When you walk into a marble and granite yard in Arizona for the first time, you’re entering a specialized environment where raw material selection determines project outcomes for years to come. Your visiting marble granite yard Arizona guide starts with understanding what these facilities offer beyond simple retail showrooms. You’ll find inventory ranging from commodity-grade tiles to book-matched slabs worth $15,000 or more, and your ability to evaluate quality, ask informed questions, and recognize value separates successful specifications from costly mistakes.

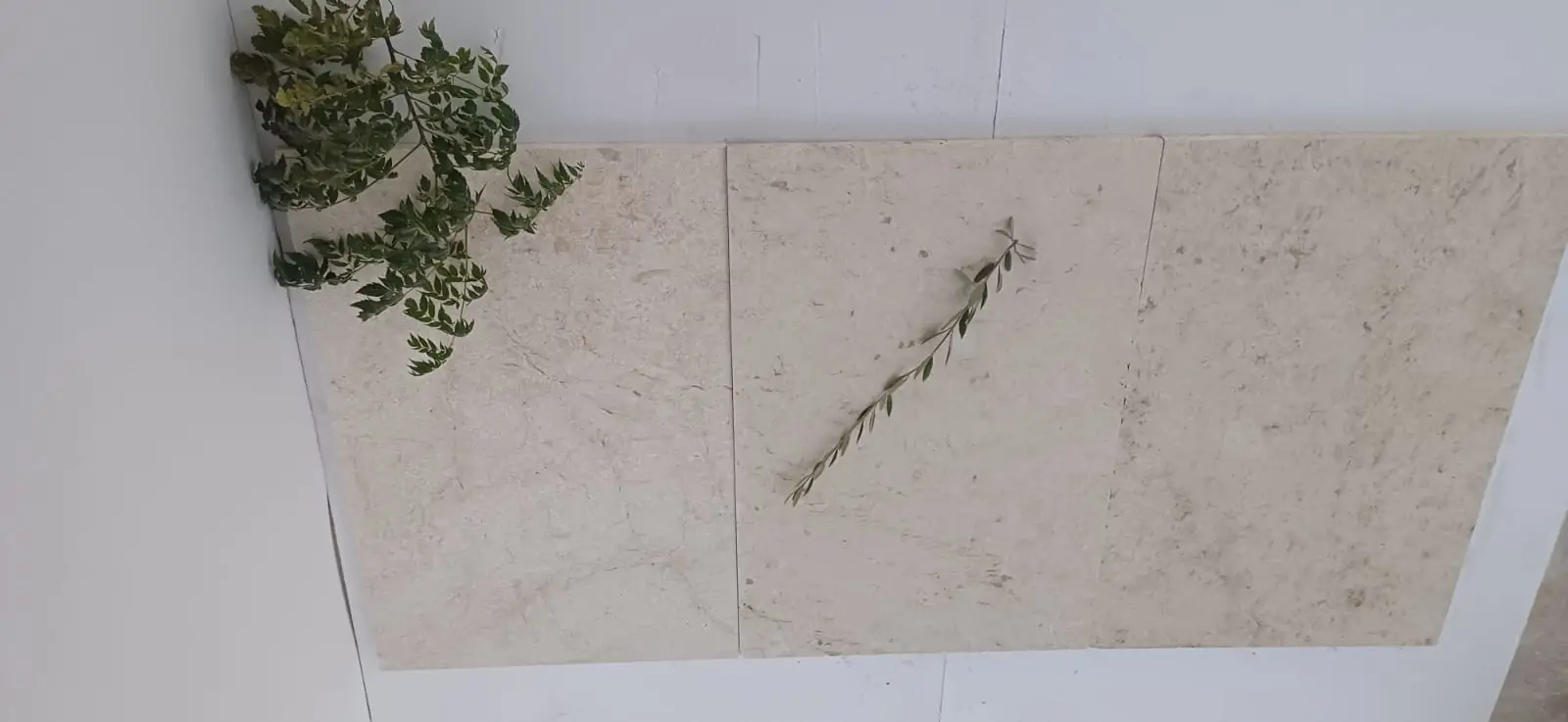

The marble stone yard in Arizona showroom experience differs significantly from selecting finishes through samples or catalogs. You’re examining full slabs under natural and artificial lighting, assessing vein continuity across 120 square feet of material, and identifying the subtle color variations that photographs simply cannot capture. Your first visit should focus on three priorities: understanding inventory organization systems, learning how yards categorize and price materials, and establishing relationships with sales staff who control access to incoming containers and reserve premium selections.

Showroom Layout and Inventory Systems

Arizona granite yards organize inventory using systems that prioritize high-turnover commodities while showcasing premium exotics. When you enter the facility, you’ll typically encounter indoor displays featuring 12-18 inch samples mounted vertically on rotating racks or wall systems. These displays represent available full slabs stored in outdoor yards or warehouse facilities. Your marble granite yard Arizona visit checklist should include verifying that display samples accurately represent current inventory, not discontinued materials or special-order-only options.

The outdoor slab yard contains the actual inventory you’re purchasing. You’ll find materials organized by stone type, color family, or country of origin depending on the facility’s system. Premium yards maintain climate-controlled indoor storage for temperature-sensitive materials like certain marbles that can develop micro-fissures from thermal cycling. Your inspection process requires walking the yard with staff, pulling slabs from bundles to examine full surface area, and photographing materials under natural light for client or team review.

- You should request to see at least three slabs from any material you’re seriously considering, as variation between slabs from the same block can be substantial

- Yards typically store slabs in A-frame bundles with protective paper or plastic between pieces, making middle slabs difficult to access without staff assistance

- You’ll find that premium exotics often arrive in small shipments of 8-15 slabs, requiring immediate inspection when containers are unpacked

- Your timing matters significantly, as desirable materials sell quickly and replenishment cycles for exotics can extend 4-6 months

Material Quality Assessment Techniques

Your ability to assess slab quality during a marble stone yard in Arizona showroom experience determines whether you’re purchasing commercial-grade material at premium pricing or legitimate first-choice selections. Start by examining the slab face under raking light, which reveals surface irregularities, filled fissures, and repair work that overhead lighting conceals. You’ll want to inspect both polished and unpolished edges, as edge condition indicates fabrication challenges and potential hidden flaws.

Fissures versus cracks represent a critical distinction that first time slab buyer Arizona professionals often misunderstand. Natural fissures are geological features that don’t compromise structural integrity, appearing as hairline separations that don’t penetrate through the slab thickness. You can verify this by inspecting the back surface and edges. Cracks, by contrast, extend completely through the material and represent structural failures that will propagate during fabrication or installation. Your specification should reject any slab with through-thickness cracks, regardless of pricing discounts offered.

Color consistency across the slab matters more than most buyers initially recognize. You should photograph the entire slab from 10-12 feet distance to capture overall appearance, then take detail shots of any concentrated veining, color shifts, or pattern disruptions. When you’re selecting multiple slabs for a large project, lay them side by side in the yard to evaluate how they’ll appear as a set. Yards typically allow this for serious buyers but may charge restocking fees if you ultimately don’t purchase.

- You need to inspect resin-filled areas by running your hand across the surface, feeling for texture differences that indicate heavy fill application

- Epoxy fills appear glossier than surrounding polished stone and become more visible over time as they yellow from UV exposure

- Your inspection should include the back surface where mesh reinforcement reveals structural concerns the fabricator didn’t want visible from the front

- Stone thickness typically measures 2cm or 3cm, but you should verify actual thickness as undersized slabs cause installation complications

Essential Questions to Ask Yard Staff

The questions you ask during your marble granite yard Arizona visit checklist reveal your experience level and directly impact the information quality you receive. Start by asking about material origin and quarry source, as this affects performance characteristics, replenishment availability, and pricing stability. You’ll find that some yards provide detailed quarry information while others offer only country of origin. For projects requiring material matching or future additions, quarry-specific identification becomes critical.

Your questions about material treatment and enhancement should be direct and specific. Ask whether the material has been resined, whether color enhancement treatments have been applied, and what percentage of the slab surface has been filled or repaired. Reputable yards disclose these treatments because they affect both pricing and long-term performance. You should also inquire about the material’s absorption rate and whether the yard has conducted ASTM C97 testing for water absorption, as this determines sealing requirements and stain resistance.

Lead times and availability represent practical concerns that affect project schedules. You need to ask whether displayed materials are in stock locally or require transfer from regional warehouse facilities. Transfer times typically add 3-7 business days, but your project timeline may not accommodate delays. Additionally, ask about reserve policies and deposit requirements, as premium materials often sell while you’re obtaining client approval. Many yards allow 24-48 hour courtesy holds, but longer reserves require deposits.

- You should ask whether the yard offers fabrication services in-house or whether they work with independent fabricators, as this affects warranty and coordination

- Your inquiry about remnant or leftover pieces from previous jobs can yield cost savings for smaller projects like vanities or fireplace surrounds

- You’ll want to confirm whether quoted pricing includes delivery to the fabricator or your job site, as transportation costs vary significantly

- Ask about return policies and restocking fees before committing, particularly for special-order materials with limited resale potential

Documentation and Photography Protocol

Professional documentation during your Arizona marble and granite suppliers tours creates the reference material you’ll need for client presentations, fabrication specifications, and future material matching. You should photograph each slab you’re seriously considering using the same protocol: one full-slab image from 10 feet distance, detail shots of distinctive veining or features, and close-ups of any concerns like fissures or filled areas. Include a color reference card or standard object in each frame to provide scale and color accuracy verification.

Your slab identification system must capture the yard’s internal tracking information. Every slab has a bundle number, lot number, or sequential identifier that the yard uses for inventory management. You need to record this information with your photographs because “the white marble with gray veining” describes 40 different materials in a typical yard’s inventory. When you return for final selection or send your fabricator to pick up material, precise identification prevents costly errors. Many professionals use their phone’s voice memo feature to verbally document slab numbers while photographing.

Lighting conditions dramatically affect how you perceive stone appearance, so your documentation should account for this variable. Photograph slabs outdoors in natural light when possible, as this reveals true color without the color temperature shifts caused by metal halide or LED warehouse lighting. You’ll also want to take reference shots under the lighting conditions where the material will be installed. For guidance on complementary materials and related specifications, see Citadel Stone granite materials yard for comprehensive selection criteria. Kitchen granite appears different under recessed LED versus pendant lighting, and your client’s expectations depend on accurate color representation.

Pricing Structures and Negotiation Leverage

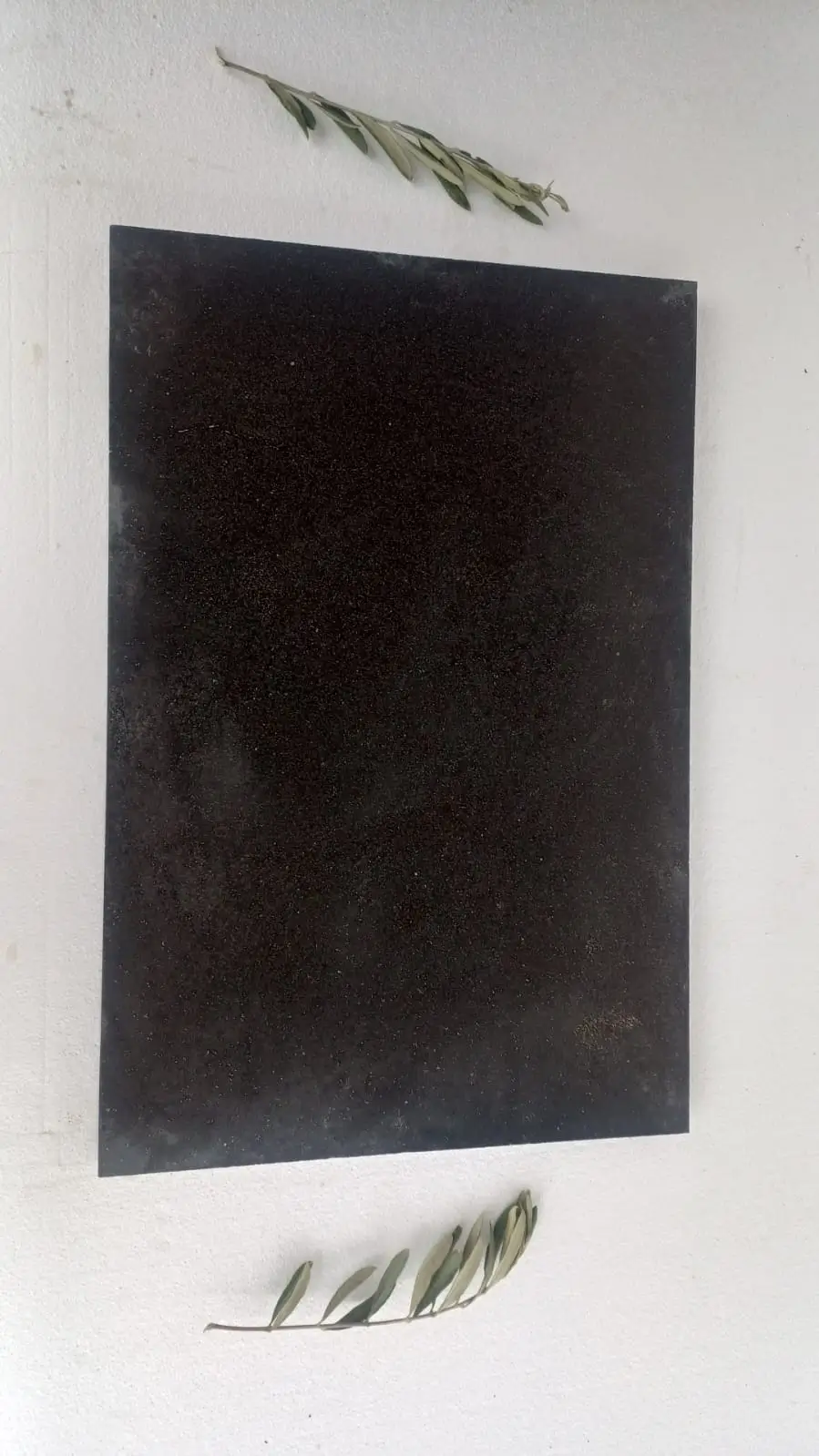

When you investigate pricing at an Arizona marble and granite suppliers tours location, you’re navigating a market with substantial price variation based on material rarity, slab size, color desirability, and your purchase volume. Commodity granites like Absolute Black or Ubatuba typically price by the square foot with minimal negotiation flexibility, as margins are thin and turnover is high. Exotic materials, by contrast, often carry significant markup and provide negotiation opportunity, particularly for multiple-slab purchases or repeat customers.

Your leverage in negotiations increases significantly when you understand industry pricing tiers. First-choice or premium-grade slabs command top pricing based on superior color consistency, minimal fissuring, and larger usable surface area. Commercial or builder-grade materials from the same quarry may cost 30-40% less due to increased variation, more pronounced fissures, or smaller slab dimensions. You should ask explicitly which grade category you’re being shown, as some yards present commercial-grade materials at premium-grade pricing to uninformed buyers.

- You can negotiate more effectively on materials that have been in inventory for extended periods, as holding costs incentivize movement

- Your purchase of multiple slabs provides volume pricing leverage that single-slab buyers don’t receive

- You’ll find that establishing yourself as a design professional with repeat business potential yields better pricing than one-time homeowner purchases

- Cash purchases sometimes provide 2-3% discounts, though this varies by yard and violates some business policies

Material Performance and Climate Considerations

Arizona’s extreme climate conditions create specific performance requirements that your first time slab buyer Arizona evaluation must address. Thermal cycling between 40°F winter nights and 120°F summer days creates expansion and contraction stresses that affect different stone types variably. Granites generally perform well due to their dense crystalline structure and low porosity, typically ranging from 0.4% to 1.5% water absorption. You’ll find that marbles, limestones, and other sedimentary stones require more careful evaluation for exterior applications.

UV exposure intensity in Arizona affects certain materials over extended timeframes. Some granites containing biotite or other iron-bearing minerals can develop slight color shifts after years of direct sun exposure, typically fading by 5-10% in saturation. Your material selection for exterior applications should account for this gradual change, selecting materials where slight fading enhances rather than detracts from aesthetic goals. Quartzites generally exhibit superior UV stability compared to granites, maintaining original color for 15-20 years in full sun exposure.

Porosity and water absorption rates determine performance in applications with moisture exposure. When you’re specifying materials for outdoor kitchens, pool decks, or exterior cladding, you need absorption rates below 0.5% to minimize freeze-thaw damage risk and reduce staining susceptibility. You should request ASTM C97 test data from the yard, though many yards don’t maintain this documentation for all materials. In the absence of test data, you can conduct a simple field test by placing water droplets on an unpolished edge and observing absorption rate.

Fabrication Coordination Requirements

Your visiting marble granite yard Arizona guide must include understanding the relationship between material selection and fabrication feasibility. Certain materials present fabrication challenges that affect labor costs, timeline, and achievable edge details. Highly figured marbles with pronounced veining require careful template alignment to achieve desired aesthetic effects, adding 2-3 hours to fabrication time for typical kitchen installations. You’ll find that materials with significant natural fissures limit edge profile options, as aggressive profiles like ogee or dupont can intersect fissure lines and create weak points.

Material hardness affects tooling wear and fabrication efficiency. When you select exotic quartzites or ultra-dense granites, fabrication costs increase by 15-25% due to accelerated blade wear and slower cutting speeds. Your fabricator should evaluate material before you commit to purchase, particularly for complex projects with numerous cutouts, radius corners, or specialized edge treatments. Most yards allow fabricators to inspect materials after you’ve made preliminary selections, and professional fabricators can identify concerns you might miss.

- You need to coordinate slab pickup timing with your fabricator’s schedule, as most fabricators lack storage capacity for materials arriving weeks before fabrication begins

- Your project may require the fabricator to visit the yard for template verification, particularly for large-format island installations requiring multiple slabs

- You should verify that your selected fabricator has experience with your specific material type, as techniques for processing marble differ substantially from granite protocols

- Fabrication lead times typically range from 10-15 business days after template, but complex projects or specialized edge treatments can extend this to 20-25 days

Inventory Availability and Timing Strategies

The marble stone yard in Arizona showroom experience includes understanding inventory cycles and timing your visit to maximize material selection. New container arrivals provide the widest selection within specific material types, as you’re viewing complete shipments before other buyers have selected premium pieces. Many yards notify preferred customers when containers arrive, giving design professionals and repeat clients first access before materials reach the display floor. You should request placement on these notification lists, as access to fresh inventory provides competitive advantages for your projects.

Seasonal patterns affect both inventory levels and pricing. You’ll find that yards increase inventory in late winter and early spring to meet peak construction season demand, then reduce stock levels in late fall as construction activity slows. Your purchases during slower periods may yield better pricing as yards seek to improve cash flow and reduce carrying costs. Additionally, year-end inventory reductions sometimes create opportunities for significant discounts on slow-moving exotics that have occupied valuable yard space for months.

Warehouse stock verification matters when you’re selecting materials from display samples rather than physical slabs. Display samples sometimes remain on view after corresponding inventory has sold, creating frustration when you select materials that aren’t actually available. You should ask staff to verify warehouse stock before investing significant time in material evaluation. Most yards maintain real-time inventory systems, though smaller operations may require physical verification in the yard.

Specialized Material Categories to Request

Beyond standard granite and marble offerings, your Arizona marble and granite suppliers tours should investigate specialized categories that many yards maintain but don’t prominently display. Remnants or leftover pieces from previous jobs provide cost-effective solutions for smaller applications like bathroom vanities, fireplace surrounds, or accent walls. You’ll find remnants priced at 40-60% of full-slab costs, though selection is limited and dimensions may not suit your specific project requirements.

Book-matched and quarter-matched slabs represent premium selections where sequential slabs from the same quarry block are arranged to create mirror-image or continuous vein patterns. You should specifically request to view book-match candidates for feature wall installations or large-format applications where visual continuity creates dramatic effect. Yards typically charge 10-15% premiums for verified book-match pairs due to the careful selection and inventory coordination required.

- You may find exotic materials available in 2cm thickness only, requiring lamination to achieve standard 3cm thickness for countertop applications

- Leather-finished or textured surfaces provide slip resistance for exterior applications while maintaining the stone’s natural character

- Your inquiry about discontinued or closeout materials can yield substantial savings on premium exotics that yards are clearing to make space for new inventory

- Some yards maintain separate sections for commercial-grade materials that don’t meet residential aesthetic standards but perform adequately for less visible applications

Citadel Stone’s Approach to landscape stone yard Arizona Material Specifications Across Regional Climate Zones

When you consider landscape stone yard Arizona applications through Citadel Stone’s technical framework, you’re evaluating how material performance intersects with regional microclimates across the state’s diverse topography. At Citadel Stone, we provide specification guidance for hypothetical projects that demonstrates how climate-specific factors influence material selection, installation protocols, and long-term maintenance requirements. This section outlines recommended approaches for six representative Arizona cities, addressing thermal performance, moisture management, and aesthetic durability considerations you would encounter in each location.

Your landscape stone yard Arizona material evaluation would prioritize different performance characteristics depending on elevation, annual precipitation, temperature extremes, and soil composition. The specifications outlined below represent how you would approach material selection for projects in each city, accounting for local conditions that affect installation success and service life expectations.

Phoenix Specifications

In Phoenix, you would specify materials capable of withstanding sustained surface temperatures exceeding 160°F during June through August. Your selection would prioritize light-colored granites or quartzites that reflect 60-70% of solar radiation, reducing heat retention and creating more comfortable surfaces for residential outdoor living spaces. You’d need to account for thermal expansion coefficients of 5.3 × 10⁻⁶ per °F, requiring expansion joints every 12-15 feet in large-format installations. The urban heat island effect in Phoenix adds 8-12°F to ambient temperatures, intensifying thermal stress on materials compared to surrounding desert areas.

Tucson Considerations

Your Tucson project specifications would address the monsoon season’s impact on material performance, as July through September delivers 40% of annual precipitation in high-intensity events. You’d specify materials with absorption rates below 0.5% to minimize efflorescence risk from the region’s calcium-rich soils. Tucson’s slightly lower elevation compared to Phoenix creates similar thermal challenges but with increased atmospheric moisture during monsoon periods. You would recommend sealed joints and proper drainage design to manage runoff from intense precipitation events that can deliver 2-3 inches in 90-minute periods.

Scottsdale Applications

For Scottsdale installations, you would focus on premium aesthetic specifications matching the area’s high-end residential market expectations. Your material selections would emphasize book-matched slabs and consistent color presentation across large pool deck and outdoor kitchen applications. You’d specify materials with proven resistance to pool chemicals and recommend enhanced sealing protocols for areas within 6 feet of water features. Scottsdale’s landscape irrigation practices create localized moisture conditions that differ from natural desert environments, requiring you to account for increased ground moisture when specifying base preparation and drainage systems.

Flagstaff Requirements

Flagstaff’s 7,000-foot elevation creates Arizona’s most challenging natural stone environment, with 60-80 annual freeze-thaw cycles that you would need to address through rigorous material selection. Your specifications would require absorption rates below 0.3% and verified freeze-thaw durability through ASTM C1026 testing. You’d specify 3cm minimum thickness for all exterior applications to provide adequate thermal mass and structural capacity. Winter snow loads and ice formation require you to avoid textured surfaces that trap moisture, instead specifying thermal-finished or flamed surfaces that provide slip resistance while facilitating drainage.

Sedona Design Integration

In Sedona, your specifications would balance performance requirements with aesthetic integration to the area’s distinctive red rock landscape. You’d select materials with warm earth tones that complement rather than contrast with surrounding geology, typically specifying desert gold granites or terra-cotta-toned quartzites. Sedona’s moderate elevation creates fewer freeze-thaw cycles than Flagstaff but more than Phoenix, requiring you to specify materials with 0.4% maximum absorption. The area’s tourism-focused commercial applications would lead you to emphasize slip resistance and long-term appearance retention under high foot traffic conditions.

Yuma Performance Standards

Your Yuma project specifications would address the state’s most extreme heat conditions, with summer temperatures consistently reaching 115-120°F and surface temperatures exceeding 170°F on dark materials. You’d specify maximum solar reflectance materials to manage surface temperatures, potentially recommending specialty cool-surface treatments for pool decks and patios. Yuma’s position along the Colorado River creates elevated atmospheric moisture compared to other low-elevation Arizona locations, requiring you to account for increased efflorescence potential. Your base preparation specifications would address the region’s clay-heavy soils that expand significantly with moisture exposure, requiring enhanced aggregate base depths of 8-10 inches compared to standard 6-inch specifications.

Specialized Applications and Edge Cases

Your marble granite yard Arizona visit checklist should include investigating materials for specialized applications that standard inventory may not address. Exterior vertical cladding requires different performance characteristics than horizontal surfaces, as water drainage patterns, wind loads, and attachment systems create unique stress conditions. You’ll need materials with verified bond strength for thin-set applications and expansion coefficients compatible with substrate materials. Many yards maintain separate inventory sections for cladding materials in 1cm or 2cm thicknesses that aren’t suitable for horizontal applications.

High-temperature applications near fireplaces, outdoor kitchens, or fire features require you to verify thermal shock resistance. Most granites perform adequately for indirect heat exposure, but direct flame contact or repeated rapid heating and cooling can cause spalling or surface deterioration in materials with certain mineral compositions. You should request information about the material’s thermal properties and any testing documentation the quarry provides regarding high-temperature performance.

- You need to consider whether your application requires food-safe certification for surfaces like cutting boards or serving platters, as some imported materials may not meet FDA standards

- Your outdoor shower or water feature applications require materials with superior slip resistance when wet, typically requiring textured or thermal finishes rather than polished surfaces

- You’ll find that certain applications in healthcare or food service environments require specific antimicrobial properties or NSF certification that limits material options

Comparative Evaluation Across Multiple Facilities

Professional specification practices recommend visiting multiple marble and granite suppliers Arizona represents before finalizing material selections. You’ll discover that inventory overlap between yards is typically 40-60% for commodity materials but less than 20% for exotic stones. Your comparative evaluation should document pricing variations, which can range from 15-30% for identical materials between competing facilities. Transportation and overhead costs, volume purchasing power, and target market positioning all contribute to these pricing differences.

When you visit multiple facilities during your first time slab buyer Arizona education process, you’re also evaluating customer service quality, technical knowledge, and post-sale support capabilities. The yard with the lowest pricing may not provide the fabrication coordination, delivery flexibility, or problem-resolution support that complex projects require. You should assess how staff respond to technical questions, whether they proactively identify potential concerns with materials you’re considering, and whether they demonstrate genuine expertise or simply read from specification sheets.

Your comparative evaluation should include visiting at different times of day and week, as inventory changes rapidly and weekend staffing may differ significantly from weekday operations. Professional design trade accounts often receive preferential treatment including access to incoming inventory, extended hold periods, and volume pricing that retail customers don’t receive. You should inquire about trade account requirements and benefits at each facility you visit.

Key Takeaways

Your successful marble stone yard in Arizona showroom experience depends on preparation, systematic evaluation, and asking informed questions that demonstrate professional knowledge. You need to understand that material selection represents a permanent decision affecting both aesthetic outcomes and long-term performance, making thorough investigation essential. The time you invest in visiting facilities, examining inventory, documenting options, and verifying availability prevents costly mistakes and project delays. Your relationship with yard staff develops through professional interaction and repeat business, providing access to premium inventory and technical support that casual buyers don’t receive. For additional insights on quality evaluation protocols, review Understanding slab quality grading systems used by Arizona suppliers before you finalize your material specifications. Quartz alternatives and natural stone coexist at Citadel Stone, the most comprehensive marble and granite suppliers Arizona presents.