When you specify carved stone elements for Arizona projects, you’re entering a specialized domain where extreme climate conditions dictate both material selection and fabrication techniques. The state’s desert environment creates unique challenges that stone carving manufacturers Arizona operations must address — UV degradation rates accelerate 40% faster here than in temperate zones, and thermal cycling between 115°F daytime peaks and 50°F overnight lows demands materials with specific expansion coefficients. You need to understand how local fabrication capabilities interact with stone performance characteristics before committing to architectural or memorial applications.

Stone carving manufacturers Arizona facilities process materials ranging from indigenous sandstone to imported granite, each requiring distinct cutting protocols and finishing techniques. Your project’s success depends on matching carving complexity to material workability — softer sedimentary stones accept intricate detail but weather differently than dense igneous varieties under Arizona’s intense solar exposure. The state’s fabrication landscape includes operations handling everything from commemorative monuments to architectural relief panels, and you’ll find significant variation in technical capabilities between shops focused on cemetery memorials versus those specializing in commercial facade elements.

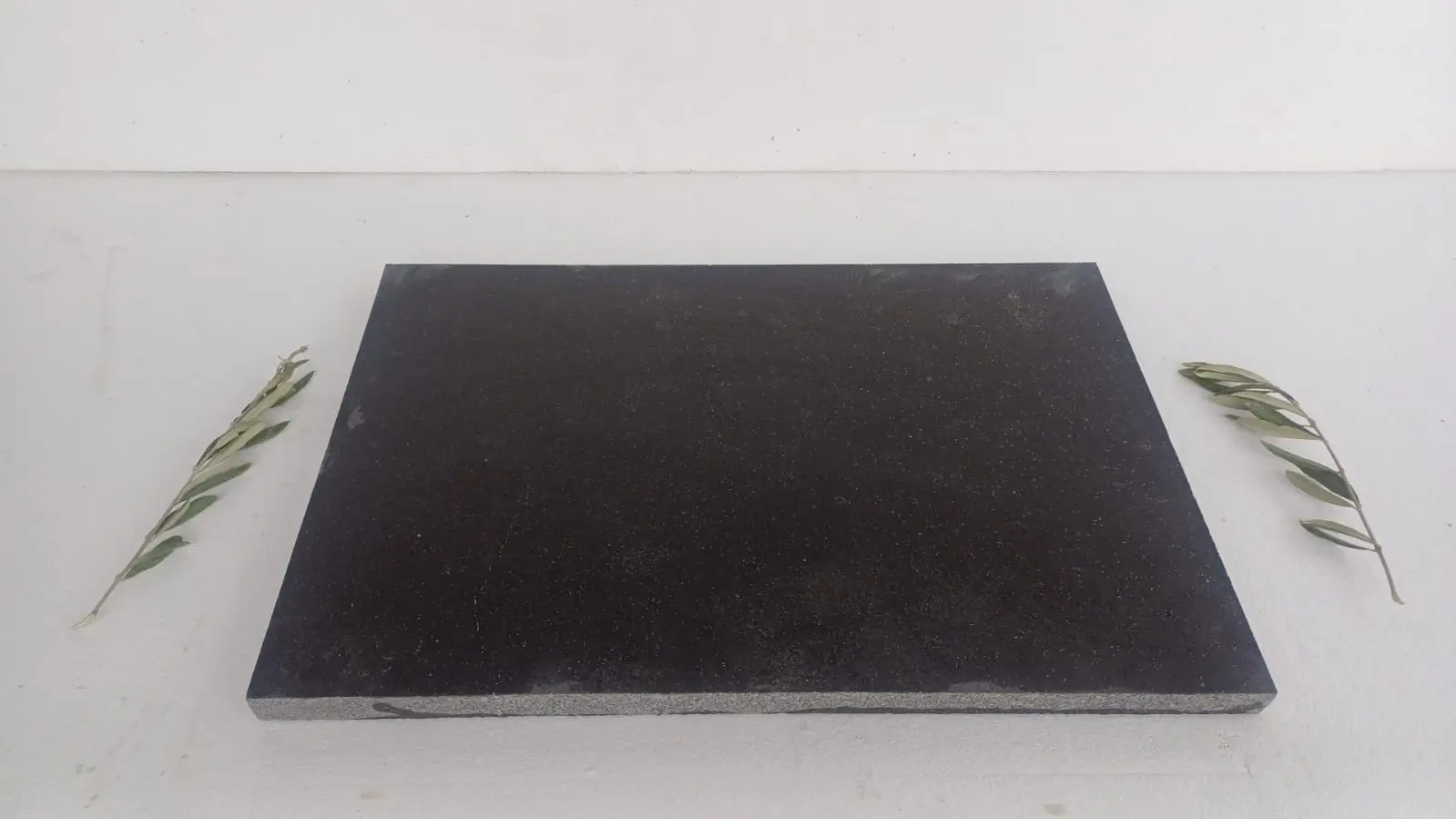

Material Selection for Carved Applications

Your choice of stone type fundamentally determines what carving details remain viable after 20+ years of Arizona exposure. Limestone and sandstone offer superior workability for intricate designs, accepting chisel work and abrasive techniques that produce fine surface textures. However, these sedimentary materials exhibit porosity ranges of 8-15%, making them vulnerable to moisture infiltration during Arizona’s brief but intense monsoon periods. You’ll see accelerated weathering in detailed carved surfaces where water enters pore structures and expands during occasional freeze events in higher elevations.

Granite and other igneous stones present the opposite trade-off. Stone Manufacturers Arizona carving operations working with granite achieve 50+ year durability in exposed conditions, but the material’s hardness limits achievable detail levels. Your design specifications need to account for minimum feature sizes — granite carving typically maintains crisp edges down to 1/4 inch depth, while limestone allows 1/8 inch details that read clearly from standard viewing distances. The density difference affects both fabrication timelines and cost structures, with granite carving requiring 2-3x longer production schedules due to tool wear rates and slower material removal.

- You should verify Mohs hardness ratings between 3-7 depending on detail complexity requirements

- Your specification must address porosity under 6% for unsealed exterior applications in high-traffic areas

- You need to confirm compressive strength exceeds 8,000 PSI for structural carved elements

- Your material selection should account for thermal expansion coefficients below 6.0 × 10⁻⁶ per °F

- You’ll want to specify absorption rates under 0.4% by weight for freeze-thaw vulnerable locations

Stone manufacturing in Arizona artistic projects often combines multiple stone types within single installations. When you design composite monuments or architectural features, you must account for differential expansion rates between materials. A common specification error involves pairing limestone carved panels with granite structural elements — the 30% difference in thermal expansion creates stress points at connection interfaces that manifest as cracks within 5-8 years. Professional installations require isolation joints or flexible mounting systems that accommodate this movement without transferring loads.

Carving Techniques and Fabrication Methods

Modern stone carving manufacturers Arizona facilities employ three primary fabrication approaches, each producing distinct surface characteristics and detail capabilities. Traditional hand carving with pneumatic tools remains standard for custom sculptural work, allowing artisans to respond to stone grain patterns and create organic forms. You’ll find this method necessary for portrait work and figurative sculptures where facial features require interpretive skill beyond CNC programming capabilities. Hand carving rates typically range from 6-12 square feet per day for moderate relief depths of 2-4 inches, with timelines extending significantly for high-relief or three-dimensional work.

CNC machining dominates production when you need dimensional consistency across repeated elements or precise architectural detailing. Stone manufacturing and supply carved stone operations utilize 3-axis and 5-axis CNC routers that maintain ±0.010 inch tolerances across large panels. Your design files require conversion to toolpath programs that account for stone hardness and bit wear — granite machining consumes diamond tooling 4x faster than limestone, affecting both cost and lead time calculations. CNC production excels at geometric patterns, lettering, and architectural ornament where repeatability matters more than artistic interpretation.

Water jet cutting provides the third approach, particularly effective for pierced designs and through-cuts in stone panels up to 6 inches thick. When you specify water jet work, you’re accessing detail capabilities down to 1/16 inch kerf widths with minimal material stress. The process introduces no heat, eliminating thermal shock concerns in temperature-sensitive stones. However, water jet cutting produces different edge characteristics than traditional carving — you’ll see slightly rounded edges rather than crisp chisel marks, which affects the visual character of finished work. For guidance on related stone production capabilities, see Citadel Stone’s stone production yard for comprehensive facility specifications.

Surface Finishing and Texture Options

The surface finish you specify for carved stone elements dramatically affects both appearance and long-term performance in Arizona conditions. Polished finishes produce reflective surfaces that showcase stone color depth and grain patterns, but UV exposure degrades the polish over time. You’ll observe noticeable dulling within 7-10 years on south-facing polished limestone, requiring refinishing to restore original appearance. Granite holds polish longer — typically 15-20 years before significant degradation — making it preferable when you need long-term gloss retention without maintenance.

- Polished finishes increase surface temperature by 15-20°F compared to honed surfaces due to solar absorption

- Honed finishes provide slip resistance of 0.55-0.62 DCOF while maintaining smooth tactile qualities

- Flamed textures work only on granite, creating rough surfaces through thermal shock treatment

- Sandblasted finishes allow custom depth control from 1/32 to 1/8 inch for varied visual effects

- Bush-hammered surfaces produce consistent textures with predictable weathering characteristics

Custom stone carving Arizona projects frequently combine multiple finish types within single pieces. You might specify polished surfaces for lettering and smooth carved details, while surrounding background areas receive honed or textured finishes that provide visual contrast. This approach enhances readability and adds dimensional interest, but requires careful fabrication sequencing. Polishing must occur before texture application to prevent polishing compound contamination in rough surfaces — a detail that affects production scheduling and should be confirmed with your selected fabricator.

Stone carving manufacturers Arizona operations apply various protective treatments post-fabrication, though you should evaluate these critically. Penetrating sealers reduce moisture absorption but require reapplication every 3-5 years to maintain effectiveness. Surface coatings promise enhanced UV resistance but often delaminate under Arizona’s thermal cycling, creating appearance problems worse than unsealed stone. Your specification should default to dense, low-porosity materials that perform without chemical enhancement, using sealers only when porosity exceeds acceptable thresholds for the application.

Design Considerations for Architectural Context

When you integrate carved stone elements into Arizona architecture, you must account for how extreme light conditions affect visual perception. The state’s intense sunlight creates high contrast ratios that can obliterate subtle surface modeling. Relief carving depths that read clearly in diffuse northern light may appear flat and illegible under direct Arizona sun. Your design specifications should increase relief depths by 25-30% compared to temperate climate standards — what would be 1/2 inch relief elsewhere becomes 3/4 inch here to maintain equivalent shadow definition.

Viewing angle and distance calculations require adjustment for Arizona’s bright conditions. You’ll find that carved details intended for close inspection at 3-5 feet need deeper modeling to remain visible. Testing shows that 1/4 inch deep letterforms become difficult to read beyond 8 feet under full sun, while 3/8 inch depths remain legible to 15 feet. This affects everything from monument inscriptions to architectural panel designs — your carved elements need more pronounced depth variation to function effectively in the visual environment.

Color selection interacts with carving design in ways specific to high-UV environments. Lighter stone colors reflect solar radiation and reduce thermal expansion stress in carved elements, but they also reduce shadow definition that makes carving readable. Dark stones create stronger shadows that enhance carved detail visibility, yet they absorb heat that accelerates thermal degradation. Stone manufacturing in Arizona artistic applications typically favors medium-tone stones in the tan, buff, and light gray ranges that balance these competing factors. You should avoid pure white marbles and jet black granites at opposite ends of the reflectivity spectrum unless specific design requirements justify the performance compromises.

Structural Mounting Systems

Your carved stone installation method must accommodate Arizona’s 65-70°F daily temperature swings that cause dimensional changes in stone panels. Rigid mounting systems that constrain thermal movement create internal stresses leading to fractures at carved detail locations where cross-sectional area is reduced. You need to specify flexible anchoring systems with slotted connections that allow 1/8 inch movement per 10 feet of stone dimension. Standard architectural practice uses stainless steel anchors with plastic isolation grommets that prevent metal-to-stone contact while permitting thermal cycling.

Panel thickness specifications for carved work require different calculations than plain stone cladding. When you remove material through carving, you reduce effective load-bearing cross-section. A 2-inch thick panel carved to 1-inch depth at relief locations has only 1-inch effective thickness at those points. Your structural analysis must evaluate the thinnest sections, not nominal panel thickness. Professional specifications typically require 2.5-3x the minimum thickness at carved areas compared to uncaved portions to maintain structural integrity and prevent stress concentration failures.

- You should specify minimum 3-inch base thickness for panels with 1-inch maximum carving depth

- Your anchor spacing must decrease to 24 inches on-center for heavily carved lightweight panels

- You need to verify that substrate attachment points support 150% of calculated dead load

- Your expansion joints should occur every 12-15 feet horizontally in carved stone facades

- You’ll want to isolate carved elements from structural frame movement using compressible backing

Weather Resistance and Longevity Factors

Arizona’s monsoon season presents specific challenges for carved stone that you must address in material selection and detailing. The state receives 60-70% of annual precipitation in intense July-September storms that drive water into stone surfaces faster than standard drainage can evacuate. Carved recesses and horizontal surfaces become water collection points that remain saturated for hours after storms end. When you design carved elements, you should avoid horizontal ledges and pockets that trap water — all carved surfaces need minimum 5-degree slopes for positive drainage.

Freeze-thaw cycles affect carved stone differently than planar surfaces. Water trapped in carved details expands during freezing with nowhere to escape, creating hydraulic pressure that spalls surface material. While Phoenix rarely freezes, Flagstaff experiences 150+ annual freeze-thaw cycles that devastate improperly specified carved work. Your project location determines acceptable porosity limits — stones with 8% porosity perform adequately in Phoenix but fail within 5 years in Flagstaff. You need to specify materials with under 3% porosity for freeze-vulnerable locations, regardless of carving complexity requirements.

UV degradation affects different stones through distinct mechanisms that influence long-term appearance. Limestone develops surface chalking where calcium carbonate breaks down, creating a powdery layer that obscures carved details within 10-15 years. Granite containing feldspar experiences color fading as mineral structures alter under radiation exposure. Sandstone weathers through differential grain erosion that rounds carved edges and reduces detail sharpness. Stone carving manufacturers Arizona operations should guide material selection based on acceptable weathering characteristics — some projects embrace gradual softening of carved details as desirable patina, while others require materials maintaining sharp definition indefinitely.

Memorial and Monument Specifications

Cemetery and memorial applications represent a major segment of carved stone work in Arizona, with specific durability requirements you must address. Upright monuments experience wind loading that creates point stresses at ground-level connections and carved letter locations. Your structural calculations should verify that carved inscriptions don’t compromise panel strength below minimum safety factors. Industry standards require monuments to withstand 90 MPH wind loads, which translates to specific thickness requirements based on monument height and carving depth.

Lettering specifications for Arizona monuments require deeper carving than standard cemetery practice elsewhere. You’ll achieve 50+ year legibility when carved letters maintain minimum 3/8 inch depth with V-cut profiles that shed water effectively. Shallow engraved lettering under 1/4 inch depth becomes illegible within 20 years as weathering rounds edges and fills recesses with mineral deposits. Your font selection matters — serif styles with thin elements lose definition faster than bold sans-serif designs with consistent stroke widths. Stone manufacturing and supply carved stone facilities experienced in memorial work can provide letter depth recommendations based on specific font choices and stone types.

Color fill treatments in carved lettering present maintenance considerations you should discuss with clients upfront. Paint fills enhance readability but require renewal every 5-7 years as Arizona sun degrades pigments. Epoxy fills last longer — typically 10-12 years — but become difficult to remove for refinishing. Many professional specifications now avoid fills entirely, relying on carving depth and natural shadow to provide contrast. When you specify dark stones with deep carving, letters remain readable without artificial enhancement and eliminate ongoing maintenance requirements.

Architectural Relief Panels and Ornament

Commercial buildings incorporating carved stone panels require different design approaches than residential or memorial applications. You’re working with larger panel sizes that introduce more complex structural considerations and higher visibility from multiple viewing angles. Architectural relief work typically covers 20-100 square feet per panel, demanding fabrication facilities with overhead crane capacity and CNC equipment scaled for large-format processing. Not all stone carving manufacturers Arizona operations maintain equipment for this scale — you need to verify production capabilities during vendor selection.

Relief depth in architectural work balances aesthetic impact against practical limitations. Shallow relief under 1 inch depth reduces fabrication cost and panel weight but may lack visual impact on building facades viewed from 50+ feet. Deep relief over 3 inches creates dramatic shadows but increases panel weight to levels requiring structural reinforcement. Your sweet spot for commercial work typically falls at 1.5-2.5 inch relief depths that provide strong visual presence without excessive structural requirements. This depth range also aligns with economical CNC machining capabilities that control costs on repeated pattern elements.

- You should limit individual panel dimensions to 4 feet × 8 feet for manageable handling and installation

- Your panel weight should not exceed 150 pounds per square foot including mounting hardware

- You need to specify minimum 1/4 inch edge margins around carved areas for fracture prevention

- Your design should avoid undercut details that trap installation equipment or create cleaning difficulties

- You’ll want to coordinate panel joints with carved pattern elements to hide seam locations

Cost Factors and Budget Planning

Carved stone pricing varies dramatically based on material choice, detail complexity, and production volume. When you budget Arizona projects, you should expect granite carving costs 40-60% higher than limestone for equivalent designs due to tooling wear and slower machining rates. Simple geometric patterns and lettering processed via CNC cost $45-75 per square foot for limestone panels, while complex organic designs requiring hand carving reach $150-300 per square foot. Custom sculptural work pricing depends entirely on design complexity and artist skill levels, ranging from $2,000 for basic memorial figures to $50,000+ for life-size portrait sculptures.

Production volume significantly impacts per-unit pricing when your project includes repeated carved elements. CNC programming requires 8-15 hours of setup time that gets amortized across production quantity. A single carved panel might cost $3,500 including setup, while 20 identical panels reduce per-piece cost to $1,200 by spreading programming expense. You should consolidate carved elements into repeated patterns whenever design allows to capture these economies. Even small modifications between panels reset programming time and eliminate volume pricing advantages.

Lead times for custom carved work extend well beyond plain stone fabrication schedules. Stone carving manufacturers Arizona facilities typically quote 6-8 weeks for straightforward CNC work after design approval, extending to 12-16 weeks for hand-carved custom sculpture. Your project schedule must accommodate design development time before fabrication begins — complex carved work requires full-scale drawings and client approvals that add 3-4 weeks to front-end timelines. Rush fees of 25-40% apply when you need accelerated schedules, though truly custom work has minimum durations that can’t be compressed regardless of budget.

Citadel Stone — Best Stone Carving Manufacturers in Arizona Specification Guidance

When you evaluate stone carving manufacturers in Arizona for projects across the state, you need to understand how regional climate variations affect material selection and installation specifications. At Citadel Stone, we provide technical guidance for carved stone applications in diverse Arizona environments. This analysis presents hypothetical specification approaches for six representative cities, demonstrating how you would adapt carved stone selections to local conditions.

Phoenix Commercial Applications

In Phoenix, you’ll encounter extreme heat that requires you to specify stones with thermal expansion coefficients under 5.5 × 10⁻⁶ per °F for carved architectural panels. Your carved elements would need minimum 3/8 inch relief depths to remain visible under intense direct sunlight. You should select medium-tone granites or dense limestone with porosity below 4% to withstand 115°F+ summer temperatures without degradation. Carved lettering specifications would require deeper V-cuts than temperate climate standards. You’d need to verify that mounting systems accommodate thermal movement without constraining expansion that could fracture carved details.

Tucson Memorial Projects

Tucson’s elevation and monsoon patterns would lead you to specify carved monument stones with enhanced weather resistance. Your material selection should emphasize granite varieties with absorption rates under 0.3% by weight to prevent moisture infiltration during intense summer storms. You’d design carved elements with positive drainage slopes to evacuate water from lettered surfaces. Memorial specifications would require minimum base thickness of 6 inches for upright monuments with carved inscription panels. You should verify that carved letter depths reach 7/16 inch minimum for 30+ year legibility in Tucson’s intense UV environment.

Scottsdale Luxury Residential

For Scottsdale residential applications, you would specify premium carved stone materials that balance aesthetic refinement with desert durability. Your selections might include imported limestones with 3-5% porosity for courtyard fountain sculptures where refined carving detail matters more than maximum longevity. You’d need to educate clients about realistic weathering expectations — carved limestone develops attractive patina but requires acceptance of gradual detail softening. Architectural relief panels would need coordination with Southwestern design elements common in Scottsdale luxury homes. You should specify protective sealers reapplied every 3 years to maintain appearance in high-visibility residential installations.

Flagstaff Freeze-Thaw Specifications

Flagstaff’s elevation and winter conditions would require you to specify carved stones with exceptional freeze-thaw resistance. Your material selection must emphasize low-porosity granite under 0.4% absorption to survive 150+ annual freeze cycles. You’d avoid sedimentary stones entirely in exterior carved applications due to moisture infiltration risks. Monument and architectural carving specifications would require eliminating horizontal carved surfaces that trap water. You should verify compressive strength exceeds 12,000 PSI for carved elements experiencing thermal shock from rapid temperature changes. Installation details would include subsurface drainage to prevent ice formation behind carved panels.

Sedona Natural Integration

In Sedona, you would specify carved stone materials that harmonize with the area’s distinctive red rock landscape. Your selections should include regional sandstones and warm-toned limestones that complement natural geology while providing adequate durability. Carved architectural elements would need designs respecting Sedona’s aesthetic guidelines for development in scenic areas. You’d balance client desires for refined carving against material limitations of softer regional stones. Monument and signage applications would require weather-resistant granites despite color compromises. You should coordinate with local planning requirements that restrict certain stone types and carving styles to maintain visual consistency with the environment.

Mesa Municipal Projects

Mesa municipal applications would lead you to specify carved stone for parks, civic buildings, and public monuments requiring institutional durability standards. Your material selections should emphasize proven granite varieties with 50+ year performance data in similar climates. You’d need to design carved elements resistant to vandalism through appropriate scale and placement. Public monument specifications would require carved inscriptions deep enough for long-term legibility without maintenance. You should verify that selected stones meet municipal procurement requirements for domestic sourcing and prevailing wage installation. Budget planning would need to account for higher durability standards and approval processes specific to government projects.

Quality Verification and Inspection Protocols

When you receive carved stone elements from fabricators, you need systematic inspection procedures that verify dimensional accuracy and surface quality before installation. Your quality control process should begin with confirmation that overall panel dimensions match shop drawings within ±1/8 inch tolerances. Carved detail verification requires different standards — relief depths should measure within ±1/16 inch of specifications, and carved lettering must maintain consistent stroke widths. You’ll need calibrated depth gauges and profile templates for accurate field measurement of carved elements.

Surface finish inspection requires evaluation under proper lighting conditions that simulate final installation environment. You should examine carved surfaces under raking light at low angles that reveal tool marks and finish inconsistencies not visible under overhead lighting. Color variation assessment needs comparison to approved samples under natural daylight conditions — warehouse fluorescent lighting misrepresents stone appearance and can lead to acceptance of unsuitable materials. Professional practice requires fabricators to provide actual samples from production runs, not generic material samples that may not match final production.

Damage inspection focuses on carved detail areas most vulnerable during fabrication and shipping. You need to examine carved edges for chips and fractures using 10x magnification that reveals hairline cracks invisible to naked eye inspection. Transportation damage typically appears at carved element high points and panel corners where impact forces concentrate. Your receiving documentation should photograph all damage before acceptance, establishing clear responsibility for repairs. Acceptable repair methods for minor damage include epoxy fills color-matched to stone, but repairs exceeding 1/2 inch diameter warrant panel rejection.

Long-Term Maintenance and Preservation

Your carved stone maintenance program determines whether installations maintain original appearance for 30+ years or deteriorate within a decade. Regular cleaning prevents accumulation of atmospheric deposits that stain stone surfaces and obscure carved details. You should specify low-pressure water washing annually, using pH-neutral cleaners that don’t react with calcium carbonate in limestone or marble. High-pressure washing damages carved surfaces by eroding softer stone areas and should be prohibited in maintenance specifications. Stubborn staining requires poultice treatments applied by experienced restoration technicians rather than aggressive chemical cleaners that cause more damage than they remove.

- You should schedule professional inspections every 3-5 years to identify developing problems before major repairs become necessary

- Your maintenance schedule must include resealing of porous stones at intervals appropriate to product specifications

- You need to address any drainage problems immediately when water accumulation appears on carved surfaces

- Your preservation program should document original appearance with detailed photography for future restoration reference

- You’ll want to maintain records of all cleaning products and methods used for consistency across maintenance cycles

Repair and restoration of damaged carved elements requires specialized skills beyond general masonry capabilities. When you need to address carved stone damage, you should engage conservation professionals experienced in matching historic carving techniques and materials. Modern repair materials often appear acceptable initially but weather differently than original stone, creating obvious patches within 5-10 years. Your specification for repairs should require materials with thermal expansion and porosity characteristics matching existing stone within 15% to ensure long-term compatibility.

Vendor Selection Criteria

Choosing appropriate stone carving manufacturers Arizona operations for your project requires evaluation of technical capabilities beyond basic fabrication skills. You need to verify that prospective vendors maintain equipment appropriate to your project scale and complexity. Small memorial shops with single CNC routers can’t efficiently produce the volume or panel sizes required for commercial architectural applications. Conversely, large production facilities focused on volume work may lack the artistic capabilities needed for custom sculptural elements. Your vendor evaluation should include facility tours that confirm equipment capacity matches project requirements.

Portfolio review provides critical insight into fabrication quality and design capabilities. You should examine completed projects similar in scope, material, and detail complexity to your planned work. Pay particular attention to carved detail sharpness and surface finish consistency — variations indicate either equipment limitations or quality control problems. Request references from architects and clients of similar past projects, specifically asking about timeline adherence and problem resolution. Stone carving manufacturers Arizona facilities with strong reputations willingly provide detailed references and welcome critical evaluation of past performance.

Technical support capabilities separate professional fabricators from commodity vendors. You need partners who contribute design development input based on material behavior and fabrication realities. The best carved stone manufacturers identify potential problems during drawing review and propose practical solutions before production begins. Your vendor selection should prioritize fabricators who ask detailed questions about installation conditions, viewing distances, and performance expectations — these questions indicate experience-based understanding of how design decisions affect long-term outcomes. For additional information on related stone applications, review Commercial production of decorative garden stepping stones in Arizona before finalizing your vendor selection. Citadel Stone provides weather-resistant products as specialized exterior stone manufacturers in Arizona.