Case Study Overview

Client & Project Background

A luxury hotel in Santorini, Greece, envisioned a one-of-a-kind lobby clad in vivid blue marble rare to the Cyclades region. The design called for large-format 3 m × 1.5 m slabs with bookmatched veining. The budget target was €1.2 million for stone procurement, and installation needed to align with a tight 8‑month construction schedule.

Stone Supplier Selection Criteria

The client’s procurement team identified three vendors. Key criteria included:

Quarry relationships: proven ties to the Cyclades marble quarries.

Certification: ISO 9001 quality management and CE marking.

Logistical capability: in-house crating and global shipping experience.

Minimums & exclusivity: willingness to reserve blocks exclusively for this project.

Two vendors lacked direct quarry ties and proposed markups 25% higher than the third—our case study partner, Cyclades Stone Co.

Quarry Direct Partnership Process

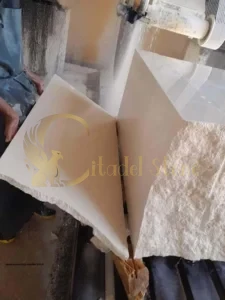

Site Visits & Sample Extraction

Cyclades Stone Co. organized an on-site tour of the quarry face. You inspect block integrity, microfractures, and natural veining patterns. The team extracted three pilot blocks, transported as 1 m cubes for factory prototyping.

Negotiating Quarry Terms

Negotiations covered:

Pricing model: cost-per-cubic-meter basis, eliminating reseller margins.

Minimum purchase: 200 m³ with option to return unused blocks within 3 months.

Exclusivity agreement: no other projects within a 100 km radius could use the same vein blocks during a 12‑month period.

This direct agreement cut stone costs by 18% compared to natural stone suppliers.

Logistics & Shipping from Quarry

Custom crating used foam-lined steel frames and weatherproof wrapping. Freight by roll-on/roll-off ferry minimized handling; road transport used air-ride suspension trucks. Import/export compliance was handled via the natural stone supplier’s in-house customs brokerage.

Technical & Quality Control Measures

Material Testing & Certification

Each slab batch underwent:

Compressive strength tests (average 135 MPa).

Water absorption (0.08%).

Color consistency: spectrophotometer comparisons to mock-up panel standards.

Certificates accompanied each shipment, ensuring compliance with EN 12407 testing standards.

Fabrication & Finishing

Workroom processes included CNC precision cutting to ±1 mm, hand-polished edges, and finish approvals by the client’s design team. Digital finish samples were reviewed via high-resolution photos and in-person mock-ups.

Financial & Risk Management

Cost Breakdown: Quarry vs. Distributor

| Cost Element | Quarry Direct (€) | Distributor (€) | Savings (%) |

|---|---|---|---|

| Raw Block Cost | 600,000 | 720,000 | 16.7% |

| Fabrication & Cutting | 300,000 | 310,000 | 3.2% |

| Logistics & Handling | 120,000 | 150,000 | 20.0% |

| Total Procurement Cost | 1,020,000 | 1,180,000 | 13.6% |

Risk Mitigation Strategies

Currency hedging: Forward contracts locked EUR/USD at project inception.

Supply guarantees: Penalty clauses for block defects or delivery delays.

Insurance: All-risk marine and inland transit coverage to project site.

Outcomes & Performance Metrics

Project Timeline & Budget vs. Actual

| Metric | Planned | Actual | Variance |

| Procurement Duration | 4 months | 4.2 months | +5% |

| Installation Duration | 2 months | 1.8 months | -10% |

| Budget | €1,200,000 | €1,150,000 | -4.2% |

Material Performance & Client Feedback

The marble exhibited consistent hue under varied lighting; no cracks or delamination occurred. The client praised the bespoke stone sourcing process for its transparency and cost-effectiveness.

Long-Term Value & Residual Benefits

Post-completion, unused block remnants were cataloged for future expansions, ensuring vein matches. The exclusivity clause added prestige, enabling the hotel to market its unique stone finish as a guest draw.

Key Lessons & Best Practices

Vet stone suppliers for true quarry access: demand proof of quarry lease or partnership.

Conduct on-site inspections: verify block quality and vein continuity in person.

Negotiate exclusivity and return terms: protect against oversupply and markups.

Structure clear logistics plans: use specialist crating and direct shipping routes.

Embed quality tests: insist on EN/ISO test certificates pre-shipment.

Manage currency and insurance: hedge exposures and insure transit.

Leverage project leftovers: catalog and store remnants for maintenance or future design phases.

How to Identify Your Own Quarry-Direct Supplier

Research regional quarry operators: consult geological surveys and industry associations.

Request proof of lease or extraction rights: legal documentation of quarry access.

Perform supplier audits: factory visits or virtual tours to confirm capabilities.

Review reference projects: seek case studies demonstrating direct sourcing success.

Negotiate terms: set cost bases, exclusivity, and return options.

Draft robust contracts: include penalties, quality specs, and delivery schedules.

Conclusion & Next Steps

Quarry-direct sourcing from a rare stone supplier yields cost savings, quality assurance, and project exclusivity. To recap:

Direct procurement cuts distributor markups.

On-site sampling and testing ensure consistent quality.

Logistical planning minimizes handling damage and delays.

Financial safeguards protect budgets and timelines.

Ready to elevate your high-end stone procurement? Explore our rare stone collection or Partner with our quarry-direct experts at Citadel Stone to secure truly exclusive materials for your next masterpiece. Unlock special discounts exclusively from your best stone supplier!