The 10 Critical Questions

Asking the right questions to ask before hiring a stone supplier isn’t just about gathering information; it’s about understanding their processes, identifying potential risks, and evaluating their commitment to your project. Here are the ten essential questions you must pose to any prospective stone vendor.

1. What Are Your Stone Grading and Quality Standards?

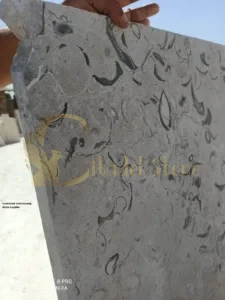

Understanding a stone supplier’s quality control mechanisms is paramount. Different stone suppliers may have varying definitions of “quality,” and their internal grading systems can significantly impact the consistency and appearance of the stone you receive. A reputable supplier will have clear, documented standards for evaluating their materials. This includes criteria for color variation, veining, presence of fissures, and overall structural integrity.

A strong answer will detail their specific grading categories (e.g., commercial, premium, select), explain the characteristics associated with each, and outline how they ensure consistency across batches. They should be able to articulate how they classify stone based on factors like density, porosity, and strength, and how these classifications align with industry benchmarks. This deep dive into their quality standards helps prevent surprises upon delivery and ensures the stone meets your project’s aesthetic and structural requirements.

2. Can You Provide Samples or Mock-Ups?

Seeing is believing, especially when it comes to natural stone, which can vary widely in appearance. Requesting samples is a fundamental step in hiring a stone supplier. Samples allow you to assess the true color, texture, and finish of the stone in your project environment. They help confirm that the material aligns with your design vision and functional needs.

A reliable natural stone supplier will readily provide samples, ideally in the actual size and finish you intend to use. They might also offer to create mock-ups or small-scale installations that replicate a portion of your project. This is particularly valuable for complex designs or large-scale applications, as it allows you to visualize the stone in context and make any necessary adjustments before full-scale procurement. Beware of suppliers hesitant to provide representative samples, as this could indicate inconsistencies in their stock.

3. Where Are Your Stones Sourced From?

The origin of stone can impact its quality, availability, ethical implications, and even its price. This stone vendor interview question delves into the supplier’s supply chain transparency. Knowing the quarries and regions from which a supplier sources their stone can provide insights into the stone’s geological properties, potential variations, and compliance with ethical sourcing practices.

An ideal response will clearly identify their primary sourcing locations and explain their relationships with these quarries. They should be able to provide documentation or certifications related to ethical labor practices and environmental sustainability, if applicable. Understanding their sourcing network also helps you gauge their ability to meet specific material demands and whether they have alternative sources in case of supply chain disruptions. Look for suppliers with diverse and well-established sourcing channels.

4. What Is Your Lead Time and Delivery Process?

Timelines are critical for any project. This question addresses the logistics of getting the stone from the supplier to your site. Understanding the stone supplier near me‘s lead times and delivery procedures is essential for accurate project scheduling and avoiding costly delays. This includes the time from order placement to shipment, as well as the transit time.

A comprehensive answer will outline their standard lead times for various stone types and order sizes. They should detail their delivery methods, whether they use their own fleet or third-party logistics, and how they handle shipping to your specific location. Inquire about their packaging methods to ensure the stone arrives undamaged, their notification procedures for delivery, and any specific site access requirements. Clarity on these points is crucial for smooth project execution and helps you plan your receiving logistics effectively.

5. Do You Offer Volume Discounts or Pricing Tiers?

Cost is always a significant factor, and understanding a stone supplier in my area’s pricing structure can lead to substantial savings. This question explores their flexibility in pricing, particularly for larger orders. Knowing if a supplier offers volume discounts or has tiered pricing can help you optimize your budget, especially if your project requires a substantial quantity of stone.

A transparent local stone supplier will be upfront about their pricing models. They should be able to explain how their pricing scales with order size and if there are any specific benchmarks for qualifying for discounts. Beyond just unit price, ask about any additional costs such as cutting, finishing, sealing, or specialized packaging. A good supplier will provide a detailed, itemized quote that clearly breaks down all costs involved, allowing for direct comparison with other bids.

6. What Warranties and Return Policies Do You Provide?

Even with the highest quality stone, unforeseen issues can arise. This is where robust warranties and clear return policies become invaluable. Understanding these terms before hiring a stone supplier protects your investment and provides recourse if the stone doesn’t meet expectations or arrives damaged. It demonstrates the supplier’s confidence in their product and their commitment to customer satisfaction.

A reliable local stone supplier near me will offer clear, written warranties covering material defects, and their return policy should be straightforward and fair. Inquire about the duration of their warranty, what specific issues are covered, and the process for making a claim. Similarly, understand their policy on returns for incorrect orders, damaged goods, or surplus material. Avoid suppliers with vague or non-existent warranty and return policies, as this could indicate a lack of accountability.

7. Can You Share References or Past Project Examples?

One of the most effective ways to vet a potential natural stone supplier is by examining their track record. Requesting references or examples of past projects allows you to verify their claims and assess their performance with previous clients. This provides objective insight into their reliability, product quality, and customer service.

A confident natural stone supplier near me will readily provide contact information for past clients who can speak to their experience. When speaking with references, ask about the supplier’s responsiveness, adherence to timelines, quality of materials, and how they handled any challenges that arose. Reviewing past project examples, especially those similar to yours, can also help you visualize the supplier’s capabilities and the quality of their finished product. This step is a crucial part of your supplier due diligence.

8. How Do You Handle Quality Control and Inspection?

Beyond initial grading, how does the supplier maintain quality throughout the order fulfillment process? This question delves into their ongoing quality assurance protocols. Effective quality control procedures minimize the risk of receiving substandard materials and ensure consistency from the moment the stone is sourced to when it’s delivered to your site.

A thorough explanation will describe their inspection points throughout the supply chain, from quarry selection and block cutting to slab preparation and final packaging. They might mention specific certifications, in-house testing procedures, or third-party inspections they utilize. Ask about their process for addressing non-conforming materials and how they communicate any potential variations or issues to clients. A transparent quality control process builds trust and assures you of consistent material standards.

9. What Are Your Payment Terms and Financing Options?

Financial terms are a practical but critical aspect of any business relationship. Clearly understanding a natural stone wholesale supplier’s payment terms and any available financing options helps you manage your project budget and cash flow effectively. Misunderstandings here can lead to delays or unexpected financial strain.

Natural stone suppliers should clearly outline their required deposit, payment schedule (e.g., net 30, payment upon delivery), and accepted payment methods. If your project is large, inquire about potential financing solutions, credit lines, or deferred payment options they might offer. It’s also wise to ask about any penalties for late payments or discounts for early payments. Ensure all payment terms are clearly stipulated in the contract before committing.

10. Do You Offer Post-Sale Support and Technical Guidance?

A natural stone distributor near me‘s responsibility shouldn’t end at delivery. Post-sale support and technical guidance can be invaluable, especially for natural stone, which often requires specific installation, maintenance, and care. This question assesses their commitment to long-term customer satisfaction and their expertise beyond simply selling the product.

A comprehensive answer will detail the type of support they offer, such as technical advice on installation methods, sealing recommendations, cleaning guidelines, or troubleshooting common issues. They might provide access to technical data sheets, maintenance manuals, or even connect you with recommended installers. Knowing that you have ongoing support can provide peace of mind and help you ensure the longevity and beauty of your stone investment.

How to Use These Questions in Your Vetting Process

Effectively utilizing these questions to ask before hiring a stone supplier can streamline your selection process significantly. Here’s a step-by-step approach to conducting a successful stone vendor interview:

Prepare Thoroughly: Before meeting or calling, have a clear understanding of your project’s specific stone requirements, budget, and timeline. This will help you tailor your questions and evaluate responses effectively.

Create a Scorecard: Develop a simple scoring system for each question. After each interview, rate the supplier’s response based on clarity, completeness, and how well it aligns with your needs. This objective approach helps in comparing multiple suppliers.

Listen Actively and Take Notes: Don’t just tick boxes. Listen carefully to their answers, ask follow-up questions for clarification, and note down key details, promises, and any red flags.

Compare and Contrast: Once you’ve interviewed several suppliers, compare your scorecards. Look for consistent strengths and weaknesses across different candidates. Consider not just the answers themselves, but the supplier’s overall professionalism and responsiveness.

Trust Your Gut (But Verify): While data is important, sometimes a “gut feeling” about a supplier’s trustworthiness and professionalism can be valuable. However, always back up this feeling with concrete information and verified references.

Common Red Flags and Follow-Up Queries

Even with the best stone procurement checklist, some warning signs can emerge during your supplier due diligence. Being aware of these red flags and knowing how to address them with follow-up queries is crucial:

Vague Answers or Evasiveness: If a supplier is unwilling or unable to provide clear, direct answers to your questions, especially regarding quality standards, sourcing, or lead times, it’s a major concern.

Follow-up Query: “Can you elaborate on [specific vague point]? What specific processes or documentation support that claim?”

No References or Past Project Examples: A reluctance to share client references or examples of their work should raise a significant red flag. Reputable suppliers are usually proud to showcase their successes.

Follow-up Query: “Could you explain why you’re unable to provide references at this time? What other assurances can you offer regarding your experience?”

Unrealistically Low Pricing: While a good deal is appealing, prices significantly lower than competitors might indicate compromises in quality, ethical sourcing, or hidden costs.

Follow-up Query: “Your pricing seems very competitive. Can you walk me through how you achieve this without compromising on quality or service?”

Poor Communication or Responsiveness: If a supplier is slow to respond to inquiries, difficult to reach, or lacks professionalism in their communication during the vetting process, this behavior is likely to worsen once you’ve committed.

Follow-up Query: “What is your typical response time for client inquiries, and who would be my primary point of contact?”

Lack of Documentation: A reliable supplier will have contracts, warranties, specifications, and other vital documents readily available. Absence or delays in providing these can be problematic.

Follow-up Query: “Can you provide copies of your standard contract, warranty, and return policies for my review?”

Innovative Stone Solutions: Transforming Modern Architecture in the U.S.

Case Study 1: Georgia College Science Building Addition

Client Objectives

The University of Georgia sought a contemporary stone façade that integrated solar shading fins to boost energy efficiency.

Supplier Selection & Material Specs

Material: Custom precast limestone fins with integrally cast louvers

Testing: ASTM C1364 solar reflectance index of >65

Timeline & Collaboration

Lead time: 8 weeks

Bi‑weekly coordination meetings with campus engineers ensured the fins met structural and thermal requirements.

Outcomes

Budget adherence: 101% (within contingency)

Completed one week early, reducing scaffolding rental costs by 15%

Post‑occupancy surveys report 8% lower cooling loads in sun‑exposed labs

Case Study 2: New Mexico Desert Amphitheater

Scope of Supply

Santa Fe’s new outdoor performance venue required locally quarried sandstone seating risers and stage cladding.

Quality Controls

Color consistency maintained across batches via spectrophotometer checks

Sealant rated for 20-year UV exposure, validated in accelerated aging tests

Installation Challenges

Unpaved access roads limited delivery sizes; supplier used modular panel sections trucked in under 12 ft height restrictions.

Outcomes

Lead time: 10 weeks

Budget adherence: 99%

Amphitheater launched on schedule, drawing 20% higher attendance in its opening season

Case Study 3: Montana Alpine Research Station

Public Bidding & Sustainability

A federal grant required a stone exterior with a minimal carbon footprint, sourced within 300 miles.

Community Impact

A natural stone manufacturer provided a live stream of the quarrying process to local schools, promoting geology education.

Durability Metrics

Freeze/thaw cycles: Passed 30 cycles without microfractures per ASTM C666

Maintenance budgets projected 40% lower over 20 years

Outcomes

Lead time: 12 weeks

Delivered at 100% of budget

Research staff cite “exceptional thermal mass” in lab temperature stability

Case Study 4: South Carolina Coastal Shopping Complex

Salt‑Humidity Resistance Needs

A Charleston retail center needed shell‑reef limestone cladding and limestone pavers to withstand 80% relative humidity and saline air.

Finish Selection & Testing

Brushed finish for slip resistance

Salt‑spray chamber: <0.05 mm surface change over 1,500 hours

Delivery Logistics

Coordinated nighttime deliveries to avoid daytime traffic, using GPS‑tracked trucks to assure schedule adherence.

Outcomes

Lead time: 9 weeks

Budget adherence: 98%

Retail tenants report 0% complaints related to stone discoloration or wear

Case Study 5: Kansas Agricultural Museum Plaza

Design Goals

A Wichita museum plaza required Kansas limestone seating walls and decorative water troughs that echoed regional heritage.

Supplier Partnership & Mock‑ups

CNC‑routed mockups of trough profiles approved in 10 days

Final blocks cut with custom veining to match museum exhibits

Timeline & Outcomes

Lead time: 7 weeks

Budget adherence: 97%

Museum volunteers report 30% increased visitor dwell time in the plaza

Case Study 6: Maine Waterfront Condominium Lobby

Corporate Branding & Performance

A Portland development firm specified polished granite and honed bluestone accent walls for a luxury lobby.

Quality Controls

Slip resistance: Exceeded ADA Class II standards on bluestone

Polish durability: Taber abrasion loss < 0.1 g per 1,000 revolutions

Timeline & Collaboration

Lead time: 8 weeks

Weekly design syncs used 3D‑rendered panels to verify color and finish before fabrication.

Outcomes

Delivered at 102% of estimated cost, within client contingency

Lobby posted a 25% uplift in positive resident feedback on aesthetics

Conclusion & Next Steps

Choosing the right stone supplier is a critical decision that impacts the aesthetic, durability, and financial success of your project. By diligently asking these questions to ask before hiring a stone supplier, you’ll gain invaluable insights into their capabilities, reliability, and commitment to quality. Remember these key takeaways:

Prioritize Quality: Always prioritize a supplier’s quality standards and transparent sourcing over simply the lowest price.

Demand Transparency: A reputable supplier will be open and honest about their processes, pricing, and potential limitations.

Verify Everything: Use references and samples to corroborate their claims and ensure they can deliver on their promises.

Plan for the Unexpected: Understand their warranties, return policies, and post-sale support to mitigate future risks.

Armed with this comprehensive guide, you are now well-prepared to confidently navigate the stone procurement landscape. Take the time to conduct thorough supplier due diligence, and you’ll secure the ideal stone partner for your next endeavor.

Ready to discuss your project’s unique stone requirements with a trusted expert? Get in touch with our experts at Citadel Stone today for personalized guidance and exceptional quality materials.