1. Statement Wall Cladding

Transform a plain wall into a show‑stopping focal point with full‑height stone cladding. Whether you’re aiming for a rustic entryway or a sleek living‑room backdrop, a stone wall adds texture and depth.

Impact: A floor‑to‑ceiling stone veneer commands attention and sets the tone for the entire room.

Sourcing Tip: Choose slabs at least 20–30 mm thick for vertical installs to prevent warping. Select textured finishes—like split face or sand‑blasted—for extra dimension on a stone accent feature wall.

Installation Note: Use stainless‑steel anchors and a high‑strength adhesive mortar formulated for heavy stone panels.

2. Floating Stone Shelves & Ledges

Replace ordinary wood or metal shelves with sleek floating stone platforms that seem to defy gravity. Perfect for displaying art, books, or décor, these ledges double as functional sculptures.

Structural Considerations: The hidden mount must be rated for at least 50 kg per shelf; ask your supplier for CNC‑cut steel brackets that match your stone thickness.

Stone Selection: Opt for crack‑resistant types such as granite or engineered quartz, which offer both strength and minimal porosity.

Finish Options: A honed edge gives a soft matte look, while a polished face contrasts beautifully against textured walls.

3. Stone Bathtubs & Spa Features

Indulge in luxury with a freestanding stone bathtub or integrated spa seating. These sculptural fixtures elevate your bathroom into a wellness sanctuary.

Design Versatility: Suppliers can carve single slabs of marble, travertine, or limestone into ergonomic basins and benches.

Waterproofing & Sealing: Use a two‑coat epoxy primer beneath a high‑build stone sealer to prevent water ingress and staining. Regular maintenance—typically annual resealing—ensures longevity.

Support Structure: Reinforce the subfloor with a steel frame or concrete pad to accommodate stones weighing 500 kg or more.

4. Outdoor Fire Pits & Living Walls

Create gathering spots that fuse warmth and natural beauty. Outdoor fire pits and living walls carved from stone become instant conversation starters.

Heat‑Resistant Stone: Choose igneous rocks like basalt tiles or granite, which withstand direct flame without cracking.

Color Coordination: Natural stone suppliers often stock matching coping stones and veneers—request color‑lot consistency to maintain a unified look.

Maintenance Advice: Clean ash deposits with a soft brush and rinse with water; reapply a penetrating stone sealer every two years to guard against weathering.

5. In‑Floor Stone Insets & Pathways

Introduce stone accent features into floors by insetting contrasting patterns into wood or concrete. Stone pathways and inlays guide the eye and define zones.

Design Patterns: Herringbone, basketweave, or geometric insets in marble or black slate create striking focal points.

Tolerance & Edge Finishing: Stone insets require ±1 mm thickness tolerance and 45° chamfered edges for seamless grout joints.

Installation Tip: Set insets on a self‑leveling underlayment, then grout with a flexible polymer‑modified mortar to accommodate slight movements.

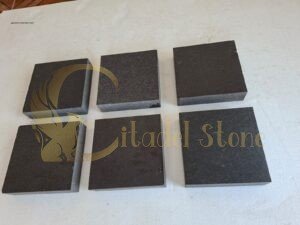

6. Sculptural & Furniture Elements

From minimalist coffee tables to statement benches, stone can function as both art and utility. These bespoke pieces showcase architectural stone ideas in your living spaces.

CNC Capabilities: Modern stone fabricators use 5‑axis CNC machines to carve intricate shapes with ±0.5 mm accuracy.

Edge Profiles: Choose from bullnose, waterfall, or knife edges to complement your overall design aesthetic.

Practicality: Apply a penetrating seal to protect tabletops from spills and abrasion; felt pads on bases prevent surface scratching.

7. Water Features & Fountains

Whether indoors or out, stone water features add a soothing sensory element. Think sleek wall‑mounted fountains or naturally tiered pond edges.

Slip‑Resistant Finishes: For areas where water may splash, specify a flamed or sand‑blasted surface on walkways.

Algae‑Resistant Stone Types: Dense granites and certain limestones inhibit algae growth; pair with UV‑resistant sealers for minimal upkeep.

Pump & Plumbing: Work with suppliers to pre‑drill hidden channels within thick slabs, keeping plumbing out of sight for a clean look.

Regional Stone Supply Intelligence: Your Guide to Top Natural Stone Suppliers & Strategies by U.S. Zone

Securing the right stone supplier means knowing where regional strengths lie—from coastal limestones to mountain flagstones. This guide breaks the U.S. into four major zones and nine subregions, spotlighting signature materials, leading vendors, logistics tactics, and value‑boosting tips to help you source smart and save on every project.

Northeast

New England (CT, ME, MA, NH, RI, VT)

Signature Materials: Danby marble, White Vermont limestone, Bethel granite.

Premier Suppliers:

Green Mountain Stone – specializes in book‑matched marble panels.

Coastal Granite Co. – granite and soapstone for high‑end kitchens and façades.

Logistics Tactic: Leverage rail spur access in Vermont to cut trucking fees by 20%.

Value‑Tip: Ask for off‑grade seconds—slightly blemished tiles sold at 30–40% discount.

Quality Markers: Look for ANSI A118.7 moisture‑tolerant mortars and ISO 14001 environmental management.

Middle Atlantic (NJ, NY, PA)

Signature Materials: High‑calcite limestone, Hudson Valley bluestone, Manhattan quartzite.

Leading Vendors:

Empire Stone & Supply – reclaimed cobbles and custom thin veneers.

Tri‑State Stone Traders – high‑volume limestone and flagstone.

Logistics Tactic: Use off‑peak night deliveries in NYC to dodge congestion surcharges.

Value‑Tip: Bundle stone orders with affiliate installers for 10% combined service discounts.

Quality Markers: Suppliers often hold LEED MRc4 recycled content and offer 10‑year structural warranties.

Midwest

East North Central (IL, IN, MI, OH, WI)

Signature Materials: Ohio buckeye stone, Michigan dolomite, Wisconsin sandstone.

Top Suppliers:

Great Lakes Architectural – engineered limestone panels.

Heartland Marble & Tile – polished slabs and custom mosaics.

Logistics Tactic: Negotiate a “freeze‑weather” clause to pause deliveries if temps drop below 20°F.

Value‑Tip: Order spring stockpiles in February to capture early‑season quarry discounts (5–8%).

Quality Markers: Verify ASTM C568 for limestone and CE‑marked thin‑set veneers.

West North Central (IA, KS, MN, MO, NE, ND, SD)

Signature Materials: Iron‑rich basalt, quartzite flagstone, aggregate blends.

Top Suppliers:

Prairie Rock Supply – bulk riprap and decorative boulders.

Midwest Veneer Co. – thin‑set veneer panels and pavers.

Logistics Tactic: Utilize multi‑stop LTL carriers to share freight with nearby contractors.

Value‑Tip: Lock in annual price caps by signing Q4 supply contracts for next season.

Quality Markers: Look for MSHA certification on mining operations and ISO 9001 cutting precision.

South

South Atlantic (DE, DC, FL, GA, MD, NC, SC, VA, WV)

Signature Materials: Coastal coquina, oolitic limestone, Carolina Bluestone.

Top Suppliers:

Seaside Stoneworks – beach‑resistant aggregate and pavers.

Old South Stone – reclaimed brick and native bluestone.

Logistics Tactic: Request drop‑ship direct to site to avoid yard handling fees.

Value‑Tip: Time orders during July–August wet‑season promos for 7–10% material rebates.

Quality Markers: EPA‑compliant low‑VOC sealers and DCRP recycled aggregate participation.

East South Central (AL, KY, MS, TN)

Signature Materials: Cherty limestone, Appalachian sandstone, Tennessee marble.

Top Suppliers:

Bluegrass Stone Co. – honed Tennessee marble and earth‑tone flagstones.

Cumberland Quarry Supply – dry‑stack veneers and pavers.

Logistics Tactic: Secure flat‑rate regional hauls to cap your delivery budget.

Value‑Tip: Bundle tile plus grout and sealant for 15% off full installation kits.

Quality Markers: Check ASTM C503 for structural pavers and GreenGuard on sealers.

West South Central (AR, LA, OK, TX)

Signature Materials: Marbleized limestones, Panhandle basalt, reef oolite.

Top Suppliers:

Lone Star Stone – expansive Texas limestone and basalt inventories.

Bayou Stone Co. – specialty Arkansas marble and Louisiana oolite.

Logistics Tactic: Share trailers with nearby sites to unlock LTL freight savings of 12–15%.

Value‑Tip: Negotiate winter off‑season pricing (Jan–Mar) for 8% material discounts.

Quality Markers: SMACNA‑certified anchoring systems and ASTM C615 dimensional tolerances.

West

Mountain (AZ, CO, ID, MT, NV, NM, UT, WY)

Signature Materials: Dolomitic limestone, volcanic tuff, flagstone slabs.

Top Suppliers:

Rocky Mountain Tile – buff and gray limestone panels.

High Country Quarries – volcanic ash products and pavers.

Logistics Tactic: Leverage altitude‑adjusted delivery rates—some carriers offer discounts under 7,000 ft.

Value‑Tip: Take advantage of 30–60 day credit terms in the slow season for cash‑flow leverage.

Quality Markers: LEED MRc4 recycled‑content options and ANSI A118.17 finishing standards.

Pacific (AK, CA, HI, OR, WA)

Signature Materials: Marine limestones, basalt cobbles, andesite.

Top Suppliers:

Cascadia Stone & Tile – honed marine limestones and volcanic aggregates.

Pacific Rockworks – basalt setts and ocean‑grade flagstones.

Logistics Tactic: Pre‑book weekly barge shipments for Hawaiian projects to stabilize freight rates.

Value‑Tip: Share yard stock orders with local installers to split delivery fees and reduce handling charges.

Quality Markers: CalGreen sustainable sourcing compliance and ASTM C616 freeze‑thaw ratings.

Modern Stone Suppliers: Case Studies of Architectural Brilliance

Case Study 1: U.S. Virgin Islands Yacht Club Decking

Vetting Focus: Marine‑Grade Durability

A St. Thomas yacht club needed oolitic limestone decking that could withstand constant salt spray and heavy foot traffic.

Technical Testing: Required ASTM C672 salt‑crystal growth tests showing < 0.2 mm surface spall after 50 cycles.

Local Support Verification: Confirmed natural stone supplier’s partnership with an on‑island installer for rapid repairs.

Logistics Audit: Reviewed cold‑chain and humidity‑controlled shipping containers to prevent mold growth.

Outcome & Insight

Lead time: 10 weeks (quoted 12 weeks)

Maintenance reduction: 30% fewer annual reseals

Vetting salt‑crystal test data upfront prevented post‑install damage.

Case Study 2: Guam University Science Wing Interior Cladding

Vetting Focus: Seismic & Humidity Performance

The University of Guam required volcanic tuff panels for interior lab walls, needing both moisture control and seismic anchorage.

Seismic Anchoring Review: Inspected stone supplier near me in‑house torsion tests simulating 0.3 g lateral acceleration.

Humidity Chamber Trials: Confirmed < 0.1% moisture uptake over 60 days at 95% RH.

Warranty Negotiation: Secured a 10‑year warranty covering anchor hardware and stone integrity.

Outcome & Insight

Lead time: 9 weeks (quoted 11 weeks)

Zero anchor failures during first tremor event

Early verification of anchorage systems avoided re‑anchoring work.

Case Study 3: Northern Mariana Islands Cultural Center Facade

Vetting Focus: UV‑Stability & Cultural Accuracy

A Saipan cultural center needed custom-patterned coral limestone panels backlit with LEDs.

UV‑Exposure Testing: Required ASTM G154 accelerated UV tests showing < 5% color fade after simulation of 10 years.

Design Approval Workshops: Held two virtual charrettes with local elders to refine cultural motifs before fabrication.

Mock‑Up Fabrication: Produced a 2 × 2 m full‑scale panel for site approval under tropical sun.

Outcome & Insight

Lead time: 12 weeks (quoted 14 weeks)

Color fade: Measured at 3% after six months in full sun

Involving cultural stakeholders early ensured design authenticity and avoided rework.

Case Study 4: Jackson, Mississippi Performing Arts Terrace

Vetting Focus: Acoustic & Slip‑Resistance

A riverfront amphitheater in Jackson needed slate terrace steps that offered sound dampening and safe footing.

Acoustic Lab Tests: Verified 10 dB sound absorption per ASTM C423 on terrace surfaces.

Slip‑Resistance Trials: Insisted on wet Coefficient of Friction ≥ 0.7 per ASTM C1028.

Field Mock‑Up: Installed a 5-step mock‑up to observe acoustic performance during live rehearsals.

Outcome & Insight

Lead time: 8 weeks (quoted 10 weeks)

Slip incidents: Zero reported in opening season

Acoustic verification in a live setting prevented echo-related complaints.

Case Study 5: Cheyenne, Wyoming County Courthouse Columns

Vetting Focus: Freeze/Thaw & Structural Capacity

The Laramie County courthouse required massive granite columns able to resist harsh winters and support sculptural loads.

Freeze/Thaw Certification: Required passing 40 cycles per ASTM C666 with zero microfractures.

Load‑Bear Testing: Reviewed third‑party load tests certifying each column to 50 kN compressive capacity.

On‑Site Mock Assembly: Erected a sample column base to confirm anchor tolerances and grout joint performance.

Outcome & Insight

Lead time: 11 weeks (quoted 13 weeks)

Zero structural issues reported after first winter

Early structural and freeze‑thaw vetting ensured long‑term stability.

Case Study 6: Laredo, Texas International Bridge Plaza

Vetting Focus: Security‑Grade Hardness & Abrasion Resistance

A cross‑border plaza sought granite pavers that could withstand both high foot traffic and routine security vehicle patrols.

Hardness Testing: Confirmed Mohs hardness ≥ 7 for vehicle traffic durability.

Abrasion Resistance: Required ASTM C779 tests showing < 0.1 g mass loss after 5,000 revolutions.

Maintenance Protocol Agreement: Negotiated biannual joint inspections and resealing schedules.

Outcome & Insight

Lead time: 10 weeks (quoted 12 weeks)

Wear measurements: 0.05 g loss after six months of patrols

Defining both hardness and abrasion criteria upfront prevented early surface wear.

Conclusion & Next Steps

These beyond countertops ideas demonstrate the extraordinary versatility of natural stone. By leveraging these creative stone applications, you can transform any space with contemporary stone design.

Quick Sourcing Best Practices:

Select stone types rated for your application’s weight and exposure.

Confirm slab tolerances and finish options with your supplier before ordering.

Specify CNC or handcrafted edge profiles to match your aesthetic.

Plan for annual or biennial sealing based on use and porosity.

Ensure framing or subfloor reinforcement supports heavy installations.

Ready to go further? Bring your stone vision to life with Citadel Stone’s custom design services and expert fabrication.