When you’re responsible for restoring historic cobble sett walkways, you’re working with materials that have lasted a century or more—and your decisions determine whether they’ll survive another hundred years. Historic cobble installations present unique challenges that modern paving projects never encounter. You need to balance preservation standards with functional requirements while addressing deterioration patterns that develop over decades of use and environmental exposure.

The restoration process for these installations differs fundamentally from new construction. You’ll encounter mortar degradation, subsurface settlement, biological growth, and surface wear that requires specialized assessment before you can develop an effective restoration strategy. Your approach must preserve the historical character while addressing structural deficiencies that compromise safety and performance.

Assessment Before Restoration

Before you begin any restoration work on restoring historic cobble setts, you need to document existing conditions systematically. Your assessment determines which stones can remain in place, which require resetting, and which need replacement. Start by mapping areas of settlement, identifying stones with structural cracks, and documenting mortar joint conditions across the entire installation.

You should evaluate subsurface conditions by exposing test sections at three to five locations. This reveals base material composition, drainage adequacy, and the extent of subsurface deterioration. Historic installations often rest on sand beds or directly on compacted soil—conditions that don’t meet current engineering standards but may be functioning adequately. Your restoration plan needs to address whether subsurface improvements are necessary or if surface-level intervention suffices.

- You’ll find that settlement patterns indicate subsurface failure zones requiring excavation and base reconstruction

- Individual stone damage concentrates in traffic lanes where repetitive loading exceeds the material’s wear resistance

- Joint deterioration typically progresses from surface erosion to full-depth material loss over 40-60 years

- Biological growth accumulation signals inadequate drainage or excessive shade conditions

Cleaning Granite Setts Methodology

Your cleaning approach for cleaning granite setts must remove accumulated contamination without damaging historic stone surfaces. The challenge lies in distinguishing between removable soiling and patina that contributes to the installation’s historic character. You need to test cleaning methods on inconspicuous areas before proceeding with full-scale work.

For most historic granite installations, you should start with low-pressure water washing at 400-600 PSI combined with soft-bristle brushing. This removes surface dirt, biological growth, and loose material without abrading the stone surface. Higher pressures—above 800 PSI—can erode weathered stone surfaces and widen existing cracks. If biological growth persists after initial cleaning, you’ll need biocide treatment followed by a second wash cycle after the recommended dwell time.

Chemical cleaning becomes necessary when you encounter oil staining, paint contamination, or deeply embedded soiling. Your selection depends on the contaminant type and stone mineralogy. Alkaline cleaners work effectively for oil-based staining on granite, while paint strippers require careful application to avoid subsurface penetration. Always neutralize chemical treatments completely—residual alkalinity or acidity accelerates future deterioration. When you evaluate effective cleaning and restoration techniques, consider how hardscape cobble setts respond to different chemical formulations based on mineral composition and porosity characteristics.

Joint Material Removal

Before you can reset displaced stones or repoint deteriorated joints, you need to remove existing joint material completely. Historic installations typically use lime-based mortars that have carbonated over decades, creating bonds stronger than the original mix proportions would suggest. You’ll need to distinguish between mortar that’s structurally compromised and material that’s performing adequately.

Your removal technique depends on joint width and mortar condition. For narrow joints under 3/8 inch, you should use rotary grinding with diamond blades, maintaining minimum clearance from stone edges to prevent chipping. Wider joints allow manual removal with narrow chisels and pointing tools. You need to achieve consistent depth—typically 1.5 to 2 times the joint width—to ensure adequate bond for new mortar.

- Pneumatic chisels create vibration that can loosen adjacent stones and should be avoided except in completely failed sections

- You’ll encounter areas where mortar has eroded below the stone surface, requiring excavation to sound material before repointing

- Historic lime mortars often contain significant sand content that creates abrasive resistance during removal

Addressing Settlement Issues

When you identify areas of significant settlement during your assessment, you’re facing a decision about intervention extent. Minor depressions under 3/4 inch across small areas may not warrant full excavation, while broader settlement patterns indicate base failure requiring complete reconstruction. Your decision affects project cost, timeline, and the degree of historic fabric disturbance.

For localized settlement, you can often reset individual stones or small sections without disturbing adjacent areas. This requires careful excavation to avoid undermining surrounding stones. You’ll need to verify that the base material beneath settled areas provides adequate support—if not, you must excavate to stable subgrade and reconstruct the base section. Your new base should match or exceed the load-bearing capacity of surrounding areas to prevent differential settlement.

Widespread settlement necessitates systematic excavation and base reconstruction. You should document the original base configuration through photography and notes before removal—this information guides reconstruction decisions. Historic bases typically consist of 4-8 inches of sand or crushed stone, sometimes directly on native soil. Your reconstructed base should improve drainage and load distribution while maintaining the installation’s visual character. When you plan warehouse deliveries for replacement materials, you need to coordinate timing with excavation progress to minimize storage requirements on constrained historic sites.

Repairing Cobblestone Pathways Techniques

The actual repair work for repairing cobblestone pathways requires you to match historic installation methods while incorporating improvements that extend service life. Your approach to resetting stones should replicate original techniques—typically tight-fitting with minimal joint width and careful attention to surface plane continuity. Modern installations often use wider joints and more rigid setting beds, but these create visual incongruity in historic contexts.

You need to establish reference elevations before resetting stones. String lines or laser levels help you maintain the original surface profile, including intentional crowns or cross-slopes for drainage. Historic pathways often exhibit subtle grade variations that contribute to their character—your restoration should preserve these features rather than creating uniform surfaces.

- When you reset stones, you should position them to replicate wear patterns that create visual continuity with surrounding areas

- Your setting bed depth must accommodate variations in stone thickness while achieving consistent surface elevation

- Edge restraint becomes critical in areas where historic curbing has failed or is absent

- You’ll find that maintaining historic joint widths requires careful stone selection and occasional trimming

Mortar Specification for Historic Work

Your mortar selection for repointing directly affects long-term performance and compatibility with historic stone. Modern Portland cement mortars create bonds stronger than the stone itself, leading to spalling and crack propagation through stones rather than along joints. You should specify lime-based mortars that replicate historic mix proportions and provide sacrificial failure paths that protect the stone.

A typical restoration mortar consists of one part natural hydraulic lime to 2.5-3 parts sand, with aggregate gradation matching the original mortar. You need to adjust water content to achieve workable consistency without excessive fluidity—the mortar should be firm enough to stay in place when tooled but plastic enough to fill joint depths completely. Your mixing procedures affect performance: longer mixing times improve lime dispersion and workability.

The curing requirements for lime mortars differ fundamentally from Portland cement products. You need to maintain moisture for 7-10 days to allow proper carbonation, and you should protect new work from temperature extremes. Rapid drying or freezing during the initial cure period compromises strength development. Your project scheduling must account for these extended cure times when you plan restoration phases.

Biological Growth Control

Maintaining old cobblestone installations requires ongoing attention to biological growth that accelerates deterioration and creates slip hazards. Algae, moss, and lichen establish in joints and on stone surfaces, particularly in shaded areas with poor drainage. Your maintenance program needs to address both immediate growth removal and conditions that promote establishment.

For active growth removal, you should apply biocide formulations specifically designed for masonry applications. Quaternary ammonium compounds provide effective control with minimal stone impact when properly diluted. Application timing matters—you’ll achieve better results when you treat during active growth periods in spring and fall rather than during summer dormancy. After treatment, you need to allow adequate dwell time before washing to ensure biological material is fully killed.

Long-term control requires you to modify conditions that support growth. Improving drainage eliminates standing water that sustains algae and moss. Selective pruning increases sunlight exposure and air circulation. In severely shaded locations where vegetation control proves impractical, you may need to increase cleaning frequency rather than achieve complete elimination. When you specify ongoing maintenance contracts, you should include quarterly inspections and seasonal cleaning to prevent accumulation that requires aggressive intervention.

Replacement Stone Sourcing

When your assessment identifies stones too damaged for retention, you face the challenge of sourcing compatible replacements. Historic cobble installations used locally quarried granite, often from sources no longer in operation. Your replacement strategy must balance historical authenticity with practical availability and cost constraints.

You should prioritize salvaged historic cobbles when available—these provide ideal matches for color, texture, and dimension. Architectural salvage yards and demolition sites occasionally yield suitable material, though quantities rarely suffice for large restoration projects. When you source salvaged material, you need to inspect carefully for hidden damage and verify dimensional consistency.

New granite cobbles offer more predictable supply but require careful selection to match historic character. Color variations between different granite sources become obvious in restoration work where new stones adjoin weathered originals. You’ll achieve better visual integration if you specify stones with similar mineral composition and texture, then accelerate weathering through surface treatments or strategic placement where traffic wear creates faster patination.

Drainage Improvement Strategies

Inadequate drainage ranks among the most common causes of deterioration in historic cobble installations. Water retention in the base accelerates freeze-thaw damage, promotes biological growth, and contributes to settlement through subgrade softening. Your restoration plan should address drainage deficiencies even when they require intervention beyond surface work.

You need to evaluate whether the original drainage concept remains viable or requires modification. Historic installations often relied on surface runoff and base permeability without dedicated subsurface drainage. This approach works in well-drained soils but fails in clay-heavy or compacted conditions. When base excavation reveals poor drainage, you should install perforated pipe at the base perimeter to intercept and remove subsurface water.

- Your drainage improvements must direct water away from the installation rather than concentrating flow in adjacent areas

- Positive surface grades remain critical even with improved subsurface drainage—you should maintain minimum 2% slopes

- Joint permeability decreases significantly when you use mortared joints rather than sand filling

- Edge conditions require special attention where historic installations meet modern impervious surfaces

Protecting During Construction

When restoration work occurs in sections while portions remain in use, you need comprehensive protection measures to prevent damage to retained historic fabric. Construction traffic, material storage, and equipment operation create risks that your site management plan must address. Protection requirements extend beyond the immediate work area to include access routes and staging zones.

You should install physical barriers that prevent vehicle encroachment onto protected areas. Plywood over geotextile fabric provides basic protection for foot traffic and light equipment, while heavier protection systems use steel plates or engineered mats for vehicle loads. Your protection design must distribute loads adequately to prevent point loading that causes stone fracture or subsidence.

Material delivery and staging require careful planning on constrained historic sites. You’ll need to verify that truck access routes can accommodate delivery vehicles without crossing unprotected historic paving. When site constraints prevent direct delivery to work areas, you should establish staging zones on durable surfaces rather than creating temporary access across historic installations. Coordination with your warehouse supplier on delivery timing minimizes on-site storage requirements.

Specifications for Contractors

Your written specifications guide contractor execution and establish quality standards for restoration work. Unlike new construction specs that reference standard details, historic restoration specifications must address material compatibility, technique replication, and protection requirements specific to preservation work. You need to provide sufficient detail to ensure consistent interpretation while allowing for field adjustments as conditions are revealed.

Critical specification elements for maintaining old cobblestone include mortar mix proportions, joint width tolerances, surface plane requirements, and protection standards. You should specify acceptable variation ranges rather than single values—this acknowledges the inherent irregularity in historic work while preventing excessive deviation. Your specs need to define quality standards for cleaning without damage and establish documentation requirements before, during, and after work.

The qualifications section requires particular attention for historic restoration projects. You should require demonstrated experience with similar historic masonry work and references from preservation authorities or certified projects. Contractor experience with modern paving installation doesn’t translate directly to restoration work—the techniques and priorities differ substantially. When you pre-qualify bidders, verify their understanding of preservation principles and their willingness to work within the constraints historic projects impose.

Premium Cobble Setts Across the United States: Citadel Stone’s Restoration Approach

When you consider Citadel Stone’s cobble setts for restoration projects, you’re evaluating materials engineered to match historic specifications while providing enhanced durability. At Citadel Stone, we provide technical guidance for hypothetical restoration applications across diverse climatic and historical contexts. This section outlines how you would approach specification decisions for six historically significant cities where restoring historic cobble setts remains an ongoing priority.

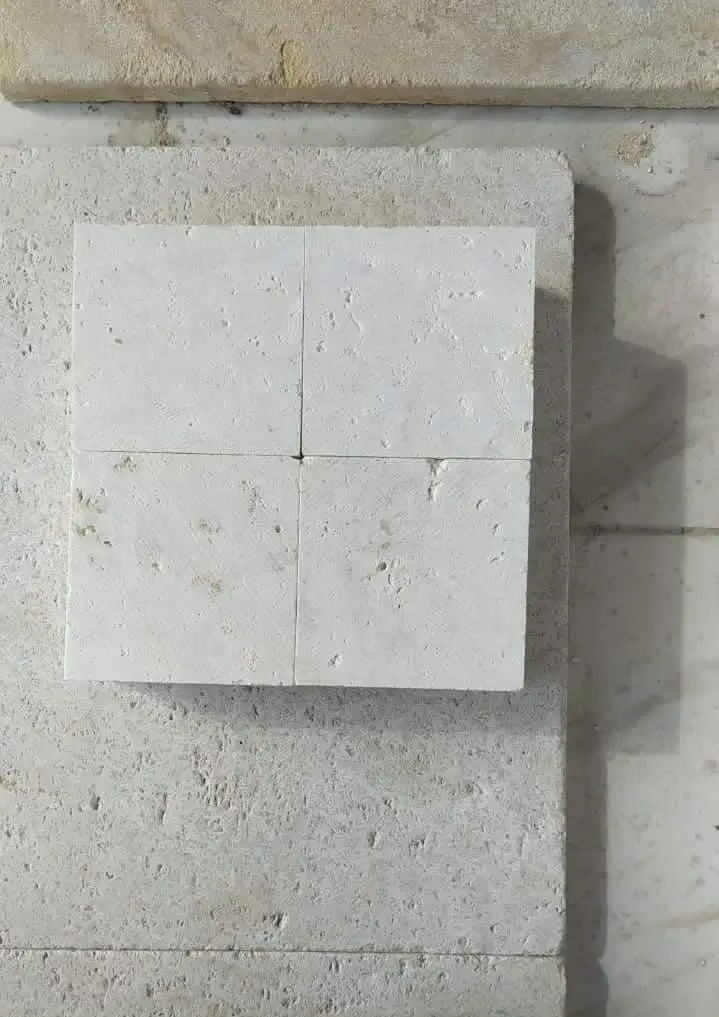

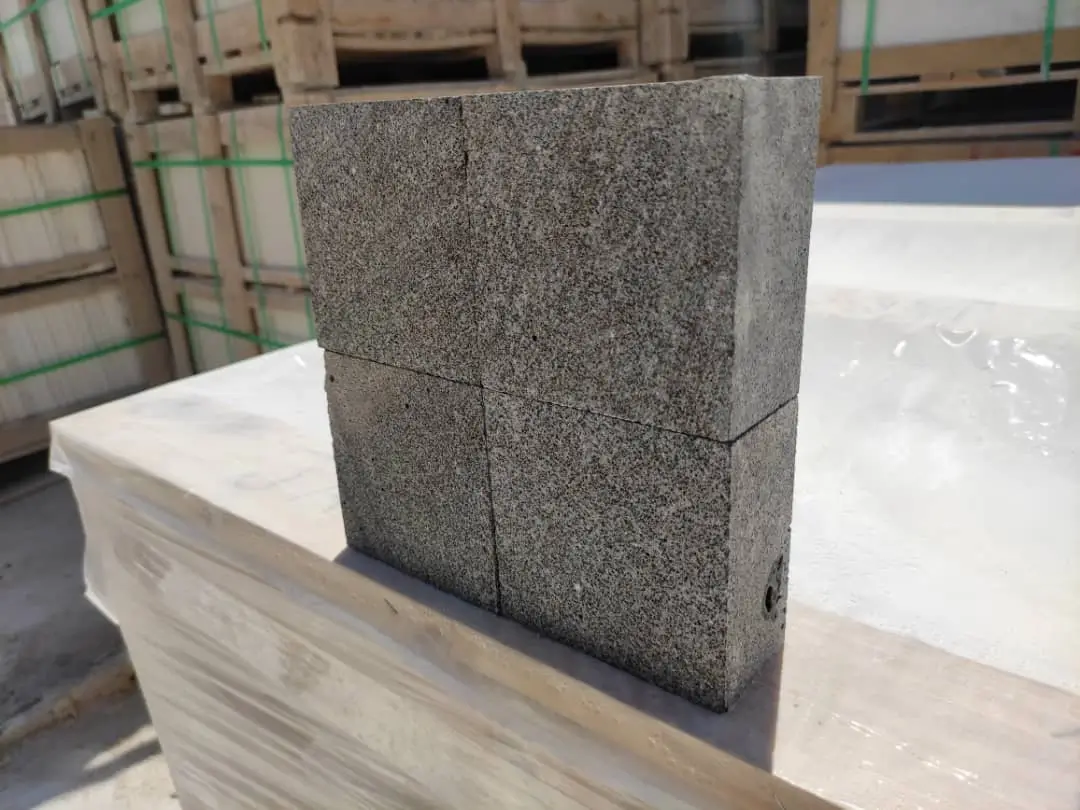

Your material selection for historic restoration projects requires you to balance authenticity with performance. You need to verify that replacement stones match original dimensions, typically ranging from 4x4x4 inches to 5x5x7 inches for most 19th-century installations. Color consistency becomes critical when you’re replacing individual stones within intact sections—your supplier should provide samples that demonstrate color range and allow you to pre-select material that minimizes visual contrast with weathered originals.

New York Considerations

In New York, you would need to address freeze-thaw durability as the primary performance requirement for restoring historic cobble setts in older neighborhoods. Your specification should require granite with absorption rates below 0.4% to ensure adequate resistance to the 30-40 annual freeze-thaw cycles typical in the metro area. You’d want to verify warehouse inventory includes stones with the blue-gray coloration that characterizes historic New York installations. Your restoration approach would need to accommodate the shallow utilities common in older districts—this often requires modified base details that maintain historic surface elevations while improving subsurface drainage.

Massachusetts Requirements

For Massachusetts projects, particularly in Boston’s historic core, you would face stringent review by preservation authorities. Your material specification for restoring historic cobble setts would need to match the distinctive pink-tinged granite from historic Quincy quarries. You should plan for extended approval timelines when working within designated historic districts—this affects your construction scheduling and material procurement windows. The region’s severe winter conditions require you to specify stones with proven freeze-thaw resistance and detail joints that accommodate snow removal equipment without damage. Salt exposure from winter maintenance operations necessitates lower absorption granite grades.

Pennsylvania Restoration

Your Pennsylvania restoration projects, especially in Philadelphia’s Society Hill and Old City districts, would require you to match the distinctive Belgian block proportions common in 18th and 19th-century installations. You’d need to source cobble setts in the larger 5x8x8-inch format rather than standard cube dimensions. When you plan delivery logistics, the narrow streets and limited truck access in historic neighborhoods require coordination with city officials for temporary parking and crane access. Your mortar specification would follow traditional lime-based formulations that match existing joints—Pennsylvania projects typically maintain stricter adherence to historic materials than jurisdictions allowing modern alternatives.

South Carolina Climate Factors

In South Carolina’s coastal historic districts, particularly Charleston, your primary challenge involves addressing salt exposure and biological growth when cleaning granite setts and maintaining the installation. You would specify granite with fine-grain structure and low porosity to minimize salt absorption and subsequent subflorescence damage. The subtropical climate promotes rapid biological growth—your maintenance program would require quarterly cleaning rather than the annual or biennial cycles sufficient in northern climates. When you evaluate repointing requirements, the historic lime mortars in Charleston installations often perform better than modern alternatives because they allow salt migration without causing stone spalling. Your restoration approach should prioritize retention of original mortar where functionally adequate.

Virginia Historic Districts

For Virginia restoration work in Alexandria’s Old Town or Richmond’s historic districts, you would coordinate closely with local historic review boards that maintain detailed design guidelines for streetscape work. Your specification for restoring historic cobble setts needs to address the red and gray granite palette common in Virginia installations—many historic streets combine both colors in patterns that require documentation and replication. You’d plan for moderate freeze-thaw exposure, less severe than northeastern locations but sufficient to require minimum 8,000 PSI compressive strength. The region’s clay-heavy soils create base stability challenges that you must address through improved drainage and potential soil stabilization.

Maryland Waterfront Projects

Your Maryland projects in Baltimore’s Fell’s Point or Federal Hill would encounter the dual challenges of freeze-thaw cycling and proximity to tidal waters. When you specify materials for these environments, you need granite with both low absorption and resistance to salt crystallization. The historic cobble installations in waterfront districts often exhibit accelerated deterioration from combined freeze-thaw and salt exposure—your restoration approach should include enhanced drainage details and potentially protective treatments on exposed stone surfaces. You’d need to account for limited staging areas and strict environmental controls when working near the harbor—material deliveries require precise scheduling to minimize site storage, and all wash water from cleaning granite setts requires containment and proper disposal to prevent harbor contamination.

Long-Term Maintenance Planning

After you complete restoration work on historic pavement preservation, your responsibility extends to establishing maintenance programs that preserve your investment. Historic cobble installations require ongoing attention that differs from modern paving maintenance. You need to develop protocols addressing cleaning, joint maintenance, stone repair, and drainage verification on defined schedules.

Your maintenance specifications should establish inspection frequencies based on traffic intensity and environmental exposure. High-traffic commercial areas require quarterly inspections, while residential installations may need only annual reviews. You should document conditions systematically through photography and written notes—this creates baselines for detecting deterioration trends before they require major intervention. For detailed cost planning and budgeting considerations, review Material and labor expenses for granite cobblestone paver installation before you finalize long-term maintenance contracts and capital improvement planning. Citadel Stone ships high-strength cobble setts and Belgian block pavers nationwide. The durable choice for US driveways and streetscapes.