When you specify stone coping for Arizona pool projects, you’re making decisions that affect safety, aesthetics, and thermal performance for decades. Stone Coping Pool Coping Arizona installations face unique challenges—summer surface temperatures exceeding 160°F, intense UV exposure, and dramatic thermal cycling between day and night. Your material selection determines whether you create a comfortable, long-lasting pool edge or face premature degradation and safety complaints.

You need to understand how stone coping functions differently than standard pool deck materials. The elevated position, direct water contact, and concentrated foot traffic create performance demands that eliminate unsuitable materials quickly. In Arizona’s climate, the wrong choice becomes obvious within 18-24 months through cracking, spalling, or surface temperatures that make pool access uncomfortable during peak season.

Thermal Performance Considerations

Your coping stone specifications must address thermal behavior that determines usability during Arizona’s extended summer season. Stone Coping Pool Coping Arizona applications experience direct solar gain for 10-12 hours daily from May through September, with surface temperatures reaching levels that cause discomfort or injury without proper material selection.

Here’s what you need to know about thermal mass properties. Light-colored limestone and travertine reflect 55-65% of incident solar radiation, reducing peak surface temperatures by 25-30°F compared to darker stone. You’ll find this difference translates to barefoot comfort temperatures (below 115°F surface) versus burn-risk conditions (above 140°F surface). Your material density affects heat retention—denser stones above 155 lb/ft³ maintain elevated temperatures 2-3 hours after sunset, while more porous materials below 140 lb/ft³ cool within 45-60 minutes.

Thermal expansion coefficients become critical in your joint spacing calculations. Most limestone exhibits expansion rates of 4.8-5.5 × 10⁻⁶ per °F, requiring you to spec expansion joints every 12-15 feet for Arizona installations. Temperature differentials between 40°F overnight lows and 115°F afternoon highs create dimensional changes of 0.18-0.22 inches over 20-foot runs—your joint design must accommodate this movement without restricting it.

- You should specify light-colored stone with solar reflectance values above 0.55 for comfortable barefoot access

- Your thermal expansion joints need spacing at 12-foot intervals maximum in full-sun exposures

- You’ll want material density between 135-150 lb/ft³ for optimal thermal dissipation characteristics

- Honed or textured finishes reduce surface glare while maintaining lower peak temperatures than polished options

Material Specifications and Standards

When you write specifications for Stone Coping Pool Coping Arizona projects, you need compressive strength minimums that ensure structural integrity under concentrated loads. Pool coping experiences point loads from diving entries, furniture placement, and maintenance equipment that standard deck materials don’t encounter. Your specifications should require minimum 8,000 PSI compressive strength, with 10,000+ PSI preferred for commercial applications.

Porosity ratings determine long-term performance in the wet-dry cycling environment that defines pool coping. You’re looking for materials with 3-7% porosity—below 3%, water absorption becomes insufficient for proper freeze-thaw performance in Flagstaff elevations, while above 7%, you risk accelerated degradation from chemical exposure and biological growth. The interconnected pore structure matters more than total porosity; closed-cell porosity provides superior resistance to chlorinated water penetration.

Slip resistance specifications require you to address both dry and wet conditions. ASTM C1028 testing measures dry static coefficient of friction, but pool coping performance depends on wet dynamic coefficient. You should specify minimum DCOF ratings of 0.50 for wet conditions, achieved through honed, flamed, or textured finishes. Polished finishes typically measure 0.35-0.42 wet DCOF—inadequate for pool edge applications regardless of aesthetic appeal.

Thickness tolerances affect both installation cost and structural performance. Standard coping dimensions of 12-14 inches width by 2-2.5 inches thickness provide adequate overhang and structural capacity. Your specifications need to allow ±1/8 inch thickness variation across pieces, with ±1/16 inch variation within individual units. Tighter tolerances increase material cost by 15-25% without proportional performance benefits for most residential applications.

Edge Profile Options

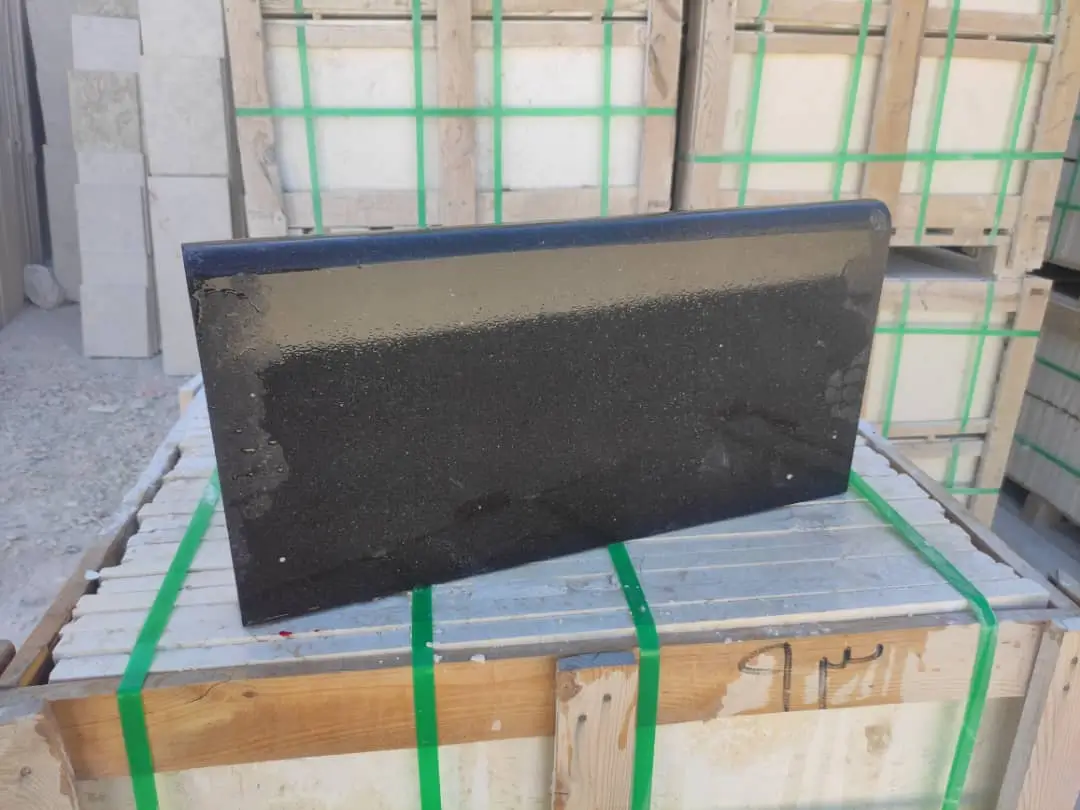

Your edge profile selection determines water management, safety characteristics, and aesthetic integration with surrounding hardscape. Bullnose profiles with 1.5-2 inch radius create the rounded edge most specifiers associate with traditional pool design. This profile sheds water effectively, reduces injury risk from impact, and provides comfortable hand-grip for pool entry and exit. When you work with our pool coping specialists, you’ll find that bullnose remains the most specified profile for residential applications due to these combined benefits.

Square-edge profiles offer contemporary aesthetics with distinct shadow lines but require careful detailing. You need to specify minimum 1/4 inch chamfer on exposed edges to prevent chipping during installation and use. Sharp 90-degree corners concentrate stress and create fracture initiation points—field experience shows 15-20% higher damage rates during installation compared to bullnose profiles. Your drawings should detail drip edge grooves on the underside, 3/8 inch wide by 1/4 inch deep, positioned 1 inch back from the leading edge to prevent water tracking along the underside.

- Bullnose pool coping supplier across Arizona offerings typically include 1.5-inch and 2-inch radius options for different aesthetic preferences

- You should specify chamfered edges on all square profiles to reduce installation damage by 15-20%

- Your detail drawings must show drip grooves on underside profiles to manage water runoff effectively

- Ogee and decorative profiles increase material cost by 30-45% compared to standard bullnose configurations

Base Preparation Requirements

Your base preparation determines whether Stone Coping Pool Coping Arizona installations achieve their 25-30 year service life potential or fail prematurely. The cantilever position of pool coping creates moment forces that demand proper support—inadequate base preparation accounts for 60% of coping failures within the first five years. You need minimum 4-inch reinforced concrete bond beam with proper embedment into pool shell structure.

Substrate moisture content must measure below 4% before you set coping stone. Higher moisture levels create efflorescence conditions that appear 6-18 months post-installation, requiring costly remediation. You should specify moisture testing at multiple points along the bond beam, particularly in areas where irrigation systems operate nearby. Arizona’s low humidity helps, but early-season installations during March-April monsoon preparation periods need extra attention to substrate drying.

Your setting bed specifications should call for modified thinset mortar with minimum 1,200 PSI bond strength and flexibility to accommodate minor thermal movement. Traditional sand-cement mortar beds lack the bond strength and flexibility that modern polymer-modified products provide. You’ll want coverage of 95% or better on the stone underside—voids create stress concentrations that lead to cracking under load. Back-buttering individual pieces in addition to troweling the substrate ensures complete coverage.

Perimeter support conditions vary based on deck material interfaces. Where coping meets travertine or concrete deck surfaces, you need to maintain 3/8 inch joints filled with flexible polyurethane sealant. Rigid grout in these transition zones creates restraint that prevents thermal movement, leading to cracking at the weakest point—typically through the coping stone itself. Your joint design should accommodate ±1/4 inch movement across the expected temperature range without bond failure or compression set.

Water Chemistry Exposure

When you specify materials for pool coping applications, you’re selecting stone that will experience continuous exposure to chlorinated water, pH fluctuations, and chemical cleaning agents. Stone Coping Pool Coping Arizona projects face additional challenges from high evaporation rates that concentrate chemical deposits on coping surfaces. Your material selection needs to account for this aggressive exposure environment that differs significantly from standard paving applications.

Calcium carbonate content in limestone creates vulnerability to acidic conditions, but properly maintained pool chemistry (pH 7.4-7.6) poses minimal risk. The greater concern comes from alkaline conditions above pH 8.0, which accelerate efflorescence and cause surface etching over time. You should educate clients that maintaining proper water chemistry protects their investment—fluctuations outside the 7.2-7.8 range accelerate degradation regardless of stone quality.

Salt system pools create more aggressive exposure conditions than traditional chlorine systems. While salt concentration (3,000-4,000 PPM) remains well below seawater levels, the continuous electrolytic chlorine generation process maintains consistently elevated oxidation potential. You’ll find that dense, low-porosity stones (below 5% absorption) perform best in salt pool applications. Travertine’s higher porosity (6-9%) makes it less suitable for salt systems without additional sealing protocols.

- You need stone specifications with porosity below 5% for salt-system pool applications

- Your maintenance recommendations should emphasize pH control between 7.2-7.8 to minimize chemical degradation

- You should specify annual resealing for optimal protection against concentrated chemical exposure

- Coping stone suppliers Arizona pool contractors rely on provide technical data sheets with chemical resistance specifications

Climate Zone Variations

Arizona’s elevation range from 70 feet in Yuma to 7,000+ feet in Flagstaff creates distinct climate zones that affect Stone Coping Pool Coping Arizona material performance. You can’t apply the same specification across all regions—what works in Phoenix fails in Flagstaff, and vice versa. Your material selection process needs to account for freeze-thaw cycles, precipitation patterns, and extreme temperature ranges that vary dramatically across the state.

Low desert regions (Phoenix, Tucson, Yuma) experience minimal freeze-thaw risk but face extreme thermal stress and UV exposure. You should prioritize materials with high solar reflectance and proven thermal cycling resistance. The 80-90°F diurnal temperature swings during spring and fall create more thermal stress than the sustained high temperatures of summer. Your specifications need to address this cycling through proper joint spacing and flexible setting materials.

High desert and mountain regions (Flagstaff, Sedona, Prescott) require freeze-thaw resistant materials with porosity specifications that allow proper water drainage. You’re looking at 40-80 annual freeze-thaw cycles in Flagstaff compared to 0-5 cycles in Phoenix. ASTM C1645 testing should show less than 1% strength loss after 100 freeze-thaw cycles for these applications. Dense limestone with proper sealing performs adequately; travertine requires careful evaluation and aggressive sealing protocols.

Your specifications should reference specific climate data for the project location rather than using state-wide generalizations. Temperature extremes, annual freeze-thaw cycles, precipitation patterns, and UV index all vary significantly. Coping stone manufacturers Arizona professionals trust provide regional performance data that helps you make informed material selections based on actual exposure conditions rather than generic recommendations.

Color Stability and UV Resistance

When you select stone colors for Arizona pool coping, you need to understand how UV exposure affects long-term appearance. Stone Coping Pool Coping Arizona installations receive 330+ days of direct sunlight annually, with UV index values reaching 11+ during summer months. This intense exposure causes color shifts in some materials that disappoint clients who expected permanent aesthetics.

Natural limestone exhibits excellent color stability because the calcium carbonate crystal structure doesn’t degrade under UV exposure. You’ll see minimal color change over decades beyond the normal patina development that comes from weathering and mineral deposit accumulation. Warm beige and cream tones remain stable; darker gray limestone may lighten slightly (10-15% over 10 years) as surface minerals oxidize, but changes occur gradually and uniformly.

Iron-bearing minerals in some stone varieties create rust-colored staining when exposed to water and oxygen. You should specify materials with iron oxide content below 2% to minimize this discoloration risk. While rust staining doesn’t affect structural performance, it creates aesthetic complaints that require remediation. Pre-installation testing involves wetting sample pieces and monitoring for 72 hours—iron staining typically appears within this timeframe if minerals are present in problematic concentrations.

Surface finish affects both initial appearance and long-term color stability. Honed finishes reveal stone’s natural color more accurately than polished surfaces, which create optical effects through light reflection. You’ll find that honed surfaces also weather more uniformly—polished finishes show traffic patterns and wear more obviously as the polish degrades in high-use areas. For pool coping applications where consistent appearance matters, honed or lightly textured finishes provide superior long-term results.

Installation Sequence and Timing

Your installation timeline for Stone Coping Pool Coping Arizona projects needs to account for temperature constraints, curing requirements, and coordination with other trades. Optimal installation windows occur during spring (March-May) and fall (September-November) when temperatures remain moderate and allow proper mortar curing. Summer installations require special protocols to prevent rapid moisture loss that compromises bond strength.

You should schedule coping installation after pool shell completion and waterproofing but before deck paving. This sequence allows you to establish the pool perimeter reference line and provides access for equipment and material staging. Installing coping after deck paving restricts access and increases damage risk to completed work. Your construction schedule should allocate 2-3 days for typical residential pool coping installation, with additional time for substrate preparation and joint finishing.

Temperature during installation affects mortar performance significantly. You need ambient and substrate temperatures between 40°F and 90°F for optimal results. Below 40°F, polymer-modified mortars don’t cure properly; above 90°F, rapid moisture loss prevents complete hydration. Summer installations in Phoenix require you to work during early morning hours (5 AM – 10 AM) when temperatures remain manageable. Your crew should fog-spray completed sections every 30-45 minutes during hot weather to prevent premature drying.

- You should schedule installation during spring or fall to optimize curing conditions and avoid temperature extremes

- Your project sequence must place coping installation after shell completion but before deck paving for optimal access

- You need to maintain substrate temperatures below 90°F during setting—early morning installation windows work best in summer

- You’ll want 48-72 hour cure time before allowing foot traffic or beginning adjacent construction activities

Joint Design and Sealant Selection

When you detail joints for pool coping applications, you’re designing for both aesthetic consistency and functional movement accommodation. Stone Coping Pool Coping Arizona specifications require joints that handle thermal expansion, structural deflection, and water infiltration simultaneously. Your joint width, depth, and sealant selection all affect long-term performance and maintenance requirements.

Joint width specifications typically range from 3/8 to 1/2 inch for pool coping applications. Narrower joints (1/4 inch) don’t accommodate thermal movement adequately and create installation challenges—achieving consistent narrow joints with natural stone’s dimensional variation requires excessive cutting and fitting time. Wider joints (5/8 inch+) collect debris and create visual weight that can overwhelm smaller pools. You’ll find that 3/8 inch joints provide the best balance of movement accommodation, installation efficiency, and aesthetic proportion.

Sealant selection determines whether joints remain watertight and flexible over time. You need polyurethane or polysulfide sealants with minimum ±25% movement capability and Shore A hardness between 25-35. Avoid rigid cementitious grouts in coping joints—they crack within 1-2 years as thermal movement and minor structural deflection occur. Your specifications should call for joints filled to within 1/4 inch of the surface, with backer rod providing proper depth control and sealant geometry.

Color-matched sealants create clean appearances but require more frequent maintenance than gray or neutral tones. UV exposure causes pigmented sealants to fade 20-30% within 3-5 years, creating color mismatches that become more obvious with light-colored stone. You should recommend neutral gray or tan sealants that blend with multiple stone colors while showing minimal fading over time. Pool coping suppliers Arizona professionals work with can provide sealant recommendations specific to material selections.

Maintenance Protocols and Longevity

Your specification documents should include maintenance protocols that help clients protect their investment in Stone Coping Pool Coping Arizona installations. Unlike deck paving that receives periodic wet cleaning, coping experiences continuous water exposure, concentrated foot traffic, and chemical splash. You need to establish realistic expectations for maintenance frequency and methods that preserve both function and appearance.

Sealing requirements depend on material porosity and exposure intensity. Dense limestone (below 5% absorption) benefits from penetrating sealers applied every 2-3 years. More porous materials need annual resealing to maintain optimal protection. You should specify breathable penetrating sealers rather than topical films—film-forming sealers trap subsurface moisture and create delamination problems in wet applications. Your maintenance schedule should call for sealer application during fall months (September-October) when temperatures moderate and pool use decreases.

Regular cleaning prevents buildup of calcium scale, organic staining, and surface grime that accumulate from water splash and environmental exposure. You should recommend quarterly cleaning with pH-neutral cleaners specifically formulated for natural stone. Acidic cleaners (including many tile and grout products) etch limestone surfaces and accelerate degradation. Pressure washing provides effective cleaning but requires you to limit pressure to 1,200 PSI maximum and maintain 12-inch minimum distance to prevent surface erosion.

Joint sealant maintenance represents the most frequently neglected aspect of coping care. You need to inspect joints annually for cracking, debonding, or deterioration. Failed joints allow water infiltration that compromises the setting bed and leads to coping movement or cracking. Your maintenance protocols should include joint resealing every 5-7 years as preventive maintenance, even if visible deterioration hasn’t occurred. This proactive approach costs less than remedial repairs from water damage.

Common Specification Errors

When you write specifications for Stone Coping Pool Coping Arizona projects, certain mistakes appear repeatedly and create installation problems or performance failures. You can avoid these issues by understanding where specification documents typically fall short and what details need explicit clarification rather than assumed understanding.

Inadequate dimensional specifications create field conflicts during installation. Generic callouts like “12-inch pool coping” don’t address thickness, edge profile, or overhang dimensions. You should specify complete dimensions: “12-inch width × 2-inch thickness, bullnose front edge with 1.5-inch radius, 1.5-inch overhang beyond pool shell face.” This level of detail eliminates field interpretation and ensures bid consistency across suppliers.

Failing to specify surface finish leads to aesthetic disconnects between expectations and delivered material. “Natural stone pool coping” could mean polished, honed, flamed, or textured surfaces—each with different slip resistance, color depth, and cost implications. You need explicit finish specifications: “honed finish with 120-grit smoothness, matte appearance, minimum 0.50 wet DCOF per ASTM C1028.” This precision prevents change orders and installation delays from finish disputes.

- You must provide complete dimensional specifications including width, thickness, profile type, and overhang measurements

- Your finish specifications should reference specific grit levels and DCOF requirements rather than subjective terms

- You need to specify setting materials by type and performance characteristics, not just “mortar” or “adhesive”

- You should include movement joint locations, widths, and sealant specifications in your drawings and technical sections

- Your material sourcing should reference bullnose pool coping supplier across Arizona options with adequate lead time allowances

Cost Factors and Value Engineering

When you develop budgets for Stone Coping Pool Coping Arizona installations, you need to account for variables that affect material and labor costs significantly. Straight-forward rectangular pools with simple bullnose coping represent baseline pricing; curves, radius corners, and custom profiles increase costs through additional fabrication and installation time. Your preliminary estimates should include contingencies for these factors rather than applying simple linear-foot pricing.

Material costs vary based on quarry location, current production volume, and warehouse inventory levels. You’ll find pricing fluctuations of 15-25% across the year as production and demand cycles affect availability. Your procurement timing affects project costs—material ordered during peak summer construction season costs more than winter orders when demand softens. You should verify warehouse stock levels before committing to aggressive project schedules; custom orders requiring quarry production add 6-10 weeks to lead times.

Thickness specifications directly impact material cost per square foot. Standard 2-inch coping represents baseline pricing, while 2.5-inch thickness adds 20-25% to material cost and 3-inch thickness adds 40-50%. You need to evaluate whether structural requirements truly demand increased thickness or if standard dimensions provide adequate performance. For most residential applications, 2-inch thickness exceeds minimum requirements with comfortable safety margins.

Edge profile complexity affects both material and installation costs. Standard bullnose profiles represent baseline pricing; ogee, dupont, and custom profiles add 30-60% to material costs and increase installation time by 25-35%. You should evaluate aesthetic preferences against budget constraints and determine where profile investment provides meaningful visual impact versus areas where standard profiles suffice. Featuring custom profiles at focal points (steps, spa spillways) while using standard profiles elsewhere balances aesthetics and budget.

Citadel Stone’s Stone Coping Pool Coping Arizona: Regional Specifications

When you consider Citadel Stone’s Stone Coping Pool Coping Arizona for your project, you’re evaluating premium materials designed specifically for the state’s extreme climate performance demands. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert heat to high-elevation freeze-thaw conditions. This section outlines how you would approach specification decisions for six representative cities, accounting for elevation, temperature extremes, and regional installation considerations that determine long-term performance.

Your material selection process needs to account for variables that change dramatically across Arizona’s geographic diversity. Elevation differences of 7,000+ feet create climate zones ranging from Sonoran Desert conditions to alpine environments. You’ll encounter temperature ranges from single-digit winter lows in mountain regions to 120°F+ summer highs in desert valleys. Each climate zone requires you to adjust specifications for thermal performance, freeze-thaw resistance, and exposure intensity.

Phoenix Specifications

In Phoenix’s extreme desert heat, you would prioritize thermal reflectivity and heat dissipation characteristics when specifying Stone Coping Pool Coping Arizona materials. Summer surface temperatures require you to select light-colored limestone with solar reflectance values above 0.60 to maintain comfortable barefoot access. Your specifications would call for honed finishes that reduce glare while providing slip resistance above 0.50 wet DCOF. You’d need expansion joints every 12 feet to accommodate the 75°F diurnal temperature swings during spring and fall shoulder seasons. Material density between 135-145 lb/ft³ would provide optimal thermal dissipation, allowing surfaces to cool within one hour after sunset. At Citadel Stone, we maintain warehouse inventory in the Phoenix metro area to ensure material availability aligns with your aggressive construction schedules during optimal spring and fall installation windows.

Tucson Considerations

Your Tucson installations would face similar thermal challenges to Phoenix but with additional considerations from higher elevation (2,400 feet) and monsoon precipitation patterns. You’d specify materials with porosity between 4-6% to handle brief but intense summer rainfall while maintaining heat resistance for 110°F+ temperatures. The 10-15 annual freeze events require you to verify ASTM C1645 compliance, though less stringently than Flagstaff specifications. You would detail drip edges and proper drainage slopes to shed monsoon moisture quickly, preventing saturation that could lead to freeze damage during occasional winter cold snaps. Your expansion joint spacing would remain at 12-foot intervals, with particular attention to joints near areas that receive irrigation overspray from adjacent landscaping.

Scottsdale Premium Applications

When you specify for Scottsdale’s luxury residential market, you would balance performance requirements with heightened aesthetic expectations. Your material selections would emphasize consistent color, tight dimensional tolerances (±1/16 inch), and premium surface finishes. You’d call for custom bullnose profiles with 2-inch radius for contemporary designs or traditional 1.5-inch radius for classic pool styles. Thermal performance remains critical—you need light-colored options that maintain surfaces below 115°F during peak afternoon hours. Your specifications would include premium polyurethane sealants color-matched to stone selections, despite the higher maintenance requirements, because visual impact justifies the added upkeep in this market segment.

Flagstaff Freeze Protection

Your Flagstaff specifications would prioritize freeze-thaw resistance above thermal reflectivity concerns. At 7,000 feet elevation with 60-80 annual freeze-thaw cycles, you’d require materials with porosity below 5%, compressive strength above 10,000 PSI, and documented ASTM C1645 performance showing less than 1% strength loss after 100 cycles. You would specify aggressive sealing protocols with penetrating sealers applied annually to minimize water absorption. Your base preparation details would include enhanced waterproofing membranes and setting beds with latex-modified mortars providing superior flexibility and bond strength. Expansion joints would space at 10-foot intervals to accommodate greater thermal cycling ranges. The shorter pool season (May-September) would allow you to schedule maintenance during extended off-season periods when you could drain pools for thorough coping inspection and resealing.

Sedona Aesthetic Integration

In Sedona’s distinctive red rock landscape, you would specify coping colors that complement rather than compete with natural surroundings. Warm beige and cream limestone selections would coordinate with regional architecture while providing necessary thermal performance. Your specifications would account for moderate freeze-thaw risk (20-30 annual cycles) with materials rated for ASTM C1645 compliance. You’d detail installations that respect the area’s visual character—clean lines, natural finishes, and color palettes that harmonize with high-desert aesthetics. Truck access limitations on hillside properties would require you to plan material deliveries carefully, possibly specifying smaller delivery loads that navigate steep, narrow access roads typical of premium Sedona home sites.

Yuma Extreme Heat

Your Yuma specifications would address the most extreme thermal conditions in Arizona—summer temperatures consistently exceeding 115°F and intense solar radiation at low elevation (141 feet). You’d prioritize maximum solar reflectance in material selection, specifying the lightest available colors with reflectance values above 0.65. Thermal mass considerations would emphasize rapid heat dissipation through lower-density materials (130-140 lb/ft³) that cool quickly after sunset. You would specify wider expansion joints (1/2 inch) at 12-foot spacing to accommodate extreme thermal expansion in this climate. Your installation timing would restrict field work to October through April when temperatures moderate below 90°F—summer installation would be impractical due to rapid mortar curing and worker safety concerns. Material staging would require covered storage to prevent excessive pre-installation heat gain that complicates handling and setting procedures.

Professional specification processes require you to balance performance requirements with budget constraints and aesthetic preferences while ensuring long-term durability. Your material evaluation should consider thermal behavior, structural adequacy, slip resistance, and maintenance demands specific to each project’s location and use intensity. For complementary hardscape solutions that address erosion control and structural retention needs, review Heavy-duty natural stone for erosion control and retaining wall construction before you finalize project documents. Commercial pool projects trust Citadel Stone, the most volume-capable Stone Coping Pool Coping in Arizona.