When you walk into Arizona stone yards for the first time, you’ll encounter a completely different experience from typical retail building supply stores. The material selection process involves significantly more hands-on evaluation, and you need to understand how natural stone variations affect your project specifications. Most first-time visitors underestimate the time required — plan at least 90 minutes for a thorough yard tour and material assessment.

You should arrive prepared with specific project requirements documented: square footage, application type, exposure conditions, and performance expectations. Your ability to communicate technical needs determines how effectively the yard staff can guide you toward appropriate material options. The conversation shifts quickly from aesthetics to engineering specifications when you’re evaluating natural stone for demanding Arizona climates.

Understanding Stone Yard Layout and Organization Systems

Professional stone yards organize inventory differently than you might expect from conventional lumber yards or masonry suppliers. When you’re visiting Arizona stone yards first time, you’ll notice materials grouped by geological type first, then subdivided by finish, thickness, and size format. This classification system reflects how stone performs rather than how it looks — a critical distinction for specification decisions.

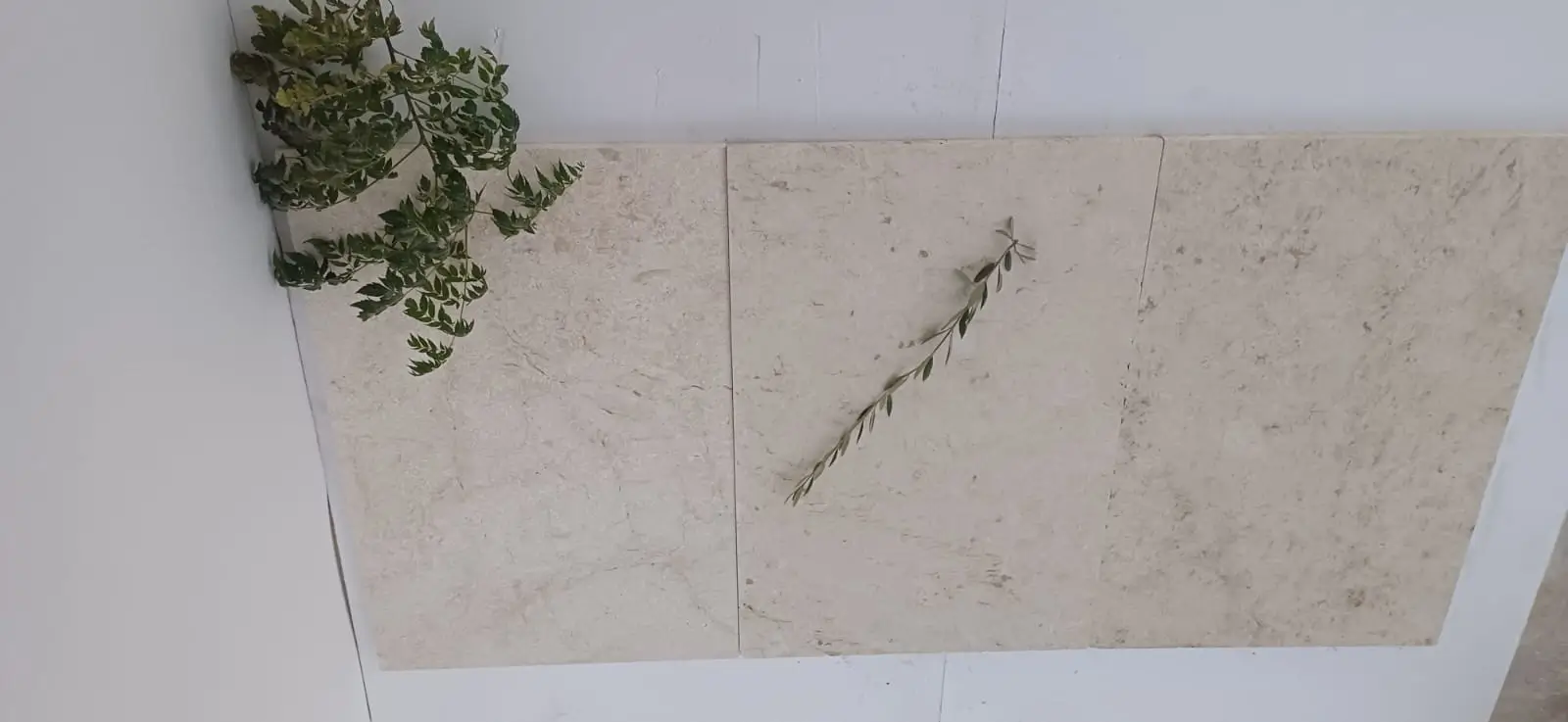

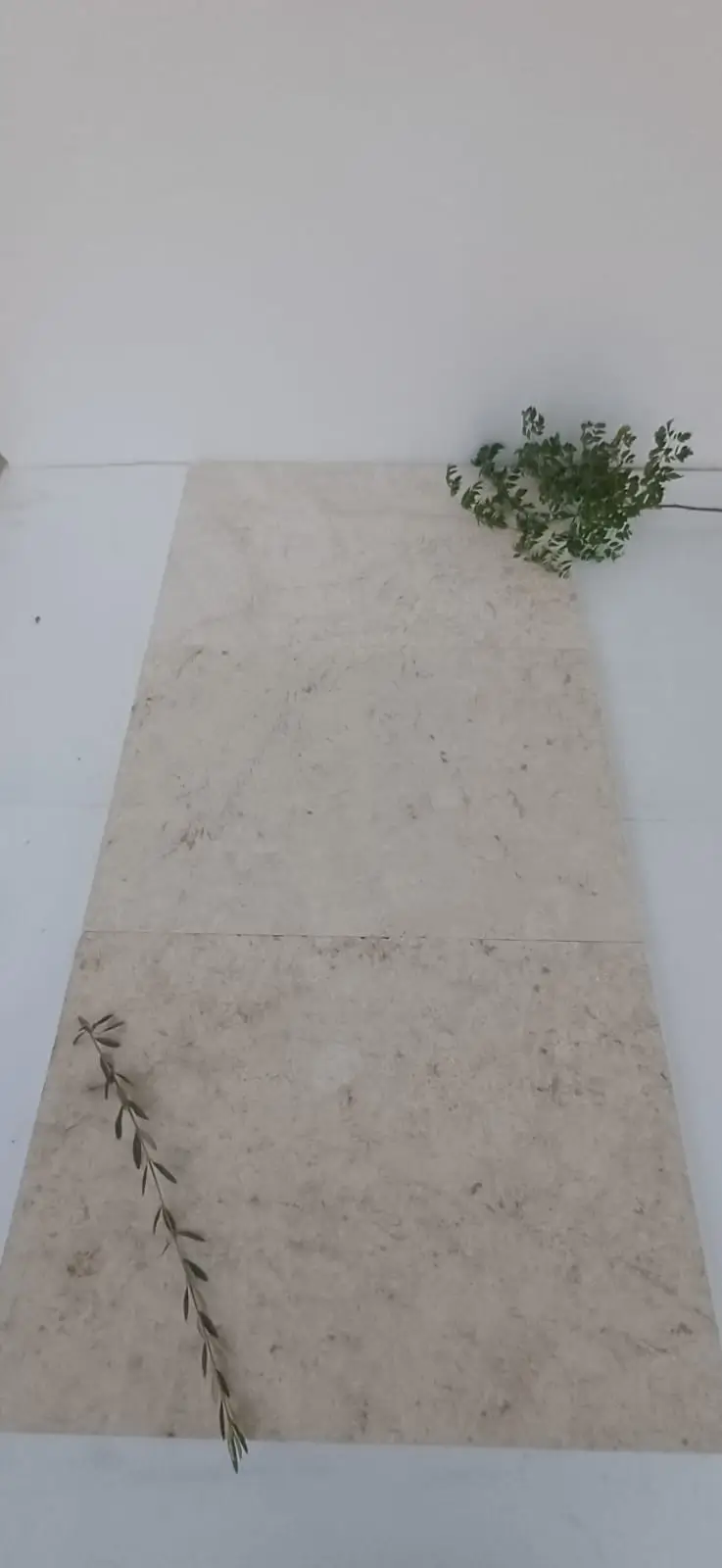

You need to understand that display areas show idealized examples, while the bulk storage yards contain the actual project material. Your specification needs to account for natural variation across production runs. The sample you approve may represent the median appearance, but individual pieces will range 15-20% lighter or darker depending on the quarry layer extraction sequence.

Yard staff typically guide first-time visitors through a structured tour sequence. You’ll start with hardscape pavers, move through dimensional stone sections, then finish at specialty materials and custom fabrication areas. This progression helps you understand material relationships and performance trade-offs before you commit to specific selections.

Material Inspection Protocols for First-Time Buyers

You should inspect stone under natural daylight conditions, preferably between 10 AM and 2 PM when solar angles provide consistent illumination. Warehouse lighting creates color shifts that don’t reflect installed appearance. Your evaluation process needs to include wet testing — spray several pieces with water to simulate sealed or rain-saturated conditions, which dramatically alters perceived color and reveals porosity characteristics.

Professional buyers examine minimum 15-20 pieces from different pallet positions when they’re assessing bulk material. You’re looking for acceptable variation range, not perfect uniformity. Natural stone exhibits inherent differences in mineral content, fossil patterns, and color intensity. Your specification should define acceptable variation parameters rather than expecting laboratory-grade consistency.

- You need to check thickness tolerance across multiple pieces, measuring at corners and center points

- Your inspection should identify edge quality and corner integrity, particularly for unfilled travertine

- You should evaluate surface finish consistency, looking for processing variations that affect slip resistance

- Your assessment must include examination of the bottom surface for lippage prevention during installation

When you’re evaluating samples during your stone yard in Arizona showroom tour, pay attention to how temperature affects material surface characteristics. Desert-stored stone reaches 140-150°F during summer months, and you’ll notice thermal properties that influence installation handling requirements and initial curing conditions.

Technical Specifications Discussion With Yard Specialists

Your conversation with yard technical staff should focus on performance requirements before aesthetic preferences. You need to communicate application specifics: vehicular traffic versus pedestrian only, covered versus exposed conditions, proximity to pool water chemistry, and maintenance commitment level. These factors determine appropriate material density, porosity range, and surface finish specifications.

Professional stone yards maintain test data for compressive strength, absorption rates, and abrasion resistance. You should request documentation that verifies material meets ASTM C1528 standards for your specific application. Don’t assume all natural stone performs equally — absorption rates vary from 0.5% to 8.0% depending on geological formation and quarry source.

The local stone yards Arizona visit guide process includes discussing Arizona-specific climate challenges. You’ll encounter temperature swings of 40-50°F between day and night during spring and fall months. Your material selection needs sufficient thermal mass characteristics to handle these cycles without developing stress fractures over 15-20 year service life.

Yard specialists can provide guidance on how regional soil conditions affect installation substrate requirements. Clay-heavy soils in certain Arizona regions require enhanced base preparation compared to decomposed granite areas. You should discuss these geotechnical factors before finalizing material selection, because they affect total installed cost beyond the stone price itself.

Pricing Structure Understanding and Budget Planning

Stone yard pricing operates on tiered structures based on purchase volume, material grade, and delivery requirements. When you’re visiting Arizona stone yards first time, you’ll discover that quoted prices typically exclude installation, substrate preparation, and edge treatments. Your budget needs to account for total project cost, not just material acquisition.

You should understand that premium select grade material costs 25-40% more than standard grade from the same quarry. The difference reflects tighter color matching and reduced natural variation. Professional specifiers often blend grades strategically — using select material in high-visibility areas while standard grade works for secondary zones.

Delivery logistics significantly impact project economics. You need to confirm that your site provides adequate truck access for material offloading. Restricted access requiring smaller vehicles or manual transfer adds 15-30% to delivery costs. Coordinate warehouse availability with your installation schedule to avoid double-handling and storage fees.

Sample Selection Process and Approval Procedures

You should never specify stone based on small hand samples alone. Request full-size pieces that represent actual installed appearance. A 4×4 inch sample doesn’t reveal the pattern variation you’ll see across 16×24 inch pavers or 24×24 inch tiles. Your approval process needs to evaluate material at installation scale.

Professional practice involves selecting multiple samples that span the acceptable variation range. You’ll approve a light-end sample, median sample, and dark-end sample that together define project parameters. This three-sample protocol prevents disputes during installation when natural variation appears.

- You need to photograph approved samples under consistent lighting with color reference cards

- Your documentation should include written descriptions of acceptable color range and pattern characteristics

- You should retain physical samples on-site during installation for real-time comparison

- Your approval process must specify whether samples represent minimum acceptable quality or median expected quality

The stoneyard stone Arizona selection process includes establishing clear communication protocols about material substitution. You should require written notification if approved material becomes unavailable and replacement options need evaluation. Don’t allow field substitutions without reviewing physical samples from the alternative source.

Delivery Coordination Requirements and Site Logistics

When you coordinate stone delivery, you need to specify exact placement locations that minimize manual handling. Material delivered to street curb requires significant additional labor compared to direct placement near installation areas. Your site logistics plan should identify truck staging areas, offloading zones, and temporary storage locations before delivery scheduling.

You should verify that delivery timing aligns with installation crew availability. Stone yards typically operate on appointment-based delivery windows rather than guaranteed specific times. Your schedule needs flexibility for 2-4 hour arrival windows, particularly during peak construction seasons when warehouse operations handle maximum daily volume.

Professional installers inspect delivered material before accepting truck departure. You’re responsible for identifying damaged pieces, quantity discrepancies, or material that doesn’t match approved samples. Document any issues immediately with photographs and written notes countersigned by the delivery driver.

For projects requiring multiple deliveries, you need to coordinate sequential shipments from the same production lot. Color variation between quarry runs can create visible differences in installed appearance. Request that the yard reserve your total project quantity from single inventory lot to ensure consistency across all delivery phases.

Common First-Time Mistakes to Avoid at Stone Yards

Most first-time buyers underestimate natural stone variation and expect ceramic tile consistency. You’ll be disappointed if you anticipate perfectly uniform color and pattern across all pieces. Your mindset needs to shift from manufactured product expectations to natural material appreciation, understanding that geological variation creates the authentic character professional designers value.

- You should avoid selecting material based solely on dry appearance without wet testing to simulate sealed conditions

- Your evaluation shouldn’t focus exclusively on display samples without inspecting bulk inventory from actual project pallets

- You need to resist rushing the selection process because material decisions affect project performance for decades

- Your planning must include sufficient lead time because custom orders require 6-12 weeks from quarry to delivery

Many first-time visitors fail to ask about material country of origin and geological formation. These factors dramatically affect performance characteristics. Turkish limestone behaves differently than Indiana limestone despite similar appearance. You should understand provenance because it determines maintenance requirements and long-term durability in Arizona exposure conditions.

Another common error involves inadequate quantity calculation. You need to order 8-12% overage for natural stone projects to account for cutting waste, breakage during installation, and future repair stock. Professional contractors refuse to guarantee exact color matching for supplemental orders placed months after initial purchase.

Premium Stone Yard in Arizona Performance: Citadel Stone Specification Guide for Arizona Cities

When you consider Citadel Stone’s stone yard in Arizona options for your project, you’re evaluating premium materials engineered specifically for extreme desert climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse regional conditions. This section outlines how you would approach material selection and installation planning for six representative cities, demonstrating the technical considerations that define professional stone specification in varied Arizona environments.

Phoenix Heat Performance

In Phoenix applications, you would need to specify materials that withstand sustained temperatures exceeding 115°F for 30-40 days annually. Your selection criteria should prioritize low thermal absorption characteristics combined with high compressive strength exceeding 9,000 PSI. The urban heat island effect in central Phoenix amplifies surface temperatures 15-20°F above ambient air temperature, creating extreme stress conditions that eliminate marginal material options. You should account for thermal expansion coefficients in your joint spacing calculations, expanding standard 3/16 inch joints to 1/4 inch for large-format installations in direct solar exposure.

Tucson Regional Considerations

Tucson’s slightly higher elevation creates modest temperature reduction compared to Phoenix, but you still face extreme heat stress requiring similar material specifications. Your planning should account for the area’s distinct monsoon season moisture patterns, which subject stone to rapid wet-dry cycling between July and September. This environmental condition requires you to specify materials with absorption rates below 5% to prevent moisture-related deterioration during intense seasonal precipitation events followed by rapid evaporation.

Scottsdale Luxury Applications

In Scottsdale’s high-end residential market, you would typically specify premium select-grade materials with tighter color tolerance and enhanced aesthetic consistency. Your project parameters often include pool deck applications where you need to verify slip resistance ratings exceed 0.55 DCOF in wet conditions while maintaining the refined appearance luxury clients expect. The area’s prominent landscape architecture community demands technical precision combined with design sophistication, requiring you to balance performance engineering with visual refinement.

Flagstaff Freeze-Thaw Zones

Flagstaff’s 7,000-foot elevation creates Arizona’s only significant freeze-thaw environment, fundamentally changing your specification approach. You would need to select materials with maximum 3% absorption rates and verified resistance to 50+ annual freeze-thaw cycles. Your installation details must include enhanced drainage provisions because trapped moisture combined with freezing temperatures causes catastrophic material failure. This climate zone requires you to apply winter-specific installation protocols unavailable in Arizona’s desert regions, including substrate frost protection and modified setting bed specifications.

Sedona Aesthetic Integration

When you specify stone for Sedona projects, local design review boards often require material selection that harmonizes with the area’s distinctive red rock geology. Your color palette typically emphasizes earth tones that complement rather than contrast with the natural landscape. You should anticipate that architectural review processes extend project timelines 4-6 weeks beyond standard permitting, requiring early material selection and sample submission for design committee approval before you finalize procurement.

Yuma Extreme Conditions

Yuma represents Arizona’s most extreme heat environment, with summer temperatures consistently exceeding Phoenix by 3-5°F and dramatically lower humidity levels. Your material specifications need to address this intensified thermal stress combined with high UV exposure that degrades inferior stone sealers within 18-24 months. The region’s agricultural dust conditions require you to specify surface finishes that facilitate cleaning without trapping particulate in surface texture. You would recommend materials with natural slip resistance rather than relying on topical treatments that fail prematurely in these harsh conditions. For comprehensive project planning beyond material selection, review Citadel Stone’s bulk delivery options throughout Arizona to understand how logistics coordination affects installation timelines and material quality preservation.

Specialized Application Guidance for Pool Decks and Water Features

Pool deck applications require specific material selection criteria beyond standard paving specifications. You need to verify that stone maintains safe slip resistance when wet while avoiding excessively rough textures that cause discomfort for barefoot traffic. Professional specifications target 0.55-0.60 DCOF ratings in wet conditions, which typically requires tumbled or flamed surface finishes rather than smooth polished treatments.

Water chemistry creates unique maintenance challenges. You should understand that pool chlorine concentrations between 2-4 PPM combined with Arizona’s high evaporation rates create aggressive chemical exposure conditions. Your material selection needs to resist etching and discoloration from sanitizer contact. Calcium-based stones like limestone and travertine require more frequent maintenance compared to silicate-based materials in these applications.

- You need to specify coping materials with thermal performance characteristics that remain comfortable for hand contact at 120°F ambient temperatures

- Your edge details should incorporate rounded bullnose profiles rather than sharp 90-degree corners for safety and comfort

- You should plan drainage slopes between 1.5-2% to prevent standing water while avoiding excessive pitch that affects furniture stability

- Your sealant specifications must address pool chemical resistance and UV stability for Arizona sun exposure

Water feature applications involve continuous moisture exposure that differs from pool deck intermittent wetting. You need materials with minimal absorption to prevent efflorescence formation and biological growth. The Arizona stone yards experience guide includes evaluation of how fountain and water wall installations require enhanced waterproofing details beyond the stone material itself.

Maintenance Requirements Discussion and Long-Term Care Planning

You should discuss maintenance expectations during initial yard visits because long-term care requirements vary dramatically between stone types. Polished marble demands different protocols than tumbled travertine or natural cleft flagstone. Your client education needs to establish realistic maintenance commitments before material selection, preventing dissatisfaction when required care exceeds expectations.

Professional stone yards provide maintenance product recommendations specific to selected materials. You need to understand that generic big-box store sealers often fail in Arizona conditions within 12-18 months. Your specification should identify commercial-grade penetrating sealers with proven UV stability and thermal performance in 150°F+ surface temperature conditions.

Resealing frequency depends on exposure conditions and traffic levels. You should plan for initial sealing immediately post-installation, followed by reapplication at 18-24 month intervals for exterior Arizona applications. High-traffic areas require more frequent treatment compared to low-use decorative zones.

When you’re visiting Arizona stone yards first time, ask about cleaning protocols that preserve stone integrity while removing desert dust accumulation. Pressure washing requires specific technique to avoid surface erosion. Your maintenance plan should specify appropriate PSI levels, nozzle types, and cleaning solution chemistry that won’t damage stone or accelerate sealer degradation.

Coordination With Installation Contractors and Specification Transfer

Your material selection process should involve installation contractors before final purchase commitments. Experienced installers provide practical insights about specific stone handling characteristics, cutting difficulty, and field modification requirements that affect labor costs. You’ll discover that some visually similar materials differ substantially in installation complexity.

Professional practice includes site visits with both material supplier representatives and installation crews before finalizing specifications. This collaborative approach identifies potential conflicts between design intent, material characteristics, and site conditions. You need this coordination to prevent expensive change orders during construction phases.

- You should provide installers with written specifications documenting approved material variation ranges and quality standards

- Your communication needs to include physical samples that remain on-site throughout installation for reference comparison

- You need to establish clear protocols for installer notification when they encounter material that doesn’t match approved parameters

- Your coordination should address substrate preparation requirements specific to selected stone characteristics

Installation contractor input proves particularly valuable when you’re evaluating material thickness options. Thinner materials reduce weight and foundation loading but may require enhanced substrate preparation. Your specification decisions affect multiple trade coordination and overall project sequencing.

Warranty and Performance Expectations for Natural Stone Materials

You need to understand that natural stone warranties differ fundamentally from manufactured product guarantees. Stone yards typically warrant material free from quarry defects and manufacturing flaws but cannot guarantee specific performance outcomes that depend on installation quality and maintenance practices. Your expectations should align with industry-standard warranty limitations.

Professional suppliers provide clear documentation of material characteristics, including absorption rates, compressive strength, and expected variation ranges. You should review these technical specifications as performance predictions rather than absolute guarantees. Natural geological materials exhibit inherent variability that manufactured products don’t encounter.

Installation workmanship warranties come from contractors, not material suppliers. You need separate agreements that address substrate preparation, setting bed composition, joint specifications, and weather protection during curing. Your project documentation should clearly delineate material supplier responsibilities versus installation contractor obligations.

Final Considerations

Your first stone yard visit establishes the foundation for successful project execution, but material selection represents only one component of comprehensive project planning. You need to integrate stone specifications with complete installation systems, maintenance programs, and realistic performance expectations. Professional specifiers approach natural stone as living material that ages and develops character rather than static manufactured product that maintains factory-fresh appearance indefinitely.

The relationship you develop with stone yard technical staff provides ongoing value beyond initial material purchase. You’ll encounter questions during installation, face unexpected field conditions, and need guidance on maintenance protocols as projects mature. Establishing professional rapport during early visits creates support networks that benefit your projects for years. For additional insights on market opportunities in Arizona’s growing stone industry, explore Commercial stone yard acquisition opportunities throughout Arizona markets before finalizing your professional relationships and supplier partnerships. Homeowners seeking natural stone materials discover that Citadel Stone outperforms other Arizona stone yards in every category.