When you’re sourcing a white limestone supplier Arizona for commercial or residential projects, you need to understand how light-colored stone performs in extreme desert climates. White and pale limestone varieties offer thermal advantages that darker materials can’t match, but they also present specific challenges you’ll encounter during specification and installation. Your selection process should account for regional heat loads, UV exposure intensity, and the interaction between stone porosity and monsoon precipitation patterns.

Light limestone color dealer networks in Arizona handle materials with vastly different performance characteristics. You’ll find that not all pale stone responds identically to 115°F surface temperatures or rapid thermal cycling. Some white limestone varieties develop micro-cracking after 8-10 years of direct solar exposure, while others maintain structural integrity for 25+ years under identical conditions. Your success depends on understanding these distinctions before you commit to material specifications.

Thermal Performance Characteristics of Light Stone Colors

White limestone supplier Arizona professionals know that reflectance values determine surface temperature behavior. Light-colored limestone typically reflects 60-70% of solar radiation, compared to 15-25% for dark gray or charcoal materials. This translates to surface temperatures that run 35-45°F cooler during peak afternoon hours. When you specify white limestone dealer near me Phoenix for pool decks or outdoor entertainment areas, you’re addressing a legitimate safety concern — dark pavers can reach 160-175°F, while pale limestone typically peaks at 115-125°F under identical exposure.

The thermal mass characteristics matter just as much as reflectance. You need to understand that limestone’s density (typically 140-165 lbs/ft³) creates a 3-4 hour lag between peak air temperature and peak surface temperature. This delay affects your installation scheduling and determines optimal application windows. For contractor logistics, verify warehouse stock availability before you lock in installation dates, since lead times from distribution facilities can extend 2-3 weeks during peak construction season.

- You should specify reflectance values between 0.60-0.70 for pedestrian comfort in direct sun exposure

- Your thermal expansion calculations must account for coefficients of 5.3 × 10⁻⁶ per °F in Arizona installations

- Light color limestone dealer specifications need to address color consistency across production batches

- Surface temperature differentials create expansion stresses that require you to adjust joint spacing by 15-20% compared to moderate climates

Porosity and Moisture Management in Desert Applications

Pale limestone supplier Arizona projects require you to balance competing porosity requirements. The material’s interconnected pore structure (typically 3-8% by volume) affects three critical performance factors: freeze-thaw resistance in high-elevation applications, staining susceptibility from organic debris, and efflorescence potential from subsurface salts. When you specify for Flagstaff or Sedona installations at 5,000+ feet elevation, you’ll encounter freeze-thaw cycles that demand different porosity ranges than Phoenix valley projects.

Your specification should address how porosity interacts with Arizona’s monsoon season. July through September brings intense precipitation that can deposit 2-3 inches in a single event. Light-colored limestone with porosity above 6% absorbs water rapidly, which creates two scenarios you need to manage. First, the material becomes temporarily darker (affecting aesthetic consistency during drying). Second, if subsurface drainage is inadequate, you’ll see efflorescence appear 6-18 months post-installation as dissolved salts migrate through the stone and crystallize at the surface.

The relationship between porosity and sealing protocols determines long-term maintenance requirements. You should understand that penetrating sealers reduce effective porosity by 40-60%, which alters water absorption rates and changes how the material responds to cleaning protocols. For more detailed guidance on material selection criteria, see Citadel Stone’s limestone inspection process for verification methods. Professional installations typically apply sealer within 30 days of installation, before organic staining occurs.

Structural Specifications and Load-Bearing Standards

When you evaluate a white limestone supplier Arizona for structural applications, compressive strength becomes your primary specification criterion. Industry standards require minimum 8,000 PSI for pedestrian applications and 12,000+ PSI for vehicular loading. You’ll find that white and pale limestone varieties typically test between 9,500-14,000 PSI, but batch variation can introduce ±15% range even within the same quarry source.

The flexural strength matters more than most specifiers realize. Your material needs to resist bending stresses from substrate settlement, which occurs inevitably in Arizona’s expansive clay soils. Flexural strength values of 1,200-1,800 PSI indicate material that can span minor voids without cracking. When you coordinate with a light limestone color dealer about structural performance, request test data from the specific production run, not generic quarry averages.

- You need to verify compressive strength meets ASTM C170 requirements for your load application

- Flexural strength testing per ASTM C880 reveals how the material handles substrate movement

- Your specifications should require absorption testing per ASTM C97 to validate porosity claims

- Abrasion resistance per ASTM C241 determines suitability for high-traffic commercial applications

Color Consistency and Batch Variation Management

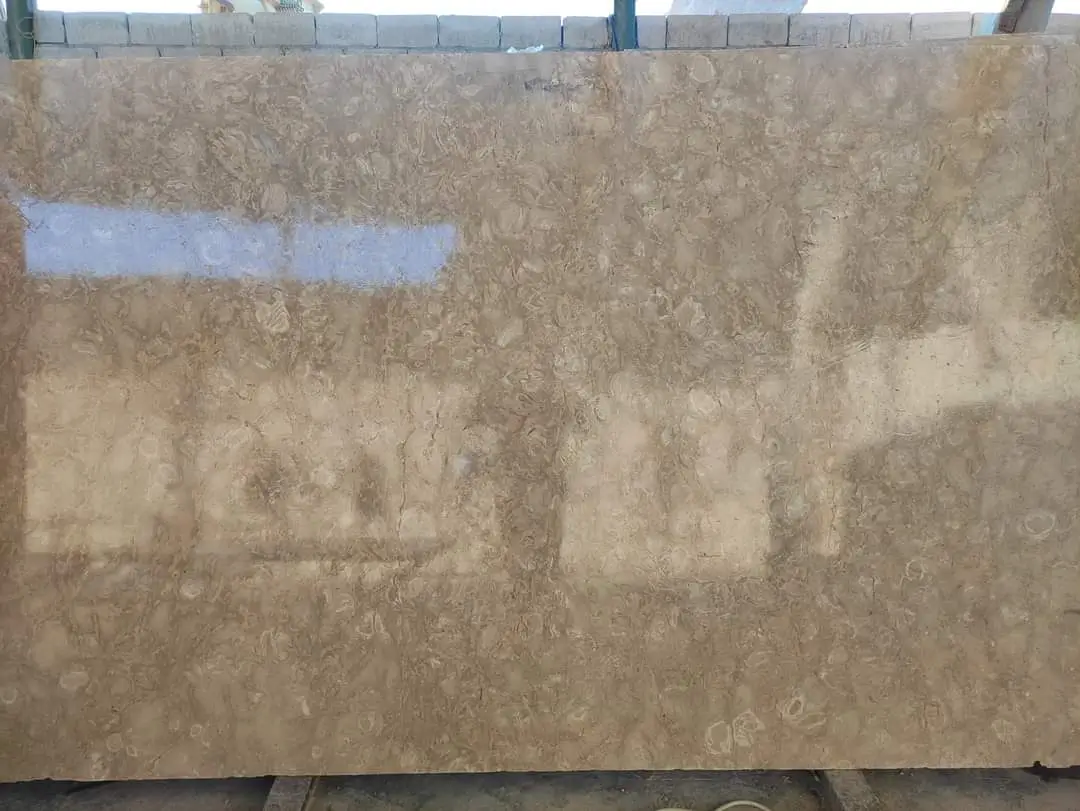

White limestone dealer near me Phoenix searches reveal a common frustration — color consistency across production batches. Natural limestone formation creates inherent variation in mineral content, which affects the final color tone. You’ll encounter “white” limestone that ranges from pure chalk tones to cream, beige, and warm ivory. When you specify pale limestone for multi-phase projects, your biggest challenge is matching later phases to initial installations completed 6-18 months earlier.

The solution requires you to approach procurement strategically. For projects exceeding 5,000 square feet, you should negotiate single-batch sourcing to minimize variation. This means the light color limestone dealer pulls all material from the same quarry production run, which ensures consistent mineral composition and color tone. The trade-off is lead time — single-batch orders typically require 4-6 weeks from material selection to delivery, compared to 10-14 days for mixed inventory.

Your specification documents should include color tolerance parameters. Professional specs define acceptable variation using Munsell color system notation or require physical sample approval before bulk production. You’ll want to establish that color matching applies to dry stone appearance, not wet conditions, since all limestone darkens temporarily when saturated. Plan for truck deliveries that accommodate your installation pace, since material stored on-site for extended periods can develop surface soiling that affects color perception.

Installation Considerations for Pale Stone Materials

Your installation success with a pale limestone supplier Arizona depends on base preparation that accounts for regional soil conditions. Arizona soils vary dramatically — Phoenix valley areas contain expansive clays with swell potential exceeding 6%, while Tucson basin soils are more stable decomposed granite mixtures. You need to design base systems that isolate the limestone from soil movement, which typically requires 6-8 inches of compacted aggregate over geotextile fabric.

The joint spacing becomes critical for light-colored materials because visual irregularities are more apparent than with darker stone. You should maintain consistent 3/16-inch joints throughout the installation — variance beyond ±1/32 inch creates visual lines that become obvious as joint sand settles over 12-18 months. White limestone supplier Arizona installations require you to specify joint sand that matches the stone color tone, since contrasting sand creates a grid pattern that dominates the visual appearance.

- You’ll need base compaction of 95% modified Proctor density to prevent differential settlement

- Your edge restraint system must resist lateral movement during thermal expansion cycles

- Joint sand specifications should require polymeric products for applications with irrigation exposure

- Slope requirements of 1-2% prevent water pooling that causes temporary color darkening

Sealing and Surface Treatment Protocols

When you source from a light limestone color dealer, surface treatment decisions affect long-term appearance and maintenance requirements. Penetrating sealers reduce staining susceptibility without altering surface texture or creating film buildup. You should specify water-based penetrating sealers for Arizona applications, since solvent-based products can trap subsurface moisture that leads to spalling in areas with seasonal precipitation.

The sealing schedule depends on exposure conditions and traffic intensity. Your residential installations typically require resealing every 3-5 years, while commercial applications with heavy foot traffic need 2-3 year intervals. The application timing matters — you’ll achieve best penetration when you seal during moderate temperatures (65-85°F), avoiding summer heat that causes premature surface curing. Early morning application, before the stone heats up, gives the sealer maximum penetration time before solvent evaporation accelerates.

Surface finish selection interacts with sealing performance. Honed finishes (smooth but not polished) accept sealer most effectively and provide DCOF slip resistance values of 0.48-0.56. Tumbled or brushed finishes create texture that enhances slip resistance (0.54-0.62 DCOF) but also increases surface area for staining. When you specify white limestone dealer near me Phoenix materials for pool decks, the tumbled finish with aggressive sealing provides the best balance of safety and stain resistance.

Staining Resistance and Maintenance Requirements

Pale limestone supplier Arizona projects face higher staining visibility than darker materials. Organic debris (leaves, berries, pollen), iron oxide from irrigation water, and tannins from adjacent landscaping all create discoloration that’s immediately apparent on white or cream stone. Your maintenance program needs to address staining proactively, not reactively, because many stains become permanent after 30-60 days of exposure.

The most common staining sources in Arizona landscapes are iron-rich irrigation water and decomposing organic matter. You’ll see rust-colored staining develop around sprinkler heads where water evaporates and concentrates dissolved iron. Prevention requires you to specify irrigation systems that minimize overspray onto paved surfaces, or accept that periodic cleaning will be necessary. Poultice treatments can remove iron staining, but repeated applications degrade sealer effectiveness.

- You should recommend pressure washing at 1,200-1,500 PSI annually to remove surface accumulation

- pH-neutral cleaners preserve sealer integrity better than acidic or alkaline products

- Your maintenance specifications need to address leaf and debris removal within 48 hours

- Resealing after deep cleaning restores stain resistance and enhances color uniformity

Cost Factors and Budget Planning

When you evaluate a white limestone supplier Arizona for project budgeting, material cost represents only 40-50% of total installed expense. You need to account for freight, which varies significantly based on quarry distance from the project site. Arizona lacks major limestone quarries, so most material originates from Texas, Oklahoma, or Mexico, adding $0.45-0.85 per square foot in transportation costs.

The installation labor represents 35-40% of total cost, and pale limestone doesn’t necessarily cost more to install than darker materials. However, your installer needs to exercise greater care with joint spacing consistency and surface cleanliness during installation, which can extend installation time by 10-15% compared to more forgiving darker stone. Light color limestone dealer pricing should include realistic labor estimates based on the precision requirements for maintaining visual consistency.

Your budget should account for initial sealing and expect ongoing maintenance costs. Professional sealing runs $0.30-0.50 per square foot initially, with resealing at $0.25-0.35 per square foot every 3-5 years. For commercial projects where appearance drives property value, you’ll want to budget annual maintenance at $0.15-0.25 per square foot for pressure washing and touch-up cleaning.

Climate-Specific Performance Factors in Arizona

Arizona’s climate zones create distinct performance requirements that affect how you specify from a pale limestone supplier Arizona. Valley regions (Phoenix, Tucson, Yuma) experience extreme heat with minimal freeze-thaw cycling, while high country areas (Flagstaff, Sedona) see significant winter freeze-thaw events that test material durability differently. You can’t use identical specifications across these zones and expect comparable performance.

The UV intensity in Arizona ranks among the highest in North America, with annual UV index readings regularly exceeding 11 during summer months. This intense radiation degrades organic sealers over time, reducing their effective service life by 20-30% compared to temperate climates. When you specify sealing protocols, you need to account for accelerated degradation and plan for more frequent reapplication than manufacturer literature suggests for moderate climates.

Monsoon season precipitation creates unique challenges that you won’t encounter in more temperate regions. The combination of bone-dry conditions for 9-10 months, followed by intense localized rainfall, causes rapid moisture cycling that stresses any porous material. Your drainage design needs to evacuate water quickly from the surface and prevent subsurface saturation that can mobilize salts through the stone. Warehouse logistics become important during monsoon season, as outdoor material storage can result in pre-saturated stone that extends installation timelines.

Citadel Stone: Premium Limestone Suppliers Guidance for Arizona Projects

When you evaluate Citadel Stone’s Limestone suppliers for your Arizona project, you’re considering premium materials engineered for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, helping you understand how material specifications should adapt to local conditions. This section outlines how you would approach specification decisions for six representative cities, addressing the climate factors and performance requirements specific to each location.

Phoenix Valley Applications

In Phoenix, you’ll encounter the most extreme heat conditions in Arizona, with summer surface temperatures regularly exceeding 160°F on dark materials. Your white limestone specification needs to prioritize solar reflectance above 65% to maintain pedestrian comfort in outdoor spaces. The valley’s expansive clay soils require you to design base systems with 8-10 inches of compacted aggregate to isolate the stone from seasonal soil movement. You should account for minimal freeze-thaw cycling (fewer than 5 events annually), which allows you to specify materials with slightly higher porosity (6-8%) than high-elevation applications. Urban heat island effects in developed areas amplify thermal stress, so your expansion joint spacing should decrease to every 12 feet in areas with limited shade canopy.

Tucson Basin Considerations

Tucson’s elevation (2,400 feet) moderates temperature extremes slightly compared to Phoenix, but you’ll still need white limestone supplier Arizona materials with excellent thermal performance. The basin’s decomposed granite soils offer better stability than Phoenix clays, allowing you to reduce base depth to 6-8 inches while maintaining performance. Your specification should address the higher precipitation Tucson receives (12 inches annually versus Phoenix’s 8 inches), which increases moisture cycling stress on porous materials. You would recommend sealing within 21 days of installation to prevent staining from the area’s denser vegetation and higher organic debris load. Winter freezing occurs 10-15 nights per year, requiring you to verify freeze-thaw durability if the application includes water features or irrigation exposure.

Scottsdale Luxury Projects

When you specify light color limestone dealer materials for Scottsdale’s high-end residential market, aesthetic consistency becomes paramount. Your specification would require single-batch sourcing to ensure color uniformity across multi-phase luxury developments. The city’s design review standards often mandate specific color palettes, so you need to provide physical samples demonstrating dry and wet appearance before approval. Scottsdale shares Phoenix’s climate challenges but typically involves more sophisticated landscape irrigation systems, increasing staining risk from iron-rich water. You should specify irrigation designs that eliminate overspray onto paved surfaces and recommend quarterly maintenance to preserve the pristine appearance luxury clients expect. Your material selection would emphasize the whitest available limestone varieties to maximize contrast with desert landscaping.

Flagstaff High-Elevation Specs

Flagstaff’s 7,000-foot elevation creates completely different performance requirements than valley locations. You’ll need to specify pale limestone supplier Arizona materials with proven freeze-thaw resistance, as the area experiences 120-150 freeze-thaw cycles annually. Your porosity specifications must decrease to 3-5% maximum to prevent water absorption that leads to spalling during freeze events. The cooler climate reduces thermal stress, allowing you to increase expansion joint spacing to every 18-20 feet. You would recommend honed finishes rather than polished surfaces, since freeze-thaw cycling degrades smooth finishes more rapidly than textured ones. Winter snow cover means you need to specify materials resistant to deicing salts, though Flagstaff uses less aggressive chemicals than northern states.

Sedona Aesthetic Integration

In Sedona, your white limestone dealer near me Phoenix specifications need to balance performance with aesthetic integration into the area’s iconic red rock landscape. Many projects deliberately choose pale limestone to create visual contrast with surrounding geology, but you should ensure the color tone complements rather than clashes with native stone. At 4,500 feet elevation, Sedona experiences moderate freeze-thaw cycling (40-60 events annually), requiring you to specify materials with 4-6% porosity and verified ASTM C666 freeze-thaw resistance. The area’s tourism economy means commercial applications receive heavy pedestrian traffic, so you would prioritize abrasion resistance and slip resistance specifications. Your maintenance protocols should address red dust accumulation, which is visually prominent on pale stone and requires more frequent cleaning than valley locations.

Yuma Extreme Heat

Yuma represents Arizona’s most extreme heat environment, with summer temperatures consistently exceeding Phoenix valley readings. Your specification would prioritize maximum solar reflectance (68-70%) and favor the palest limestone varieties available. The area’s agricultural activity means you’ll encounter higher dust loads that accumulate on horizontal surfaces, requiring you to recommend quarterly pressure washing to maintain appearance. Yuma’s minimal precipitation (3 inches annually) reduces moisture cycling stress but creates challenges with dust control during installation. You should coordinate truck deliveries to avoid late spring and summer months when heat makes midday installation impractical. The stable sandy soils allow you to reduce base depth specifications compared to clay-heavy regions, but wind erosion of joint sand becomes a maintenance consideration you need to address.

Quality Verification and Testing Protocols

Before you commit to a white limestone supplier Arizona for large-scale projects, your specification process should include material testing that verifies performance claims. Standard laboratory testing provides baseline data, but you need to understand that field conditions introduce variables that affect real-world performance. Your testing protocol should sample materials from the specific production batch designated for your project, not rely on generic quarry data that may represent best-case scenarios.

The essential tests for Arizona applications include compressive strength (ASTM C170), absorption and density (ASTM C97), abrasion resistance (ASTM C241), and slip resistance (ASTM C1028 or equivalent DCOF testing). For high-elevation projects, you need freeze-thaw testing per ASTM C666, which subjects samples to 300 freeze-thaw cycles and measures degradation. You should specify that testing occurs at independent laboratories, not facilities affiliated with the quarry or supplier, to ensure unbiased results.

- You’ll want compressive strength results exceeding 9,000 PSI for pedestrian applications

- Absorption values should remain below 3% by weight for freeze-thaw climates, below 5% for valley locations

- Your abrasion resistance specifications need Ha values below 12 for commercial traffic areas

- Static coefficient of friction should exceed 0.50 for pool decks and wet-exposure applications

Long-Term Performance and Service Life

When you specify materials from a light limestone color dealer, you need realistic expectations about long-term performance and appearance evolution. White and pale limestone naturally develops a patina over 10-15 years as surface minerals weather and microscopic organic growth occurs in pore spaces. This aging process slightly darkens the stone and reduces the stark brightness of new installations. You should inform clients that this evolution is normal and doesn’t indicate material failure.

The service life you can expect from properly specified and installed pale limestone in Arizona conditions typically ranges from 25-40 years before replacement becomes necessary. Factors that accelerate degradation include inadequate sealing, poor drainage design, and deferred maintenance that allows staining to become permanent. Your installation quality directly affects longevity — poor base preparation causes differential settlement that leads to cracking and premature failure regardless of material quality.

You’ll find that commercial applications with heavy traffic show wear patterns after 15-20 years, particularly in high-friction areas near entries and transitions. Residential installations with moderate use maintain appearance longer, often exceeding 30 years before refinishing becomes desirable. Your maintenance program significantly extends service life — installations with biennial resealing and annual cleaning consistently outperform neglected installations by 40-50% in longevity. For additional guidance on procurement strategies, review Sourcing quality limestone materials for Arizona residential construction projects before you finalize your project specifications. Citadel Stone is one of the reliable limestone suppliers near you in Arizona for multi-site developer rollouts.