When you evaluate stone manufacturing in Arizona, you’re entering a supply chain shaped by extreme heat, rapid urban expansion, and demanding architectural standards. The state’s construction industry requires materials that perform under thermal stress, resist UV degradation, and maintain structural integrity through dramatic temperature swings. Your material selection decisions need to account for how stone manufacturing in Arizona addresses these regional challenges through specialized production processes, quality control protocols, and climate-responsive fabrication techniques.

Arizona’s stone manufacturing sector serves residential developments, commercial projects, municipal infrastructure, and high-end architectural installations across eleven major metro areas. You’ll find that local fabricators understand the relationship between material density, porosity, and thermal mass in ways that out-of-state suppliers often overlook. Stone manufacturing in Arizona integrates regional geology, climate-specific processing methods, and logistics networks designed for efficient delivery across sprawling urban corridors and remote job sites.

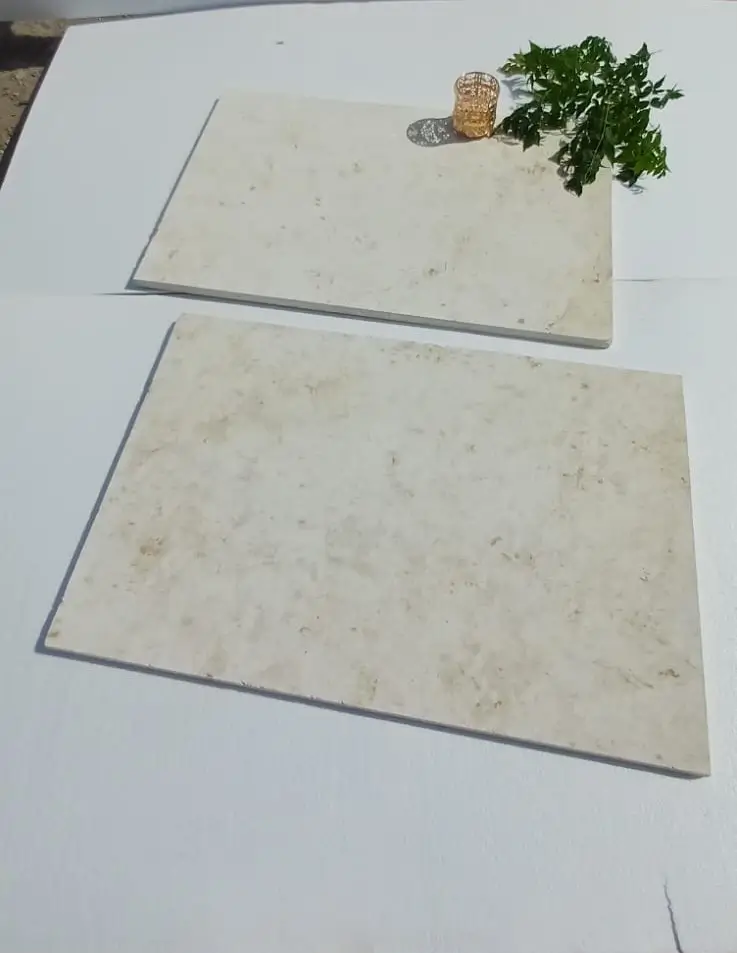

Material Sourcing and Climate Adaptation

Your stone specification process starts with understanding how Stone Manufacturers Arizona custom capabilities influence material performance in desert environments. Arizona’s fabricators source materials from regional quarries and international suppliers, then adapt processing methods to enhance climate resilience. You need to recognize that stone manufacturing in Arizona involves more than cutting and finishing — it requires thermal treatment protocols, sealing processes, and edge detailing that prevent expansion-related failures.

The state’s 120°F+ summer temperatures create material stress that accelerates degradation in improperly prepared stone. You’ll encounter installations where surface temperatures reach 160-180°F, requiring you to specify materials with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F. Stone manufacturing and supply Arizona construction professionals rely on incorporates heat cycling tests that simulate decades of exposure in compressed timeframes, identifying failure points before materials reach job sites.

When you work with Arizona fabricators, you should verify their material testing protocols include UV exposure analysis, thermal shock resistance verification, and alkalinity compatibility assessments. Regional soil conditions — particularly in areas with pH levels above 8.0 — interact with stone composition in ways that cause efflorescence, staining, and structural degradation. For comprehensive supplier evaluation criteria, see Citadel Stone manufacturing in Scottsdale for performance benchmarking standards. Your due diligence should include reviewing fabricator certifications, inspecting warehouse storage conditions, and examining samples from recent production runs.

Fabrication Precision and Dimensional Tolerances

Stone manufacturing companies Arizona services encompass cutting, finishing, edge profiling, and quality verification processes that directly affect installation success. You need to understand that dimensional tolerances stack throughout the supply chain — quarry extraction variance combines with fabrication tolerances to create field conditions that rarely match specification drawings precisely. Professional stone manufacturing in Arizona operations maintain tolerances within ±1/16″ for most applications, tightening to ±1/32″ for premium architectural installations.

Your specification documents should address several fabrication parameters:

- You must specify acceptable thickness variance ranges based on application requirements

- Your edge detail specifications should account for how different finishing methods affect dimensional accuracy

- You need to define surface flatness tolerances that installation crews can realistically achieve

- Your quality acceptance criteria should include color variation standards specific to natural stone

- You should establish inspection protocols for verifying compliance before materials leave the warehouse

Stone mfg & supply Arizona fabricators use water jet cutting, bridge saws, and CNC processing equipment that achieve precision impossible with manual methods. When you specify custom profiles, radiused edges, or complex geometric patterns, you’re relying on equipment calibration and operator expertise that varies significantly between fabricators. You’ll find that lead times from the warehouse extend by 3-5 weeks for custom work compared to standard dimensions, requiring you to adjust project schedules accordingly.

Surface Finishing Methods and Performance Impact

The finishing process fundamentally alters stone performance characteristics in ways that affect long-term durability, maintenance requirements, and user safety. You need to recognize that surface treatments modify porosity, slip resistance, heat retention, and aesthetic appearance simultaneously — optimizing one parameter often compromises another. Stone manufacturing in Arizona includes finishing options ranging from polished (requiring aggressive maintenance) to thermally treated (providing superior slip resistance but showing wear patterns faster).

Your finish selection should balance multiple performance factors:

- Polished finishes offer dramatic aesthetics but create slip hazards in wet conditions and amplify surface temperatures

- Honed surfaces provide moderate slip resistance while maintaining refined appearance suitable for interior applications

- Flamed or thermal finishes deliver excellent traction but expose more surface area to staining and moisture absorption

- Brushed finishes create texture that hides minor wear while preserving natural color depth

When you specify finishes for Arizona installations, you should account for how surface treatment interacts with sealing protocols. Stone manufacturing and supply Arizona construction practices typically include factory-applied sealers for premium projects, ensuring uniform coverage impossible to achieve during field application. You’ll need to verify that sealer chemistry matches both stone composition and intended finish — silane-based sealers penetrate deeper but don’t enhance color, while siloxane blends provide superior water repellency with slight darkening effects.

Custom Fabrication Capabilities and Design Flexibility

Stone Manufacturers Arizona custom capabilities extend beyond standard dimensional cutting to include radius work, inlay patterns, waterjet artistry, and structural components engineered for specific load requirements. You should understand that custom fabrication increases both cost and lead time substantially — complex projects require engineering review, template creation, test cuts, and quality verification stages that add 6-12 weeks to standard production schedules.

Your custom specification process requires detailed communication with fabricators about tolerances, assembly sequences, and field adjustment provisions. Stone manufacturing in Arizona for architectural features involves coordinating with structural engineers, reviewing load paths, and verifying that fabricated components integrate with steel supports, masonry substrates, or concrete anchoring systems. You need to provide fabricators with dimensioned shop drawings, not just design intent sketches, to avoid misinterpretation that leads to costly remakes.

At Citadel Stone, we maintain capabilities for producing custom architectural elements including column cladding, stair treads with integrated nosing, countertops with undermount sink profiles, and facade panels with concealed anchoring systems. When you specify custom work, you should visit the fabrication facility to review processes, inspect quality control measures, and verify that equipment capacity matches project requirements. Your site visit should include checking warehouse organization, examining finished inventory from recent jobs, and discussing contingency plans for damaged or out-of-tolerance pieces.

Quality Control Standards and Testing Protocols

Professional stone manufacturing in Arizona incorporates testing regimens that verify material compliance with ASTM standards, project specifications, and performance expectations. You need to distinguish between basic quality checks (visual inspection, dimensional verification) and comprehensive testing protocols (compressive strength, absorption rates, freeze-thaw resistance). Stone manufacturing companies Arizona services should include documented test results for material batches, particularly when you’re specifying large quantities where performance consistency affects long-term appearance.

Your quality assurance program should require fabricators to provide:

- Compressive strength test results meeting minimum 8,000 PSI for structural applications

- Water absorption data verified through ASTM C97 protocols showing porosity within acceptable ranges

- Flexural strength documentation for applications involving spanning or cantilever conditions

- Slip resistance certification using DCOF AcuTest methods for pedestrian surfaces

- Thermal cycling results demonstrating stability through temperature ranges exceeding field conditions

Stone mfg & supply Arizona operations that maintain ISO certification or equivalent quality management systems provide documentation trails essential for project closeout, warranty claims, and long-term maintenance planning. When you review test reports, you should verify that sample testing represents actual production material, not idealized specimens. Your specification should require batch testing at intervals appropriate to project scale — every 5,000 square feet for large installations, with increased frequency when switching material lots from the warehouse.

Logistics Infrastructure and Delivery Coordination

Stone manufacturing and supply Arizona construction depends on logistics networks capable of moving heavy, fragile materials across vast distances while maintaining quality and meeting tight installation schedules. You need to account for delivery constraints when planning project timelines — warehouse locations, truck access limitations, crane requirements, and staging area availability all influence material flow from fabricator to installation crew.

Your logistics planning should address several critical factors. Arizona’s sprawling metro areas create delivery challenges where traffic congestion, restricted access hours, and residential neighborhood limitations affect material arrival timing. You’ll find that coordinating warehouse shipments with installation crew availability requires 2-3 week advance scheduling during peak construction seasons. Stone manufacturing in Arizona increasingly incorporates just-in-time delivery systems that reduce on-site storage requirements but demand precise coordination between multiple trades.

When you specify stone materials, you should verify that fabricators maintain adequate inventory buffers to accommodate breakage, dimensional adjustments, and unforeseen installation complications. Truck capacity constraints mean that large projects require multiple deliveries, each introducing opportunities for damage during loading, transport, and unloading sequences. Your project specifications should assign clear responsibility for material inspection at delivery, establishing protocols for rejecting damaged pieces before installation crews accept them.

Climate-Specific Installation Considerations

Arizona’s extreme climate creates installation challenges that affect material performance, installer productivity, and long-term durability. You need to recognize that summer temperatures above 110°F limit effective installation windows to early morning hours — adhesive curing rates, worker safety constraints, and material handling difficulties restrict productive work periods to 4-6 hours daily during peak season. Stone manufacturing in Arizona accounts for these limitations through production scheduling that aligns warehouse shipments with installation weather windows.

Your installation specifications should address climate-related factors:

- You must specify adhesive and grout products formulated for high-temperature application and curing

- Your joint spacing requirements should increase by 15-20% compared to moderate climate standards

- You need to require substrate moisture testing showing levels below 4% before installation begins

- Your quality control protocols should include thermal imaging to verify adhesive coverage and bonding quality

- You should mandate acclimation periods allowing materials to stabilize at ambient temperature before installation

Stone Manufacturers Arizona custom capabilities extend to pre-treating materials for accelerated curing, applying factory sealers that eliminate field application complications, and providing installation guidance specific to regional conditions. When you coordinate installation schedules, you should account for how monsoon season affects outdoor work — July through September brings humidity spikes, sudden storms, and lightning hazards that interrupt installation sequences and potentially damage unsealed materials.

Maintenance Requirements and Longevity Planning

Your material selection decisions determine maintenance intensity, lifecycle costs, and performance longevity over 20-30 year service periods. Stone manufacturing and supply Arizona construction professionals recognize that initial material cost represents only 15-25% of total ownership expense — sealing, cleaning, repair, and eventual replacement constitute the majority of lifecycle spending. You need to evaluate stone options based on maintenance requirements appropriate to ownership capacity and project type.

Different stone types and finishes exhibit varying maintenance profiles. Polished surfaces require frequent resealing (annually in high-traffic areas) and show wear patterns that necessitate refinishing every 8-12 years. Honed finishes hide minor scratches better but absorb stains more readily without aggressive sealing protocols. Textured surfaces provide durability at the cost of cleaning difficulty — dirt and organic material accumulate in surface irregularities, requiring pressure washing that gradually erodes softer stone compositions.

When you specify stone manufacturing in Arizona projects, you should provide owners with realistic maintenance expectations. Desert dust, monsoon-deposited sediment, and irrigation water minerals create cleaning challenges that coastal or temperate climate installations don’t face. Your project closeout documentation should include maintenance schedules, recommended cleaning products, resealing intervals, and contact information for qualified service providers. Stone mfg & supply Arizona fabricators increasingly offer maintenance contracts that ensure proper care from professionals who understand regional conditions and material-specific requirements.

Cost Structure and Budget Planning Variables

Understanding stone manufacturing in Arizona cost components helps you develop accurate project budgets and identify value engineering opportunities without compromising performance. Material costs vary based on stone type, sourcing distance, fabrication complexity, and market demand fluctuations. You should recognize that “price per square foot” comparisons oversimplify cost analysis — installation complexity, waste factors, and long-term maintenance expenses significantly affect total project economics.

Your budget planning should account for multiple cost drivers:

- Base material costs range from $8-$45 per square foot depending on stone type and finish specifications

- Custom fabrication adds 35-80% premiums for complex profiles, radius work, or specialty edge details

- Installation labor costs in Arizona metro areas range from $12-$28 per square foot based on complexity

- Sealing, edge treatments, and finishing processes add $3-$8 per square foot to material preparation

- Delivery and logistics typically represent 8-12% of material costs for projects over 1,000 square feet

Stone manufacturing companies Arizona services include value engineering consultations that identify cost savings through material substitutions, simplified details, or modified installation methods. When you face budget constraints, you should explore options with fabricators before finalizing specifications — switching from polished to honed finishes might reduce costs by 15-20% while maintaining aesthetic intent. Your procurement strategy should include requesting quotes from multiple fabricators to establish competitive pricing, but recognize that lowest bid doesn’t guarantee best value when quality variations exist.

Stone Manufacturers Arizona — How Citadel Stone Would Specify for Arizona Cities

When you consider Citadel Stone’s approach to stone manufacturing in Arizona projects, you’re evaluating comprehensive technical guidance for materials engineered to withstand extreme desert conditions. At Citadel Stone, we provide hypothetical specification frameworks for diverse Arizona cities, each presenting unique climate challenges, soil conditions, and architectural contexts. This section outlines how you would approach material selection and installation planning for six representative municipalities across the state’s varied climate zones.

Arizona’s geographic diversity creates microclimates requiring you to adjust specifications based on elevation, temperature extremes, precipitation patterns, and soil chemistry. You need to recognize that specification approaches effective in low-desert Phoenix differ substantially from high-desert Flagstaff requirements. Stone manufacturing and supply Arizona construction practices must account for these regional variations through climate-responsive material selection, modified installation protocols, and maintenance planning appropriate to local conditions.

Phoenix Thermal Specifications

In Phoenix, you would encounter the most extreme heat conditions in Arizona, with summer temperatures regularly exceeding 115°F and surface temperatures reaching 170-180°F. Your material specifications would need to prioritize thermal stability, requiring stone with expansion coefficients below 5.5 × 10⁻⁶ per °F and compressive strength exceeding 9,000 PSI. You should specify light-colored materials that reflect 60-70% of solar radiation, reducing surface temperatures by 15-25°F compared to darker alternatives. Stone manufacturing in Arizona for Phoenix applications would incorporate thermal cycling tests simulating 50+ years of exposure, with quality verification showing zero structural degradation. Your installation specifications would require expansion joints every 12-15 feet and mandate early morning installation windows when temperatures remain below 95°F.

Tucson Elevation Factors

Tucson’s 2,400-foot elevation creates temperature ranges slightly more moderate than Phoenix but introduces monsoon moisture considerations you would need to address. Your specifications would balance thermal performance with moisture management, requiring materials with porosity between 3-6% that allow drainage while resisting freeze-thaw damage during occasional winter freezes. You would specify slip resistance ratings minimum DCOF 0.50 for exterior applications exposed to monsoon precipitation. Stone Manufacturers Arizona custom capabilities would include factory-applied penetrating sealers providing water repellency without altering surface appearance. Your installation protocols would account for July-September humidity spikes affecting adhesive curing, requiring modified setting materials formulated for elevated moisture conditions.

Scottsdale Luxury Standards

Scottsdale’s high-end residential and resort market would drive your specifications toward premium materials with refined finishes and custom fabrication details. You would specify stone manufacturing in Arizona that delivers consistent color matching across multiple production batches, dimensional tolerances within ±1/32″, and custom edge profiles meeting architectural design intent. Your material selections would emphasize aesthetics while maintaining performance appropriate to desert heat — honed finishes providing visual sophistication with slip resistance suitable for pool decks and outdoor living areas. You would require fabricators to maintain warehouse inventory buffers ensuring replacement availability for damaged pieces during installation. At Citadel Stone, we would recommend acclimation periods allowing materials to stabilize at site conditions before installation begins, preventing thermal shock failures common in rushed luxury projects.

Flagstaff Freeze-Thaw Resistance

Flagstaff’s 7,000-foot elevation creates Arizona’s most challenging freeze-thaw environment, requiring you to specify materials tested through minimum 300 freeze-thaw cycles per ASTM C666. Your specifications would prioritize low-porosity materials (below 4%) with proven durability in alpine conditions. You would require compressive strength minimum 10,000 PSI and flexural strength exceeding 1,500 PSI to resist stress from ice formation within material pores. Stone manufacturing and supply Arizona construction for Flagstaff applications would incorporate deicing salt resistance testing, as winter maintenance chemicals accelerate surface degradation. Your installation specifications would mandate comprehensive sealing protocols applied in controlled conditions, with reapplication intervals shortened to 18-24 months compared to 36-48 months typical in lower elevations.

Sedona Aesthetic Integration

Sedona’s distinctive red rock landscape would influence your color and texture selections to complement natural surroundings while meeting municipal design guidelines. You would specify warm-toned materials in terra cotta, buff, and amber ranges that harmonize with regional geology. Your specifications would balance aesthetic goals with performance requirements for Sedona’s 4,500-foot elevation, where temperature swings of 40-50°F between day and night create expansion-contraction cycles stressing improperly specified materials. Stone mfg & supply Arizona fabricators would provide samples demonstrating color consistency and surface texture appropriate to Sedona’s architectural character. You would require UV stability testing ensuring materials maintain color fidelity through decades of intense high-altitude sun exposure.

Yuma Extreme Heat Planning

Yuma’s distinction as one of America’s hottest cities would drive your specifications toward maximum thermal performance, requiring materials proven in sustained temperatures above 120°F. Your material selections would emphasize light colors with high solar reflectance, textured finishes providing barefoot comfort, and compositions resistant to thermal degradation. You would specify stone manufacturing in Arizona incorporating extended heat cycling tests beyond standard protocols — materials exposed to 180°F+ surface temperatures for 1,000+ hours to identify failure mechanisms. Your installation specifications would restrict work to October through April when temperatures permit effective adhesive curing and worker productivity. You would require expanded joint spacing (20% above standard recommendations) and specify flexible setting materials accommodating Yuma’s extreme thermal movement.

Emerging Technologies in Stone Processing

Stone manufacturing in Arizona increasingly incorporates advanced technologies that improve precision, reduce waste, and expand design possibilities. You should understand how digital templating, CNC fabrication, and automated quality inspection systems affect project outcomes, lead times, and cost structures. Technology adoption varies significantly between fabricators — larger operations invest in equipment that smaller shops cannot justify economically, creating capability differences that influence supplier selection decisions.

Digital templating systems using laser scanning or photogrammetry capture field dimensions with accuracy impossible through manual measurement. When you specify custom installations requiring precise fit to existing conditions, you should verify that fabricators utilize digital templating integrated with CNC processing equipment. This technology chain eliminates transcription errors, reduces material waste from incorrect cuts, and shortens production cycles by 30-40% compared to traditional methods. Stone manufacturing companies Arizona services increasingly include 3D visualization allowing you to review fabricated components virtually before production begins.

Your specifications should leverage technology capabilities where they provide value:

- Waterjet cutting enables intricate inlay patterns and complex geometric shapes impossible with traditional saw cutting

- CNC edge profiling delivers consistency across large production runs, critical for commercial projects requiring uniform appearance

- Automated surface finishing maintains texture uniformity that manual processes cannot match

- Digital color matching systems identify acceptable material batches from warehouse inventory, reducing color variation

Sustainability Practices and Environmental Impact

Your material selection decisions carry environmental implications affecting project sustainability certifications, lifecycle carbon footprints, and resource conservation. Stone manufacturing and supply Arizona construction increasingly addresses sustainability through responsible sourcing, waste reduction, water recycling, and energy-efficient processing. You need to understand how fabrication practices influence environmental performance and what documentation supports green building certification requirements.

When you specify stone for LEED or other certified projects, you should require fabricators to provide environmental product declarations (EPDs) quantifying carbon footprint, water consumption, and waste generation. Stone mfg & supply Arizona operations that maintain sustainability programs offer documentation supporting multiple credit categories — regional sourcing (materials extracted and processed within 500 miles), recycled content (when applicable), and low-emitting materials certifications. Your specifications should establish clear requirements for environmental documentation to streamline certification processes.

At Citadel Stone, we recognize that stone represents a durable, low-maintenance material choice with lifecycle environmental benefits offsetting initial processing impacts. Natural stone doesn’t require manufacturing from raw materials like porcelain or concrete — it involves extraction and processing of existing geological formations. When you compare lifecycle environmental performance, stone’s 50+ year service life with minimal maintenance delivers lower total impact than alternatives requiring replacement every 15-25 years. Your sustainability analysis should account for longevity, maintenance requirements, and end-of-life disposal or recycling potential.

Code Compliance and Regulatory Standards

Stone manufacturing in Arizona must comply with building codes, accessibility standards, and material performance requirements that vary by jurisdiction and application type. You need to ensure that specified materials meet minimum standards while understanding that code compliance represents baseline performance — professional practice often exceeds code minimums to ensure long-term satisfaction and reduce liability exposure. Your specification documents should reference relevant standards explicitly, establishing clear performance criteria for fabricators and installers.

Key regulatory considerations include:

- Slip resistance requirements per ADA standards mandate minimum DCOF 0.42 for accessible routes and 0.60 for ramps

- Fire resistance ratings affect material selection for certain interior applications, particularly in commercial and institutional settings

- Structural loading requirements determine minimum thickness and compressive strength for applications involving pedestrian or vehicle traffic

- Water absorption limits specified in ANSI A137.1 establish maximum porosity for freeze-thaw exposure areas

When you navigate code requirements, you should recognize that inspectors focus on documentation demonstrating compliance — test reports, manufacturer certifications, and installation verification records. Stone manufacturing companies Arizona services should include providing necessary compliance documentation as standard practice. Your project specifications should assign responsibility for obtaining, organizing, and submitting required documentation to prevent delays during inspection processes.

Supplier Selection and Partnership Development

Your fabricator selection process determines project success more than any other single decision. Stone manufacturing in Arizona varies dramatically in quality, capability, customer service, and reliability between suppliers. You need systematic evaluation criteria assessing technical capabilities, financial stability, quality systems, and communication practices. Your supplier partnerships should develop over multiple projects, building relationships that improve outcomes through mutual understanding and trust.

When you evaluate potential fabricators, you should conduct comprehensive assessments including facility tours, reference checks, and sample reviews. Visit warehouse operations to observe material handling, storage conditions, and inventory management practices. Examine completed projects similar in scope and complexity to your requirements. Interview project managers and production supervisors to assess communication effectiveness and problem-solving approaches. Stone Manufacturers Arizona custom capabilities vary widely — verify that fabricators maintain equipment, expertise, and capacity appropriate to your project requirements before committing.

Your supplier evaluation should address both technical and business factors. Technical assessment verifies equipment capabilities, quality control systems, and production capacity. Business evaluation examines financial stability, insurance coverage, warranty provisions, and customer service responsiveness. You should request documentation supporting claims about certifications, testing capabilities, and past project experience. Professional fabricators provide transparent information readily; those hesitant to share documentation raise concerns warranting closer scrutiny or supplier alternative evaluation.

Project Success Factors

Stone manufacturing in Arizona serves a construction industry demanding materials that perform reliably in challenging environmental conditions while meeting aesthetic expectations and budget constraints. Your success depends on understanding regional requirements, selecting qualified fabricators, specifying appropriate materials, and coordinating installation timing with climate constraints. You need comprehensive knowledge spanning material science, fabrication processes, installation techniques, and long-term maintenance requirements to make decisions that deliver lasting value.

Professional specification practice recognizes that perfect outcomes rarely occur — material variations, dimensional tolerances, installation imperfections, and unforeseen conditions create field realities differing from design intent. Your role involves establishing realistic expectations, building contingency provisions into plans and budgets, and maintaining communication channels that address complications promptly. Stone manufacturing and supply Arizona construction succeeds when all parties understand their responsibilities and commit to collaborative problem-solving when challenges arise.

When you develop specifications, coordinate fabrication, and oversee installation, you should maintain focus on long-term performance rather than short-term cost minimization. Materials representing the lowest initial expense often deliver the highest lifecycle costs through maintenance requirements, premature failure, or aesthetic degradation. Your professional judgment must balance competing priorities, educate clients about trade-offs, and advocate for solutions delivering genuine value over project lifespans measured in decades. For additional technical resources and installation best practices, review Arizona architectural stone production capabilities and specialty manufacturing services before you finalize your project specifications. Citadel Stone maintains the highest standards in stone manufacturing in Arizona through certified processes.