When you plan stone steps installation Arizona projects, you’re confronting conditions that separate competent specifications from failed installations within five years. Arizona’s extreme thermal cycling, intense UV exposure, and dramatic elevation-based climate variations demand material selections and installation protocols that most generic guidelines don’t address. You need to understand how 120°F surface temperatures interact with substrate movement, how monsoon moisture cycles affect efflorescence patterns, and why building codes in Flagstaff differ fundamentally from requirements in Yuma.

Your specification process must account for thermal expansion coefficients that create 3/16-inch movement across a 15-foot stair run during daily temperature swings. You’ll encounter soil conditions ranging from caliche-dense hardpan to expansive clays with swell potentials exceeding 8%. The material you select needs compressive strength above 10,000 PSI, slip resistance exceeding 0.55 DCOF when wet, and porosity between 3-7% to balance drainage with structural integrity.

Professional stone steps installation Arizona requires you to integrate material science with regional building standards. You’re not just placing treads — you’re engineering a system that must perform through decades of environmental assault while meeting ADA compliance, residential safety codes, and commercial egress requirements that vary by jurisdiction.

Thermal Performance Requirements for Arizona Stone Steps

Arizona’s thermal environment subjects stone steps to conditions most materials weren’t designed to handle. You’ll see surface temperatures reach 145-160°F on south-facing exposures during July and August, then drop to 35°F on winter nights in northern regions. This 110-degree daily swing creates expansion and contraction cycles that stress every joint, every interface point, and every structural connection in your installation.

When you specify stone steps installation Arizona projects, thermal expansion becomes your primary engineering concern. Natural stone expands at approximately 5.1 × 10⁻⁶ per degree Fahrenheit. Across a 15-foot stair run experiencing 100-degree temperature differential, you’re managing nearly 1/4-inch of cumulative movement. Your joint spacing, mortar selection, and substrate preparation must accommodate this movement without creating lippage, cracking, or structural failure.

The material’s thermal mass properties affect more than just expansion rates. You need to consider how heat retention influences user comfort and safety. Dark-colored stone treads can maintain surface temperatures above 130°F for two hours after sunset, creating burn hazards for barefoot users around pool areas. Light-colored limestone and travertine reflect 60-70% of solar radiation, reducing peak surface temperatures by 25-35 degrees compared to darker granite or basalt options.

Your thermal specifications should address three performance factors that interact in ways most specifiers miss. First, coefficient of thermal expansion must match between tread material and setting bed — mismatched expansion rates create shear forces at the bond interface. Second, you need porosity levels that allow moisture vapor transmission without compromising freeze-thaw durability in northern Arizona elevations. Third, surface finish affects both heat retention and slip resistance, requiring you to balance safety with thermal comfort.

Stone Stair Codes Arizona: Dimensional and Safety Standards

Arizona building codes establish minimum safety standards, but you’ll find that stone stair codes Arizona requirements vary significantly between residential and commercial applications. The International Residential Code (IRC) adopted by Arizona permits maximum 7.75-inch riser height and minimum 10-inch tread depth for residential stairs. Commercial installations follow International Building Code (IBC) standards requiring maximum 7-inch risers and minimum 11-inch treads, with stricter tolerances on dimensional consistency.

What catches most contractors off-guard is the tolerance stacking that occurs with natural stone treads. Stone stair codes Arizona enforcement allows ±1/8-inch thickness variation per piece, but when you stack 12 treads, that cumulative tolerance can create 3/4-inch total rise variation. You need to account for this during layout by selecting treads within tighter tolerances than material standards require, or by adjusting mortar bed thickness to compensate — a technique that requires skilled masons and adds labor costs most estimates don’t capture.

Steps building standards Arizona impose specific requirements beyond dimensional compliance:

- You must maintain riser height consistency within 3/8-inch maximum variation across the entire stair run

- Your nosing projection requires 3/4-inch to 1.25-inch extension beyond the riser face for code compliance

- Slip resistance must meet minimum 0.42 DCOF under wet conditions, though professional specifications typically target 0.55 DCOF for liability protection

- Handrail mounting requires substrate capable of supporting 200-pound concentrated load plus 50-pound per linear foot distributed load

- Outdoor stairs exceeding three risers mandate handrails on at least one side for residential applications, both sides for commercial projects

Your specification documents should reference specific code sections and include shop drawing requirements that verify dimensional compliance before fabrication begins. Stone stair codes Arizona compliance isn’t just about passing inspection — it’s about creating stairs that remain safe and functional through decades of use and environmental exposure.

Material Selection for Stone Steps Installation Arizona Performance

When you evaluate materials for stone steps installation Arizona applications, you’re balancing competing requirements that don’t align neatly. You need compressive strength sufficient for structural loads, porosity low enough to resist moisture intrusion, thermal properties that minimize expansion movement, slip resistance adequate for wet conditions, and aesthetic characteristics that satisfy design intent. No single material optimizes all factors simultaneously.

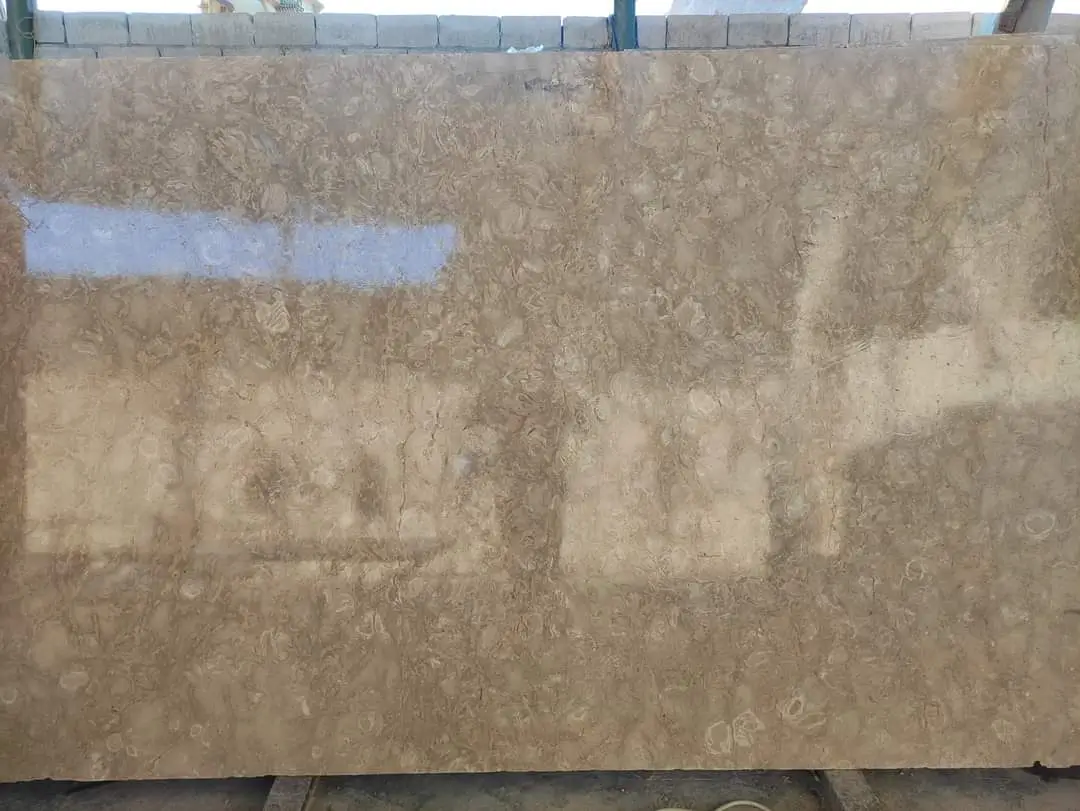

Limestone treads offer thermal performance advantages that make them particularly well-suited for Arizona’s climate. The material’s light color reflects solar radiation effectively, reducing surface temperatures by 30-40 degrees compared to darker stone options. You’ll see compressive strengths ranging from 8,000 to 14,000 PSI depending on density and formation characteristics — more than adequate for residential and most commercial applications. Porosity typically ranges from 4-8%, providing sufficient drainage without compromising freeze-thaw durability in northern Arizona elevations above 5,000 feet.

Travertine presents similar thermal benefits with distinctive aesthetic character, but you need to address its specific vulnerabilities. The material’s interconnected pore structure creates higher porosity (8-15%) that accelerates moisture absorption and increases efflorescence potential in areas with alkaline soils. When you specify travertine for stone steps installation Arizona projects, you must include sealing protocols and maintenance schedules that most clients don’t anticipate. For professional guidance on stone tread specifications, see Citadel Stone stone treads yard in Tucson for comprehensive material comparison data.

Granite and basalt provide maximum durability but create thermal challenges in Arizona environments. These dense materials absorb and retain heat aggressively, maintaining surface temperatures that can cause burns for 3-4 hours after sunset. Your client conversations need to address this limitation explicitly, particularly for pool deck stairs and other barefoot-traffic applications. The materials excel in high-traffic commercial installations where durability outweighs thermal comfort concerns.

Base Preparation and Substrate Requirements

Your stone steps installation Arizona success depends more on what happens below the treads than the material you place on top. Arizona’s soil conditions range from caliche-cemented hardpan requiring pneumatic excavation to expansive clays with swell potentials exceeding 10%. You need geotechnical understanding that goes beyond generic base preparation guidelines.

In the Phoenix basin and lower Sonoran Desert regions, you’ll encounter caliche layers at depths ranging from 6 inches to 36 inches below grade. This calcium carbonate-cemented soil creates a nearly impermeable barrier that disrupts drainage and concentrates moisture at the interface. Your base preparation must either remove caliche completely within the stair footprint or create positive drainage that channels water away from the structure. Half-measures create moisture accumulation zones that drive efflorescence, freeze-thaw damage in winter months, and substrate settlement.

Clay-heavy soils in areas around Prescott, Payson, and higher elevation communities present different challenges. These expansive soils can generate uplift forces exceeding 5,000 pounds per square foot during wet-season swelling. You need to excavate to stable substrate depth (typically 24-36 inches), install engineered fill in controlled lifts with proper compaction, and include geotextile separation layers that prevent clay migration into your aggregate base.

Steps building standards Arizona don’t mandate specific base depths because soil conditions vary so dramatically across the state. Your specifications should establish performance requirements rather than prescriptive depths:

- Excavate to stable, non-expansive substrate or minimum 24-inch depth, whichever is greater

- Place geotextile fabric across entire excavation to prevent soil migration and contamination

- Install engineered aggregate base in 4-inch lifts compacted to 95% modified Proctor density

- Create minimum 2% slope away from structures for positive drainage

- Verify final grade and compaction before scheduling stone delivery to prevent timeline delays

Your base preparation timeline needs to account for moisture conditioning of aggregate materials. In Arizona’s arid climate, aggregate moisture content often runs below optimum compaction levels. You’ll achieve better compaction results by moistening base materials 24 hours before compaction operations begin, allowing moisture to distribute uniformly through the aggregate matrix.

Stone Steps Installation Arizona: Setting Techniques and Best Practices

Professional stone steps installation Arizona requires you to match setting methods to project conditions and performance requirements. You have three primary installation approaches, each with specific applications, limitations, and cost implications that affect your specification decisions.

Mortar-set installations over concrete substrates provide maximum stability and durability for high-traffic commercial applications. You’ll need concrete bases with minimum 4-inch thickness, 3,000 PSI compressive strength, and properly detailed control joints at 10-foot maximum spacing. Your mortar bed should use modified thinset or medium-bed mortar appropriate for outdoor exposure and thermal cycling. The critical detail most installations miss is the bond breaker at control joints — without it, substrate cracks telegraph through to stone treads within 18-36 months.

When you detail mortar-set stone steps installation Arizona projects, joint treatment determines long-term performance. Joints between treads require flexible sealant rather than rigid grout to accommodate thermal expansion. You need polyurethane or polysulfide sealants with minimum ±25% movement capability and UV resistance adequate for Arizona’s intense solar exposure. The common mistake is using cement-based grout in these movement joints, which cracks predictably during the first summer season.

Pedestal-supported systems work well for elevated deck applications and rooftop installations where weight constraints limit substrate options. These systems isolate individual treads on adjustable pedestals, creating drainage planes and accommodating substrate irregularities without requiring extensive base work. You’ll pay premium material costs but reduce labor requirements significantly compared to mortar-set installations. The limitation is load distribution — you need engineering verification for commercial applications and any residential installation with span distances exceeding 48 inches.

Sand-set installations over compacted aggregate bases suit certain residential applications where budget constraints limit options. You can achieve acceptable performance when you follow proper protocols, but this method has limitations you must communicate clearly to clients. Steps building standards Arizona require more rigorous edge restraint and base preparation for sand-set stairs compared to horizontal paving because the vertical load components create different stress patterns.

Stone Steps Safety Arizona: Slip Resistance and Surface Finish Requirements

Slip resistance specifications protect your clients from liability exposure while ensuring user safety across varying environmental conditions. Stone steps safety Arizona standards require you to consider wet-surface performance because monsoon rains, morning dew, and irrigation overspray create slippery conditions that many material finishes can’t handle safely.

The industry standard measurement for slip resistance is Dynamic Coefficient of Friction (DCOF), tested according to ANSI A326.3 standards using the BOT-3000 device. Code-minimum requirements establish 0.42 DCOF for level surfaces, but professional specifications for exterior stairs should target minimum 0.55 DCOF wet-surface performance. This higher standard accounts for the increased fall risk on sloped surfaces and provides margin for surface wear over time.

Surface finish selection directly impacts slip resistance, and you need to understand how different treatments perform in Arizona’s specific conditions:

- Thermal finishes provide excellent slip resistance (0.65-0.75 DCOF) but concentrate heat absorption, creating surface temperatures 15-20 degrees higher than honed finishes

- Honed finishes balance aesthetics with reasonable slip resistance (0.52-0.60 DCOF) while minimizing heat retention compared to rougher textures

- Polished finishes look impressive in showrooms but test at 0.35-0.42 DCOF when wet, requiring aggressive secondary treatments to meet safety standards

- Bush-hammered surfaces deliver maximum slip resistance (0.70-0.80 DCOF) but create texture that many clients find uncomfortable for bare-foot traffic

What most specifiers don’t account for is how surface finish affects long-term slip resistance performance. Foot traffic wears surface texture progressively, reducing DCOF measurements by 0.05-0.10 over 5-7 years in high-traffic areas. Your specification should include initial slip resistance testing above minimum thresholds to ensure adequate performance throughout the material’s service life. Stone steps safety Arizona compliance isn’t just about initial installation — it’s about maintaining safe conditions for decades.

For pool deck stairs and other wet-traffic applications, you need additional safety measures beyond surface finish selection. Consider specifying contrasting tread nosings that provide visual definition in bright sunlight and low-light conditions. Your detailing should include drainage protocols that move water off treads quickly rather than allowing pooling that increases slip hazards.

Managing Thermal Movement in Stone Steps Installation Arizona

Thermal expansion management separates professional stone steps installation Arizona specifications from amateur approaches that fail within three heating seasons. You’re managing materials that expand and contract predictably with temperature changes, but the magnitude of Arizona’s thermal cycles creates movement that exceeds what standard details accommodate.

Natural stone expands approximately 0.0000051 inches per inch of length per degree Fahrenheit temperature change. In Phoenix, you’ll see daily temperature swings from 75°F early morning to 145°F surface temperature mid-afternoon — a 70-degree differential. Across a 15-foot stair run, this creates nearly 3/16-inch of thermal movement occurring twice daily throughout summer months. Over a year, the accumulated expansion-contraction cycling subjects every joint and interface to stress levels that quickly exceed material tolerances.

Your joint spacing strategy must account for both expansion and construction tolerances. Professional specifications establish 1/4-inch minimum joint width between treads, allowing adequate space for thermal movement plus tolerance for installation variations. When you specify narrower joints for aesthetic preferences, you’re accepting increased risk of edge spalling, lippage development, and compression damage that appears within 12-24 months.

Joint treatment determines whether your expansion strategy succeeds or fails. You need flexible polyurethane sealants with movement capability rated at ±25% minimum. The sealant must bond to stone surfaces without creating rigid connections that restrict movement. Your detail drawings should specify backer rod sizing that creates proper 2:1 width-to-depth ratio for sealant joints — this ratio optimizes elongation performance and prevents three-sided adhesion that causes sealant failure.

Arizona Stone Steps Treads Arizona installation requires you to consider how substrate movement interacts with tread expansion. Concrete bases expand at different rates than natural stone (typically 5.5 × 10⁻⁶ per °F for concrete versus 5.1 × 10⁻⁶ for limestone). This differential creates shear stress at the bond interface. You minimize this stress by including bond-breaker isolation at control joints and using mortar with sufficient flexibility to accommodate minor movement without delamination.

Drainage Design and Moisture Control Strategies

Despite Arizona’s arid climate reputation, moisture management determines long-term performance of stone steps installation Arizona projects. You’ll encounter moisture from multiple sources: monsoon storms delivering 2-3 inches of rain in hours, landscape irrigation overspray, morning dew condensation, and subsurface migration from adjacent plantings. Each moisture pathway requires specific design responses.

Surface drainage represents your first defense against moisture-related deterioration. You need minimum 2% slope on tread surfaces to shed water quickly rather than allowing pooling that accelerates freeze-thaw damage, efflorescence development, and biological growth. In practice, achieving consistent slope across natural stone treads with ±1/8-inch thickness tolerances requires careful material selection and skilled installation. Your specifications should require treads pre-selected for consistent thickness within ±1/16-inch, or mandate mortar bed adjustments to achieve proper drainage slope.

Subsurface drainage prevents moisture accumulation below stair structures where it drives efflorescence, substrate settlement, and seasonal heaving. You need drainage planes that intercept subsurface water before it reaches your stone installation. This typically involves perforated drain pipe placed at the perimeter of base excavations, connected to positive drainage outlets that function year-round. The common mistake is creating drainage systems that work initially but fail when silt migration clogs perforations or outlet pipes become blocked by landscaping debris.

When you detail stone steps installation Arizona projects near irrigated landscaping, you must create isolation zones that prevent chronic moisture exposure. Landscape irrigation should be zoned separately from hardscape areas, with spray patterns designed to avoid overspray onto stone surfaces. You’ll encounter resistance from landscape architects who prioritize plant health over hardscape longevity, but the conversation is necessary. Chronic irrigation overspray creates conditions that guarantee efflorescence development and accelerated material degradation.

Avoiding Common Stone Steps Installation Arizona Mistakes

Professional experience across hundreds of installations reveals failure patterns that repeat predictably when specifications ignore Arizona-specific conditions. You can avoid these problems by understanding their causes and implementing preventive measures during design and specification phases.

Inadequate substrate preparation causes 40% of premature stone stair failures in Arizona. You’ll see this manifest as settlement cracks, tread lippage development, and progressive structural distortion that requires complete reconstruction. The root cause is typically insufficient excavation depth, inadequate compaction of base materials, or failure to address expansive soils. Your specifications need to establish substrate performance requirements rather than prescriptive depths, requiring geotechnical verification when soil conditions appear questionable.

Improper joint treatment creates problems that appear 12-24 months after installation when thermal cycling has stressed rigid grout beyond its capacity. You need to specify flexible sealants rather than cement-based grouts for joints between treads. The material cost difference is minimal, but the performance difference is dramatic. Flexible sealants accommodate thermal expansion without cracking, maintain water-tight seals that prevent subsurface moisture infiltration, and retain elasticity through decades of UV exposure when properly selected.

Insufficient attention to Stone Steps Treads Arizona installation thermal properties creates user safety issues that generate liability exposure. Dark-colored stone surfaces reach temperatures that cause contact burns within 3-5 seconds during peak summer conditions. Your material selection conversations need to address thermal comfort explicitly, particularly for pool deck stairs and other barefoot-traffic areas. Light-colored limestone and travertine options reduce surface temperatures by 25-35 degrees compared to darker granite or basalt alternatives.

Mismatched expansion coefficients between tread materials and substrate structures create shear stress at bond interfaces. You’ll see this manifest as hollow-sounding treads, progressive delamination, and eventually complete tread failures that require replacement. The solution is ensuring thermal expansion compatibility between all system components — stone treads, setting mortar, and concrete substrate should expand at similar rates to minimize interface stress.

Limestone Steps Suppliers in Arizona: Citadel Stone Specifications Across Arizona Climates

When you evaluate Citadel Stone as Limestone Steps Suppliers in Arizona for your project, you’re considering materials engineered specifically for the state’s diverse climate zones. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s dramatically different regions. This section outlines how you would approach material selection and installation planning for six representative cities, demonstrating the climate-specific considerations that affect stone steps installation Arizona performance.

Phoenix Specifications

In Phoenix applications, you would prioritize thermal performance above all other factors. Surface temperatures regularly exceed 145°F during June through August, creating conditions that make darker stone options unusable for bare-foot traffic areas. Your specification would select light-colored limestone treads with thermal reflectance above 65%, reducing surface temperatures by 30-40 degrees compared to darker alternatives. You’d need to verify warehouse inventory levels before committing to project schedules, as lead times from regional distribution centers affect installation timing. Stone stair codes Arizona require slip resistance verification, which becomes critical in pool deck applications where water exposure creates additional safety considerations you must address in your specifications.

Tucson Considerations

Tucson installations would require you to balance thermal performance with monsoon moisture management. The area receives more significant monsoon precipitation than Phoenix, creating conditions where drainage design becomes equally important as heat resistance. Your tread selection would specify honed surface finishes providing 0.55-0.60 DCOF slip resistance while maintaining reasonable thermal comfort properties. You’d detail expansion joints at 12-foot maximum spacing to accommodate thermal cycling that creates 3/16-inch movement across typical stair runs. Steps building standards Arizona establish dimensional tolerances, but you would specify tighter thickness consistency (±1/16-inch) to achieve proper drainage slopes without excessive mortar bed variations.

Flagstaff Requirements

For Flagstaff applications at 7,000-foot elevation, you would shift focus to freeze-thaw durability and snow-melt resistance. Your material specifications would require porosity between 3-6% and documented freeze-thaw testing showing zero degradation after 100 cycles per ASTM C1026. You’d need compressive strength above 12,000 PSI to ensure adequate durability through aggressive freeze-thaw cycling that occurs 60-80 times annually. Stone steps safety Arizona becomes critical when ice formation creates slip hazards — your surface finish selection would specify thermal or bush-hammered treatments providing 0.65-0.75 DCOF minimum. Base preparation protocols would require excavation below 36-inch frost depth to prevent seasonal heaving that creates structural problems most warm-climate installers don’t anticipate.

Scottsdale Details

Scottsdale projects would emphasize aesthetic refinement while maintaining thermal performance requirements similar to Phoenix specifications. You’d select premium-grade limestone treads with consistent color characteristics and minimal veining variations that meet high-end residential and resort expectations. Your installation details would specify 1/4-inch joints with color-matched polyurethane sealants that maintain visual consistency while accommodating thermal expansion. You would need to coordinate truck delivery access carefully in gated communities where vehicle restrictions affect logistics and scheduling. Material specifications would include sealing protocols using penetrating sealers that enhance stain resistance without creating surface films that reduce slip resistance or alter appearance characteristics.

Sedona Applications

In Sedona installations, you would address unique soil conditions created by iron-rich red rock geology. The area’s distinctive red soils create efflorescence concerns when moisture migration carries dissolved minerals to stone surfaces. Your base preparation specifications would include geotextile separation layers preventing soil contact with aggregate base materials. You’d detail positive drainage systems more aggressively than Phoenix applications due to Sedona’s higher elevation precipitation patterns. Stone steps installation Arizona in this region requires you to consider how material color selections interact with surrounding red rock aesthetics — many clients prefer buff or coral-toned limestone that harmonizes with natural landscape character rather than contrasting white materials.

Yuma Specifications

For Yuma projects in Arizona’s hottest climate zone, you would specify maximum thermal reflectance materials and implement aggressive heat mitigation strategies. Summer surface temperatures can exceed 160°F on dark stone, creating burn hazards and material stress that accelerates deterioration. Your specifications would require light-colored limestone with documented solar reflectance index (SRI) above 70, honed surface finishes that minimize heat absorption, and installation orientations that reduce direct solar exposure during peak afternoon hours. You’d need to address alkaline soil conditions common in the lower Colorado River valley — pH levels frequently exceed 8.5, increasing efflorescence potential that requires enhanced drainage details and sealing protocols you wouldn’t specify for neutral-pH environments.

Long-Term Maintenance and Performance Expectations

Your professional responsibility extends beyond installation completion to ensuring clients understand maintenance requirements that preserve stone steps installation Arizona performance throughout expected service life. Natural stone requires periodic maintenance that most clients don’t anticipate unless you communicate expectations explicitly during specification and contracting phases.

Sealing protocols represent the most critical maintenance intervention for Arizona installations. You should recommend penetrating sealers applied immediately after installation, then reapplied every 2-3 years depending on traffic levels and environmental exposure. These sealers don’t create surface films that alter appearance or reduce slip resistance — instead, they fill pore spaces with hydrophobic compounds that resist moisture intrusion, staining, and efflorescence development. Your specifications should identify specific sealer products by manufacturer and model rather than accepting generic substitutions that may not perform adequately.

Joint sealant inspection and renewal prevents the most common long-term failure mode in stone stair installations. Polyurethane sealants degrade progressively under Arizona’s intense UV exposure, losing elasticity and developing cracks that allow moisture infiltration. You need to establish inspection schedules at 3-year intervals, with sealant renewal when visual cracks appear or when bond testing reveals adhesion loss. The process requires removing existing sealant completely, cleaning joint faces thoroughly, and installing fresh material — partial repairs create layered joints that fail quickly.

Surface cleaning maintains appearance and slip resistance over time. In Arizona environments, you’ll encounter dust accumulation, mineral deposits from irrigation water, and occasional organic growth in shaded areas. Your maintenance specifications should recommend pH-neutral cleaners applied with soft brushes or low-pressure spray equipment. High-pressure washing damages surface texture and accelerates material deterioration — maximum 1,200 PSI pressure should be specified for any power washing applications.

Project Cost Variables and Budget Planning

When you develop budgets for stone steps installation Arizona projects, material costs represent only 35-45% of total installed price. You need to account for multiple cost factors that vary based on site conditions, material selections, and performance requirements that affect both initial installation and long-term ownership costs.

Material costs range from $45-85 per square foot for premium limestone treads depending on thickness, finish, and dimensional specifications. You’ll pay premium pricing for consistent color selections, tight thickness tolerances, and custom fabrication that reduces field labor requirements. Standard 12-inch depth treads with random length cost significantly less than custom-sized treads fabricated to specific project dimensions. Your value engineering conversations should address this trade-off between material costs and installation labor — paying 20% more for precisely fabricated treads often reduces installation labor by 30-40%.

Installation labor costs vary from $25-55 per square foot based on project complexity, site access constraints, and substrate conditions. Simple installations over existing concrete bases run at the lower end of this range. Projects requiring extensive excavation, base preparation in difficult soils, or detailed drainage systems push costs toward the upper end. You should verify that estimates include all preparatory work, not just stone setting labor.

Transportation and logistics add 8-15% to material costs in Arizona due to the state’s geography and warehouse distribution patterns. Material sourced from out-of-state suppliers incurs higher freight costs than regional options. Your procurement strategy should evaluate total delivered cost rather than optimizing material price alone. Lead times from the warehouse typically range from 2-4 weeks for standard materials, extending to 6-10 weeks for custom fabrication or specialty items requiring import from quarry sources.

Professional Specification Development Process

Comprehensive specifications protect your professional interests while establishing clear performance expectations that reduce disputes and ensure quality outcomes. You need specification documents that address material standards, installation protocols, testing requirements, and acceptance criteria with sufficient detail to eliminate ambiguity.

Material specifications should reference industry standards while adding project-specific requirements that address Arizona conditions. Start with ASTM C568 standards for limestone dimensional stone, then add supplemental requirements for compressive strength (minimum 10,000 PSI), absorption (maximum 7% by weight), and slip resistance (minimum 0.55 DCOF wet). Your specifications should require material testing by independent laboratories, with test reports submitted before material fabrication begins.

Installation specifications must detail base preparation requirements, setting methods, joint treatment protocols, and quality control procedures. Don’t accept generic language about “industry standard practices” — specify exactly what you require. Your documents should establish compaction testing frequencies for base materials (minimum one test per 500 square feet), mortar coverage requirements (minimum 95% trowel coverage with no voids), and joint sealant application protocols including surface preparation and curing conditions.

Testing and acceptance criteria establish objective standards for verifying installation quality. You should require slip resistance testing on completed installations, documenting that actual field conditions meet specified minimums. Dimensional compliance testing verifies that riser heights remain within code-mandated tolerances. Your specifications should establish clear acceptance standards and remediation procedures for work that doesn’t meet requirements — ambiguous language creates disputes that damage professional relationships and delay project completion.

Key Takeaways

Professional stone steps installation Arizona demands expertise that integrates material science, building code compliance, climate-specific engineering, and practical field experience. You can’t approach these projects with generic specifications developed for moderate climates — Arizona’s extreme conditions require purpose-built solutions that account for thermal cycling, moisture management, and substrate challenges unique to desert and high-elevation environments.

Your material selections must prioritize thermal performance characteristics that reduce surface temperatures and accommodate expansion movement. Light-colored limestone options provide optimal balance between durability, slip resistance, thermal comfort, and aesthetic appeal for most Arizona applications. You need to specify surface finishes that deliver adequate slip resistance while minimizing heat retention, joint treatments that accommodate thermal expansion without restricting movement, and sealing protocols that protect against moisture intrusion and staining.

Code compliance requires understanding how Stone Stair Codes Arizona dimensional standards interact with natural stone tolerances. You must account for thickness variations when planning riser heights, specify materials pre-selected for consistency, and detail installation methods that achieve required tolerances despite material variability. Your specifications should address slip resistance requirements explicitly, targeting performance levels above code minimums to provide safety margins and liability protection.

Base preparation determines long-term performance more than any other factor in stone steps installation Arizona projects. You need geotechnical understanding of local soil conditions, drainage design that prevents moisture accumulation, and substrate engineering that resists settlement and seasonal movement. These elements require professional expertise that goes beyond placing stone on sand — you’re engineering systems that must perform for decades under environmental assault that destroys inadequately specified installations within five years.

Your professional specification process protects both your interests and your client’s investment. Comprehensive documents establishing material standards, installation protocols, testing requirements, and acceptance criteria eliminate ambiguity that creates disputes and quality problems. When you develop detailed specifications addressing Arizona-specific challenges, you’re demonstrating the expertise that justifies professional fees and establishes your reputation for delivering projects that perform as intended. For additional resources on material selection and installation best practices, review Natural limestone treads for residential and commercial stair applications before you finalize project specifications. Citadel Stone’s custom lengths serve varied bullnose stone steps suppliers in Arizona width requirements.