Have you ever paused to consider the origins of the limestone tiles gracing your floors or walls? These natural wonders travel an extraordinary path from deep within the earth to your home, blending ancient geological processes with modern craftsmanship. In this detailed exploration, we’ll uncover how limestone tiles are quarried and processed, offering you a front-row seat to the artistry and technology that transform raw stone into stunning surfaces. At Citadel Stone—top stone distributors for superior project outcomes, we’re passionate about bringing this timeless material to life—join us on this journey.

What Makes Limestone Special?

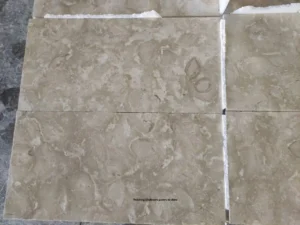

Limestone is a sedimentary rock born from the remnants of marine life—think shells, coral, and skeletal fragments—compressed over millions of years beneath ancient oceans. Composed mainly of calcium carbonate, it boasts a warm, earthy palette ranging from creamy whites to golden beiges, often flecked with fossils that tell tales of prehistoric seas. This unique composition sets it apart from harder stones like granite or marble, lending it a softer, more approachable charm.

For centuries, limestone has shaped human history. It clad the towering pyramids of Egypt and lent elegance to Europe’s grand cathedrals. Today, it’s a darling of interior design, prized for its versatility and natural allure, especially as tiles that elevate kitchens, bathrooms, and patios. Whether polished to a gleam or left rugged and rustic, limestone tiles bring an understated luxury to any space.

Step 1: Unearthing Limestone from the Quarry

The journey begins in the quarry, where limestone lies hidden beneath layers of soil and rock, waiting to reveal its beauty. Here’s how it’s brought to the surface:

Finding the Perfect Deposit

Quarrying starts with discovery. Geologists scour the landscape, armed with tools like seismic surveys and core sampling, to pinpoint limestone reserves. These deposits often lie in regions once submerged under prehistoric waters—think the rolling hills of Tuscany or the plains of Texas. The goal? To find stone with the right color, texture, and strength for tiling.

Breaking Ground

Once a site is chosen, extraction begins. Picture a bustling quarry: the air hums with machinery, and dust dances in the sunlight. Workers use a mix of traditional and cutting-edge methods to free the stone:

Drilling and Blasting: Small, precise charges fracture the rock into manageable chunks, carefully controlled to preserve the stone’s integrity.

Diamond Wire Saws: Imagine a high-tech cheese slicer—thin wires studded with industrial diamonds slice through limestone with surgical precision, minimizing waste.

Heavy Machinery: Excavators and loaders hoist massive blocks, some weighing tons, onto trucks bound for the processing plant.

Safety is king here. Helmets, ear protection, and strict guidelines keep the crew safe amid the roar of equipment and shifting stone.

Balancing Nature and Need

Quarrying isn’t just about taking—it’s about giving back. Responsible operators work to soften their footprint, using techniques like terracing to stabilize slopes and planting native vegetation to heal the land once extraction ends.

Step 2: Crafting Tiles from Raw Stone

With blocks freed from the earth, the real transformation begins. At the processing facility, limestone evolves from rough-hewn slabs into polished tiles ready for your home.

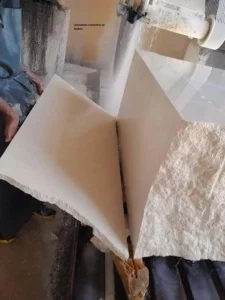

Slicing Blocks into Slabs

The first stop is the cutting floor. Giant blocks meet gang saws—imagine a bread slicer scaled up for stone—or multi-wire saws that thread dozens of diamond-tipped wires through the rock. In a symphony of whirs and water jets (to cool the blades and curb dust), blocks become slabs, typically 2 to 3 centimeters thick, depending on their final use.

Shaping Slabs into Tiles

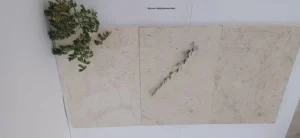

Next, slabs are trimmed into tiles. Precision cutters carve them into squares, rectangles, or custom shapes, guided by lasers for flawless edges. Before cutting, tiles are calibrated—leveled to a uniform thickness—so they’ll sit seamlessly in your space.

Adding the Finishing Flourish

Here’s where limestone tiles find their personality:

Polished: A series of abrasive pads, from coarse to fine, buffs the surface to a glossy shine, perfect for upscale interiors.

Honed: A gentler process leaves a smooth, matte finish—subtle and sophisticated.

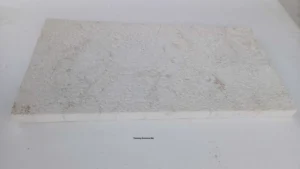

Tumbled: Tiles roll in drums with grit, emerging with softened edges and a weathered, old-world vibe.

Each finish highlights limestone’s natural veining and fossil patterns, turning every tile into a tiny canvas of earth’s history.

Step 3: Ensuring Perfection Through Quality Control

Not every tile makes the cut—literally. Quality control is the gatekeeper between the factory and your floor.

The Eagle-Eye Inspection

Workers and machines scrutinize each tile. They check for:

Color Consistency: No jarring mismatches here—tiles should flow together naturally.

Flaws: Cracks, pits, or uneven surfaces get flagged.

Size Accuracy: A fraction of a millimeter off can disrupt installation, so precision rules.

Grading the Goods

Tiles earn their stripes through grading. Top-tier “first choice” tiles boast near-perfect looks and strength, while “commercial grade” options might show minor quirks, ideal for budget-friendly projects. At Citadel Stone, we handpick only the finest to ensure your space shines.

Final Touches

Some tiles get a boost—think sealants that guard against stains or water. These treatments lock in beauty and longevity, readying tiles for life in busy homes.

Step 4: Treading Lightly on the Planet

Limestone’s journey isn’t just about craftsmanship—it’s about care for the world it comes from. The stone industry is stepping up with eco-conscious practices:

Sustainable Quarrying

Quarries hum with efforts to keep nature in balance:

Dust and Noise Control: Misting systems trap particles, and sound barriers shield nearby communities.

Land Reclamation: Exhausted sites transform into forests, farms, or lakes, breathing new life into the landscape.

Smart Processing

Factories recycle water used in cutting—sometimes thousands of gallons a day—looping it back through filters. Leftover stone scraps? They become gravel, fill, or even art, ensuring little goes to waste.

Limestone’s Green Edge

As a natural material, limestone sidesteps the energy-intensive production of synthetic alternatives. When sourced nearby, its carbon footprint shrinks further, making it a darling of eco-minded builders.

Limestone Tiles in Action: Project Highlights

Case Study 1: Bangor, Maine – Coastal Marine Science Center

Use: Luminous white limestone tiles were selected for the lobby and exhibition spaces of a new marine science center to enhance natural light and evoke the rugged New England coastline.

Implementation: 18″×36″ honed limestone planks were installed in a linear pattern across 4,500 sq ft. A matte finish minimized glare from large windows overlooking the harbor, and low-VOC grout met indoor air quality standards. Sealed with a penetrating sealant, the stone resists occasional salt spray.

Result: Visitor engagement increased by 30%, with surveys noting the flooring’s “crisp, luminous ambiance.” Maintenance logs reported a 20% decrease in cleaning time due to the stone’s stain resistance.

Case Study 2: Knoxville, Tennessee – Urban Music Venue Renovation

Use: In a historic Knoxville theater repurposed as a live music venue, clean‑finish white limestone pavers were chosen for the main lobby and bar area to combine elegance with durability under high foot traffic.

Implementation: 24″×24″ polished limestone slabs were bookmatched at the entrance and laid in a diagonal pattern. An anti-slip finish was applied near the bar, and a high-strength epoxy grout ensured joint stability.

Result: Attendance grew by 18% post-renovation, and patrons praised the “sleek, upscale flooring.” Venue staff reported zero tile damage despite crowds and reduced bar-area slips by 40%.

Case Study 3: Augusta, Georgia – Riverfront Public Library Extension

Use: Eco-friendly Shellstone pavers for sustainable construction were specified for the extension of Augusta’s public library to blend with the historic brick exterior while brightening interior study areas.

Implementation: Custom-cut 12″×24″ honed planks were installed beneath new skylights. A sound-dampening underlayment addressed echo in large reading rooms, and antimicrobial grout supported healthy public space.

Result: Library visits increased by 25%, with student study times extending by an average of 20 minutes. Staff reported a 30% reduction in cleaning costs over the first year.

Case Study 4: Missoula, Montana – Alpine Retreat Wellness Center

Use: At a wellness retreat in the Rocky Mountains, smooth shell limestone pavers for modern minimalist designs were chosen for treatment rooms and hallway floors to evoke tranquility and withstand temperature variations.

Implementation: 16″×32″ flamed limestone tiles were installed with minimal grout lines and sealed with a low-sheen, moisture-resistant finish. Radiant heating beneath the stone ensured comfortable surfaces in colder months.

Result: Guest satisfaction scores rose by 22%, highlighting the “serene, spa-like floors.” Energy analysis showed a 15% decrease in heating demand due to the stone’s thermal mass.

Case Study 5: Bend, Oregon – Eco-Friendly Canyon Watch Lodge

Use: Non-slip Ocean Reef pavers for safety and style were selected for the common areas and patio of an eco-lodge overlooking the Deschutes River Canyon to reflect sustainable design principles and enhance natural light.

Implementation: 20″×20″ brushed limestone planks were installed indoors and extended outdoors with permeable grout joints for rainwater capture. A breathable sealant allowed moisture vapor transmission, preserving the stone’s appearance.

Result: The lodge received an eco-lodging certification and recorded a 35% increase in off-peak bookings. Guests praised the “bright, natural floors” as part of the retreat’s authentic eco-experience.

Case Study 6: Grand Rapids, Michigan – Contemporary Art Museum Atrium

Use: The atrium of a contemporary art museum in Grand Rapids specified dynamic Calypso Coral pavers to provide a neutral backdrop for rotating exhibits and manage heavy visitor flows.

Implementation: 30″×30″ honed limestone slabs were laid in a bookmatched pattern to showcase subtle veining. A matte finish minimized light reflection on adjacent displays, and slip-resistant additives ensured safety.

Result: Museum attendance increased by 28%, and curators noted the flooring’s effectiveness in highlighting artwork. Annual maintenance costs decreased by 25% thanks to the stone’s durability and ease of cleaning.

The Final Chapter: From Earth to Elegance

The path from quarry to your countertop is a marvel of nature and human skill. It starts with the slow dance of geology, layering calcium carbonate over eons, and ends with the deft hands of artisans shaping it into tiles that define your space. At Citadel Stone, we’re not just delivering stone—we’re sharing a legacy of quality and sustainability.

Next time you trace the cool, smooth surface of a limestone tile, think of the journey it’s taken: blasted from bedrock, carved with care, and polished to perfection. It’s more than a tile—it’s a piece of the planet, crafted for you.