When you specify wall stone suppliers Arizona types for your project, you’re making decisions that will affect structural performance, aesthetic longevity, and installation complexity for decades. The state’s extreme temperature swings—from 115°F summer peaks in Phoenix to freezing mountain conditions in Flagstaff—create unique material demands that generic stone selections simply can’t meet. You need to understand how thermal expansion, porosity characteristics, and surface texture interact with Arizona’s climate zones before you commit to specifications.

Your choice between dry-stacked, mortared, or retaining wall configurations determines not just construction methodology but also material selection criteria. Dry-stack applications require you to specify stone with dimensional consistency within ±1/8 inch, while mortared installations allow greater tolerance but introduce concerns about mortar-stone thermal compatibility. When you evaluate wall stone suppliers Arizona types, you’ll find that limestone, sandstone, and select granites dominate professional specifications—each offering distinct trade-offs in workability, thermal performance, and long-term durability.

Material Categories for Wall Applications

Stone wall suppliers Arizona materials fall into three primary performance categories that you should evaluate based on your specific application requirements. Sedimentary stones like limestone and sandstone offer superior workability and thermal mass properties, making them ideal when you need consistent dimensional cutting for precision installations. Metamorphic options provide enhanced density and lower porosity, which becomes critical when you’re designing walls that will face direct water exposure or freeze-thaw cycling in higher elevations.

Igneous stones deliver maximum compressive strength—typically 15,000-20,000 PSI compared to 8,000-12,000 PSI for sedimentary options—but you’ll encounter significantly higher fabrication costs and increased installation complexity. The hardness that provides structural advantages also makes field modifications challenging, requiring specialized cutting equipment that adds labor time. When you specify wall stone suppliers Arizona types, you need to balance these performance characteristics against project budgets and installation timelines.

- You should verify compressive strength exceeds 8,000 PSI minimum for structural wall applications

- Porosity ratings between 3-7% provide optimal drainage without compromising freeze-thaw durability

- Your specifications must address thermal expansion coefficients, particularly for mortared installations where stone-mortar compatibility prevents cracking

- Surface texture directly affects mortar bond strength, with rougher finishes providing 25-35% better adhesion in mortared applications

Dry Stack Wall Material Specifications

Dry-stack construction places the most demanding dimensional requirements on wall stone suppliers Arizona types because you’re relying entirely on friction and gravity for structural stability. You need stone cut with tolerance precision of ±1/8 inch across all dimensions, with particular attention to bed surface flatness. Variations beyond this threshold create rocking potential that compromises wall integrity within 3-5 years as settlement occurs and joints shift under thermal cycling.

When you select materials for dry-stack applications, rectangular or square profiles provide the most reliable construction outcomes. The stone’s natural cleavage planes should align with bed surfaces to maximize load distribution—a characteristic you’ll find most consistently in quarried limestone and select sandstones. Your specifications should address corner stone requirements separately, as these elements require either additional dimensioning or specialized cutting to maintain pattern integrity and structural interlock.

Wall Stones Garden Stones wall types perform differently in dry-stack configurations based on their weight-to-surface area ratios. Limestone blocks weighing 40-60 pounds per cubic foot provide sufficient mass for walls up to 36 inches height without additional reinforcement. When you design taller structures, you need to increase individual stone mass or incorporate engineered setback specifications—typically 1 inch of setback per 12 inches of height above 36 inches. This setback creates a gravity-biased lean that counteracts overturning forces while maintaining aesthetic appeal.

- You must specify minimum stone depth of 12 inches for dry-stack walls exceeding 24 inches in height

- Stone faces should exhibit minimal bow or warp—no more than 1/16 inch deviation across the largest dimension

- Your material selection should prioritize stones with natural rough surfaces on bed planes to maximize friction coefficients

- Base course stones require 20-30% greater mass than upper courses to establish foundation stability

Mortared Wall Stone Selection Criteria

Mortared installations allow you greater flexibility in dimensional tolerances but introduce critical compatibility requirements between stone porosity and mortar composition. When you specify wall stone suppliers Arizona types for mortared applications, you need to match stone absorption rates with mortar water retention characteristics. Stones with porosity below 2% create poor mechanical bonds because insufficient water transfer occurs during mortar curing, resulting in adhesion failures that manifest 18-36 months post-installation.

The thermal expansion differential between stone and mortar creates stress concentrations that you must account for through joint spacing and mortar mix design. Arizona’s daily temperature swings—often 40-50°F between night and day—cause expansion-contraction cycles that test mortar-stone interfaces continuously. You should specify Type N or Type S mortars for most applications, with Type S providing superior bond strength for high-exposure walls where wind loading and thermal stress combine.

Garden wall stone suppliers construction methods for mortared assemblies require you to consider stone surface preparation specifications. Dusty or highly porous stone faces need wetting before mortar application to prevent rapid moisture extraction that weakens the bond. You’ll achieve optimal results when stone moisture content reaches 5-8% at the time of mortar placement—sufficient to slow water migration without creating slip conditions that compromise alignment. For guidance on complementary hardscape elements, review Citadel Stone’s wall stone facility for integrated design considerations.

- You need to verify stone absorption rates fall between 2-6% for optimal mortar bonding

- Joint depth should equal 80-100% of mortar joint width to ensure adequate mechanical interlock

- Your specifications must require tooled joints that compact mortar against stone surfaces, eliminating voids

- Expansion joints become necessary every 20-25 feet in mortared walls to accommodate thermal movement

Retaining Wall Structural Requirements

Retaining wall applications demand the most rigorous material specifications among all wall stone suppliers Arizona types because you’re designing for continuous lateral soil pressure in addition to vertical loading. You need stone with minimum compressive strength of 10,000 PSI and demonstrated durability under sustained moisture exposure from retained soil drainage. The base course requires stones with minimum 18-inch depth and individual weights exceeding 80 pounds to establish adequate bearing capacity on prepared aggregate foundations.

When you calculate retaining wall dimensions, the stone’s unit weight directly affects required wall thickness and setback angle. Limestone at 145-160 pounds per cubic foot provides sufficient mass for walls up to 48 inches height with proper batter—typically 2 inches of setback per 12 inches of vertical rise. You’ll need to increase these specifications for walls exceeding 48 inches or when designing for soil conditions that generate higher-than-typical lateral pressures, such as expansive clays common in Central Arizona valleys.

Wall building stone Arizona specifications for retaining structures must address drainage integration because hydrostatic pressure behind the wall creates the most common failure mode. You should incorporate weep holes at 8-foot horizontal spacing in the lowest course, with aggregate drain fields behind the wall directing water to these exit points. Stone porosity alone cannot manage water volumes in most retained soil conditions—you need engineered drainage that works in conjunction with the stone’s natural permeability.

- You must specify minimum stone depth of 18 inches for the base course of retaining walls

- Vertical height limitations of 48 inches apply to unreinforced stone retaining walls under most building codes

- Your drainage specifications should include 12-inch minimum aggregate backfill behind the entire wall height

- Geotextile fabric placement between native soil and aggregate prevents soil migration into drainage zones

- Stone selection should prioritize materials with demonstrated freeze-thaw durability when designing for elevations above 5,000 feet

Thermal Performance in Arizona Climates

Arizona’s extreme temperature variations create thermal stress conditions that affect wall stone suppliers Arizona types differently based on their mineral composition and porosity characteristics. When you specify materials for full sun exposure—which occurs across 80% of typical Arizona sites—you need to understand that surface temperatures can reach 150-170°F on dark-colored stones during summer afternoons. This thermal loading creates expansion forces that translate into joint stress, mortar cracking, and potential stone fracturing when materials lack sufficient thermal mass or contain moisture-sensitive mineral components.

Limestone demonstrates superior thermal performance in Arizona applications because its calcium carbonate composition exhibits moderate thermal expansion coefficients around 5.3 × 10⁻⁶ per °F. You’ll observe more stable dimensional behavior compared to granites, which can show expansion coefficients 30-40% higher depending on quartz content. The practical implication for your specifications: limestone walls require expansion joints at 25-foot intervals, while granite installations need joints every 18-20 feet to prevent stress accumulation.

Light-colored stones reflect 55-70% of incident solar radiation, maintaining surface temperatures 20-30°F cooler than dark materials under identical exposure conditions. When you design walls adjacent to outdoor living spaces or within 10 feet of structures, this temperature differential directly affects comfort and can influence building cooling loads. Your material selection should account for these thermal characteristics, particularly in urban heat island environments like Phoenix and Tucson where ambient temperatures already stress building systems.

Installation Methodology and Material Selection

Your chosen installation method fundamentally determines which wall stone suppliers Arizona types will perform optimally in your specific application. Dry-stack construction requires you to prioritize dimensional consistency and surface flatness, accepting higher material costs in exchange for reduced labor complexity. Mortared installations allow greater dimensional variation but transfer cost from material precision to skilled mason labor and increased timeline requirements for proper curing sequences.

Stone wall suppliers Arizona materials arrive at job sites with varying degrees of finish work already completed. Rough-cut stones require field trimming and fitting, which increases installation time by 40-60% compared to dimensioned products but reduces material costs by 25-35%. You need to evaluate whether your project timeline and available labor skills favor material investment or field fabrication. For commercial projects with compressed schedules, pre-dimensioned stone from suppliers with warehouse inventory typically provides the most predictable outcomes.

- You should verify that your installation crew has experience with your selected stone type before material procurement

- Field cutting requirements increase when you specify natural cleft or split-face stones for applications requiring tight tolerances

- Your project schedule must account for 7-14 day mortar curing periods in mortared installations before applying loads

- Delivery coordination becomes critical when warehouse stock levels fluctuate seasonally—verify availability 4-6 weeks before scheduled installation

Porosity and Water Management Characteristics

When you evaluate wall stone suppliers Arizona types, porosity measurements reveal critical performance characteristics that extend beyond simple water absorption. Stone with porosity between 3-7% provides optimal balance for Arizona applications—sufficient permeability to prevent hydrostatic pressure buildup behind walls while maintaining structural integrity under freeze-thaw cycling at higher elevations. You’ll encounter problems at both extremes: stones below 2% porosity can trap water behind impermeable faces, while materials exceeding 10% porosity may show accelerated weathering in areas with seasonal precipitation.

The interconnected pore structure matters as much as total porosity when you specify materials for specific applications. Limestone typically exhibits well-connected pore networks that allow water transmission without retention, making it ideal for retaining walls where drainage performance determines longevity. Sandstones vary considerably—you need to verify that your selected material shows consistent drainage characteristics rather than isolated void spaces that retain moisture and create freeze-thaw vulnerability.

Wall Stones Garden Stones wall types respond differently to Arizona’s monsoon precipitation patterns based on their porosity profiles. You should anticipate that walls will experience 2-4 hours of saturation during intense summer storms, with drainage rates determining how quickly the structure returns to equilibrium moisture content. Proper base drainage design remains essential regardless of stone porosity—you can’t rely on material permeability alone to manage water volumes from retained soils or adjacent grade conditions.

Surface Texture and Long-Term Performance

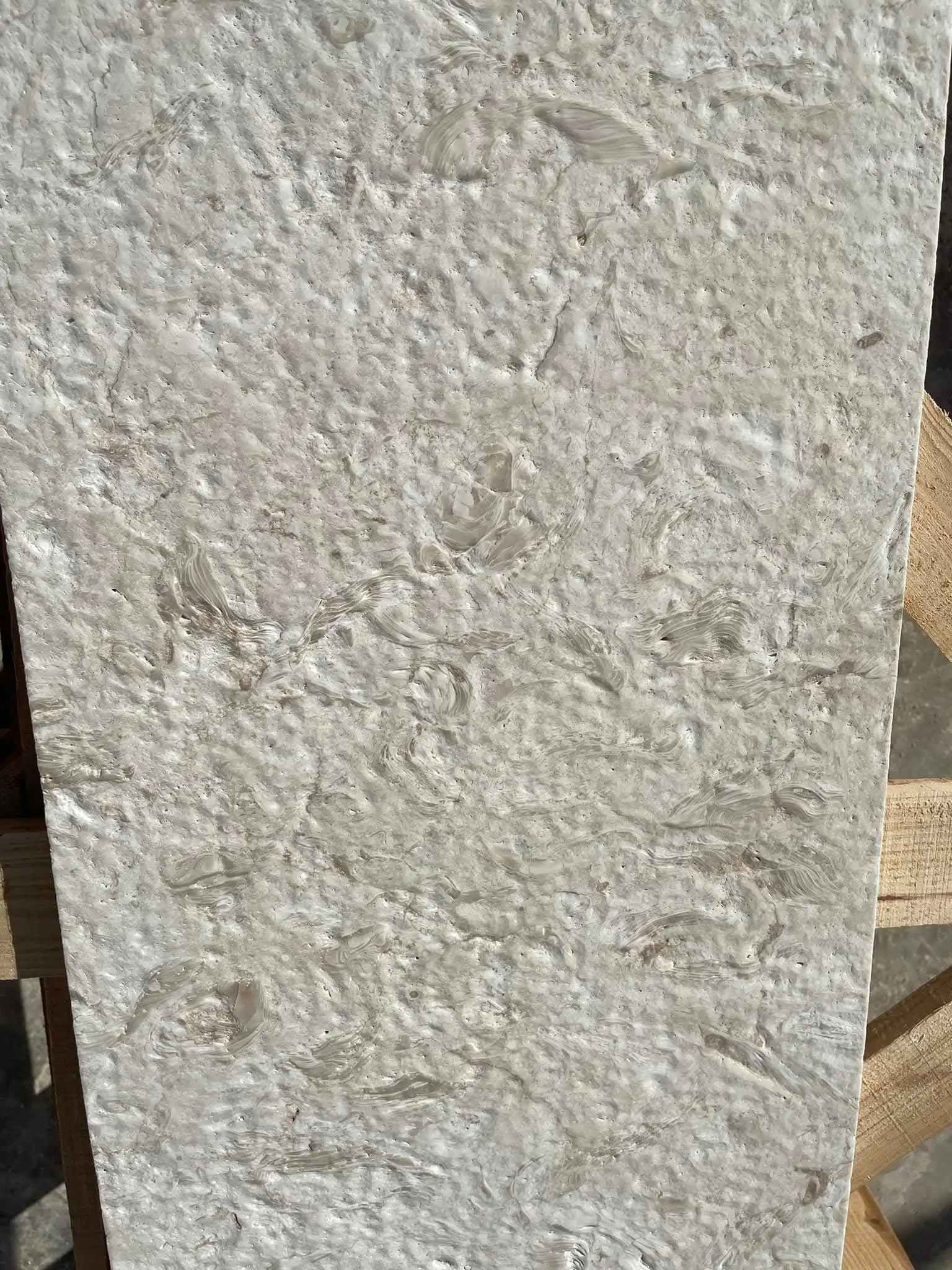

Surface texture specifications for wall stone suppliers Arizona types directly affect both aesthetic outcomes and functional performance characteristics that emerge over the structure’s lifetime. When you specify smooth or honed finishes, you’re choosing surfaces that maintain consistent appearance but may show individual stone color variations more prominently. Textured finishes like thermal, flamed, or natural cleft surfaces create visual uniformity by diffusing light reflection patterns, effectively masking minor color variations between individual stones.

The surface texture you select affects mortar bond strength significantly in mortared applications. Rough or thermaled surfaces provide 25-35% greater mechanical interlock compared to smooth finishes because increased surface area and texture irregularities enhance adhesion. Your specifications should address this relationship—if aesthetic requirements demand smooth stone faces, you need to compensate with deeper mortar joints or enhanced mortar compositions to maintain equivalent bond performance.

- You need to understand that textured surfaces accumulate dust and organic matter more readily in Arizona’s arid conditions

- Smooth finishes facilitate easier cleaning but may show water spotting more prominently after monsoon rains

- Your selection should consider maintenance access and frequency when specifying surface textures for visible wall faces

- Natural cleft surfaces provide the most variation in texture, requiring you to accept 1/8 to 1/4 inch relief variations across individual stones

Dimensional Specifications and Manufacturing Tolerances

When you write specifications for wall stone suppliers Arizona types, understanding manufacturing tolerances prevents specification conflicts and installation disputes. Dimensioned stone typically ships with ±1/8 inch tolerance on thickness and ±1/4 inch on length and width dimensions. These tolerances represent practical limitations of quarrying and fabrication equipment—tighter specifications are achievable but increase costs by 30-50% due to additional processing and higher rejection rates during quality control.

Garden wall stone suppliers construction projects require you to specify tolerances appropriate to your installation method. Dry-stack applications demand tighter control—you should specify ±1/16 inch on bed surfaces where dimensional stacking determines structural stability. Mortared installations accommodate standard ±1/8 inch tolerances because mortar joints absorb variation, though you still need consistency across individual stone lots to maintain uniform joint widths and professional appearance.

Your procurement documents should address how tolerance verification occurs and what acceptance criteria govern delivered materials. Industry practice measures dimensions at room temperature on dry stone—you need to account for moisture and temperature effects if verification occurs under different conditions. A quality control protocol requiring measurement of 10% of delivered materials provides reasonable assurance while avoiding excessive inspection burden that delays installation progress.

Color Consistency and Natural Variation

Natural stone exhibits inherent color variation that you must address in specifications for wall stone suppliers Arizona types through realistic acceptance criteria and lot management protocols. Even stone from the same quarry shows variation based on depth of extraction, mineral distribution in the geological formation, and processing methods. You should expect color variation within defined ranges rather than perfect uniformity—specifications demanding absolute color matching create unrealistic procurement requirements that increase costs and extend lead times unnecessarily.

When you evaluate color consistency requirements for your project, consider viewing distance and lighting conditions at the installation site. Walls viewed from 20-30 feet distance show effective color uniformity even when individual stones vary by 2-3 shades, because the eye averages color across the entire visible surface. You need tighter color control only for walls in close-proximity viewing conditions like entry courtyards or intimate garden spaces where individual stone characteristics become focal points.

Wall building stone Arizona suppliers typically provide sample boards showing the expected color range for specific materials. You should require these samples during the specification phase and reference them in procurement documents as the accepted variation standard. This approach establishes clear expectations and provides objective evaluation criteria when delivered materials arrive on site. Request samples from the specific quarry lot allocated to your project when timing permits, as this provides the most accurate representation of materials you’ll receive.

Best Wall Stone Suppliers in Arizona: Citadel Stone Regional Application Guidelines

When you consider Citadel Stone’s Wall Stone Suppliers in Arizona for your project, you’re evaluating materials engineered specifically for the state’s diverse climate zones and challenging installation conditions. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s geographical regions, from low desert valleys to high-elevation mountain communities. This section demonstrates how you would approach material specification and installation planning for six representative cities, each presenting distinct environmental factors that influence stone selection and construction methodology.

Arizona’s climate diversity creates unique specification requirements that you need to address on a region-by-region basis. Your Phoenix installation encounters dramatically different conditions than a Flagstaff project—temperature ranges, precipitation patterns, freeze-thaw exposure, and soil characteristics all vary significantly. You should evaluate Wall Stone Suppliers in Arizona options through this regional lens, understanding that optimal material choices and installation practices differ based on specific site conditions rather than generic state-wide recommendations.

Phoenix Heat Performance

In Phoenix, you’ll encounter the most extreme heat conditions in Arizona, with summer temperatures regularly exceeding 115°F and pavement surface temperatures reaching 160-180°F. Your material selection should prioritize light-colored limestone or sandstone that reflects 60-70% of solar radiation, maintaining surface temperatures 25-35°F cooler than dark materials. When you design walls for south or west exposures, you need to account for thermal expansion requiring joints every 20 feet in mortared installations. The urban heat island effect in Phoenix amplifies these concerns—walls near concrete hardscaping or buildings experience additional thermal loading that accelerates expansion-contraction cycling.

Tucson Monsoon Considerations

Your Tucson projects face intense monsoon precipitation between July and September, with individual storms delivering 1-2 inches of rain in less than an hour. You would need to specify enhanced drainage provisions for retaining walls, including 18-inch aggregate backfill zones and weep holes at 6-foot spacing rather than standard 8-foot intervals. The combination of extreme heat and periodic saturation creates challenging conditions for mortar durability—you should specify Type S mortar with enhanced water retention for optimal curing in Tucson’s low-humidity environment. Wall stone selections should demonstrate porosity in the 4-6% range for proper drainage without compromising structural integrity.

Flagstaff Freeze-Thaw Requirements

At 7,000 feet elevation, your Flagstaff installations would encounter 100-120 freeze-thaw cycles annually, making stone durability under these conditions your primary specification criterion. You need materials with proven freeze-thaw resistance verified through ASTM C666 testing or documented performance in similar climate zones. When you specify Wall Stone Suppliers in Arizona materials for Flagstaff applications, limestone with porosity between 3-5% provides optimal performance—sufficient permeability to prevent hydrostatic pressure buildup while maintaining structural integrity through repeated freezing cycles. Your wall designs should incorporate 2-inch minimum setback per 12 inches of height to create gravity advantage that compensates for potential mortar degradation over time.

Scottsdale Design Integration

Scottsdale projects typically emphasize architectural integration with contemporary desert design aesthetics. You would select dimensional cut limestone in consistent heights ranging from 4 to 8 inches, with lengths varying between 16 and 36 inches to create modern linear patterns. Your specifications should address color consistency more rigorously for Scottsdale applications because viewing distances in luxury residential settings tend to be closer, making individual stone variation more noticeable. When you design for Scottsdale’s demanding aesthetic standards, you need tight dimensional tolerances of ±1/16 inch on thickness and ±3/16 inch on length to maintain precise coursing and minimal joint width variation.

Sedona Red Rock Context

Your Sedona specifications would address aesthetic compatibility with the region’s iconic red rock formations while meeting technical performance requirements for the area’s elevation and climate. You should consider local sandstones in earth tones that complement rather than compete with the natural landscape. When you design walls in Sedona, local planning requirements often encourage materials that blend with the geological context—specifications should demonstrate this contextual sensitivity. The area’s 4,500-foot elevation creates moderate freeze-thaw exposure requiring you to verify 60-80 cycle durability, less demanding than Flagstaff but more rigorous than Phoenix valley locations.

Yuma Extreme Aridity

In Yuma’s extreme desert conditions—annual rainfall below 4 inches and summer temperatures exceeding 120°F—you would focus entirely on heat resistance and thermal performance rather than moisture management. Your material selections should prioritize maximum solar reflectance to minimize thermal stress and maintain manageable surface temperatures. When you specify for Yuma applications, light buff or cream limestone provides optimal performance, reflecting 65-75% of solar radiation. The extreme aridity actually simplifies certain aspects of wall construction because you face minimal concern about moisture-related durability issues, allowing you to focus specifications on dimensional accuracy and thermal compatibility between stones and any mortar components.

Procurement Timeline and Lead Time Planning

When you plan procurement for wall stone suppliers Arizona types, realistic timeline expectations prevent project delays and costly schedule disruptions. Standard lead times from specification approval to on-site delivery typically range from 4-8 weeks depending on material availability, fabrication requirements, and transportation logistics. You need longer lead times—potentially 10-14 weeks—when specifying custom dimensional cutting, specialized surface finishes, or materials from specific quarry lots chosen for color matching requirements.

Your procurement schedule should account for sample approval processes that can add 2-3 weeks to front-end timelines. When you request samples from specific quarry lots, shipping time for sample delivery, your review period, and any iteration for alternative selections all consume schedule. Building these approval cycles into your overall project timeline prevents compression of subsequent phases that could compromise installation quality through rushed execution.

- You should initiate material procurement 8-12 weeks before scheduled installation for standard dimensioned products

- Custom fabrication requirements typically add 3-4 weeks to standard lead times

- Your timeline must account for seasonal demand fluctuations that can extend lead times during peak construction periods in spring and fall

- Delivery scheduling requires coordination with job site access and staging area availability—plan these logistics 2 weeks before material arrival

Key Specification Factors

Your professional approach to specifying wall stone suppliers Arizona types requires you to synthesize multiple performance criteria into comprehensive procurement documents that serve both design intent and long-term functionality. You need to balance aesthetic objectives with structural requirements, budget constraints with quality expectations, and timeline demands with realistic procurement capabilities. The most successful specifications demonstrate understanding of material behavior in Arizona’s specific climate conditions while providing clear acceptance criteria that prevent disputes during construction.

When you develop wall specifications, remember that generic templates rarely address the nuanced requirements of Arizona applications. You should customize specifications based on specific site conditions—elevation, exposure, soil characteristics, and intended use patterns all influence optimal material selection and installation methodology. Your investment in detailed, project-specific specifications reduces field problems, prevents costly change orders, and delivers walls that perform reliably for decades. For comprehensive technical guidance on integrated design approaches, review Natural stone materials for Arizona landscape and structural walls before finalizing your project documentation. Citadel Stone supplies limestone blocks as elegant wall stone suppliers in Arizona formal gardens.