When you’re specifying slate for Arizona projects, you face a critical decision that affects both performance and longevity: indoor versus outdoor application. The Slate Suppliers Arizona applications landscape demands material understanding beyond basic aesthetics. You need to account for thermal cycling that exceeds 80°F daily swings, UV degradation that accelerates surface oxidation, and moisture dynamics that create expansion stress patterns most specification sheets ignore.

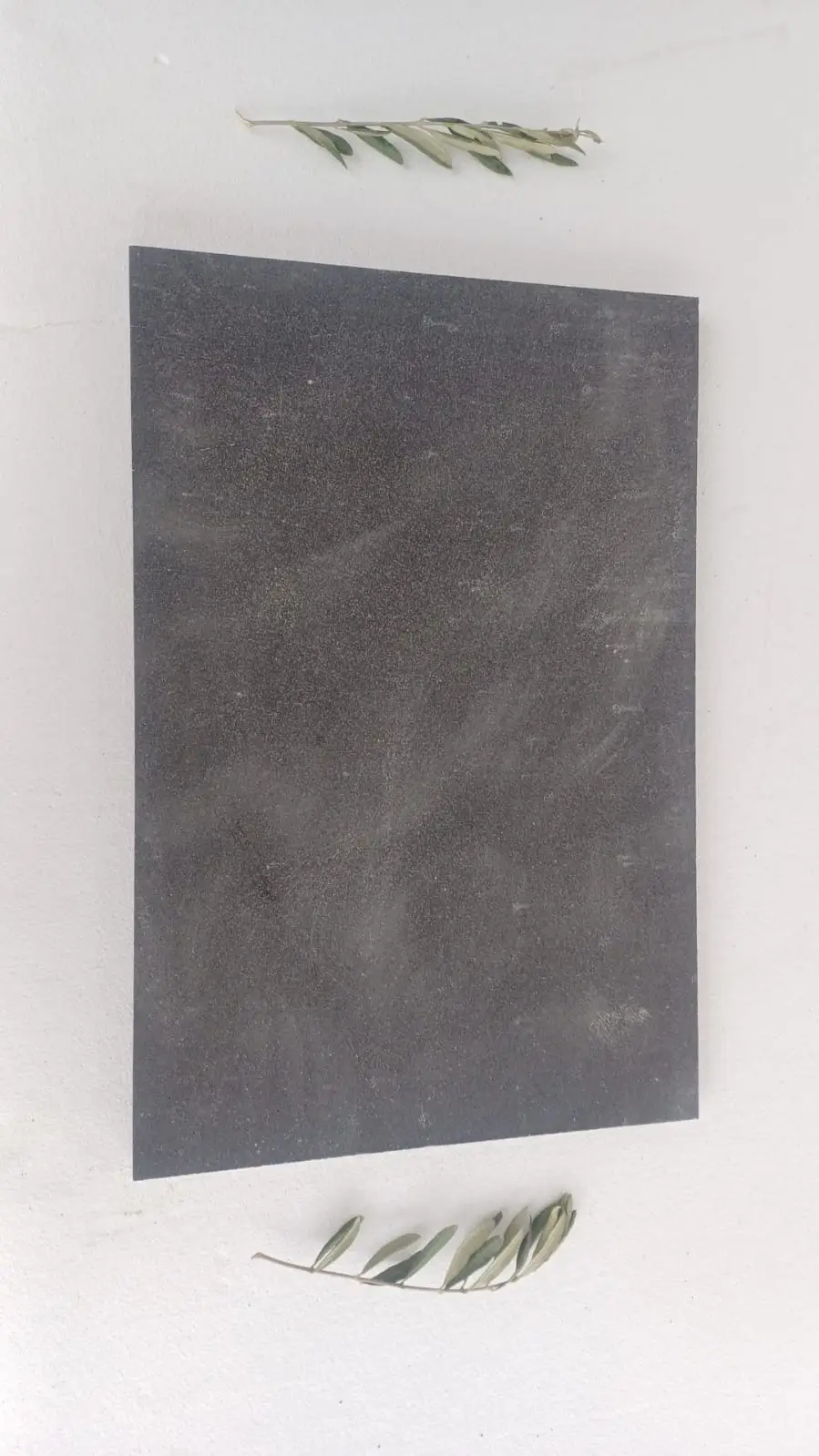

Your slate selection process should address the fundamental material behavior differences between climate-controlled interior installations and exposed exterior environments. Indoor applications allow you to prioritize visual consistency and surface finish refinement. Outdoor specifications require you to focus on porosity management, thermal mass characteristics, and slip resistance performance across wet and dry conditions. The slate suppliers Arizona installation protocols you choose determine whether your project achieves 25-year performance or requires remediation within 8-12 years.

Material Behavior: Climate-Controlled vs Exposed Environments

You’ll encounter dramatically different performance requirements when you compare indoor and outdoor slate applications. The Slate Suppliers Arizona applications environment creates thermal stress that indoor installations never experience. Interior slate maintains relatively stable temperature ranges between 68-78°F with minimal UV exposure and consistent humidity levels. Your outdoor specifications must account for surface temperatures reaching 145-160°F during summer months, followed by overnight cooling to 75-85°F.

The porosity interaction with moisture becomes critical in outdoor applications. When you specify slate tiles Arizona indoor outdoor projects, you need to understand that the same 4-6% porosity rating behaves differently under varying environmental conditions. Indoor installations experience minimal moisture cycling, allowing you to select materials based primarily on aesthetic and traffic durability. Outdoor applications expose slate to monsoon moisture absorption followed by rapid solar-driven evaporation cycles that create internal stress patterns.

Thermal expansion coefficients of 5.8 × 10⁻⁶ per °F create joint movement that you must accommodate differently in interior versus exterior installations. Your indoor specifications typically allow 1/8″ joints with minimal expansion provision. Outdoor slate pavers Arizona guide requirements demand 3/16″ to 1/4″ joints with compressible fill materials that accommodate 0.040″ to 0.065″ linear movement per 10-foot run during daily thermal cycles.

Indoor Application Specifications and Performance Factors

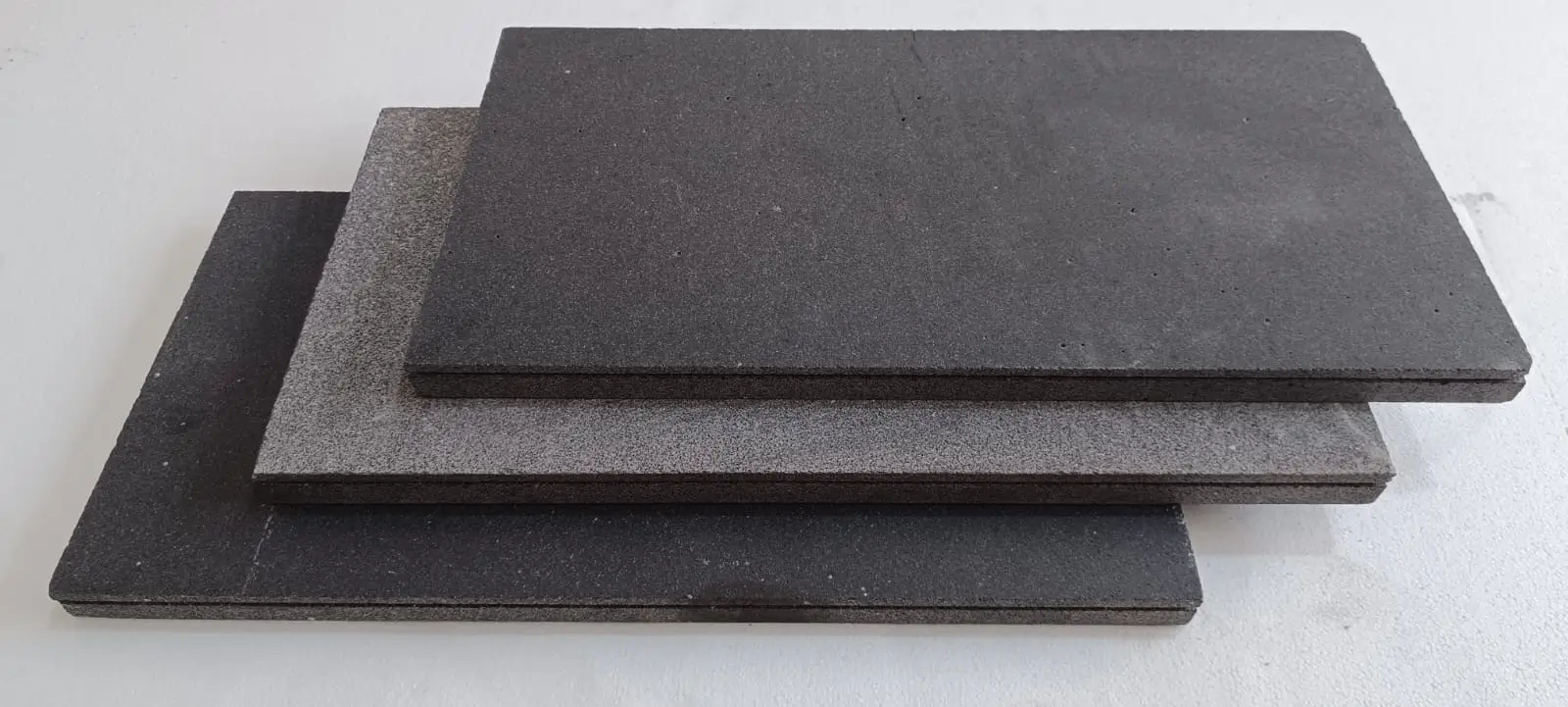

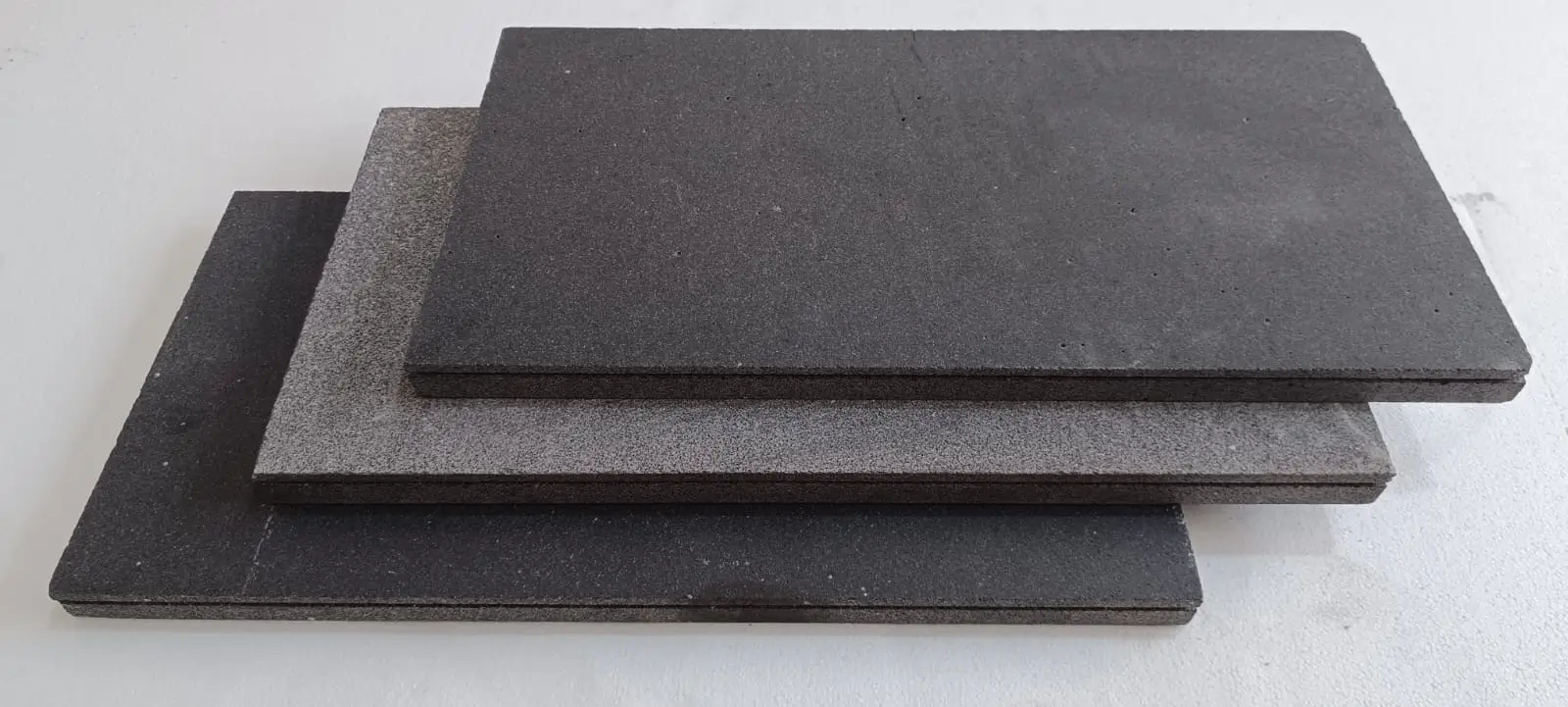

When you specify slate for interior applications, you’re working within controlled parameters that simplify material selection. The slate tiles Arizona indoor outdoor distinction becomes apparent in thickness requirements and substrate preparation protocols. Interior installations typically utilize 3/8″ to 1/2″ thickness materials, while outdoor applications require 3/4″ to 1-1/4″ thickness to handle structural loads and thermal stress.

Your interior specification checklist should address these performance factors:

- You need to verify flatness tolerances within 1/16″ over 10 feet for proper thin-set adhesion

- Your substrate must exhibit deflection ratings not exceeding L/360 under live loads to prevent grout joint cracking

- You should specify slip resistance ratings between 0.42-0.50 DCOF for most interior applications, increasing to 0.52-0.60 for wet areas

- Your material selection should account for Mohs hardness ratings between 2.5-4.0 that affect scratch resistance in high-traffic commercial installations

The cleavage planes inherent in slate create surface texture variations that you can leverage for interior design effect. When you select materials for our slate materials supply, you’ll find that honed finishes provide contemporary aesthetics while natural cleft surfaces offer traditional character. Your finish selection directly impacts maintenance requirements and long-term appearance retention.

Interior moisture exposure remains minimal, but you still need to address sealing protocols. Unsealed slate in interior applications absorbs household spills and cleaning solutions that create staining patterns within 18-24 months. Your specification should include penetrating sealer application with 3-5 year reapplication intervals for residential projects, reducing to 18-24 months for commercial installations with higher soil exposure.

Outdoor Application Requirements and Environmental Challenges

You face substantially more complex specification requirements when you design slate flooring suppliers Arizona outdoor installations. The environmental exposure creates performance demands that exceed interior applications by significant margins. Solar radiation in Arizona delivers 6.5-7.5 peak sun hours daily, creating surface UV exposure that degrades organic binders and oxidizes iron-bearing minerals within slate composition.

Your outdoor slate specification must address these critical environmental factors:

- You should account for thermal cycling that creates expansion stress exceeding 850 PSI during peak temperature differential events

- Your base preparation needs to accommodate frost heave potential even in Phoenix metro areas where winter ground temperatures occasionally reach 28-32°F

- You need to specify drainage slopes between 1.5-2.5% to prevent standing water that accelerates efflorescence and biological growth

- Your joint spacing must increase by 40-50% compared to indoor installations to accommodate thermal movement

The porosity management becomes exponentially more important in outdoor applications. When you evaluate slate pavers Arizona guide specifications, you’ll find that materials with porosity exceeding 6% create moisture retention problems during monsoon season. Your slate absorbs precipitation rapidly, then experiences solar-driven evaporation that draws dissolved minerals to the surface, creating efflorescence patterns that appear as white crystalline deposits.

Slip resistance performance changes dramatically between wet and dry conditions outdoors. Materials that test at 0.52 DCOF dry often drop to 0.38-0.42 DCOF when wet, falling below safe threshold requirements for pedestrian traffic. You need to specify textured or thermal-finished surfaces that maintain minimum 0.50 DCOF ratings in wet conditions for pool decks, patios, and walkway applications.

Installation Protocol Differences Between Applications

Your installation methodology varies significantly between indoor and outdoor slate applications. Interior installations typically utilize thin-set mortar bed applications over concrete or cementitious backer board substrates. The controlled environment allows you to achieve proper cure conditions without weather-related complications. Outdoor installations require thick-bed mortar applications or sand-set systems that accommodate substrate movement and drainage requirements.

When you plan slate suppliers Arizona installation projects, you need to understand that outdoor base preparation determines long-term performance more than any other factor. Your typical outdoor installation assembly includes:

- You start with compacted aggregate base minimum 4-6 inches depth, achieving 95% modified Proctor density

- Your leveling layer consists of 1-1.5 inch coarse sand bedding that provides lateral drainage and minor substrate irregularity accommodation

- You set pavers on this bedding layer with joint spacing that accommodates thermal expansion requirements

- Your joint fill material should be polymeric sand that resists washout while maintaining permeability for drainage

The curing requirements differ substantially between applications. Interior thin-set installations achieve functional cure within 24-48 hours, allowing you to open spaces to light traffic relatively quickly. Outdoor thick-bed mortar installations require 5-7 day cure periods before grouting, extending to 14-21 days before you should permit full vehicular loads on driveway applications.

Temperature constraints during installation become critical for outdoor projects. You can install interior slate year-round in climate-controlled conditions. Outdoor installations require ambient temperatures above 40°F during application and for 72 hours post-installation to ensure proper mortar hydration. Summer installations in Arizona create opposite problems when surface temperatures exceed 105°F, causing accelerated moisture loss from mortar beds that compromises bond strength.

Sealing Protocols: Application-Specific Requirements

Your sealing strategy must adapt to the dramatically different environmental exposure between indoor and outdoor applications. The slate suppliers Arizona installation guidance you follow should differentiate between penetrating sealers, surface sealers, and enhancing sealers based on application type and performance goals. Indoor applications typically utilize penetrating sealers that provide stain resistance without altering surface appearance or creating slip hazards.

Outdoor sealing requirements become more complex because you need to balance water repellency with vapor permeability. When you apply film-forming surface sealers to outdoor slate, you risk trapping subsurface moisture that creates delamination and spalling during thermal cycling. Your outdoor specification should prioritize breathable penetrating sealers that reduce water absorption by 75-85% while maintaining vapor transmission rates above 0.8 perms.

The reapplication frequency differs substantially between applications:

- You should plan interior sealer reapplication every 3-5 years for residential projects and 2-3 years for commercial installations

- Your outdoor horizontal surfaces require sealer renewal every 18-24 months due to UV degradation and traffic wear

- You need to increase outdoor reapplication frequency to annual intervals for pool decks where chlorinated water accelerates sealer breakdown

- Your vertical outdoor applications like wall cladding extend sealer life to 4-6 years due to reduced UV exposure and minimal traffic wear

Application technique affects sealer performance significantly. You should apply penetrating sealers to completely dry slate, requiring 48-72 hours after cleaning for interior applications. Outdoor slate may require 5-7 days of dry weather before sealing to ensure subsurface moisture content drops below 4%. Your application should achieve saturation coverage where surface appears wet for 5-10 minutes before buffing excess material to prevent surface residue.

Thickness Selection and Structural Considerations

When you specify slate thickness, you’re making a decision that affects structural performance, thermal mass behavior, and installation methodology. The slate tiles Arizona indoor outdoor applications demonstrate clear thickness differentiation based on loading conditions and support systems. Interior floor applications over properly prepared concrete substrates perform adequately with 3/8″ thickness materials in residential settings and 1/2″ thickness in commercial environments.

Your outdoor thickness requirements increase substantially to handle point loads, thermal stress, and reduced substrate support. Pedestrian patio applications require minimum 3/4″ thickness when you install over compacted aggregate base with sand setting bed. Vehicular applications like driveways demand 1-1/4″ to 1-1/2″ thickness to distribute wheel loads without cracking.

The relationship between thickness and thermal performance creates trade-offs you need to understand. Thicker slate provides greater thermal mass, creating beneficial temperature moderation in outdoor living spaces. This same thermal mass characteristic causes thicker materials to experience greater absolute expansion during thermal cycling, requiring you to increase joint spacing proportionally. Your 1-1/4″ outdoor pavers need approximately 35% wider joints compared to 3/4″ materials to accommodate equivalent thermal movement.

Edge detail specifications change with thickness selection. When you work with 3/8″ interior tiles, you can specify standard square or slightly beveled edges. Your outdoor paver applications using 3/4″ to 1-1/4″ materials should incorporate thermal-cut or guillotine-cut edges that provide clean, straight profiles. Hand-cut or natural-edge materials create wider joint spacing requirements and complicate pattern layout.

Color Stability and Fading Concerns by Application

You need to set realistic expectations about color stability when you compare indoor versus outdoor slate applications. The slate flooring suppliers Arizona market includes materials with varying mineral compositions that respond differently to UV exposure and weathering. Indoor installations maintain original color characteristics indefinitely because they avoid solar radiation that causes photo-oxidation of iron-bearing minerals.

Outdoor slate applications experience measurable color shifts within 12-24 months of installation. Your darker slate varieties containing higher iron content show more dramatic lightening as ferrous minerals oxidize to ferric states under UV exposure. Black slate often shifts to dark gray with subtle brown tones. Dark green materials migrate toward lighter sage tones. These changes stabilize after initial weathering, but you should prepare clients for 15-25% reduction in color depth compared to fresh-cut appearance.

The Slate Suppliers Arizona applications environment accelerates this weathering process compared to moderate climates. You’ll observe color evolution completing within 18 months in Arizona installations versus 30-36 months in Pacific Northwest environments. This rapid weathering actually benefits project aesthetics by quickly establishing the long-term appearance that clients will experience throughout the installation’s service life.

Your material selection strategy should account for color stability characteristics. When you specify slate pavers Arizona guide projects where color consistency is critical, you should select prefinished or pre-weathered materials. Some suppliers provide UV-exposed inventory that has already completed initial color transition. You pay 8-12% premium for this material, but you eliminate the visual transition period that concerns some clients.

Maintenance Requirements: Application Comparison

Your maintenance protocols must adapt to the environmental conditions and soiling patterns specific to indoor versus outdoor applications. Interior slate maintenance focuses on protecting against staining, managing appearance of foot traffic patterns, and periodic deep cleaning. The controlled environment allows you to maintain slate appearance with weekly dust mopping, monthly damp mopping with pH-neutral cleaners, and annual deep cleaning with mechanical scrubbing.

Outdoor maintenance requirements expand significantly because you’re managing biological growth, mineral staining, and weathering effects. Your outdoor slate develops algae and moss growth in shaded areas with consistent moisture exposure. These biological organisms create slip hazards and aesthetic degradation within 6-12 months in untreated installations. You should implement quarterly treatment with appropriate biocides diluted to manufacturer specifications.

The joint maintenance differs substantially between applications:

- You can largely ignore interior grout joints except for periodic cleaning to remove soil accumulation

- Your outdoor polymeric sand joints require annual inspection and repair where washout occurs from drainage flow or irrigation overspray

- You need to budget for complete joint sand replacement every 5-7 years as UV degradation breaks down polymer binders

- Your outdoor mortar joints should receive inspection every 3-5 years with repointing where weathering creates depth loss exceeding 1/4 inch

Efflorescence management becomes a primary maintenance concern for outdoor installations. When you notice white crystalline deposits forming on slate surfaces, you’re observing dissolved minerals migrating from substrate or stone composition. Your maintenance program should include annual efflorescence removal using dilute acidic cleaners followed by thorough rinsing. Persistent efflorescence indicates ongoing moisture problems that require you to address substrate drainage or irrigation management.

Cost Implications Between Application Types

When you develop project budgets, you’ll find that outdoor slate installations typically cost 35-55% more than comparable indoor applications. This cost differential stems from multiple factors including thickness requirements, base preparation complexity, and installation labor intensity. Your interior slate flooring installation over existing concrete slab requires minimal preparation beyond surface leveling and crack repair.

Outdoor installation costs escalate due to comprehensive base preparation requirements. You need to excavate existing soil to depths of 8-10 inches, install and compact aggregate base layers, and create proper drainage slopes. These base preparation activities alone add $4.50-$7.50 per square foot before slate installation begins. Your material costs increase by 40-60% when you specify the thicker pavers required for outdoor applications.

The slate suppliers Arizona installation labor rates reflect complexity differences. Interior tile setting typically ranges $8-$12 per square foot for standard installations. Your outdoor paver installation labor increases to $12-$18 per square foot due to heavy material handling, precision grading requirements, and joint filling procedures. Complex pattern installations or areas requiring extensive cutting can push labor costs to $22-$28 per square foot.

Maintenance cost projections over 20-year service life show interesting patterns. Your interior installations require minimal maintenance expenditure, typically $0.15-$0.25 per square foot annually for routine cleaning and periodic sealing. Outdoor applications demand $0.65-$0.95 per square foot annually when you properly account for sealing, joint maintenance, efflorescence treatment, and biological growth control. These maintenance cost differences often equal 25-30% of initial installation cost over typical service life.

Climate Zone Performance Variations Across Arizona

You can’t treat Arizona as a monolithic climate when you specify slate applications. The state encompasses diverse climate zones from low desert regions at 1,000-foot elevation to high country areas exceeding 7,000 feet. Your Slate Suppliers Arizona applications strategy must account for these regional variations that affect material performance and installation protocols.

Low desert regions including Phoenix, Tucson, and Yuma create extreme heat exposure that drives material selection. You’re specifying for environments where slate surface temperatures reach 155-165°F during peak summer months. These thermal extremes accelerate UV degradation, increase thermal expansion movement, and create handling challenges during installation. Your specifications should prioritize lighter-colored slate varieties that reflect 45-55% of solar radiation compared to dark materials reflecting only 15-25%.

High country regions including Flagstaff, Prescott, and Payson introduce freeze-thaw cycling that low desert areas never experience. When you specify slate for these climate zones, you need to verify freeze-thaw durability through ASTM C666 testing or equivalent. Materials must withstand minimum 300 freeze-thaw cycles without structural degradation. Your installation details must provide complete drainage to prevent water accumulation that creates spalling damage during freeze events.

Transitional climate zones create the most challenging specifications because you’re designing for both extreme heat and occasional freeze conditions. Areas like Sedona and higher elevation portions of metro Phoenix experience summer temperatures exceeding 105°F and winter nights dropping to 25-30°F. Your material selection must balance these opposing environmental stresses while maintaining acceptable performance across the full annual temperature range.

Best Slate Suppliers in Arizona — Citadel Slate Hypothetical Applications

When you consider Citadel Stone’s Slate Suppliers in Arizona materials for your Arizona project, you’re evaluating slate specifically selected for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate regions. This section outlines how you would approach specification decisions for six representative cities, addressing the unique environmental factors each location presents.

Arizona’s climate diversity requires you to adapt your slate selection and installation protocols to regional conditions. The hypothetical scenarios below demonstrate how you would modify specifications based on temperature extremes, elevation differences, and local soil characteristics. These recommendations reflect professional best practices for slate suppliers Arizona installation projects across varying environmental conditions.

Phoenix Heat Performance

In Phoenix, you’ll encounter the most extreme heat conditions in Arizona, with summer temperatures consistently exceeding 110°F and surface temperatures reaching 160°F. Your slate selection would prioritize lighter colors that reduce solar absorption. You would specify minimum 3/4-inch thickness for pedestrian applications and 1-1/4 inch for vehicular uses. Your installation would require 1/4-inch joint spacing to accommodate the substantial thermal expansion from daily temperature swings exceeding 85°F. At Citadel Stone, we would recommend warehouse delivery scheduling during morning hours when material handling remains manageable. You’d need to plan installation during October through April to avoid concrete curing complications from extreme heat.

Tucson Desert Considerations

Tucson presents similar heat challenges to Phoenix but with slightly higher elevation affecting temperature moderation. You would approach slate pavers Arizona guide specifications accounting for 105-112°F peak temperatures and intense UV exposure. Your material selection would emphasize UV-stable slate varieties with proven color retention in desert environments. You’d specify penetrating sealers with enhanced UV inhibitors for extended service intervals. The caliche soil conditions common in Tucson require you to address substrate preparation carefully, ensuring proper base compaction over expansive soils. Your drainage design would account for monsoon rainfall patterns that deliver 2-3 inches in short-duration events.

Scottsdale Luxury Specifications

Scottsdale applications typically involve higher-end residential and commercial projects where you would specify premium slate grades. Your material selection would emphasize consistent color throughout each pallet and tighter dimensional tolerances. You’d recommend pre-sealed materials to establish immediate stain resistance for entertaining areas around pools and outdoor kitchens. The slate tiles Arizona indoor outdoor distinction becomes critical here because you’d likely specify matching materials for interior-exterior transitions. Your installation would incorporate decorative patterns with mixed slate colors or sizes, requiring increased labor for layout complexity. You would coordinate truck delivery access carefully in established neighborhoods with restricted construction hours.

Flagstaff Freeze-Thaw

Flagstaff’s 7,000-foot elevation creates dramatically different performance requirements. You would specify slate with verified freeze-thaw durability ratings, ensuring materials withstand 300+ freeze cycles without degradation. Your installation would prioritize complete drainage to prevent water accumulation during winter months. You’d increase substrate depth to minimum 6 inches compacted aggregate base to handle frost heave potential. The slate flooring suppliers Arizona materials you’d select would emphasize low porosity ratings below 4% to minimize moisture absorption. Your sealing protocol would require breathable penetrating sealers that don’t trap subsurface moisture during freeze-thaw cycling.

Sedona Aesthetic Integration

Sedona projects require you to consider aesthetic harmony with the distinctive red rock landscape. Your slate selection would incorporate earth tones including rust, tan, and brown varieties that complement natural surroundings. You’d need to address both summer heat exceeding 100°F and winter freeze events in this transitional climate zone. Your specifications would balance thermal performance with freeze-thaw durability. The tourist-oriented commercial applications would require you to specify enhanced slip resistance for heavy pedestrian traffic. You would recommend textured surface finishes maintaining minimum 0.55 DCOF wet ratings for outdoor walkways and plaza areas.

Yuma Extreme Conditions

Yuma represents Arizona’s most extreme desert environment with summer temperatures consistently reaching 115-120°F. Your Slate Suppliers Arizona applications approach would emphasize maximum solar reflectance through light-colored material selection. You’d specify increased joint spacing up to 5/16 inch to accommodate exceptional thermal expansion rates. The sandy soil conditions require you to increase base depth to 8-10 inches with proper compaction verification. Your installation timeline would restrict work to November through March to avoid dangerous heat exposure for crews. You would recommend accelerated sealer reapplication schedules every 12-18 months due to extreme UV degradation rates in this environment.

Common Specification Mistakes to Avoid

You’ll want to avoid several specification errors that compromise performance in both indoor and outdoor applications. The most frequent mistake involves failing to differentiate thickness requirements based on application type. When you specify 1/2-inch slate for outdoor vehicular applications, you’re setting up inevitable cracking failures within 2-4 years. Your outdoor pedestrian areas require minimum 3/4-inch thickness, increasing to 1-1/4 inch for driveways regardless of base quality.

Another critical error occurs when you apply interior installation methods to outdoor projects. Thin-set mortar applications work perfectly for indoor installations over stable concrete substrates. Your outdoor applications require thick-bed mortar or sand-set systems that accommodate base movement and provide drainage. Using thin-set methods outdoors creates bond failures within 18-36 months as substrate movement exceeds the thin-set’s flexibility capacity.

Joint spacing represents a specification area where you’ll see frequent errors:

- You can’t use the same 1/8-inch joint spacing outdoors that works for interior applications

- Your outdoor joints must increase to 3/16-inch minimum and 1/4-inch preferred to handle thermal expansion

- You need to avoid using cement-based grout in outdoor joints where polymeric sand or flexible sealants perform better

- Your interior grout joints work fine with standard cement grout but outdoor conditions demand flexible alternatives

Sealer selection errors create problems in both applications. When you specify film-forming acrylic sealers for outdoor slate, you’re creating slip hazards and trapping moisture that causes delamination. Your outdoor specifications should mandate penetrating sealers only. The opposite error occurs indoors when you over-seal slate with multiple coats that create surface buildup and unnatural appearance.

Final Considerations

Your professional specification process requires you to balance multiple performance factors when selecting between indoor and outdoor slate applications. You need to account for environmental exposure differences, installation complexity variations, and long-term maintenance requirements that affect total cost of ownership. The slate tiles Arizona indoor outdoor decision framework should prioritize durability and safety alongside aesthetic preferences.

When you develop specifications, you should verify that your material selection, thickness requirements, installation methods, and sealing protocols all align with application type and environmental conditions. Your attention to these details determines whether installations perform successfully for 25+ years or require costly remediation within a decade. For comprehensive guidance on material quality standards, review Natural slate grading systems and quality standards in Arizona before you finalize your project documents. Citadel Stone offers Chinese slate as economical Slate Suppliers in Arizona budget options.