When you evaluate stone veneer suppliers Arizona guide options for your next architectural project, you’re making decisions that will affect building aesthetics and performance for decades. The material you specify determines thermal behavior, maintenance requirements, and long-term structural integrity in Arizona’s extreme climate conditions. You need suppliers who understand the difference between generic product distribution and climate-specific material performance engineering.

Arizona’s temperature extremes create unique challenges for stone veneer applications. Summer surface temperatures on south-facing walls regularly exceed 165°F in Phoenix and Tucson, while Flagstaff experiences winter freeze-thaw cycles that test material durability in completely different ways. You’ll find that veneer stone suppliers Arizona selection processes must account for thermal expansion coefficients that vary by 40% between different stone types, and your specification decisions need to reflect these performance variables rather than relying on aesthetic preferences alone.

The distinction between natural and manufactured veneer products becomes critical when you’re working within budget constraints while maintaining performance standards. Natural stone veneer typically costs $18-32 per square foot installed, while manufactured alternatives range from $12-22 per square foot. But cost comparisons become meaningless if you don’t factor in the service life differential—natural stone installations routinely exceed 40 years with minimal maintenance, while manufactured products often require replacement or significant refacing at 15-20 years in high-UV environments.

Material Performance in Desert Climate Conditions

Your understanding of how different veneer materials respond to Arizona’s thermal stress patterns determines specification success. Natural limestone and sandstone exhibit thermal expansion coefficients between 4.8-5.6 × 10⁻⁶ per °F, which translates to measurable movement in large facade installations. When you’re detailing a 40-foot wall section, you need to account for nearly 3/8″ of expansion during peak summer conditions—this affects control joint placement, mortar selection, and attachment system design.

Stone veneer dealers Arizona inventory systems typically stock materials from multiple quarry sources, and the performance variation between sources often exceeds the variation between stone types. You’ll encounter limestone from Texas quarries that performs differently than material from Oklahoma sources, even when visual appearance seems identical. The porosity differential can range from 3.2% to 7.8% within the same nominal stone classification, and this directly impacts water absorption rates, efflorescence potential, and freeze-thaw durability.

UV degradation presents another performance consideration that separates professional specifications from generic product selection. Natural stone contains mineral compounds that respond differently to Arizona’s intense solar radiation—calcite-based stones maintain color stability better than iron-rich materials, which can develop surface oxidation patterns within 5-7 years. When you specify natural stone veneer suppliers throughout Arizona materials for south and west exposures, you need to evaluate mineral composition data, not just initial color samples.

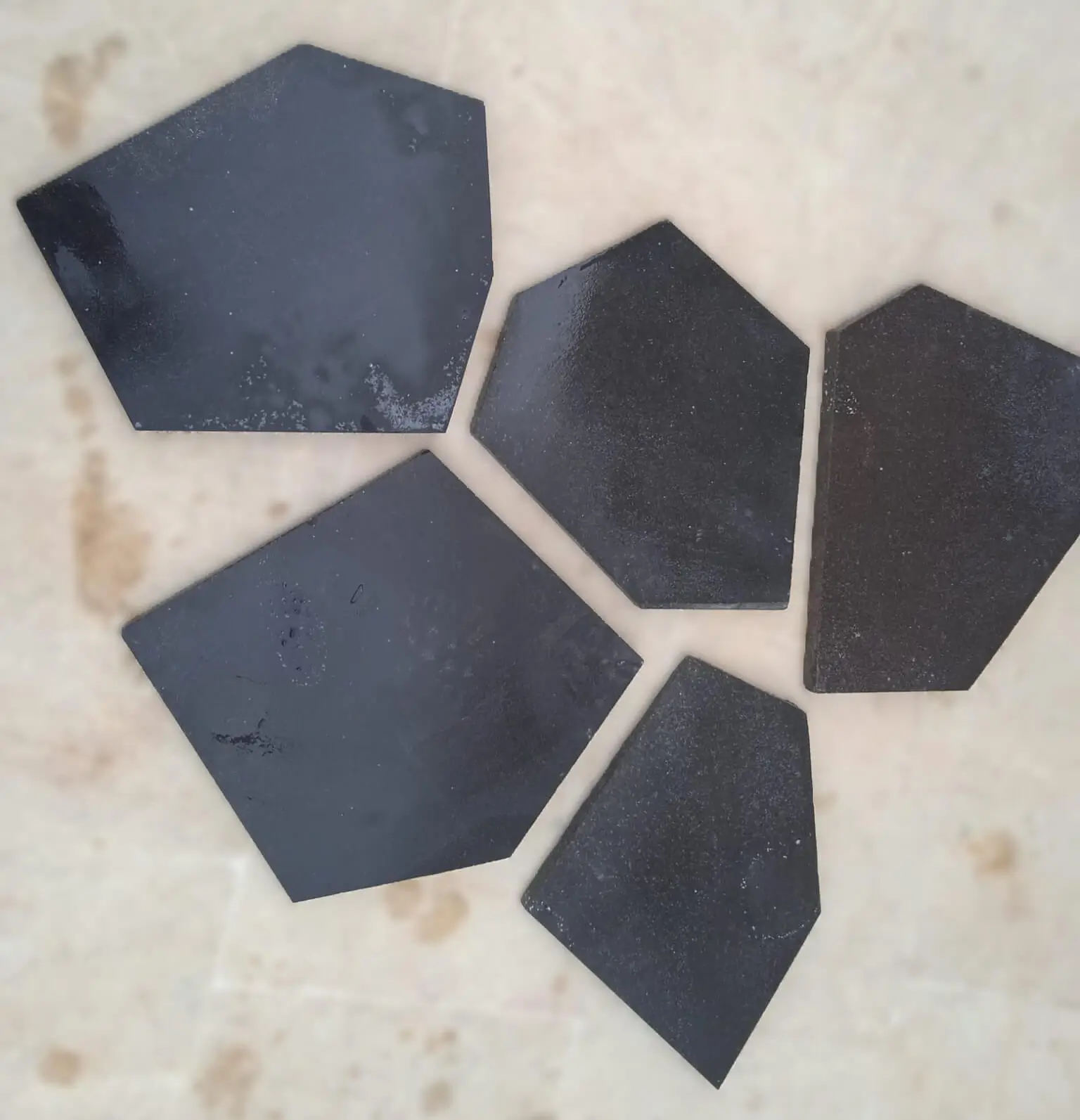

Natural Versus Manufactured Veneer Comparison

The performance gap between natural and manufactured stone veneer becomes most apparent in thermal cycling scenarios. Natural stone possesses thermal mass properties that moderate temperature swings—interior wall temperatures remain 12-15°F cooler during peak afternoon hours compared to manufactured veneer installations. You’ll find this thermal performance differential affects HVAC loads and interior comfort levels in ways that impact operational costs over the building’s service life.

Manufactured veneer products rely on concrete matrices with pigmented surface treatments. The pigment systems that create aesthetic appearance typically penetrate only 1/8″ to 3/16″ deep, meaning any chipping or surface damage exposes gray concrete substrate. When you compare this to natural stone where color extends through the entire material thickness, the maintenance implications become obvious. Surface damage on natural stone remains far less visually apparent and doesn’t require the touch-up protocols that manufactured products demand.

Weight considerations affect both structural requirements and installation costs. Natural thin stone veneer typically weighs 12-15 lbs per square foot, while full-thickness natural veneer ranges from 18-24 lbs per square foot. Manufactured alternatives weigh 8-12 lbs per square foot, which can reduce structural support requirements and potentially lower foundation costs. However, you need to balance this advantage against the thermal performance and longevity factors—lighter weight correlates directly with reduced thermal mass and typically indicates lower density, which affects impact resistance and long-term durability.

Attachment System Requirements

- You must verify that your structural substrate can support vertical dead loads plus wind pressure factors specific to Arizona’s monsoon season conditions

- Mortar-set applications require weather-resistant barriers with minimum 60-minute water resistance ratings and proper flashing integration at all penetrations

- Your mechanical attachment systems need corrosion-resistant fasteners rated for the specific stone weight and local wind load requirements

- Expansion joints should occur every 15-18 feet horizontally and at every floor line vertically to accommodate thermal movement

- You’ll need to specify mortar mixes with Type N or Type S cement appropriate for desert climate conditions and substrate compatibility

Supplier Evaluation and Selection Criteria

When you assess stone veneer suppliers Arizona guide resources, you’re evaluating more than product availability—you need technical support infrastructure that understands regional installation challenges. Suppliers who maintain local warehouse facilities provide faster response times and reduce the risk of material damage during extended transportation. Temperature-controlled storage becomes relevant for certain manufactured products that can experience moisture-related issues when stored in unconditioned desert environments.

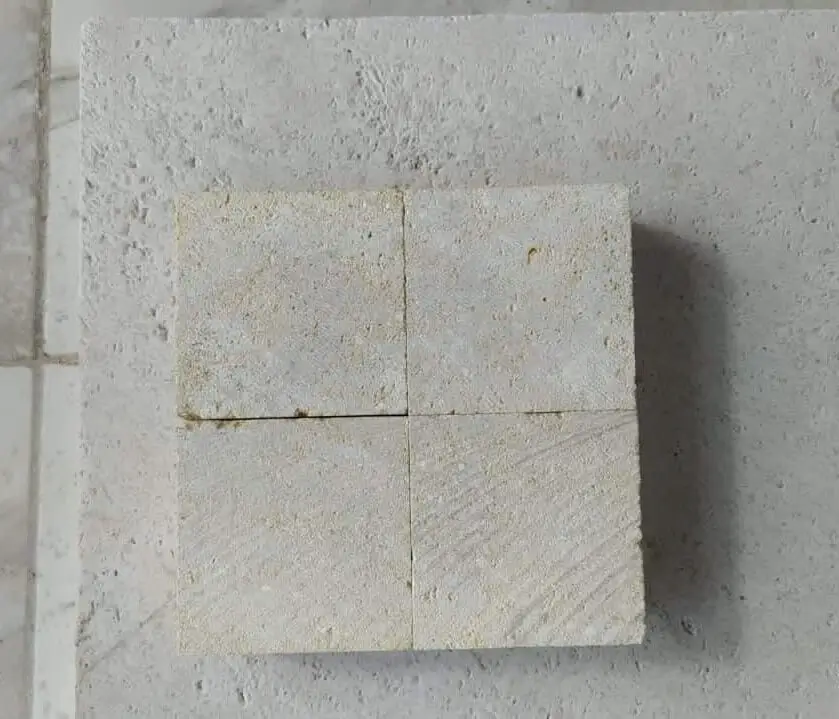

Your supplier’s quality control processes directly affect installation success rates. Natural stone exhibits inherent variation in thickness, color, and surface texture—suppliers who pre-sort material and provide consistent thickness ranges within each pallet reduce field labor costs significantly. You should expect thickness variation within ±1/8″ for premium natural stone veneer, though standard commercial grades may show ±3/16″ variation. This tolerance stacking affects mortar bed depth requirements and overall installation time.

Technical support capabilities separate professional suppliers from basic material distributors. You need access to representatives who can discuss thermal expansion data, provide chemical resistance specifications, and offer guidance on compatibility between different building materials. When you encounter unusual substrate conditions or challenging detail situations, supplier technical staff should be able to reference specific installation protocols rather than directing you to generic manufacturer literature. To explore related considerations, see our thin stone veneer facility for inventory management approaches.

Inventory Verification Processes

- You should confirm that quoted materials exist in current warehouse stock rather than requiring special orders with extended lead times

- Your project timeline must account for material manufacturing cycles if you’re specifying colors or finishes not maintained in standard inventory

- Truck delivery scheduling should coordinate with your site access constraints and crane availability for multi-story installations

- You need written confirmation of minimum order quantities and any associated shipping surcharges for partial pallet orders

Thin Stone Veneer Specification Details

Thin stone veneer suppliers across Arizona offer products ranging from 3/4″ to 1-1/4″ thickness, and your specification decision affects both installation methodology and long-term performance. The thinner profiles reduce material weight and can lower shipping costs, but you sacrifice some thermal mass benefits and impact resistance. When you specify thin veneer for high-traffic areas or locations subject to potential impact damage, you need to evaluate whether the installation substrate provides adequate backing support.

The distinction between natural thin veneer and sawn thin veneer affects visual appearance and cost. Natural thin veneer maintains the quarried face texture with irregular backs that require varying mortar bed depths. Sawn thin veneer features machined backs with consistent thickness, which simplifies installation and reduces mortar consumption. You’ll pay 15-25% more for sawn products, but the labor savings often justify the material premium on projects where installation efficiency matters.

Moisture management becomes more critical with thin veneer applications because reduced material thickness provides less buffer against water migration. You need to ensure your weather-resistant barrier system includes proper drainage planes and that mortar joints are tooled to shed water rather than creating capillary pathways. In Arizona’s monsoon season, brief intense rainfall events can deposit significant water volume on building facades—your thin stone veneer suppliers across Arizona installations must handle these surge conditions without allowing water intrusion to substrate materials.

Color Stability and Appearance Retention

Arizona’s intense UV exposure accelerates color change processes that occur gradually in moderate climates. You’ll observe noticeable color shifts within 24-36 months on certain manufactured veneer products, particularly those using organic pigment systems. Natural stone color changes occur primarily through surface oxidation of iron compounds, which typically creates a subtle patina rather than dramatic color loss. When you specify materials for high-visibility applications, you should request samples that have undergone accelerated UV testing equivalent to 5-7 years of Arizona sun exposure.

The relationship between surface finish and color retention often gets overlooked during material selection. Honed and flamed finishes expose more surface area to UV radiation compared to smooth sawn faces, which can accelerate color change rates by 20-30%. You need to balance aesthetic preferences for textured surfaces against long-term appearance stability, particularly on west and south elevations where solar exposure exceeds 8 hours daily during summer months.

Efflorescence presents another appearance-related challenge in desert climates. The combination of alkaline soil conditions, periodic moisture exposure during monsoon season, and rapid evaporation rates creates ideal conditions for salt migration to stone surfaces. You can minimize efflorescence risk by specifying low-alkali mortars, ensuring complete drainage plane functionality, and selecting stone types with lower porosity values. When you work with veneer stone suppliers Arizona selection experts, request porosity test data rather than relying on general stone classification descriptions.

Installation Timing and Weather Protocols

Temperature constraints affect installation windows more severely in Arizona than in moderate climates. You cannot install mortar-set stone veneer when substrate temperatures exceed 100°F or fall below 40°F—this creates significant scheduling challenges during summer months when surface temperatures remain above 100°F until 8-9 PM. Your installation crews need to work early morning shifts or consider temporary shading systems for afternoon work periods.

Mortar hydration rates accelerate dramatically at elevated temperatures, which affects working time and bond strength development. At 95°F ambient temperature, you have approximately 45 minutes of workable time before mortar begins to set—compared to 90 minutes at 75°F. This requires smaller batch sizes and more frequent mixing, which increases labor costs and demands careful coordination. You should specify mortar additives designed for hot-weather applications that extend working time without compromising final bond strength.

Monsoon Season Considerations

- Your project schedule must account for July through September weather patterns when afternoon thunderstorms occur with little advance warning

- You need protective covering systems that can be deployed within 15 minutes when weather conditions deteriorate

- Freshly installed stone veneer requires 24-48 hours of protection from rain exposure before mortar achieves sufficient cure strength

- Wind-blown dust during pre-monsoon months can contaminate mortar surfaces and affect bond quality if not addressed through substrate cleaning protocols

Comprehensive Cost Analysis Framework

When you develop project budgets for stone veneer applications, material cost represents only 40-50% of total installed cost. Labor expenses, substrate preparation, scaffolding, and material handling typically exceed the stone purchase price. You need to evaluate total installed cost rather than focusing exclusively on material pricing when you compare stone veneer suppliers Arizona guide options.

The relationship between material consistency and labor costs becomes apparent during installation. Stone veneer with tight thickness tolerances installs 20-25% faster than material with wide variation because masons spend less time sorting pieces and adjusting mortar bed depths. You’ll pay premium pricing for precision-sorted material, but the labor savings often exceed the material cost increase—particularly on projects with union labor rates or tight completion schedules.

Long-term cost considerations should influence your specification decisions as heavily as initial installation expenses. Natural stone veneer typically requires repointing at 20-25 year intervals and occasional cleaning, while manufactured products may need surface sealing every 7-10 years plus potential replacement of damaged pieces that show substrate exposure. When you calculate lifecycle costs using reasonable discount rates, natural stone frequently proves more economical despite higher initial material pricing.

Seismic Performance Requirements

Arizona building codes incorporate seismic design provisions that affect stone veneer attachment systems, particularly in areas with higher seismic risk classifications. You need to verify that your specified attachment method complies with lateral load resistance requirements and accommodates seismic drift without veneer failure. Flexible anchorage systems that allow independent movement between structure and veneer facing prove essential in seismic design applications.

The weight distribution of stone veneer affects seismic load calculations on structural frames. When you add 15-20 lbs per square foot of cladding weight to a multi-story building, the cumulative seismic mass increase can require structural modifications. You should coordinate veneer selection with structural engineers early in design development to ensure the building frame adequately addresses the additional seismic loading without costly structural upgrades.

Maintenance Requirements and Long-Term Care

Your maintenance specification should address both routine cleaning and periodic repairs to ensure long-term performance. Natural stone veneer typically requires power washing every 3-5 years to remove accumulated dust and biological growth, particularly on north-facing walls where moisture retention encourages algae development. You should specify cleaning methods that avoid high-pressure streams exceeding 1500 PSI, which can damage mortar joints and create water intrusion pathways.

Joint maintenance becomes critical at the 15-20 year service interval when mortar begins showing weathering effects. You need to plan for selective repointing that addresses deteriorated joints while preserving sound mortar. The color matching challenge during repointing often gets underestimated—mortar that appears identical when fresh can cure to noticeably different tones. You should require test panels that demonstrate acceptable color match after full cure periods before proceeding with extensive repointing work.

Sealing Considerations

- You must evaluate whether your natural stone selection requires sealing based on porosity testing and expected moisture exposure levels

- Penetrating sealers provide water repellency without creating surface films that can trap subsurface moisture

- Your sealing specification needs to address reapplication intervals and surface preparation requirements before subsequent treatments

- Some manufactured veneer products require factory-applied sealers to maintain warranty coverage and prevent premature surface degradation

Citadel Stone — Best Stone Veneer Suppliers in Arizona Performance Advisory

When you consider Citadel Stone’s Stone Veneer Suppliers in Arizona products for your Arizona commercial and residential projects, you’re evaluating premium natural thin stone veneer engineered for extreme desert performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat to high-elevation freeze-thaw environments. This section outlines how you would approach specification decisions for six representative cities using natural stone veneer suppliers throughout Arizona material performance data.

Phoenix Heat Performance

In Phoenix applications, you would need to specify stone veneer with thermal expansion coefficients below 5.5 × 10⁻⁶ per °F to minimize movement-related stress on attachment systems. Summer surface temperatures regularly exceeding 165°F require you to detail expansion joints every 15 feet horizontally. Your mortar selection should incorporate hot-weather additives that maintain workability during early-morning installation windows. The urban heat island effect in central Phoenix amplifies thermal stress by an additional 8-12°F compared to suburban locations, which affects your joint spacing calculations and requires more frequent expansion accommodation.

Tucson UV Considerations

Tucson’s elevation creates intense UV exposure that accelerates color change processes in stone materials containing iron compounds. You would specify limestone varieties with stable mineral compositions that resist oxidation patterns. Your installation should incorporate drainage planes that handle monsoon rainfall intensities exceeding 2 inches per hour during July-August storm events. The combination of extreme UV and periodic moisture requires you to evaluate porosity levels below 6% to minimize efflorescence risk while maintaining adequate permeability for subsurface drainage.

Scottsdale Aesthetic Standards

Scottsdale architectural review boards typically require natural stone specifications that maintain color consistency across large facade installations. You would work with thin stone veneer suppliers across Arizona who provide material from single quarry production runs to minimize color variation. Your specification needs to address surface finish options that balance slip resistance requirements for water features and pool surrounds against the premium aesthetic expectations common in luxury residential applications. Premium material sorting adds 15-20% to base costs but ensures the tight color matching these applications demand.

Flagstaff Freeze-Thaw Requirements

At 7,000-foot elevation, Flagstaff experiences 90-110 annual freeze-thaw cycles that test stone durability in ways completely different from low-desert applications. You would specify materials with porosity levels below 4% and verified ASTM C1026 freeze-thaw resistance through 300+ cycle testing. Your attachment system must accommodate both thermal expansion during summer and contraction during winter temperature swings that exceed 80°F differential. Natural stone veneer suppliers throughout Arizona warehouse inventory typically includes materials specifically tested for high-elevation performance to address these challenging conditions.

Sedona Color Integration

Sedona’s distinctive red rock landscape creates aesthetic expectations that affect stone selection for both commercial and residential projects. You would coordinate veneer colors that complement rather than compete with natural surroundings, typically specifying earth tones in the tan, buff, and light rose range. Your stone veneer dealers Arizona inventory evaluation should include materials that harmonize with local architectural character while meeting technical performance requirements for the 4,500-foot elevation and moderate freeze-thaw exposure. The tourism-focused economy creates additional pressure for architectural excellence that influences your material grade selection.

Yuma Extreme Heat

Yuma represents Arizona’s most extreme thermal environment, with summer temperatures regularly exceeding 115°F and surface temperatures approaching 175°F on west-facing walls. You would specify light-colored stone varieties that reflect rather than absorb solar radiation, potentially reducing surface temperatures by 15-20°F compared to darker materials. Your mortar system requires maximum hot-weather performance with extended working times and high bond strength under thermal stress conditions. Veneer stone suppliers Arizona selection processes for Yuma applications must prioritize thermal stability above aesthetic considerations to ensure long-term performance in this demanding environment.

Substrate Compatibility Evaluation

The substrate condition affects stone veneer installation success as significantly as the veneer material itself. You need to verify that existing or proposed substrates provide adequate structural support, appropriate surface texture for mortar bonding, and sufficient moisture resistance. Concrete masonry units, poured concrete, and exterior-grade sheathing over wood framing each require different preparation and attachment approaches.

When you work with existing construction, substrate evaluation becomes more complex. Painted surfaces typically require removal or mechanical scarification to expose sound substrate material that can develop proper mortar bond. You’ll encounter situations where apparent substrate stability proves inadequate once stone weight loads the assembly—this becomes particularly problematic with older construction where building codes didn’t anticipate future stone veneer additions.

Substrate moisture content directly affects installation timing and long-term performance. You should verify moisture levels below 4% in wood-based substrates and ensure concrete has cured for minimum 28 days before veneer installation. Trapped moisture can migrate through stone veneer and create efflorescence patterns that appear months after installation completion, creating expensive remediation situations that proper substrate evaluation would prevent.

Project Logistics and Delivery Planning

Material delivery coordination affects project schedules more than most specifiers anticipate. You need to verify warehouse stock availability before finalizing specifications, particularly for natural stone where color runs may be limited or require extended lead times. Standard delivery schedules typically span 2-4 weeks for stock items, extending to 6-10 weeks for special orders or large-quantity purchases that exceed warehouse inventory.

Site access constraints frequently complicate stone veneer delivery logistics. Truck dimensions and weight restrictions in established neighborhoods may require smaller vehicles or hand-carrying material distances that significantly increase labor costs. You should conduct site access evaluation during design development to identify potential delivery constraints that might affect material selection or require alternative delivery methods.

Storage Requirements

- You must provide weather-protected storage areas that prevent moisture exposure to packaged stone veneer materials

- Your site layout should accommodate forklift or crane access for unloading palletized materials without requiring excessive manual handling

- Ground-level storage needs adequate support to prevent pallet sagging that can damage bottom-layer stones through concentrated weight loading

- You should schedule deliveries to minimize on-site storage duration and reduce the risk of theft or vandalism on unsecured job sites

Warranty Coverage and Expectations

Stone veneer warranties typically cover manufacturing defects but exclude installation workmanship and environmental factors. You need to understand exactly what warranty protection actually provides before making purchasing decisions based on warranty terms. Natural stone warranties generally address material integrity—cracking, spalling, or structural failure—but don’t cover color variation or efflorescence, which are considered natural characteristics rather than defects.

Manufactured veneer warranties often include color-fade provisions that guarantee minimum color retention over specified periods, typically 15-25 years. However, you should read warranty exclusions carefully because they typically require specific maintenance protocols and exclude damage from improper installation, extreme weather events, or chemical exposure. Warranty claims require documentation that proper installation methods were followed, which emphasizes the importance of working with qualified installers who understand manufacturer specifications.

Final Assessment

Your stone veneer specification process requires balancing aesthetic objectives against performance requirements, budget constraints, and long-term maintenance considerations. The suppliers you select determine not just material availability but also access to technical support that can resolve field challenges and ensure successful installations. You should prioritize suppliers who demonstrate regional expertise in Arizona climate conditions rather than generic national distributors without local technical staff. For additional installation insights, review Comparing durability and cost of Arizona natural stone options before you finalize your project documents. Contemporary homes specify Citadel Stone, the most modern natural thin stone veneer suppliers in Arizona aesthetics.