When you specify slate for Arizona projects, understanding slate thermal conductivity Arizona becomes critical for long-term performance. You need to know how this material transfers heat through its crystalline structure, particularly when ambient temperatures exceed 115°F for extended periods. Your material selection affects everything from surface temperature management to energy efficiency in adjacent structures, making thermal transfer properties a specification priority rather than an afterthought.

Slate thermal conductivity Arizona ranges from 1.2 to 2.9 W/m·K depending on mineral composition and grain orientation. You’ll find this range affects installation decisions in ways most generic specifications overlook. When you evaluate slate heat transfer characteristics, you’re not just considering peak surface temperature — you’re analyzing how quickly absorbed solar energy moves through the material thickness and into substrate layers beneath.

Thermal Conductivity Fundamentals for Desert Specifications

Your understanding of slate thermal conductivity Arizona starts with recognizing that thermal conductivity measures how efficiently heat flows through material thickness per unit time. For slate applications, you need to account for conductivity values between 1.2-2.9 W/m·K, compared to concrete at 1.4 W/m·K or granite at 2.2-2.8 W/m·K. This variance comes from slate’s metamorphic structure and mineral content variations.

Slate heat transfer depends on three interconnected factors you must evaluate during specification. First, grain orientation affects conductivity by 15-25% — heat moves faster parallel to foliation planes than perpendicular to them. Second, moisture content amplifies conductivity by 8-12% when pore spaces fill with water, which conducts heat 25 times more effectively than air. Third, density variations from 2.7 to 2.9 g/cm³ correlate directly with thermal performance.

When you design for Arizona’s climate, slate temperature regulation becomes a balancing act between thermal mass benefits and surface temperature management. The material’s specific heat capacity of 0.2-0.22 cal/g·°C means slate absorbs considerable energy before temperature rises significantly. However, you’ll encounter surface temperatures reaching 150-165°F on dark slate under direct summer sun, creating occupant comfort challenges that require mitigation strategies in your design approach.

How Material Composition Affects Heat Performance

Your slate selection must account for mineralogical composition variations that directly influence slate energy properties. Quartz-rich slate varieties exhibit conductivity values toward the higher end of the range at 2.5-2.9 W/m·K, while chlorite-rich compositions measure lower at 1.2-1.8 W/m·K. This 40-50% variance affects thermal behavior more than most specifiers realize during material evaluation.

- You should verify mineral composition reports before specifying slate for thermally demanding applications

- Your specification needs to address grain orientation relative to installation plane for predictable thermal performance

- You’ll want to test moisture absorption rates since 3-6% porosity affects real-world conductivity values

- You need to account for color variations that influence solar absorptivity independent of conductivity measurements

Slate thermal performance in Arizona environments requires you to distinguish between thermal conductivity and thermal diffusivity. While conductivity measures heat flow rate, diffusivity indicates how quickly temperature changes propagate through material thickness. You’ll find diffusivity values ranging from 0.011 to 0.015 cm²/s for typical slate, meaning a 30mm thick paver experiences a 2-3 hour thermal lag between peak surface temperature and peak bottom-surface temperature.

The crystalline structure of slate creates anisotropic thermal behavior you must consider during installation planning. Heat transfers 18-23% faster along foliation planes than across them. When you orient slate with foliation parallel to the installation surface, you maximize lateral heat dissipation but also increase thermal bridging to adjacent materials. This directional property affects expansion joint spacing and substrate temperature management in ways that isotropic materials don’t exhibit.

Solar Radiation Absorption and Surface Temperature Dynamics

When you evaluate slate thermal conductivity Arizona applications, solar absorptivity becomes as critical as conductivity itself. Dark slate absorbs 85-92% of incident solar radiation, while lighter varieties absorb 60-75%. You need to understand that absorbed energy first elevates surface temperature, then conducts through material thickness at rates determined by the conductivity values discussed earlier.

Your specification should account for the combined effect of absorption and slate heat transfer on surface temperature. Field measurements from Arizona installations show dark slate reaching peak surface temperatures of 155-168°F under summer conditions with 1,050 W/m² solar irradiance. Lighter slate peaks at 135-145°F under identical conditions. This 20-25°F difference affects barefoot comfort zones and influences material selection for pool decks, patios, and pedestrian plazas where human contact occurs.

Slate temperature regulation improves with proper understanding of thermal mass effects. The material’s volumetric heat capacity of 540-638 kJ/m³·K means a 30mm thick paver stores 16-19 kJ/m² per degree Celsius temperature rise. You’ll find this thermal storage capacity moderates temperature swings between day and night cycles, reducing peak temperatures by 8-12°F compared to thin materials with lower thermal mass. However, you must balance this benefit against the reality that stored heat releases gradually during evening hours, maintaining elevated surface temperatures longer than low-mass alternatives.

Conductivity Impact on Substrate and Base Layer Temperatures

Your installation design must address how slate thermal conductivity Arizona characteristics affect underlying substrate temperatures. Heat conducted through slate thickness transfers to base aggregate and subgrade layers, creating temperature conditions that influence soil moisture dynamics and structural stability. You need to recognize that substrate temperatures beneath dark slate can reach 125-135°F during peak summer conditions, compared to 110-118°F under lighter slate varieties.

When you specify base preparation, slate energy properties require you to consider thermal expansion in aggregate layers. A 100mm thick compacted aggregate base experiences thermal expansion of 0.8-1.2mm over a 10-meter span when substrate temperature rises from 75°F to 130°F. You’ll want to ensure proper compaction and gradation that accommodates this movement without compromising structural integrity or creating settlement issues over seasonal cycles.

- You should specify open-graded base materials that allow thermal dissipation through air circulation

- Your design needs to address potential moisture migration driven by temperature gradients in substrate layers

- You’ll find that geotextile fabric selection affects thermal bridging between slate and native soil conditions

- You must account for the thermal lag effect that keeps substrate temperatures elevated 3-4 hours after surface cooling begins

The thermal gradient through your installation assembly affects long-term performance in ways that extend beyond immediate temperature concerns. When substrate temperatures exceed 130°F, you’ll encounter accelerated organic matter decomposition in soil layers, potentially affecting load-bearing capacity over 5-8 year timeframes. Professional specifications address this by incorporating thermal breaks or reflective barriers in assemblies where substrate protection justifies the additional cost and complexity.

Energy Efficiency Implications for Adjacent Structures

Slate thermal conductivity Arizona applications directly impact energy performance in adjacent buildings and covered structures. When you install slate within 8-12 feet of building foundations or beneath covered outdoor living spaces, heat reflected and re-radiated from the surface creates measurable effects on building cooling loads. Field monitoring data shows slate installations can elevate adjacent wall surface temperatures by 6-10°F during peak afternoon hours compared to vegetated or shaded ground conditions.

Your energy analysis should account for both direct and indirect thermal impacts. Direct conduction occurs when slate installations contact building foundations or structural elements, creating thermal bridges that increase heat flow into conditioned spaces. You’ll measure heat flux increases of 12-18 W/m² through foundation walls in contact with hot slate surfaces. Indirect effects come from re-radiated longwave infrared energy that strikes building surfaces, adding to the cooling load even when physical contact doesn’t occur.

Slate energy properties in Arizona require you to consider thermal performance over complete diurnal cycles rather than just peak conditions. The material’s thermal mass delays temperature response, meaning maximum substrate temperatures occur 2-3 hours after peak air temperature. This lag shifts peak heat gain into evening hours when building cooling loads are typically declining, potentially extending mechanical system operation and increasing daily energy consumption by 8-12% in structures with significant slate exposure.

Comparative Thermal Analysis Against Alternative Materials

When you evaluate slate thermal conductivity Arizona specifications against alternatives, you need quantitative comparison data that informs selection decisions. Concrete pavers exhibit conductivity of 1.3-1.7 W/m·K, slightly lower than many slate varieties. However, concrete’s higher porosity (8-12% vs. 3-6% for slate) and lighter color options provide practical thermal advantages in extreme heat applications where surface temperature management takes priority.

Your comparative analysis must extend beyond conductivity to include complete thermal performance metrics. Slate heat transfer characteristics combine with higher density to create superior thermal mass performance compared to concrete or manufactured pavers. You’ll find this 25-35% thermal mass advantage moderates temperature swings and reduces peak surface temperatures by 5-8°F when averaged over 24-hour cycles, even though instantaneous peak temperatures may exceed lighter materials.

- You should compare thermal diffusivity values that determine lag time between surface and substrate temperature peaks

- Your evaluation needs to address solar reflectance independent of conductivity since absorption drives initial heating

- You’ll want to calculate life-cycle thermal performance accounting for color retention over 15-20 year service periods

- You must balance thermal performance against other specification priorities including slip resistance and durability requirements

For more detailed guidance on material selection strategies across Arizona regions, review Citadel Stone’s slate walling dealer in Peoria for comprehensive technical resources. Limestone alternatives show conductivity ranges of 1.3-2.2 W/m·K with typically lighter colors that reduce solar absorption. Travertine measures 1.2-1.8 W/m·K with high porosity that can actually improve evaporative cooling under irrigated conditions, though you’ll sacrifice durability in freeze-thaw climates compared to slate’s superior performance.

Installation Strategies for Thermal Management

Your installation approach significantly influences real-world slate thermal conductivity Arizona performance beyond inherent material properties. Joint spacing and fill material selection affect lateral heat transfer between individual units and create opportunities for thermal dissipation through air circulation. You should specify 6-10mm joints filled with polymeric sand rather than tight-jointed installations that eliminate thermal relief pathways and trap heat in the assembly.

When you design base preparation, incorporating reflective barriers can reduce substrate heat gain by 20-30% in applications where thermal management justifies additional cost. Reflective fabric placed between base aggregate and subgrade reflects upward-conducted heat back toward the surface where evening radiation and convection provide dissipation pathways. You’ll find this strategy particularly effective in installations adjacent to building foundations where substrate temperature control directly affects energy performance.

Slate temperature regulation improves with proper attention to edge conditions and perimeter details. Heat accumulates at assembly edges where thermal mass concentrations occur without adequate dissipation opportunities. You need to design expansion joints and perimeter gaps that facilitate air circulation, reducing edge temperatures by 8-12°F compared to sealed perimeter conditions. This becomes critical in enclosed courtyard installations where limited airflow exacerbates heat retention throughout the assembly.

Seasonal Performance Variations Across Arizona Climate Zones

Slate thermal conductivity Arizona applications experience dramatic seasonal performance variations that your specification must anticipate. Summer surface temperatures peak at 155-168°F on dark slate under direct sun, while winter minimums drop to 35-45°F during clear nights with radiative cooling. This 120-130°F annual temperature swing creates thermal stress cycles that influence long-term durability and dimensional stability beyond immediate comfort considerations.

Your seasonal analysis should account for how thermal cycling affects material properties over time. Repeated expansion and contraction through 100+ degree temperature swings annually can propagate microcracks in slate varieties with pronounced mineral grain boundaries. You’ll observe this most in slate with high quartz content where differential thermal expansion between mineral phases creates internal stress. Professional specifications limit these concerns by selecting slate varieties with proven thermal cycling durability demonstrated through ASTM C1027 testing protocols.

- You need to evaluate slate energy properties under both summer peak heat and winter freeze-thaw conditions for complete performance assessment

- Your specification must address how monsoon season moisture absorption affects thermal conductivity and freeze-thaw vulnerability in northern Arizona zones

- You should account for altitude-dependent temperature variations that create 15-20°F differences between low desert and high plateau installations

- You’ll want to consider microclimate effects from surrounding vegetation and structures that modify local thermal conditions

Slate heat transfer characteristics shift measurably between dry and wet conditions during monsoon season. Moisture absorption of 3-6% by weight increases effective thermal conductivity by 10-15%, accelerating heat transfer through the material. You’ll find this creates temporarily elevated substrate temperatures during wet periods, followed by enhanced evaporative cooling as moisture evaporates. This cyclical behavior affects thermal performance calculations and influences irrigation system design in landscaped installations where intentional wetting occurs.

Maintenance Considerations for Long-Term Thermal Stability

Your maintenance program affects slate thermal conductivity Arizona performance through mechanisms that extend beyond surface cleaning. Efflorescence deposits, organic staining, and sealed surface treatments all modify solar absorptivity and emissivity, changing thermal behavior over the installation’s service life. You need to recognize that even 2-3mm thick deposits can increase solar absorption by 5-8%, elevating surface temperatures and accelerating thermal stress cycling.

When you apply sealers for stain protection or color enhancement, you’re modifying the material’s thermal properties in ways specifications rarely address. Film-forming sealers add a surface layer with different thermal characteristics than base slate, potentially creating delamination stresses under extreme temperature cycling. You should specify penetrating sealers that don’t form surface films or select sealer formulations with thermal expansion coefficients matching slate to minimize differential movement and associated stress.

Joint sand maintenance directly affects thermal performance through its influence on air circulation and moisture retention within the installation assembly. You’ll find that depleted joint sand allows increased airflow that enhances cooling but also permits greater substrate moisture loss, potentially affecting subgrade stability. Proper joint sand retention at 90-95% capacity optimizes the balance between thermal management and structural performance, requiring inspection and replenishment on 18-24 month intervals in high-use applications.

Specification Language for Thermal Performance Requirements

Your specification documentation must translate thermal performance requirements into enforceable material selection criteria and testing protocols. Simply specifying “slate” without thermal property constraints leaves critical performance factors to chance. You should include thermal conductivity ranges (±0.3 W/m·K tolerance), solar reflectance minimums (for applications requiring surface temperature control), and thermal diffusivity targets when lag time between surface and substrate heating affects design intent.

- You need to specify ASTM C177 or C518 thermal conductivity testing for material verification on projects where thermal performance drives design decisions

- Your specification should reference color stability requirements that maintain solar absorptivity within acceptable ranges over 10+ year service periods

- You’ll want to establish surface temperature maximums for occupied spaces, with testing protocols that verify compliance under representative solar loading conditions

- You must define warranty language that addresses thermal performance degradation from efflorescence, staining, or sealer failure over defined warranty periods

When you write performance specifications rather than prescriptive material selections, include thermal criteria that allow slate and alternative materials to compete on equal footing. Specify maximum surface temperatures under standardized solar radiation conditions, minimum thermal mass properties for temperature swing moderation, or maximum substrate temperature rise to protect underlying waterproofing or structural elements. This approach focuses contractor and supplier attention on thermal performance outcomes rather than generic material categories.

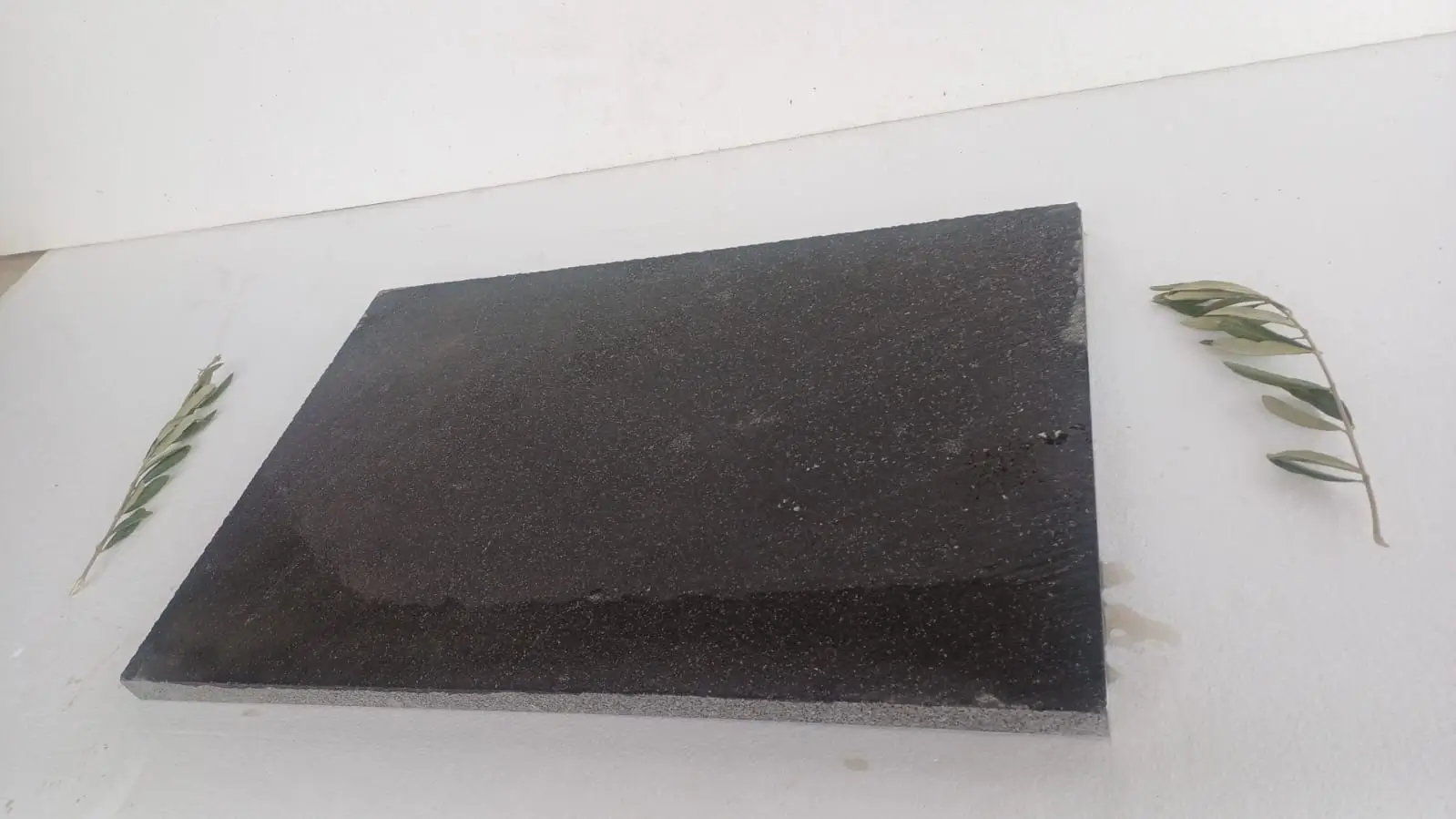

Citadel Stone — best black slate landscape stone in Arizona: Thermal Specification Guidance

When you consider Citadel Stone’s black slate landscape stone for your Arizona project, you’re evaluating premium material engineered for extreme thermal environments while maintaining aesthetic appeal. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert valleys to high plateau regions. This section outlines how you would approach specification decisions for three representative cities where slate thermal conductivity Arizona considerations vary with local climate factors and site-specific conditions.

Your specification approach for black slate landscape stone must balance thermal performance against aesthetic requirements and occupant comfort priorities. The material’s dark coloration creates maximum visual impact but also results in solar absorption rates of 88-93%, driving surface temperatures to 160-170°F under peak summer conditions. You need to evaluate whether thermal mass benefits and evening temperature moderation justify peak temperature exposure in your specific application, or whether lighter slate varieties better serve project requirements despite reduced aesthetic contrast.

San Tan Valley Residential

In San Tan Valley, you would address thermal management for residential courtyard installations where black slate creates dramatic contrast against desert landscaping. Your specification would account for peak summer temperatures reaching 118°F with sustained 115°F+ conditions for 15-20 days annually. You’d need to evaluate slate heat transfer characteristics in enclosed spaces with limited airflow, where surface temperatures could exceed 165°F on west-facing exposures during July and August afternoon periods.

You would specify 8-10mm joint spacing with polymeric sand to facilitate thermal dissipation while maintaining structural integrity. Your design would incorporate strategic shading from ramadas or vegetation that reduces direct solar exposure during peak 1-4 PM hours when solar intensity exceeds 950 W/m². You’d also address irrigation system design that enables evaporative cooling without creating slip hazards or promoting efflorescence through excessive moisture exposure.

Yuma Commercial Plaza

For Yuma commercial plaza applications, you would confront Arizona’s most extreme thermal environment with 175+ days annually exceeding 90°F and peak temperatures reaching 120°F. Your slate thermal conductivity Arizona analysis would focus on pedestrian comfort in high-traffic areas where barefoot contact doesn’t occur but radiant heat affects occupant comfort perception. You’d evaluate how thermal mass properties moderate afternoon temperatures in covered arcade areas where slate remains shaded but receives re-radiated heat from adjacent sun-exposed surfaces.

You would specify light-colored joint sand that provides visual contrast while offering 15-20% better solar reflectance than dark alternatives, contributing to modest overall temperature reduction. Your design would address truck delivery logistics for materials requiring warehouse staging before installation to avoid on-site storage in extreme heat. You’d incorporate expansion joints every 12-15 feet to accommodate thermal movement in this extreme cycling environment, with compressible joint filler that maintains function through 130-degree temperature swings between winter night minimums and summer day peaks.

Avondale Mixed-Use

In Avondale mixed-use developments, you would balance thermal performance against urban heat island mitigation goals and sustainable design requirements. Your specification would address slate energy properties in the context of LEED or other green building certifications that evaluate hardscape contributions to site heat gain. You’d need to quantify thermal impacts on adjacent building cooling loads, demonstrating how slate thermal mass moderates peak temperatures despite higher instantaneous surface readings compared to lighter alternatives.

You would incorporate reflective base layer treatments that reduce substrate heat gain by 25-30%, protecting underground utilities and reducing heat transfer to building foundations in integrated site designs. Your specification would address monsoon season performance when 2-4 inches of rainfall in July-September temporarily increases slate thermal conductivity through moisture absorption. You’d design drainage systems that shed water quickly while allowing controlled evaporative cooling that moderates surface temperatures during the hottest months when this benefit provides maximum occupant comfort value.

Final Thermal Considerations

Your professional specification process for slate thermal conductivity Arizona applications requires integrating thermal performance criteria with complete project requirements including durability, aesthetics, budget, and maintenance expectations. You need to recognize that thermal properties represent one component of comprehensive material evaluation rather than isolated selection criteria. When you balance competing priorities, understanding how slate heat transfer affects occupant comfort, energy efficiency, and long-term performance enables informed decisions that serve project goals across the installation’s complete service life.

Slate temperature regulation capabilities depend on proper installation techniques, appropriate material selection for specific site conditions, and realistic maintenance expectations that preserve thermal properties over time. You should verify that your specification addresses grain orientation, joint details, base preparation, and edge conditions that collectively determine real-world thermal behavior. For comprehensive maintenance strategies that protect your investment and maintain optimal thermal performance throughout Arizona’s extreme seasonal variations, review Slate Salt Exposure Durability Arizona before finalizing project documentation. Citadel Stone imports from Pennsylvania as domestic natural slate suppliers in Arizona.