When you’re specifying premium paving materials for Arizona projects, Black Limestone Paving in Arizona delivers the thermal performance and aesthetic durability your clients demand. Citadel Stone’s natural black limestone products combine low solar reflectance with genuine structural integrity, making them ideal for desert climates where surface temperatures routinely exceed 140°F. You’ll find that the material’s dense crystalline structure resists thermal shock better than many alternatives, though you need to account for expansion coefficients that can reach 0.0000044 inches per inch per degree Fahrenheit.

The reality is that most specifiers underestimate how Arizona’s extreme diurnal temperature swings affect paving performance. Citadel Stone black limestone maintains dimensional stability across these cycles, but your joint spacing calculations need to reflect actual thermal movement—not textbook values. Here’s what you’re really looking for: a material that won’t spall during the 60-80°F temperature drops that occur between midday and predawn hours in Phoenix and Flagstaff.

Material Composition and Performance Characteristics

Black limestone paving slabs in Arizona applications start with understanding the material’s geological properties. Citadel Stone sources dense carbonatic limestone with minimal clay content, which directly affects long-term performance. You’ll want to verify that the material exhibits a Mohs hardness rating between 3 and 4, providing adequate abrasion resistance for pedestrian traffic without the brittleness issues common in harder stones.

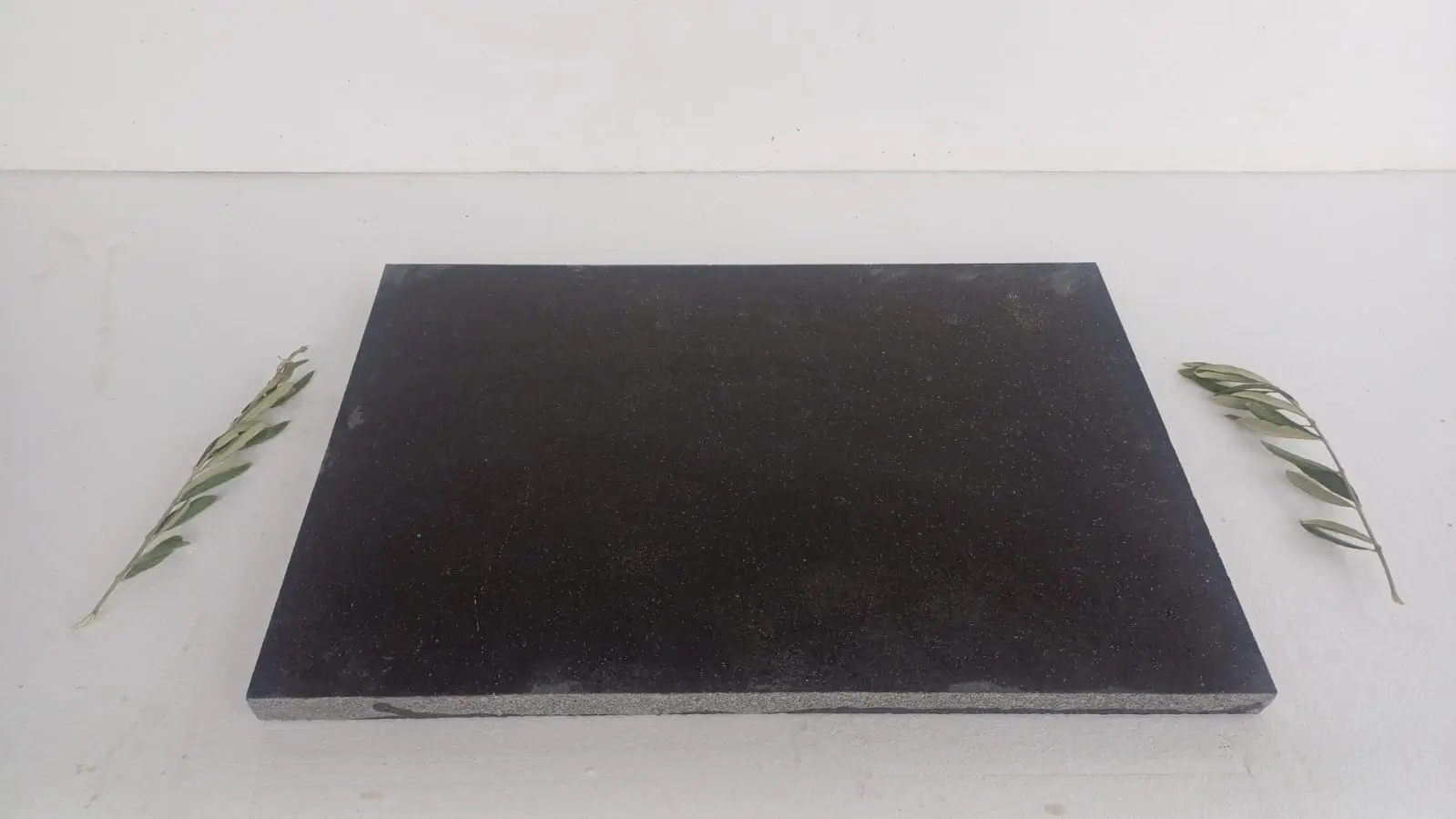

The color in natural black limestone paving in Arizona comes from organic matter and fine pyrite inclusions within the calcium carbonate matrix. This isn’t a surface treatment that’ll wear away—it’s integral to the stone. That said, you should expect some natural color variation between slabs, typically ranging from deep charcoal to blue-black tones. Most projects show a 15-20% color range across the installation, which evens out visually once the material weathers for 6-12 months.

- Water absorption rates for Citadel Stone black limestone typically measure 0.4-1.2% by weight, meeting ASTM C170 requirements for exterior applications

- Compressive strength exceeds 12,000 PSI in properly sourced material, adequate for vehicular loading when installed over engineered bases

- Thermal conductivity ranges from 1.3-1.7 W/mK, meaning the material absorbs and releases heat more slowly than granite or concrete

- Slip resistance varies significantly by finish: flamed surfaces achieve DCOF ratings above 0.55, while honed finishes drop to 0.35-0.42

Pay particular attention to the porosity structure. Limestone black paving in Arizona performs best when the pore network is fine and disconnected. You can assess this during material selection by checking water absorption under vacuum per ASTM C97—values above 2% indicate a material that’ll require more frequent sealing and may experience freeze-thaw damage in Flagstaff’s climate.

Thermal Behavior in Desert Climates

Arizona’s solar intensity creates surface conditions that eliminate many paving materials from consideration. Black limestone paving slabs in Arizona reach surface temperatures between 135°F and 165°F during peak summer afternoons, depending on finish and orientation. Citadel Stone’s material testing shows that thermal gradient stress—the temperature difference between the slab surface and its underside—can exceed 40°F, creating internal stresses that lesser-quality stone can’t tolerate.

Here’s what that means for your specifications: you need to detail expansion joints every 12-15 feet in both directions, not the 20-foot spacing that works in temperate climates. The coefficient of thermal expansion for limestone black slabs in Arizona averages 0.0000044 inches per inch per °F. Calculate this for a 90°F temperature swing, and a 10-foot slab will expand nearly 3/32 inch. If you don’t accommodate this movement, you’ll see lippage, cracking, or complete slab failure within the first summer.

Don’t make the common mistake of assuming black surfaces are automatically unsuitable for Arizona. The thermal mass of Citadel Stone black limestone actually moderates temperature fluctuations compared to thinner materials. Yes, the surface gets hot—but it releases that heat more gradually during evening hours, creating more comfortable outdoor spaces after sunset when you actually want to use them.

- Surface temperatures peak 2-3 hours after solar noon, not at midday when the sun is directly overhead

- Thermal cycling causes approximately 0.02-0.03% dimensional change per cycle, accumulating stress over thousands of cycles

- Dark finishes absorb 85-92% of incident solar radiation, compared to 60-70% for lighter limestone colors

- Subsurface temperatures at 2 inches depth remain 25-35°F cooler than the surface during peak heating

Structural Specifications and Base Requirements

Your base preparation determines whether black limestone slabs for sale in Arizona will perform for decades or fail within three years. Citadel Stone recommends a minimum 8-inch compacted aggregate base for pedestrian applications, increasing to 10-12 inches for driveways and vehicular traffic. The reality is that Arizona’s expansive soils—particularly in the Phoenix and Tucson basins—require more substantial preparation than you’d specify in stable soil regions.

You’ll need to verify subgrade California Bearing Ratio (CBR) values before finalizing your base design. Most Arizona native soils test between CBR 4 and 8, which means you can’t skip the aggregate base layer. If you’re working with caliche layers, you might think you can reduce base thickness—don’t. Caliche is hygroscopic and will expand during monsoon season, creating the differential movement that cracks natural black limestone in Arizona installations.

The bedding layer matters more than most specifiers realize. You need a 1-1.5 inch sand setting bed screeded to consistent thickness, or a mortar bed with minimum 3,000 PSI compressive strength. For Citadel Stone natural black limestone installations over concrete slabs, verify the substrate has cured at least 28 days and shows no active cracking or delamination.

- Aggregate base should be Class 2 or Class 3 road base, compacted to 95% Modified Proctor density

- Geotextile fabric between subgrade and aggregate base prevents soil migration in expansive clay conditions

- Edge restraints must be installed before paver placement—concrete curbs or steel edging anchored at 24-inch intervals

- Slope requirements are 1-2% minimum for drainage, increasing to 2-3% for large-format slabs exceeding 24 inches

Finish Options and Performance Trade-offs

When you’re selecting black natural limestone paving in Arizona, the surface finish affects both aesthetics and functionality. Citadel Stone offers thermal finish, honed, and sawn finishes, each with distinct performance characteristics. Thermal (flamed) finishes provide superior slip resistance—critical for pool decks and wet areas—but they also increase surface roughness, which accumulates dirt and organic staining in outdoor environments.

Honed finishes deliver the smooth, contemporary aesthetic most designers prefer, but you’ll sacrifice slip resistance. The DCOF rating drops from 0.55+ for thermal finishes to around 0.38-0.42 for honed surfaces. That’s below the 0.42 threshold required by most building codes for exterior walking surfaces. You can specify honed finishes for covered areas or low-traffic spaces, but don’t use them for primary walkways or pool surrounds unless you’re prepared for code compliance issues.

Sawn finishes represent a middle ground—adequate slip resistance (DCOF 0.45-0.50) with a more refined appearance than thermal treatments. The surface shows subtle saw marks that provide texture without excessive roughness. Most commercial projects using cheap black limestone paving in Arizona specify sawn finishes because they balance performance, aesthetics, and maintenance requirements.

- Thermal finishes expose the crystalline structure, creating a textured surface that hides minor scratches and wear patterns

- Honed finishes require professional polishing equipment and will show water spots and etching from acidic exposure

- Sawn finishes maintain consistent slip resistance over time as the surface texture doesn’t depend on applied treatments

- Polished finishes are inappropriate for exterior Arizona applications—they become hazardous when wet

Thickness and Sizing Considerations

Slab thickness directly affects installation cost and structural performance for buy black limestone paving in Arizona projects. Citadel Stone stocks material in 1.25-inch, 2-inch, and 3-inch thicknesses, each suited for different applications. Here’s the reality: 1.25-inch material works fine for residential patios with proper base preparation, but it won’t survive vehicular traffic. You need minimum 2-inch thickness for driveways, increasing to 3 inches for commercial loading areas.

The thing is, thicker material isn’t just about load-bearing capacity—it’s about thermal mass and dimensional stability. Thinner slabs experience greater temperature differentials between top and bottom surfaces, creating more severe thermal stress. In Phoenix summer conditions, a 1.25-inch slab might see a 35°F gradient, while a 2-inch slab reduces that to 25°F. Less stress means less risk of thermal shock cracking.

Slab sizing affects both installation efficiency and long-term performance. Citadel Stone’s natural black limestone slabs in Arizona come in modular sizes from 12×12 inches up to 24×36 inches. Larger formats create fewer joints, which means less maintenance—but they also require more precise base preparation. A 24×36-inch slab placed on an uneven bed will rock, leading to corner cracking within months. You’ll need to balance aesthetic preferences against installation realities.

- Standard residential patio applications typically use 1.25-1.5 inch material over 6-8 inch aggregate base

- Vehicular applications require 2-3 inch thickness with 10-12 inch engineered base and reinforced edges

- Large format slabs (24 inches or greater in any dimension) need professional installation—DIY attempts usually fail

- Tolerance variations in hand-cut material can reach ±3mm, requiring skilled masons to achieve level installations

Sealing Requirements and Maintenance Realities

You can’t skip sealing when specifying limestone black natural paving in Arizona. The material’s porosity makes it vulnerable to organic staining, mineral deposits from irrigation water, and efflorescence from subsurface salts. Citadel Stone recommends penetrating sealers—not topical coatings—applied within 30 days of installation. Penetrating sealers fill the pore structure without creating a surface film that’ll delaminate under Arizona’s UV exposure.

The common mistake is assuming one sealing application provides permanent protection. You’ll need to reapply penetrating sealers every 2-3 years for residential applications, annually for commercial installations with heavy traffic or exposure to pool chemicals. The sealer doesn’t wear away—it breaks down from UV radiation and chemical exposure. When you notice water absorption increasing (you can test with a few drops of water), it’s time to reseal.

Here’s what most maintenance guides won’t tell you: the monsoon season accelerates sealer degradation. The combination of intense UV radiation, high temperatures, and sudden moisture exposure during July-August storms breaks down sealer chemistry faster than in temperate climates. Plan resealing schedules around seasonal patterns—apply fresh sealer in October-November after monsoons end but before winter weather arrives.

- Penetrating sealers should meet ASTM C1583 breathability standards to allow subsurface moisture vapor transmission

- Initial sealer application requires clean, dry surfaces with ambient temperatures between 50-90°F

- Application rates typically range from 100-150 square feet per gallon, depending on material porosity

- Efflorescence issues require specific treatment with pH-neutral cleaners before sealing

Installation Methodology and Critical Details

Professional installation separates successful black limestone paving Arizona projects from failures. You can’t hand this work to general laborers—it requires experienced masons who understand natural stone behavior. The base must be screeded to within 1/4 inch of final elevation, accounting for bedding layer thickness. If your installer is eyeballing elevations or using inconsistent bedding depths, you’ll see lippage that creates trip hazards and accelerates wear patterns.

Joint spacing and fill material affect both aesthetics and structural performance. Citadel Stone recommends 3/8-inch joints for most applications, filled with polymeric sand or fine aggregate. Tighter joints (1/4 inch or less) don’t accommodate thermal expansion adequately. Wider joints (1/2 inch or more) collect debris and require more maintenance. The joint fill material must be permeable to allow water drainage while preventing sand loss and weed growth.

Don’t overlook edge restraint installation. Every paving slabs black limestone in Arizona project needs positive edge restraint—concrete curbs, steel edging, or soldier course pavers set in concrete. Without restraint, the pavers will creep over time, especially on sloped installations. The restraint must be installed before paver placement and anchored into the aggregate base, not just set on top.

- Layout should start from a fixed reference line, typically a building edge or property line, working outward in both directions

- Cut edges should face property perimeters where they’re less visible, with full pavers in high-traffic sight lines

- Mechanical compaction after placement is essential—plate compactors with rubber pads prevent surface damage while seating pavers

- Initial joint filling requires sweeping material into joints, compacting, then adding more fill to compensate for settlement

Cost Factors and Budget Planning

Material costs for limestone paving black in Arizona vary significantly based on thickness, finish, and order volume. You’re looking at $8-15 per square foot for material alone from Citadel Stone, with thicker slabs and specialized finishes pushing toward the upper range. That’s material cost at the warehouse—you’ll need to factor freight, which can add $2-4 per square foot for residential quantities delivered to Phoenix metro areas, more for Flagstaff or Yuma.

Installation costs typically equal or exceed material costs for properly executed work. Expect $10-18 per square foot for professional installation, depending on site conditions, access constraints, and design complexity. Projects requiring extensive base preparation, complex patterns, or difficult site access can push installation costs to $20-25 per square foot. When you’re calculating project budgets, use $20-30 per square foot as a realistic all-in estimate for quality black limestone slabs Arizona installations.

The thing is, trying to save money by reducing base preparation or using inexperienced installers will cost you more long-term. A properly installed Citadel Stone paving system lasts 25-30 years with routine maintenance. A budget installation might look acceptable initially, but you’ll see failures within 3-5 years requiring complete replacement. The incremental cost of doing it right—perhaps 20-25% more upfront—eliminates the risk of total failure.

- Volume discounts typically begin at 500 square feet, with pricing improvements continuing to 2,000+ square feet

- Project timing affects costs—winter installations (November-February) may command premium pricing due to reduced contractor availability

- Site access restrictions requiring hand-carrying materials can double installation labor costs

- Removal and disposal of existing paving adds $3-6 per square foot to project budgets

Common Specification Errors to Avoid

The most frequent mistake in natural black limestone in Arizona specifications is inadequate joint detailing. You can’t just write “install per manufacturer recommendations” and expect proper results. Your specifications need to explicitly state joint width (3/8 inch), joint fill material (polymeric sand meeting ASTM C144 gradation), and expansion joint locations (every 12-15 feet). Without this detail, you’ll get whatever the installer thinks is easiest.

Another critical oversight is failing to specify sealer type and application timing. Generic language like “seal as needed” results in inappropriate topical coatings or deferred sealing that allows staining to occur. Your specs should require penetrating sealer meeting specific breathability standards, applied within 30 days of installation, with a defined reapplication schedule included in maintenance documentation.

Don’t make the mistake of specifying limestone paving black slabs in Arizona without addressing substrate drainage. The material itself is relatively permeable, but water must drain away from the installation. If you don’t detail positive drainage slopes (minimum 1% grade), subsurface drainage systems, or drainage outlets, you’ll create standing water conditions that promote efflorescence and accelerate freeze-thaw damage in northern Arizona locations.

- Specifications must include actual ASTM standard numbers for material properties, not just generic quality language

- Base preparation requirements should reference compaction testing methods and acceptance criteria

- Edge restraint details need to specify material type, installation depth, and anchoring requirements

- Maintenance guidelines should be included as a deliverable, not left to owner discretion

Regional Climate Variations Across Arizona

Arizona isn’t a uniform climate—what works for limestone black paving slabs in Arizona’s Phoenix basin may fail in Flagstaff. Low desert regions (Phoenix, Tucson, Yuma) experience minimal freeze-thaw cycling but extreme heat and UV exposure. Citadel Stone’s black limestone performs well here, but you need to prioritize thermal expansion accommodation and UV-resistant sealers. The monsoon season brings brief intense rainfall that tests your drainage design—inadequate slopes will show up during July-August storms.

High desert and mountain regions (Flagstaff, Sedona, Prescott) present different challenges. Freeze-thaw cycles can reach 50-80 per year at elevations above 5,000 feet. You’ll need to verify that material water absorption rates stay below 0.8% to minimize freeze-thaw damage risk. Citadel Stone tests material specifically for freeze-thaw resistance per ASTM C666, but you still need proper installation with adequate drainage to prevent subsurface water accumulation.

Northern Arizona locations also experience greater precipitation and longer wet periods. This affects both sealer selection and joint fill materials. You’ll want sealers with higher water repellency ratings and joint fills that resist washout during extended rainfall. The maintenance schedule shifts too—resealing may be needed annually rather than every 2-3 years due to increased moisture exposure.

Citadel Stone Quality and Sourcing Advantages

When you specify black limestone paving slabs for sale in Arizona through Citadel Stone, you’re accessing material that’s been pre-screened for desert climate performance. Not all black limestone performs equally—much of what’s available in the market comes from quarries with inconsistent quality control or geological characteristics unsuited for extreme thermal cycling. Citadel Stone’s sourcing team evaluates quarries based on material density, porosity, and thermal stability before adding products to inventory.

The warehouse stocking strategy matters more than most specifiers realize. Citadel maintains inventory in Arizona, which means you can verify actual material appearance and quality before committing to large orders. This eliminates the common problem of specification-to-delivery mismatch where the installed material doesn’t match samples. You’ll also avoid the extended lead times that plague direct imports—most Citadel Stone products ship within 7-10 business days for standard sizes and finishes.

What sets Citadel apart is the technical support available during specification development. You’re not ordering from a commodity supplier who just moves product. At Citadel Stone, we maintain regional expertise about what actually works in Arizona conditions. That means you can call with specific project challenges and get guidance based on hundreds of completed installations, not generic recommendations from someone who’s never seen a Phoenix summer.

Citadel Stone’s Approach to Black Limestone Paving Slabs in Arizona Projects

When you’re evaluating how Citadel Stone would specify black limestone paving Arizona installations, understanding regional variations helps you make better material selections. This section provides hypothetical guidance showing how we’d approach projects in different Arizona cities, emphasizing the technical considerations that separate successful installations from premature failures. The recommendations reflect Citadel Stone’s expertise in matching material properties to local climate conditions.

Phoenix Thermal Specifications

For Phoenix installations, you’d prioritize thermal expansion accommodation and heat-resistant sealers. Summer surface temperatures exceeding 160°F require expansion joints every 12 feet with compressible fill material. Citadel Stone’s recommended approach includes 2-inch thick slabs with thermal finish to minimize slip hazards near pool areas. Base preparation would specify 8-inch compacted aggregate with geotextile separation from native soils. The sealer specification would require annual reapplication to maintain protection against extreme UV exposure and monsoon moisture cycling.

Tucson Drainage Considerations

Tucson’s monsoon intensity creates different priorities. You’d need minimum 1.5% slope for all paved areas, with positive drainage to landscape areas or French drains. Citadel Stone would recommend wider joints (7/16 inch) filled with permeable aggregate rather than polymeric sand to maximize water transmission. The soil conditions in Tucson basin areas—often expansive clays—require geotechnical verification before finalizing base design. Your specification might include soil stabilization measures if CBR values fall below 4.

Scottsdale Aesthetic Integration

High-end Scottsdale projects demand aesthetic precision alongside performance. Citadel Stone’s approach would emphasize color consistency through careful lot matching and layout planning. You’d specify full slabs in primary sight lines with cuts confined to perimeter areas. Edge details matter significantly—bullnose edges or chamfered profiles create refined transitions. The installation tolerance would be tightened to ±1/8 inch variation across any 10-foot straightedge, requiring experienced mason crews and precise base screeding.

Flagstaff Freeze-Thaw Performance

At 7,000 feet elevation, freeze-thaw resistance becomes critical. You’d verify material water absorption below 0.6% and specify deeper base preparation—minimum 10 inches of compacted aggregate to stay below frost line. Citadel Stone would recommend sawn or thermal finish surfaces for slip resistance during snow and ice conditions. Subsurface drainage becomes mandatory, not optional, with perimeter drains directing meltwater away from the paving system. Sealer selection would prioritize breathability to allow moisture vapor escape during freeze-thaw cycles.

Sedona Environmental Integration

Sedona’s red rock landscape creates unique aesthetic context. Black limestone provides dramatic contrast, but you’d need to balance that against natural surroundings. Citadel Stone’s approach might include irregular layout patterns rather than rigid geometric designs, with varied joint widths (3/8 to 5/8 inch) creating more organic appearance. The elevation (4,500 feet) requires moderate freeze-thaw consideration—you’d specify material with absorption rates below 0.8% and ensure proper drainage without the extreme measures needed in Flagstaff.

Yuma Extreme Heat Protocol

Yuma’s status as one of the hottest US cities intensifies thermal management requirements. You’d specify maximum joint spacing at 10-foot intervals due to extreme expansion potential. Citadel Stone would recommend 2-3 inch thickness to provide thermal mass that moderates surface temperature fluctuations. Installation timing matters significantly—work scheduled during May-September faces heat-related setting challenges with mortar applications. The specification would likely require construction during October-April weather windows. Irrigation system design needs careful separation from paving edges to prevent subsurface saturation and soil expansion.

Performance Verification and Testing

You can’t assume material quality based on appearance or supplier claims. Before finalizing large orders for natural limestone black paving in Arizona, request test certificates documenting ASTM compliance. Citadel Stone provides test results for water absorption (ASTM C97), compressive strength (ASTM C170), flexural strength (ASTM C880), and abrasion resistance (ASTM C241). These aren’t generic industry values—they’re batch-specific results from accredited testing laboratories.

Pay particular attention to freeze-thaw testing results if you’re working in Flagstaff, Prescott, or other high-elevation locations. ASTM C666 testing subjects samples to 300 freeze-thaw cycles and measures degradation. Material passing this test with less than 15% strength reduction will perform adequately in Arizona mountain climates. Material showing greater degradation may still work in low desert applications where freeze-thaw isn’t a concern.

Don’t overlook slip resistance verification, especially for commercial projects or pool surrounds. DCOF testing per ANSI A326.3 provides actual coefficient values you can compare against code requirements. Generic descriptions like “slip-resistant” don’t meet specification standards. You need documented test results showing DCOF values above 0.42 for wet surfaces in pedestrian areas, higher for ramps or sloped walkways.

Project Timeline and Procurement Planning

Material lead times affect project scheduling more than most planners anticipate. Citadel Stone’s warehouse inventory covers standard sizes and finishes with 7-10 day delivery to most Arizona locations, but custom sizes or specialized finishes can extend to 6-8 weeks. You’ll need to account for this during design development—finalizing material selections before schematic design ends gives you adequate procurement time.

Installation timing matters in Arizona’s climate. Summer installations (June-September) face heat challenges that slow productivity and affect setting materials. Winter work (December-February) can be ideal in Phoenix and Tucson but problematic in Flagstaff where freezing temperatures prevent proper mortar curing. Plan major installations for spring (March-May) or fall (October-November) weather windows when temperatures range between 60-85°F consistently.

Don’t forget that truck access to your site affects delivery timing and costs. Citadel Stone typically delivers on flatbed trucks that need adequate maneuvering space and stable ground conditions. If your site has restricted access, narrow roads, or soft soil conditions during monsoon season, you’ll need to coordinate deliveries carefully. Material staged improperly on-site can suffer damage from moisture exposure or thermal stress before installation even begins.

Essential Planning Factors

Specifying black limestone paving requires balancing aesthetic goals against performance realities and budget constraints. You’ve seen how thermal behavior, base preparation, installation methodology, and regional climate variations all influence material selection and detailing decisions. Citadel Stone’s natural black limestone products deliver the durability Arizona conditions demand when you account for thermal expansion, provide adequate drainage, and maintain proper sealing schedules.

The key is recognizing that successful installations depend on systems thinking—the paving material is just one component. Your base design, edge restraints, joint spacing, drainage provisions, and maintenance planning all contribute equally to long-term performance. Cut corners on any single element, and you’ll compromise the entire installation. For additional guidance on related stone materials and installation techniques, review Natural slate suppliers offering wholesale pricing throughout Arizona before finalizing your project specifications. When searching for premium Black Limestone Paving Arizona architects consistently specify Citadel Stone for its quality.