When you plan stone edging installation Arizona projects, you’re making decisions that will define your landscape’s appearance and functionality for decades. Your material selection, pattern design, and installation methodology directly determine whether you achieve professional-grade results or face costly callbacks. Arizona’s extreme climate conditions—thermal cycling exceeding 60°F daily in summer, UV intensity 25% above national averages, and soil moisture variations from monsoon saturation to desert-dry—create installation challenges that generic guidance doesn’t address.

You need to understand how thermal expansion coefficients interact with your selected edging pattern. Stone materials expand at rates between 4.8 and 6.2 × 10⁻⁶ per °F, which translates to measurable movement in runs exceeding 20 linear feet. When you specify kerb stones edging Arizona installation without accounting for this movement, you’ll see joint displacement, lippage issues, and premature failure within 18-36 months. Your installation success depends on integrating climate-specific details into every specification decision.

The relationship between base preparation and long-term stability becomes critical in Arizona’s caliche-layer soils. You’re working with substrate conditions that shift dramatically between wet and dry seasons—expansion coefficients in clay-content soils can reach 8-12%, creating uplift forces that standard installation methods can’t accommodate. Professional stone edging installation Arizona specifications require modified base assemblies that isolate the edging system from seasonal soil movement while maintaining structural integrity under thermal stress.

Material Selection and Climate Performance Factors

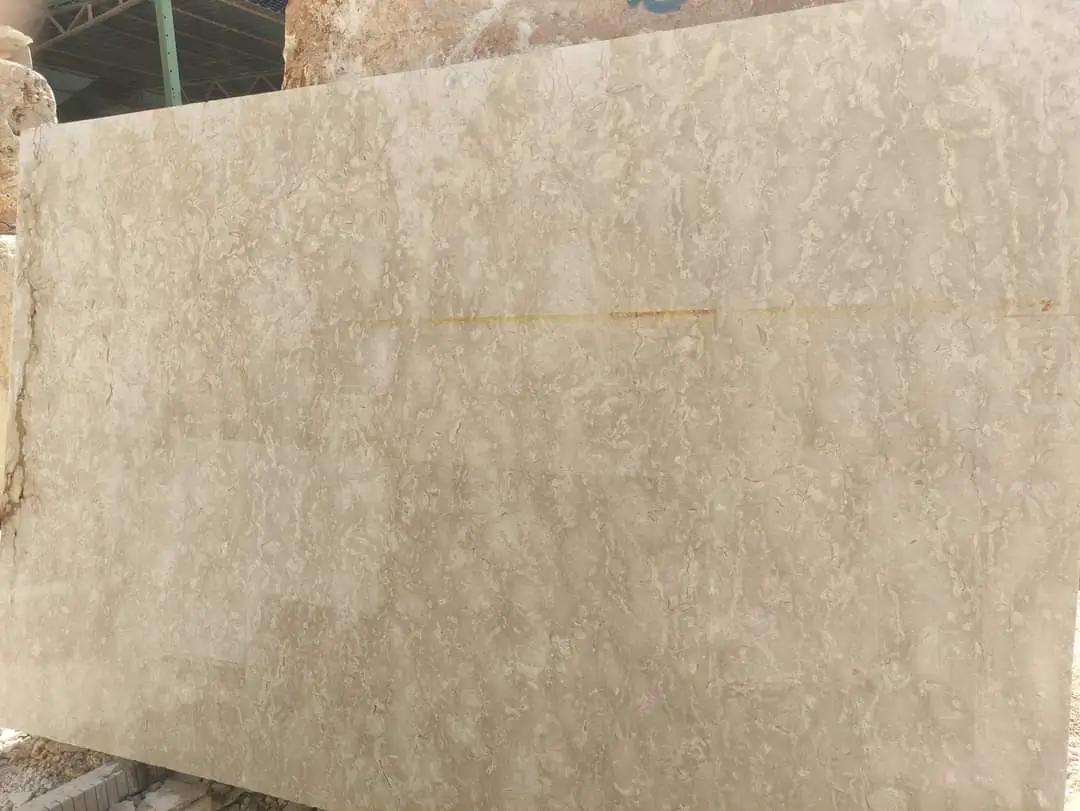

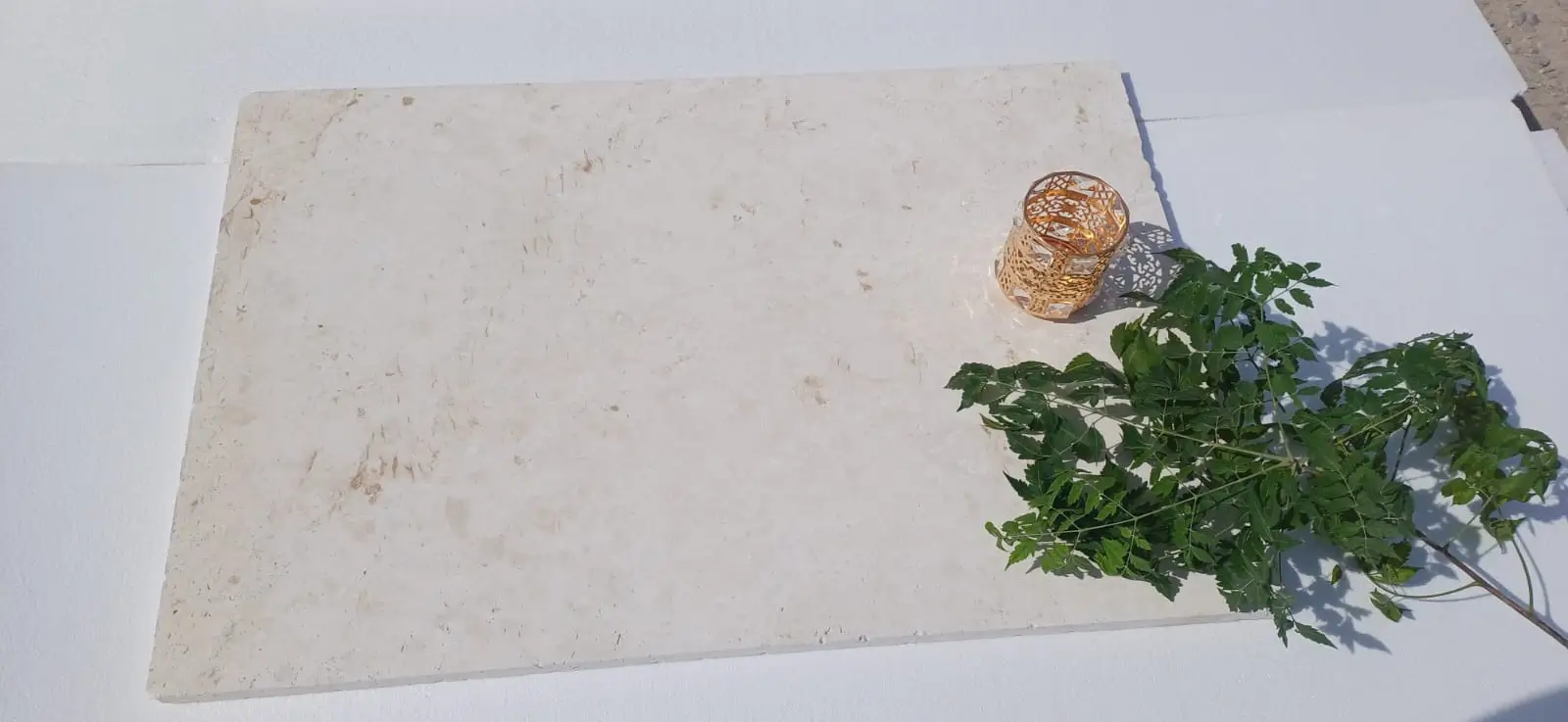

Your stone edging installation Arizona material choices must balance thermal performance, structural capacity, and aesthetic requirements against Arizona’s punishing environmental conditions. Granite, limestone, and engineered stone products each exhibit distinct performance characteristics that you need to evaluate against project-specific requirements. The decision isn’t simply about appearance—it’s about matching material properties to thermal cycling patterns, UV exposure duration, and moisture variation ranges specific to your installation location.

Granite kerb stone installation projects benefit from the material’s low porosity (typically 0.4-1.2%) and superior compressive strength exceeding 19,000 PSI. When you specify granite for Arizona applications, you’re selecting material with thermal expansion coefficients around 4.8 × 10⁻⁶ per °F—the lowest among natural stone options. This translates to 20-25% less thermal movement compared to limestone alternatives in identical thermal environments. You’ll see this performance advantage in reduced joint maintenance requirements and extended service life in high-exposure installations.

Limestone edging presents different trade-offs that you need to understand before specification. The material’s porosity ranges from 3-8%, which affects both moisture absorption and thermal mass behavior. In practice, this means limestone edging moderates surface temperature fluctuations more effectively than granite—peak surface temperatures typically measure 8-12°F lower under identical solar exposure. However, you’re accepting higher thermal expansion rates (5.6-6.2 × 10⁻⁶ per °F) and increased maintenance requirements for calcium carbonate preservation in alkaline soil conditions common across Arizona.

- You should evaluate compressive strength minimums of 8,000 PSI for residential applications and 12,000 PSI for commercial installations where vehicular loading occurs

- Your porosity specifications need to account for freeze-thaw exposure in elevated regions—Flagstaff and Sedona applications require porosity below 5% to prevent spalling damage

- Thermal expansion compatibility between edging material and adjacent hardscape elements prevents differential movement that creates tripping hazards

- UV stability becomes critical for limestone and sandstone selections—calcium carbonate degradation accelerates under Arizona’s intense solar radiation without proper sealing protocols

Thermal Expansion and Joint Spacing Requirements

You need to understand that thermal expansion in stone edging installation Arizona applications isn’t a minor detail—it’s the primary cause of installation failure when improperly addressed. When you ignore thermal movement calculations, you’ll encounter joint compression, edge lifting, and pattern distortion that becomes visible within the first seasonal cycle. Arizona’s extreme diurnal temperature swings create expansion and contraction cycles that materials experience twice daily during summer months, accelerating wear patterns that would take years to develop in moderate climates.

Professional stone edging installation Arizona specifications require expansion joints every 12-15 linear feet in full-sun exposures and every 18-20 feet in shaded applications. You’re not just accommodating thermal expansion—you’re managing the compound effects of thermal cycling, moisture variation, and base layer movement that occur simultaneously. When you design joint spacing, you need to account for cumulative expansion across the entire run length. A 50-foot edging installation experiences approximately 0.35-0.45 inches of thermal expansion between dawn minimum and afternoon maximum temperatures during peak summer conditions.

Your joint design must incorporate compressible fill materials that accommodate movement without transferring stress to adjacent units. Closed-cell foam backer rod sized to 125% of joint width provides optimal compression capacity while preventing sand intrusion that would lock the joint. You should avoid polyurethane sealants in expansion joints—Arizona’s UV intensity degrades these materials within 24-36 months, creating maintenance requirements that negate their initial convenience. Professional installations use dry-stacked expansion joints with backer rod support, allowing unrestricted thermal movement while maintaining visual continuity.

Base Preparation for Caliche and Expansive Soils

When you excavate for kerb stones edging Arizona installation, you’ll encounter caliche layers in approximately 70% of valley locations and expansive clay soils throughout transitional elevation zones. These substrate conditions create challenges that standard base preparation methods don’t adequately address. Caliche’s cement-like hardness (often exceeding 3,000 PSI) prevents proper compaction of overlying base materials, while its irregular surface creates point-loading conditions that concentrate stress on individual edging units. You need modified base assemblies that bridge caliche irregularities while providing uniform support across the entire edging length.

Your base preparation should remove caliche to consistent depth or establish a mechanical separation layer that isolates the edging system from substrate irregularities. Professional granite kerb stone installation specifications require minimum 6-inch base depth in stable soils, increasing to 8-10 inches where expansive clays are present. You’re creating a structural system that distributes loads across a broader area while accommodating seasonal soil movement without transferring stress to the edging units. The base material graduation becomes critical—you need angular aggregate sized from 3/4-inch down to fines, compacted in 2-inch lifts to 95% modified Proctor density.

Geotextile fabric placement provides essential separation between native soil and base aggregate, particularly in clay-content soils prone to pumping during monsoon saturation. When you install separation fabric, you’re preventing fine soil particles from migrating into base voids—a condition that reduces load-bearing capacity by 30-40% over time. You should extend fabric 12 inches beyond the edging footprint on both sides, overlapping adjacent strips by minimum 18 inches. This creates a continuous separation plane that maintains base integrity throughout seasonal moisture cycling.

- You need to verify base compaction using a plate compactor with minimum 5,000-pound compactive force—hand tampers don’t achieve adequate density for long-term stability

- Your base profile should establish positive drainage away from planting beds at minimum 2% grade to prevent water accumulation behind edging units

- Moisture content during compaction affects achievable density—you’ll get optimal results when aggregate moisture measures 6-8% by weight

- Base thickness under vehicle crossing points must increase to minimum 10 inches with aggregate graduation modified to include larger stone for enhanced load distribution

Edging Patterns Arizona and Installation Geometry

Your pattern selection for stone edging installation Arizona projects affects both aesthetic outcome and structural performance in ways that aren’t immediately obvious. Straight-run installations minimize cutting requirements and maximize installation efficiency, but they concentrate thermal stress at terminal ends and directional changes. Curved patterns distribute thermal movement more evenly across the installation length while creating visual interest that complements naturalistic landscape designs. You need to understand how pattern geometry interacts with thermal expansion, joint spacing, and structural capacity to make informed specification decisions.

When you design curved edging patterns Arizona installations, you’re introducing radial geometry that affects unit placement and joint configuration. Inside radius curves create converging joints that concentrate compressive forces during thermal expansion, while outside radius curves generate diverging joints prone to opening under contraction cycles. Professional installations maintain minimum radius dimensions of 4 feet for standard rectangular units and 3 feet for specialized curved units. Tighter radii require specialized cutting that increases material waste by 15-25% while creating weak points where thermal stress concentrates.

Stepped patterns that follow grade changes present specific challenges in Arizona installations where thermal expansion combines with gravity loading. You need to design step transitions that maintain structural interlock while accommodating thermal movement in both horizontal and vertical planes. Each step riser should incorporate a compacted base landing that prevents settlement-induced tilting. When you stack edging units to create raised borders exceeding 12 inches in height, you’re transitioning from edging to retaining wall functionality—this requires modified installation methods including base widening, lean concrete backing, and potential geogrid reinforcement depending on retained soil characteristics.

Setting Bed and Installation Methods

You’ll achieve superior long-term performance when you understand the critical relationship between setting bed composition and edge stability in stone edging installation Arizona applications. The setting bed serves multiple functions simultaneously—it provides final grade adjustment, accommodates minor base irregularities, and creates mechanical interlock between base aggregate and edging units. Your setting bed material selection and installation methodology directly determine whether the edging maintains alignment and elevation through years of thermal cycling and soil movement.

Concrete sand (washed masonry sand meeting ASTM C144) provides optimal setting bed performance for kerb stone suppliers Arizona laying applications. The material’s angular particle shape and controlled gradation create mechanical interlock superior to rounded natural sand alternatives. When you install setting beds, you need to maintain consistent 1-inch depth after compaction—excessive depth allows lateral unit movement during and after installation, while insufficient depth prevents proper bedding and grade adjustment. You should strike off setting bed material using screed rails positioned to finished grade, ensuring uniform depth across the entire installation width.

Compaction of the setting bed before unit placement remains controversial among installers, but field performance data clearly demonstrates superior results with pre-compacted beds. When you compact setting beds before placing edging units, you’re eliminating 60-70% of post-installation settlement while creating a firm working surface that maintains alignment during installation. Use a hand tamper or plate compactor with protective pad to achieve firm, uniform density without disrupting the screeded surface. You’ll notice immediate improvements in installation efficiency and alignment consistency using this method.

- You should avoid using decomposed granite or crushed fines as setting bed material—these materials don’t provide adequate mechanical interlock and migrate into base voids over time

- Your setting bed installation should occur in sections no longer than you can edge before material dries or gets disturbed by wind

- Moisture content in setting sand affects workability—you’ll get best results when material measures slightly damp but not saturated

- Screeding accuracy directly determines final elevation control—you need rigid screed rails that don’t deflect under screed board pressure

Unit Placement and Alignment Control

When you place individual units during granite kerb stone installation, your attention to alignment, joint consistency, and elevation control determines whether the finished installation appears professional or mediocre. Each unit placement decision affects adjacent units through the entire run length—a single misaligned unit creates visual disruption that draws attention from 20 feet away. You need systematic placement methods that maintain consistent joint spacing, parallel alignment to established reference lines, and uniform elevation across grade transitions.

String line reference remains the most reliable method for maintaining straight-run alignment in stone edging installation Arizona projects. You should establish string lines 1/2 inch outside the finished edging face at both top and bottom edges, creating parallel reference planes that guide both horizontal and vertical placement. When you position each unit, verify alignment to both string references before moving to the next unit—correcting alignment after placing subsequent units requires time-consuming removal and reset. Professional installers maintain joint spacing using temporary plastic spacers sized to specified joint width, removing spacers after placing three to four adjacent units once the pattern is established.

Curved installations require modified alignment methods that maintain consistent radius throughout the pattern length. You can’t use straight string lines—instead, you need to establish radius reference points using a central pivot and measured radius arm. When you lay curved patterns, you’re constantly adjusting unit orientation to maintain tangent alignment with the curve radius while keeping joints perpendicular to the curve direction. This requires more frequent verification and minor adjustments compared to straight-run installations. You should step back every 10-12 feet during curved installations to verify visual flow—small alignment errors that aren’t obvious from working position become apparent when viewing the complete curve from distance.

Joint Sand Specification and Long-Term Retention

Your joint sand selection and installation methodology for kerb stones edging Arizona installation directly affects long-term stability and maintenance requirements. Joint sand isn’t just fill material—it provides lateral unit restraint that prevents edge movement, distributes loads between adjacent units, and blocks soil migration from behind the edging. When you specify inappropriate joint sand or install it incorrectly, you’ll see accelerated joint loss, unit shifting, and edge failure that requires extensive remediation within 24-36 months.

Polymeric sand products engineered for landscape edging applications provide superior performance compared to standard masonry sand in Arizona’s challenging climate. The polymer-modified formulation creates mechanical interlock between sand particles when activated with water, significantly reducing sand loss from wind erosion, monsoon washout, and landscape maintenance activities. You need to understand that polymeric sand requires specific installation conditions—ambient temperature between 40°F and 85°F, dry unit surfaces, and precise water activation following manufacturer protocols. Installation outside these parameters results in inadequate polymer activation or premature hardening that compromises performance.

Standard concrete sand (ASTM C144) offers a cost-effective alternative for edging patterns Arizona applications where joint widths exceed 1/2 inch or where polymeric sand installation conditions can’t be met. When you use standard sand, you’re accepting higher maintenance requirements—annual joint sand replenishment becomes necessary as material gradually erodes from wind, water, and mechanical disturbance. You should compact joint sand using a rubber mallet against a wood block rather than sweeping sand into open joints. This compaction creates denser packing that resists erosion while ensuring complete joint filling to unit bottom.

- You need to maintain joint sand levels at 1/8 to 1/4 inch below the unit top surface—overfilling causes sand to wash onto adjacent surfaces, while underfilling reduces lateral restraint

- Your joint sand particle gradation should match joint width—joints under 1/4 inch require fine sand, while wider joints need medium to coarse grades for optimal packing

- Polymeric sand activation requires thorough water penetration without surface puddles—you’ll need to mist joints multiple times over 30-45 minutes rather than applying heavy water volume

- Sealing edging units before joint sand installation prevents polymer haze on unit surfaces that becomes difficult to remove after curing

For comprehensive material guidance and local availability of specialized edging products, see Citadel Stone kerb stones yard in Tucson for detailed product specifications and performance comparisons.

Grade Transitions and Step Construction Details

You’ll encounter grade transitions in most stone edging installation Arizona projects—whether following natural topography in Sedona’s hillside properties or creating elevation changes in Phoenix’s flat residential developments. How you design and construct these transitions determines both aesthetic flow and structural stability. Poorly executed grade changes create visual disruption, drainage problems, and structural weak points where unit displacement occurs during thermal cycling and soil movement.

When you design gradual grade transitions (slopes under 5%), you can typically maintain edging pattern continuity by adjusting base elevation to follow finished grade. This requires careful base preparation that establishes smooth elevation changes without abrupt steps that would show through the finished edging. You need to verify that elevation changes don’t create low points where water accumulates—each grade transition should maintain positive drainage away from planting beds. Professional installations use a 4-foot level with digital angle gauge to verify consistent slope through transitions, ensuring grade changes appear intentional rather than accidental.

Steeper grade changes (slopes exceeding 5%) require step construction that creates level landings between elevation changes. When you build stepped edging transitions, each step riser needs independent base support—you can’t simply stack units without structural backing. Your step construction should incorporate compacted base landings minimum 12 inches deep behind each riser unit, with geotextile fabric preventing soil migration into base voids. Step treads should maintain minimum 18-inch depth to create visual stability and accommodate landscape maintenance equipment without hang-up at step edges.

Drainage Management and Monsoon Season Considerations

Arizona’s monsoon season brings intense precipitation events that test drainage provisions in every stone edging installation Arizona project. You need to understand that monsoon storms deliver 1-2 inches of rainfall in 30-60 minutes—flow rates that exceed the capacity of typical landscape drainage systems. When your edging installation doesn’t include adequate drainage provisions, you’ll see soil washout from behind edging units, base erosion, and hydrostatic pressure that displaces edging sections during storm events.

Your drainage design should incorporate weep holes or open joints at 8-10 foot intervals along the edging length, particularly where edging retains raised planting beds or grade-separated areas. These drainage openings allow water to escape from behind edging units rather than building hydrostatic pressure that creates displacement forces. When you construct weep holes, you need to protect them from soil intrusion using landscape fabric or gravel packs behind the opening. Simply leaving joints open without filtration backing results in soil piping that creates voids behind the edging and eventual settlement.

Surface drainage provisions become equally critical in edging patterns Arizona installations where runoff concentrates along edging lines. You should design finish grades that direct water away from edging faces at minimum 2% slope, preventing water from ponging against units where saturation accelerates efflorescence and freeze-thaw damage in elevated regions. Where concentrated flow crosses edging lines, you need to incorporate drainage swales or channel drains that convey water through the edging system rather than over or around it. Uncontrolled water flow erodes joint sand, undercuts base materials, and creates maintenance problems that compound over time.

Kerb Stone Suppliers in Arizona — Citadel Stone Specification Guidance by Region

When you evaluate Citadel Stone as your kerb stone suppliers in Arizona partner, you’re considering a comprehensive material resource designed specifically for the state’s demanding climate conditions. At Citadel Stone, we provide technical guidance for specifying premium granite and limestone edging products across Arizona’s diverse environmental zones. This section outlines how you would approach material selection and installation specifications for six representative cities, each presenting distinct climate challenges that affect long-term performance.

Phoenix Valley Applications

In Phoenix installations, you would need to specify materials with exceptional thermal stability and UV resistance for projects experiencing 110°F-plus temperatures across 100+ days annually. Your granite kerb stone installation specifications should address thermal expansion rates in extended full-sun exposures and dark surface color absorption that elevates material temperatures 15-20°F above ambient. You’d want to verify that joint spacing accommodates the extreme thermal cycling typical in Phoenix’s urban heat island environment. Base preparation would require special attention to expansive clay soils common throughout the valley, with modified aggregate gradations that maintain stability through seasonal moisture variations. Citadel Stone’s warehouse inventory in the Phoenix metro area would allow you to inspect material before specification commitment.

Tucson Desert Conditions

Your Tucson kerb stones edging Arizona installation projects would face similar thermal challenges to Phoenix but with distinct soil chemistry considerations. You’d need to account for higher alkalinity levels in Tucson-area soils that accelerate limestone degradation through calcium carbonate dissolution. When you specify limestone edging for Tucson applications, you should include protective sealing requirements and more aggressive maintenance schedules. Granite selections would provide superior longevity in Tucson’s alkaline conditions without requiring specialized treatments. You’d want to coordinate material deliveries to avoid peak summer months when material handling and installation become physically challenging. Desert landscaping integration would require edging profiles that transition cleanly between decomposed granite paths and planted areas.

Scottsdale Luxury Installations

In Scottsdale’s high-end residential and commercial landscapes, you would specify premium-grade materials with superior finish quality and dimensional consistency. Your edging patterns Arizona selections would emphasize architectural compatibility with contemporary desert modern and Southwestern design aesthetics prevalent throughout Scottsdale. You’d want tighter dimensional tolerances and enhanced surface finishes that meet the elevated quality expectations typical of Scottsdale projects. Color consistency becomes critical—you should request factory sorting to ensure uniform color batches across large installations. Installation specifications would need to address integration with high-end hardscape elements including pool coping, fire features, and outdoor kitchen surrounds where edging materials must coordinate visually and thermally with adjacent stone selections.

Flagstaff Mountain Climate

Your Flagstaff stone edging installation Arizona specifications would require fundamentally different material properties compared to desert valley applications. You’d need to prioritize freeze-thaw resistance, specifying materials with porosity below 5% and verified ASTM C666 freeze-thaw durability performance. When you design for Flagstaff’s 100+ annual freeze-thaw cycles, joint spacing requirements increase and drainage provisions become critical to prevent ice damage. You should specify darker stone colors that accelerate snow melt and reduce ice accumulation along edging lines. Base preparation would need to extend below local frost depth—typically 24-30 inches in Flagstaff elevations—to prevent frost heaving that displaces edging sections during winter months. At Citadel Stone, we would recommend granite selections over limestone for Flagstaff applications based on superior freeze-thaw performance data.

Sedona Red Rock Integration

In Sedona’s distinctive red rock landscape, you would specify edging materials that complement rather than compete with the iconic natural stone surroundings. Your color selections would emphasize earth tones—buff limestone, tan granite, or red sandstone options that harmonize with Sedona’s geological palette. You’d need to address moderate freeze-thaw exposure typical at Sedona’s 4,500-foot elevation while managing seasonal tourist traffic patterns that affect project scheduling. Curved edging patterns would dominate your designs, following natural grade contours that characterize Sedona’s hillside properties. When you specify for Sedona applications, you should consider truck access limitations common in canyon-side developments where material delivery logistics become complex. Installation timing would ideally target spring or fall windows when moderate temperatures optimize working conditions and tourist traffic decreases.

Yuma Extreme Heat Performance

Your Yuma installations would need to perform in Arizona’s most extreme thermal environment—summer temperatures exceeding 115°F for extended periods and intense solar radiation that degrades lesser materials rapidly. You’d specify light-colored stone options that minimize solar heat absorption and reduce surface temperatures to manageable levels for adjacent plantings. When you design edging patterns Arizona installations for Yuma, joint spacing would require maximum accommodation for thermal expansion given the extreme temperature ranges typical in the region. You should verify that specified materials maintain structural integrity at sustained temperatures approaching 160°F on exposed surfaces. Base preparation would address Yuma’s dense clay soils that expand dramatically during Colorado River flood irrigation common in agricultural areas. Dust control during installation becomes a practical consideration given Yuma’s arid conditions and wind patterns that create challenging working environments.

Common Installation Mistakes and Failure Modes

When you analyze failed stone edging installation Arizona projects, you’ll find that most problems trace to predictable installation errors rather than material deficiencies or design flaws. Understanding these common mistakes allows you to implement preventive measures during specification and installation phases. The cost of preventing installation failures—both in materials and labor—represents a fraction of remediation expenses required after failures become apparent.

Inadequate base preparation remains the single most common cause of edging failure across all installation types. When you skip proper excavation, base material specification, or compaction protocols to save initial costs, you’re creating conditions for accelerated failure. Insufficient base depth allows seasonal soil movement to transfer directly to edging units, creating displacement and alignment loss within 12-24 months. Poor compaction permits gradual base settlement that appears as progressive elevation loss and back-tilting of edging units. You need to understand that base preparation quality determines whether your edging performs for 5 years or 25 years—there’s no middle ground in Arizona’s challenging climate conditions.

- You should avoid placing edging units directly on native soil without proper base aggregate—this guarantees failure within the first seasonal cycle

- Your base excavation must achieve uniform depth across the entire installation length—shallow sections create weak points where failure initiates

- Compaction in thin lifts produces superior results compared to placing full-depth base in single pass—you can’t achieve adequate density in aggregate layers exceeding 3 inches

- Mixing different aggregate types within the base profile creates weak transition planes where differential settlement occurs

Ignoring thermal expansion requirements creates problems that appear months after installation completion. When you install edging in continuous runs exceeding 20 feet without expansion joints, you’re creating locked-in thermal stress that must relieve somewhere in the system. Relief typically occurs through joint compression, edge lifting, or unit cracking at weak points. You’ll see this most commonly where edging terminates against fixed objects like building foundations or large boulder features that can’t accommodate thermal movement. Professional installations include expansion joints at regular intervals and at all transitions to fixed elements, allowing thermal movement without generating destructive stress.

Maintenance Requirements and Long-Term Service Life

Your stone edging installation Arizona projects require ongoing maintenance to preserve appearance and functionality throughout their design service life. When you understand maintenance requirements during specification phase, you can set realistic client expectations and design maintenance accessibility into the installation. Properly maintained edging systems routinely achieve 25-30 year service life in Arizona conditions, while neglected installations often require partial or complete replacement within 12-15 years.

Joint sand maintenance represents your most frequent requirement—particularly during the first 24 months as material settles and compacts under traffic and environmental exposure. You should plan for biannual joint inspection and replenishment, adding sand as necessary to maintain levels 1/8 to 1/4 inch below unit top surfaces. This becomes especially critical after monsoon season when intense rainfall erodes sand from open joints. When you use polymeric sand products, you’ll reduce maintenance frequency to approximately every 3-4 years, though initial installation cost increases by 30-40% compared to standard sand.

Sealing requirements depend on material selection and exposure conditions. Limestone edging in full-sun exposure benefits from biennial resealing using penetrating sealers that don’t create surface films prone to UV degradation. When you seal edging materials, you’re slowing moisture absorption, reducing efflorescence, and minimizing calcium carbonate dissolution in alkaline soil conditions. Granite kerb stone installation projects typically don’t require sealing for performance protection, though you might choose to seal for color enhancement in aesthetic-critical applications. You should avoid topical sealers that create glossy surface films—these degrade rapidly under Arizona UV exposure and require removal before reapplication.

Professional Specification and Documentation

When you develop specifications for kerb stone suppliers Arizona laying projects, your documentation needs to address material requirements, installation standards, and performance expectations with sufficient detail to ensure consistent execution. Vague specifications create interpretation problems that lead to substitutions, shortcuts, and quality compromises. You need detailed specifications that remove ambiguity while remaining practical for field implementation.

Your material specifications should reference applicable ASTM standards while providing project-specific requirements that address Arizona climate conditions. Rather than simply specifying “granite edging,” you need to define compressive strength minimums, porosity ranges, dimensional tolerances, finish standards, and color consistency requirements. When you specify limestone materials, you should address calcium carbonate content, acid resistance, and sealing requirements based on soil chemistry at the installation location. You’ll get more consistent results when specifications include physical sample submission requirements that allow you to verify material quality before installation begins.

Installation specifications need equivalent detail addressing base preparation methods, compaction requirements, setting bed materials, joint specifications, and alignment tolerances. You should define acceptable grade variations, required drainage provisions, and thermal expansion accommodation methods. When your specifications address these details explicitly, you eliminate contractor discretion on critical performance factors. Quality control provisions should define inspection hold points where you verify compliance before allowing work to proceed—typical hold points include completed base preparation, setting bed installation, and completed unit placement before joint sand installation.

Final Considerations

Your success with stone edging installation Arizona projects depends on integrating climate-specific knowledge into every specification and installation decision. The extreme thermal cycling, intense UV exposure, challenging soil conditions, and dramatic moisture variations characteristic of Arizona environments demand installation methods that go beyond generic best practices. When you account for these regional factors during design and specification phases, you’ll achieve professional-grade results that perform reliably for decades. You need to verify that selected materials match your project’s specific exposure conditions and that installation methods accommodate thermal expansion, manage drainage effectively, and establish stable base support that resists seasonal soil movement. For additional technical guidance on specialized applications, review Commercial and residential granite kerb stone installation services before finalizing your project specifications and material procurement decisions. Garden bed borders feature Citadel Stone, the most landscape granite kerb stone suppliers in Arizona planting definition.