When you source stone granite supplies Arizona guide materials for your next project, you need more than product catalogs—you need field-proven guidance that addresses the state’s punishing UV exposure, 120°F surface temperatures, and alkaline soil conditions that accelerate efflorescence. Arizona’s climate creates unique specification challenges that generic stone supply recommendations simply don’t address. You’re working in an environment where thermal expansion coefficients, porosity interactions with monsoon moisture, and slip resistance under extreme heat determine whether your installation performs for 25 years or fails within eight.

Your material selection decisions affect everything from substrate preparation protocols to long-term maintenance requirements. The difference between professional-grade granite specifications and commodity stone products becomes obvious within 18 months when you see how materials respond to Arizona’s temperature swings—diurnal variations exceeding 50°F that stress inferior products beyond their performance thresholds. Stone supply company Arizona granite sources must provide technical data on compressive strength, water absorption rates, and thermal cycling resistance specific to desert applications.

Granite Material Specifications for Arizona Climate Zones

You’ll encounter three distinct climate zones in Arizona that demand different granite specification approaches. The low desert zone (Phoenix, Yuma) requires materials that withstand sustained 115°F+ temperatures with minimal thermal expansion. Your specification needs to address granite with coefficients below 5.8 × 10⁻⁶ per °F—exceeding this threshold creates joint spacing problems and accelerated wear patterns in pedestrian applications.

High desert installations (Flagstaff, Sedona elevations above 4,500 feet) require freeze-thaw durability testing per ASTM C666. You should specify granite with water absorption rates below 0.4% by weight to prevent structural degradation during freeze cycles exceeding 100 annual events. Arizona stone supply inc granite inventory typically includes materials tested to these standards, but you need to verify certification documentation rather than accepting verbal assurances.

When you evaluate stone granite supplies Arizona guide specifications, pay attention to how quarry location affects mineral composition. Granites with higher quartz content (65-75%) demonstrate superior thermal stability compared to feldspathic varieties. Your selection should prioritize materials quarried from geologically stable formations—this translates to consistent density measurements across production runs and predictable long-term performance.

- You need compressive strength minimum 19,000 PSI for vehicular applications

- Your water absorption specification must not exceed 0.40% for exterior installations

- You should verify flexural strength exceeds 1,800 PSI for cantilever applications

- Thermal expansion coefficients must remain below 5.8 × 10⁻⁶ per °F in low desert zones

- You require abrasion resistance ratings (ASTM C241) below 25 for commercial pedestrian traffic

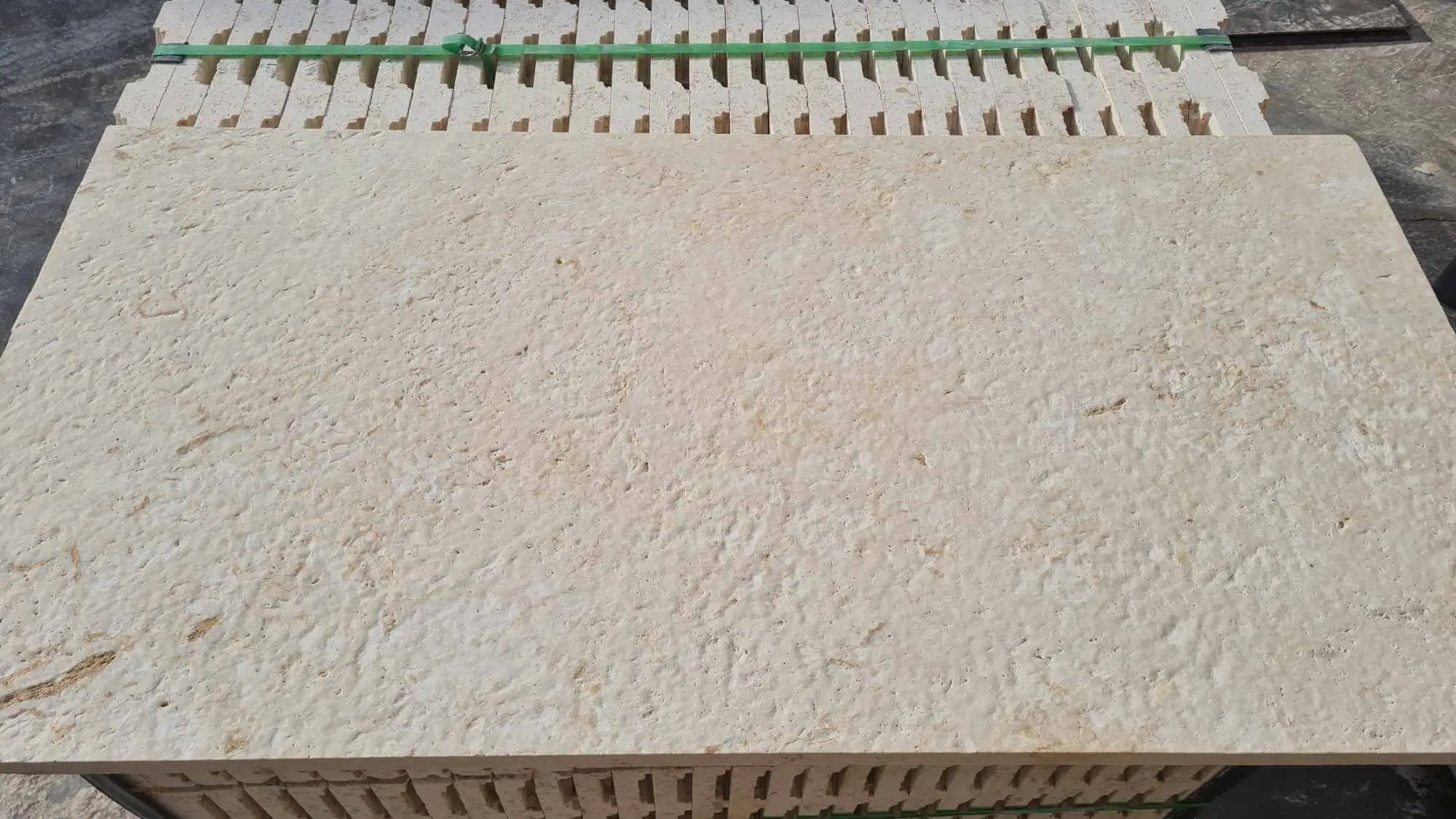

Slab Thickness and Format Specifications

Your thickness selection directly impacts structural performance and installation complexity. Standard 3cm (1-3/16 inch) granite slabs work for most interior applications and low-traffic exterior installations, but you’ll need 5cm (2 inch) material for vehicular pavers, pool copings, and high-impact commercial zones. The relationship between thickness and flexural strength isn’t linear—5cm granite provides approximately 2.8× the load-bearing capacity of 3cm material due to geometric stress distribution factors.

When you specify larger format slabs (exceeding 24×24 inches), you need to account for handling stresses during installation. Local stone supply Arizona granite options often include modular sizing (12×24, 18×18, 24×36) that balances visual scale with practical installation logistics. Your crew’s ability to handle oversized units without mechanical lifting equipment determines realistic format constraints—manual installation of granite exceeding 60 pounds per unit increases breakage rates by 15-20% based on field observations across multiple Arizona installations.

Thickness tolerances matter more than most specifiers realize. You should accept ±2mm variation on 3cm slabs, but tighter ±1mm tolerances become critical for thin-set installations over concrete substrates. Stone granite supplies Arizona guide resources need to address how tolerance stacking affects lippage—the vertical displacement between adjacent units that creates trip hazards and visual irregularities. When you work with materials at maximum positive tolerance adjacent to minimum negative tolerance, you’re managing 4mm potential lippage before accounting for substrate flatness variations.

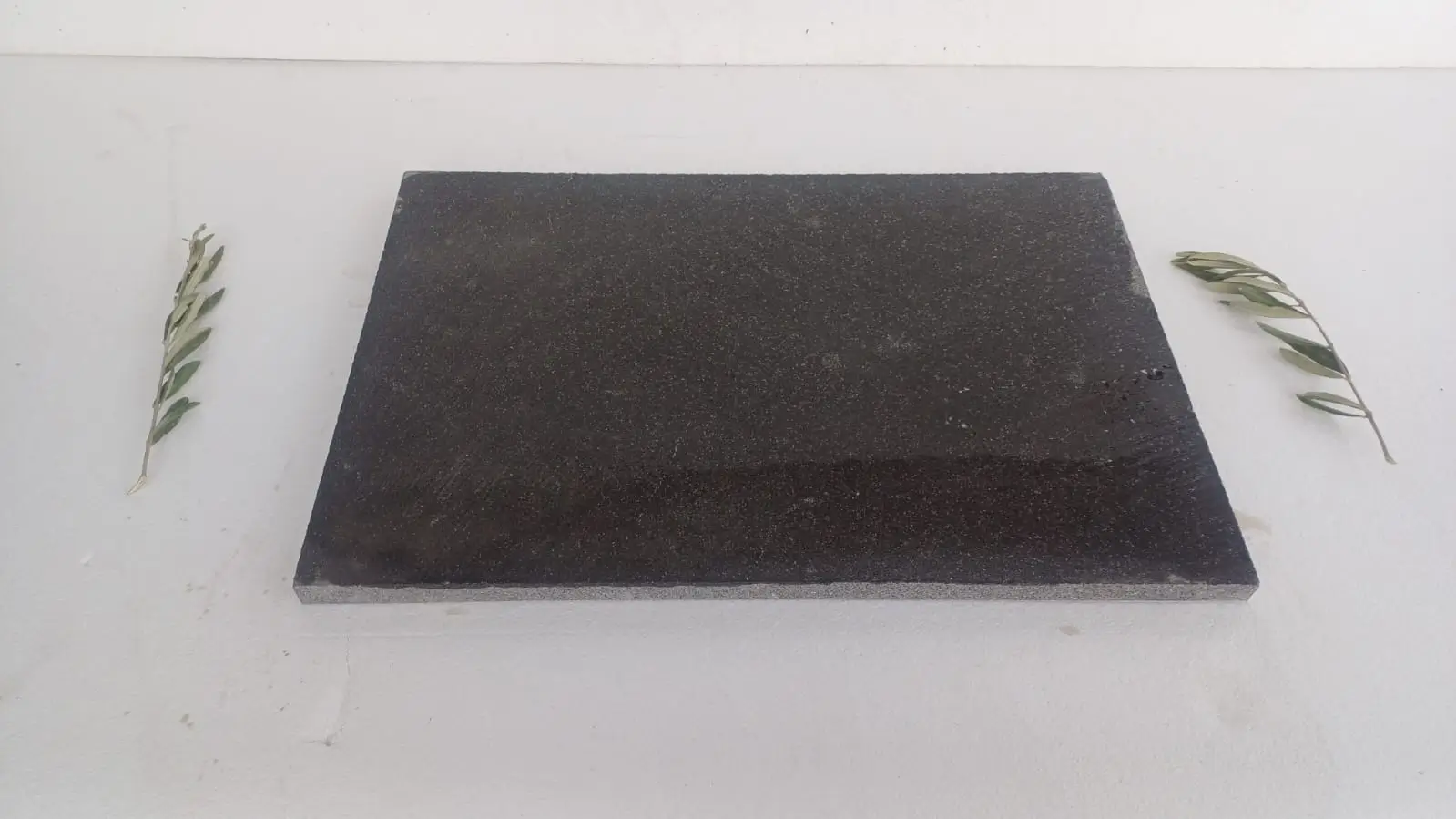

Surface Finish Performance Characteristics

You’ll choose from polished, honed, flamed, or bush-hammered finishes based on slip resistance requirements and aesthetic goals, but each finish performs differently under Arizona’s environmental stresses. Polished granite delivers the lowest initial slip resistance (DCOF 0.38-0.42 dry), making it unsuitable for pool decks, exterior walkways, or any surface exposed to moisture. Your specification needs to acknowledge that polished finishes show wear patterns in high-traffic zones after 8-12 years—a reality that affects long-term facility maintenance planning.

Honed finishes provide the optimal balance for most Arizona applications. You get DCOF ratings of 0.48-0.52 (dry) and 0.42-0.46 (wet), meeting ADA requirements for accessible routes while maintaining sophisticated appearance. The matte surface conceals minor scratching and wear better than polished alternatives. When you’re sourcing through stone supply company Arizona granite channels, verify that honed finishes receive proper sealer application—unsealed honed granite absorbs staining compounds 3-4× faster than polished surfaces due to increased surface porosity.

Thermal flaming creates the most aggressive texture for maximum slip resistance. You’ll achieve DCOF values exceeding 0.60, but the rough surface retains dirt, organic debris, and requires more intensive maintenance protocols. The flaming process also micro-fractures surface crystals, which can accelerate weathering in areas with significant freeze-thaw exposure. Your decision should weigh immediate safety performance against 20-year maintenance costs and surface degradation trajectories. For comprehensive material comparisons, see our stone supply consultations for detailed finish performance data specific to Arizona conditions.

Color Stability Under Extended UV Exposure

Arizona’s intense solar radiation (averaging 5.7-6.5 kWh/m²/day) affects granite color stability differently depending on mineral composition. You need to understand which granite colors maintain appearance over decades versus those that fade, yellow, or develop surface oxidation. Lighter granite colors (whites, light grays, beiges) generally exhibit superior UV stability because they lack the iron oxide compounds that oxidize under prolonged sun exposure.

When you specify darker granite colors—blacks, deep reds, browns—you’re accepting some degree of surface color shift over 15-20 years. The oxidation process affects surface layers (top 0.5-1mm) rather than bulk material, so periodic diamond honing can restore original coloration if aesthetic consistency matters for your application. Stone supply in Arizona granite inventories should include UV stability data from accelerated weathering tests (ASTM G154), though many suppliers lack this documentation for imported materials.

Your specification should address acceptable color variation within production lots. Natural granite exhibits inherent variation—you’ll see shifts in veining patterns, background tone, and mineral distribution even within slabs from the same quarry block. Establishing realistic expectations with clients prevents conflicts during installation when adjacent slabs show visible differences. Professional practice involves dry-laying materials before setting to optimize visual blending and identify units requiring repositioning.

Porosity and Water Management in Desert Environments

You might assume water management isn’t critical in Arizona’s arid climate, but monsoon events deliver 2-4 inches of rainfall within hours, creating temporary saturation conditions that test material porosity limits. Granite’s low porosity (typically 0.2-0.6% by volume) provides inherent moisture resistance, but you still need to address substrate drainage, joint design, and sealer selection to prevent long-term moisture-related failures.

Your substrate design must provide drainage capacity exceeding surface material permeability. When you install granite over concrete, you’re creating a virtually impermeable assembly that requires positive drainage slopes (minimum 2%) and strategic weep provisions. Flat installations trap water at the granite-concrete interface, leading to efflorescence migration through joints and delamination failures at mortar bonds. Arizona stone supply inc granite specifications should include drainage system integration details rather than treating materials as isolated components.

Sealer selection affects both moisture resistance and maintenance requirements. You’ll choose between topical sealers (forming surface film) and penetrating sealers (filling subsurface pores). Penetrating sealers perform better in Arizona’s UV environment—they don’t delaminate or yellow like topical products. Your maintenance program should include resealing intervals of 3-5 years for exterior applications, with more frequent treatment in high-traffic zones where abrasion degrades sealer performance faster than UV exposure alone.

- You should specify penetrating sealers for all exterior granite applications

- Your drainage slopes must achieve minimum 2% gradient for positive water evacuation

- You need expansion joints every 12-15 feet in direct sun exposure areas

- Joint widths should range 3/16 to 1/4 inch depending on format size and climate zone

- You must verify substrate permeability exceeds surface material by factor of 3-4×

Thermal Performance and Heat Retention Properties

When you specify granite for Arizona exterior applications, thermal mass properties create both benefits and complications. Granite’s density (2.65-2.75 g/cm³) and specific heat capacity result in significant heat storage—surface temperatures lag air temperature by 3-4 hours, meaning granite continues radiating stored heat well into evening hours. This thermal flywheel effect moderates temperature swings but creates uncomfortably hot surfaces during peak summer months.

You’ll measure granite surface temperatures reaching 140-160°F in direct Phoenix sun exposure during July-August. These temperatures exceed barefoot tolerance thresholds (120°F maximum for brief contact) and affect material selection for pool decks, patios, and pedestrian walkways. Lighter granite colors reflect 40-50% of solar radiation versus 15-25% for dark colors, translating to 20-30°F surface temperature differentials under identical conditions. Your color selection directly impacts usability during Arizona’s extended summer season.

The relationship between thermal expansion and installation detailing becomes critical in large-format applications. Granite expands approximately 0.0058 inches per 10 feet per 100°F temperature change. When you’re installing 50-foot linear runs without expansion joints, you’re managing nearly 1/4 inch of cumulative movement—enough to crack units, buckle joints, or cause delamination from substrates. Stone granite supplies Arizona guide specifications must integrate thermal movement calculations into joint spacing, edge restraint details, and substrate attachment methods.

Installation Substrate Requirements for Long-Term Performance

Your substrate preparation determines whether granite installations perform for 25+ years or fail within a decade. The base system must address three critical functions: structural support, drainage management, and dimensional stability. You can’t compensate for inadequate substrate preparation with premium granite materials—the failure mode simply shifts from material degradation to system-level collapse.

When you install over compacted aggregate bases (typical for exterior pavers), you need minimum 6-inch depth of crushed stone with 95% compaction per Proctor density testing. The base must achieve bearing capacity exceeding anticipated loads by factor of 2-3× to prevent differential settlement. In Arizona’s expansive clay soils (common in Phoenix valley, Tucson basin), your geotechnical investigation should identify soil expansion potential—PI values exceeding 25 require deeper excavation and engineered base systems including geotextile separation layers.

Concrete substrate installations demand different preparation protocols. You should verify concrete has cured minimum 28 days and achieved design strength before thin-set granite installation. Surface preparation requires mechanical scarification or shot blasting to achieve CSP-3 profile (per ICRI standards)—smooth troweled concrete lacks sufficient mechanical bond for long-term mortar adhesion. Your specification must address concrete moisture content below 4% and pH below 10 before setting materials to prevent efflorescence and bond degradation.

Joint Specification and Long-Term Maintenance

You’ll choose between sand-filled joints (for permeable paver systems) and polymer-modified mortars (for concrete-set installations), but each system requires specific maintenance protocols that affect lifecycle costs. Sand joints provide flexibility for thermal movement and allow water percolation, but they require replenishment as wind, rain, and foot traffic displace material. Your maintenance program should plan for 20-30% sand loss in the first year, then 5-10% annually thereafter.

When you specify polymeric sand products, you’re working with materials that harden after water activation but retain some flexibility. These products reduce maintenance frequency but cost 3-4× more than standard joint sand. The trade-off involves upfront material costs versus long-term labor for replenishment—you should calculate 10-year total ownership costs rather than focusing solely on installation expenses. Local stone supply Arizona granite suppliers can provide regional performance data for different joint materials under Arizona’s specific environmental stresses.

Mortar joints in concrete-set installations must accommodate thermal movement while maintaining watertight integrity. You need flexible mortar formulations with elongation capacity of 7-10% to prevent cracking under Arizona’s temperature extremes. Standard cement-based grouts lack sufficient flexibility—you should specify polymer-modified products designed for exterior applications with thermal cycling resistance. Joint width affects stress concentrations: narrower joints (1/8 inch) concentrate stresses and crack more readily than wider joints (3/16 to 1/4 inch) that distribute movement across larger volumes of flexible material.

Edge Detail Specifications for Different Applications

Your edge treatment selection affects both aesthetics and long-term durability. You’ll specify from straight-cut, beveled, bullnose, or custom-profiled edges depending on application requirements and budget constraints. Each edge profile performs differently under impact stresses and shows wear patterns at different rates. Straight-cut edges with sharp 90-degree corners are most vulnerable to chipping—any impact concentrates stress at the acute edge, causing spalling and degradation over time.

When you specify bullnose or beveled edges, you’re distributing impact stresses across larger surface areas, reducing chip susceptibility. The radius dimension matters: 1/4-inch radius provides modest improvement, while 1/2-inch radius significantly increases edge durability. This consideration becomes critical for pool copings, step treads, and bench seating where contact frequencies are high. Stone supply company Arizona granite fabricators can machine custom edge profiles, but complex details increase costs by 40-60% compared to standard cuts.

Edge details also affect installation complexity and setting material requirements. Profiled edges require more precise substrate preparation and support—you can’t rely on mortar beds to compensate for substrate irregularities when working with tight-tolerance edge profiles. Your installation specifications should address edge support requirements: cantilevered edges need structural backing within 1 inch of the unsupported edge to prevent deflection and cracking under loading. This level of detail separates professional specifications from generic installation guidelines.

Slab Yard in Arizona — How Citadel Stone Would Specify Premium Granite

When you consider Citadel Stone’s approach to sourcing and specifying stone granite supplies Arizona guide materials, you’re evaluating a methodology focused on climate-specific performance validation and long-term durability rather than commodity pricing. At Citadel Stone, we emphasize technical due diligence that verifies material certifications match actual performance characteristics under Arizona’s environmental stresses. This section outlines how you would approach specification decisions for six representative cities across the state’s diverse climate zones.

Your specification process should begin with climate zone identification and corresponding performance criteria. Low desert applications demand different material properties than high country installations—what works in Yuma fails in Flagstaff. The guidance below demonstrates how you would tailor stone supply in Arizona granite selections to regional requirements, accounting for temperature extremes, precipitation patterns, freeze-thaw exposure, and soil chemistry variations that affect long-term installation integrity.

Phoenix Valley Specifications

In Phoenix, you would encounter extreme heat requiring granite with proven thermal cycling resistance. Your specification should prioritize light-colored granite (LRV above 55) to minimize surface temperatures and thermal expansion stresses. You need to verify compressive strength exceeds 20,000 PSI and water absorption remains below 0.35% for the valley’s alkaline soil conditions. At Citadel Stone, we would recommend expansion joints every 12 feet in full-sun exposure areas, with polymer-modified setting mortars that accommodate thermal movement without bond failure. You should also address monsoon drainage requirements—August storms deliver intense precipitation that tests substrate permeability limits and joint integrity under temporary saturation conditions.

Tucson Basin Applications

When you specify for Tucson’s higher elevation and slightly cooler temperatures, you would still prioritize heat-resistant granite but can consider mid-tone colors that might be impractical in Phoenix. Your material selection should address the basin’s caliche soil layers that create challenging excavation and drainage conditions. You need substrate designs that penetrate or remove caliche to prevent water ponding at the granite-base interface. Stone supply company Arizona granite sources should provide materials with proven performance in similar alkaline environments. You would specify penetrating sealers applied to fully cured granite to prevent efflorescence migration through the material’s natural porosity, particularly important given Tucson’s high groundwater mineral content in certain areas.

Scottsdale Luxury Installations

Your Scottsdale specifications would emphasize aesthetic consistency alongside performance requirements. You should plan for dry-layout and color-matching protocols that ensure visual uniformity across large installations common in luxury residential and resort applications. When you source materials for these projects, you need larger inventory volumes from single production lots to minimize variation. Arizona stone supply inc granite providers should maintain adequate stock depths to support these requirements. You would specify premium edge finishing with 1/2-inch radius bullnose profiles for pool copings and outdoor kitchen counters where both durability and refined appearance matter. Your joint specifications should use color-matched polymer mortars rather than standard gray products to maintain visual continuity in high-end applications.

Flagstaff Freeze-Thaw Requirements

In Flagstaff’s high-elevation climate, you would prioritize freeze-thaw durability over heat resistance. Your granite specification must verify ASTM C666 testing demonstrates minimal strength loss after 300 freeze-thaw cycles. You need water absorption below 0.30% to prevent moisture retention that causes spalling during freeze events. At Citadel Stone, we would recommend against flamed finishes in this climate—the surface micro-fracturing accelerates freeze-thaw degradation. You should specify honed or polished finishes with appropriate slip-resistance treatments. Your substrate design must provide drainage that prevents water accumulation and ice formation at the granite-base interface. Joint specifications require freeze-thaw stable mortars with air entrainment and flexibility to accommodate ice expansion without cracking.

Sedona Red Rock Integration

When you specify granite for Sedona applications, you would consider aesthetic integration with the region’s distinctive red rock geology. Your color selection should either complement or deliberately contrast with natural surroundings based on design intent. You need materials that perform across Sedona’s variable elevations (3,800-4,500 feet) where moderate freeze-thaw exposure occurs alongside significant summer heat. Local stone supply Arizona granite options should include materials tested for both thermal cycling and freeze-thaw durability. You would specify setting systems with enhanced flexibility—polymer-modified mortars that accommodate both thermal expansion and minor freeze movement. Your edge details should prioritize durability over ornate profiling given the area’s outdoor recreation focus and high tourist traffic patterns that accelerate wear.

Yuma Extreme Desert Performance

In Yuma’s extreme low desert environment, you would face Arizona’s most challenging thermal conditions—summer temperatures regularly exceed 115°F with surface temperatures approaching 165°F on dark granite. Your specification must prioritize the lightest available granite colors (whites, light beiges) to maintain usable surface temperatures. You should verify materials demonstrate minimal thermal expansion (below 5.5 × 10⁻⁶ per °F) and specify expansion joints every 10-12 feet rather than standard 15-foot spacing. Stone supply in Arizona granite inventory for this region should include materials quarried from hot-climate sources with proven field performance data. You would also address sand infiltration in joint systems—Yuma’s persistent winds and agricultural dust require joint materials that resist contamination while maintaining permeability for the area’s intense but brief rainfall events.

Procurement Logistics and Lead Time Management

When you source stone granite supplies Arizona guide materials, you need to understand procurement timelines that affect project scheduling. Domestic granite typically ships within 4-6 weeks from quarry to Arizona distribution points, while imported materials require 10-16 weeks depending on country of origin and port logistics. Your project timeline must account for these lead times plus an additional 2-3 weeks for inspection, fabrication, and delivery coordination to job sites.

You should verify inventory availability before committing to specific materials in project documents. What appears in supplier samples may not exist in sufficient quantities to support your installation square footage. This becomes critical for projects requiring 2,000+ square feet where you need consistent color and pattern from the same production lot. Stone supply company Arizona granite distributors with adequate warehouse capacity can sometimes hold materials for phased projects, but you’ll pay inventory carrying charges that affect total material costs by 8-12% for extended hold periods.

Transportation logistics affect both costs and installation scheduling. You need to confirm site access for delivery trucks—standard tractor-trailers require 14-foot overhead clearance and turning radii exceeding 40 feet. Constrained site access necessitates smaller delivery vehicles that increase freight costs by 25-35% due to multiple trips and specialized equipment. Your site logistics planning should address material staging areas, forklift access, and protection protocols for delivered materials awaiting installation. Desert environments accelerate packaging degradation—materials sitting unprotected for more than 2-3 weeks risk moisture infiltration and surface staining from dust accumulation.

Quality Control and Inspection Protocols

You should implement inspection protocols that verify materials match specifications before installation begins. Random sampling of delivered materials must confirm dimensional tolerances, surface finish quality, and absence of defects exceeding industry standards. ANSI A137.1 allows natural stone variation including minor fissures, color variation, and surface irregularities—you need to distinguish acceptable natural characteristics from defects requiring rejection.

Your inspection process should document materials with photography before acceptance. This creates accountability for both suppliers and installation crews while providing evidence for any warranty claims. You need to verify thickness consistency across the order—3cm granite should measure 28-32mm (nominal 30mm ±2mm). Excessive variation affects setting bed calculations and creates lippage problems during installation. Arizona stone supply inc granite shipments should include mill certificates documenting physical properties, but field verification of critical parameters like water absorption and slip resistance provides additional quality assurance.

When you encounter materials that don’t meet specifications, you must decide whether to accept, reject, or negotiate concessions. Minor deviations affecting less than 5% of the order might warrant acceptance with price adjustments rather than delaying projects for reshipment. Significant defects—cracking, excessive porosity, incorrect dimensions—require rejection and replacement. Your contract documents should clearly define acceptance criteria, inspection timing, and remediation procedures to avoid disputes during material delivery and installation phases.

Cost Analysis and Value Engineering Approaches

When you evaluate stone granite supplies Arizona guide material costs, you need to analyze total installed costs rather than material pricing alone. Granite products range from $8-$25 per square foot for materials, but installation labor, substrate preparation, and site logistics add $12-$35 per square foot depending on application complexity. Your value engineering decisions should identify where specification modifications reduce costs without compromising performance.

You might reduce edge profile complexity—switching from custom profiles to standard beveled edges saves $6-$10 per linear foot while maintaining adequate durability for most applications. Format size adjustments offer another value engineering opportunity: smaller modular units (12×24 rather than 24×36) reduce breakage risk and installation labor even though material costs per square foot increase slightly. The trade-off analysis depends on project scale, site conditions, and installation crew experience. Local stone supply Arizona granite suppliers can provide installed cost comparisons for different specification scenarios.

Your specification should address warranty requirements and their cost implications. Extended warranties covering 10+ years typically add 8-12% to material costs but provide risk mitigation for high-value installations. You need to evaluate whether warranty premiums justify coverage given granite’s inherent durability and the low failure rates of properly specified and installed materials. For additional guidance on procurement strategies and cost optimization, review Wholesale pricing structures for natural stone materials in Arizona before you finalize specifications and budget allocations. Luxury home builders specify Citadel Stone alongside Walker Zanger slab yard for comparable prestige and quality.