnut tones that complement contemporary desert architecture. Installation scenarios would include radiant floor heating integration, requiring careful attention to thermal conductivity and expansion joint placement to prevent stress damage from the heating system’s thermal cycling.

Tucson Climate Adaptation

Tucson’s slightly milder temperatures and higher humidity during monsoon season would influence Citadel Stone’s material recommendations differently than Phoenix specifications. You’d pay more attention to moisture management in entryways and near exterior doors where monsoon storms can drive significant water infiltration. The 12mm travertine tiles in Arizona’s second-largest market would typically include more aggressive sealing protocols and consideration of textured finishes for slip resistance. University-area projects and historic district renovations would present unique challenges where Citadel Stone’s expertise in matching existing stone aesthetics while meeting modern performance standards becomes valuable, particularly in commercial applications where foot traffic durability requires careful finish selection.

Flagstaff Freeze Considerations

Flagstaff’s elevation and winter freeze conditions would require Citadel Stone to address concerns rare in other Arizona markets. You’d need to verify that travertine 12mm in Arizona’s northern communities receives adequate sealing to prevent freeze-thaw damage from moisture trapped in the stone’s pore structure. Interior installations would still perform well, but any applications near exterior doors or in enclosed but unheated spaces would require careful evaluation. The cooler climate would allow more aggressive cleaning and maintenance protocols without the rapid evaporation that complicates surface treatments in desert locations. Mountain-contemporary architectural styles popular in the area would drive specification of warmer travertine tones—rustic golds and medium browns—that complement timber and stone exterior materials.

Mesa Commercial Applications

Mesa’s growing commercial and mixed-use developments would present opportunities for Citadel Stone to demonstrate 12mm travertine’s viability in light commercial applications. You’d specify denser travertine selections with filled surfaces and potentially consider epoxy grout for retail environments where foot traffic intensity exceeds typical residential loads. Office building lobbies and medical facilities would benefit from travertine’s natural antimicrobial properties and ease of maintenance, with specifications emphasizing matte finishes that don’t show scratches as readily as polished surfaces. The challenge in these scenarios involves coordinating material delivery from Citadel Stone’s warehouse with commercial construction schedules that often compress finish work into tight timelines, requiring advance planning to ensure adequate acclimation time before installation while meeting occupancy deadlines.

Gilbert Family-Focused Durability

Gilbert’s family-oriented demographics would drive Citadel Stone recommendations toward durability and maintenance simplicity. You’d emphasize the 12mm thickness advantage for homes with active children and pets, where impact resistance prevents the chipping and cracking thinner tiles experience. Specifications would typically favor medium-toned travertines that conceal dirt and minor scratches better than very light or very dark options. The area’s newer construction stock means you’re usually working with properly engineered substrates, but you’d still need to address thermal expansion at large window walls popular in contemporary Arizona home designs. Educational discussions about realistic maintenance requirements—particularly the need for immediate spill cleanup and periodic resealing—would be critical for setting appropriate owner expectations in family households where stone floors see intensive daily use.

Comparative Format Analysis

Understanding where 12mm travertine tiles fit in the broader spectrum of natural stone formats helps you make informed specification decisions. Citadel Stone’s inventory spans thicknesses from 10mm tiles to 30mm pavers, each serving distinct applications with different performance characteristics and cost implications.

Thinner 10mm formats cost 15-20% less than 12mm versions and simplify renovation work where existing floor heights limit your thickness options. However, you’re accepting more fragility during handling and installation, plus increased sensitivity to substrate imperfections. For renovation projects where floor height is constrained, that trade-off makes sense. For new construction where you control substrate quality and have height flexibility, the 12mm option provides better long-term value.

Thicker formats—20mm and 30mm pavers—offer superior durability for high-traffic commercial applications and outdoor use but cost 40-60% more than 12mm tiles. You’re also dealing with significantly more weight, which complicates installation and may require structural reinforcement in elevated applications. For interior residential work, that additional thickness provides marginal performance benefits that rarely justify the cost premium. Save those formats for exterior patios, pool decks, and commercial lobbies where vehicular loads or extreme weather exposure demand maximum robustness.

Regional Material Variations

Not all travertine performs identically, and understanding the source quarry characteristics helps you predict long-term behavior. Citadel Stone’s 12mm travertine offerings include material from multiple quarry regions, primarily Turkey, Italy, Mexico, and Peru. Each source exhibits distinct density, color range, and porosity characteristics that affect your specification decisions.

Turkish travertine typically shows cream to ivory coloration with subtle veining and relatively uniform density. It’s a reliable mid-range option for most Arizona applications. Italian materials trend toward brighter whites and deeper golds with more pronounced veining, often commanding premium pricing. Mexican travertine in warm golden and silver tones provides excellent value with slightly higher porosity that requires more diligent sealing. Peruvian materials offer distinctive coloring in rustic browns and reds, though availability fluctuates more than established Turkish sources.

You should specify material origin when consistent appearance across multiple project phases matters or when you need to match existing installations. Citadel Stone can provide origin documentation and reserve materials from specific quarry lots for phased projects, preventing the color and texture mismatches that occur when mixing sources within visible floor fields.

Project Success

Specifying 12mm travertine tile in Arizona requires balancing the material’s natural beauty and proven durability against the state’s challenging climate conditions and proper installation requirements. You’ve seen throughout this discussion that success depends on understanding thermal movement, substrate preparation, finish selection, and realistic maintenance expectations. Citadel Stone’s expertise in regional applications provides the support structure that transforms technical specifications into successful installations across diverse Arizona markets.

The 12mm thickness represents a practical sweet spot for most residential and light commercial interiors, delivering adequate structural performance without the cost and weight penalties of thicker formats. When you combine proper material selection from Citadel Stone’s inventory with competent installation and regular maintenance, you’re providing clients with flooring that will deliver 20-30 years of service while maintaining the aesthetic appeal that makes natural stone worth specifying. For related specifications in larger format installations, review Premium natural stone flooring solutions for Arizona residential projects before finalizing project documents. Commercial floor installations trust Citadel Stone’s substantial 12mm travertine for high-traffic resilience.