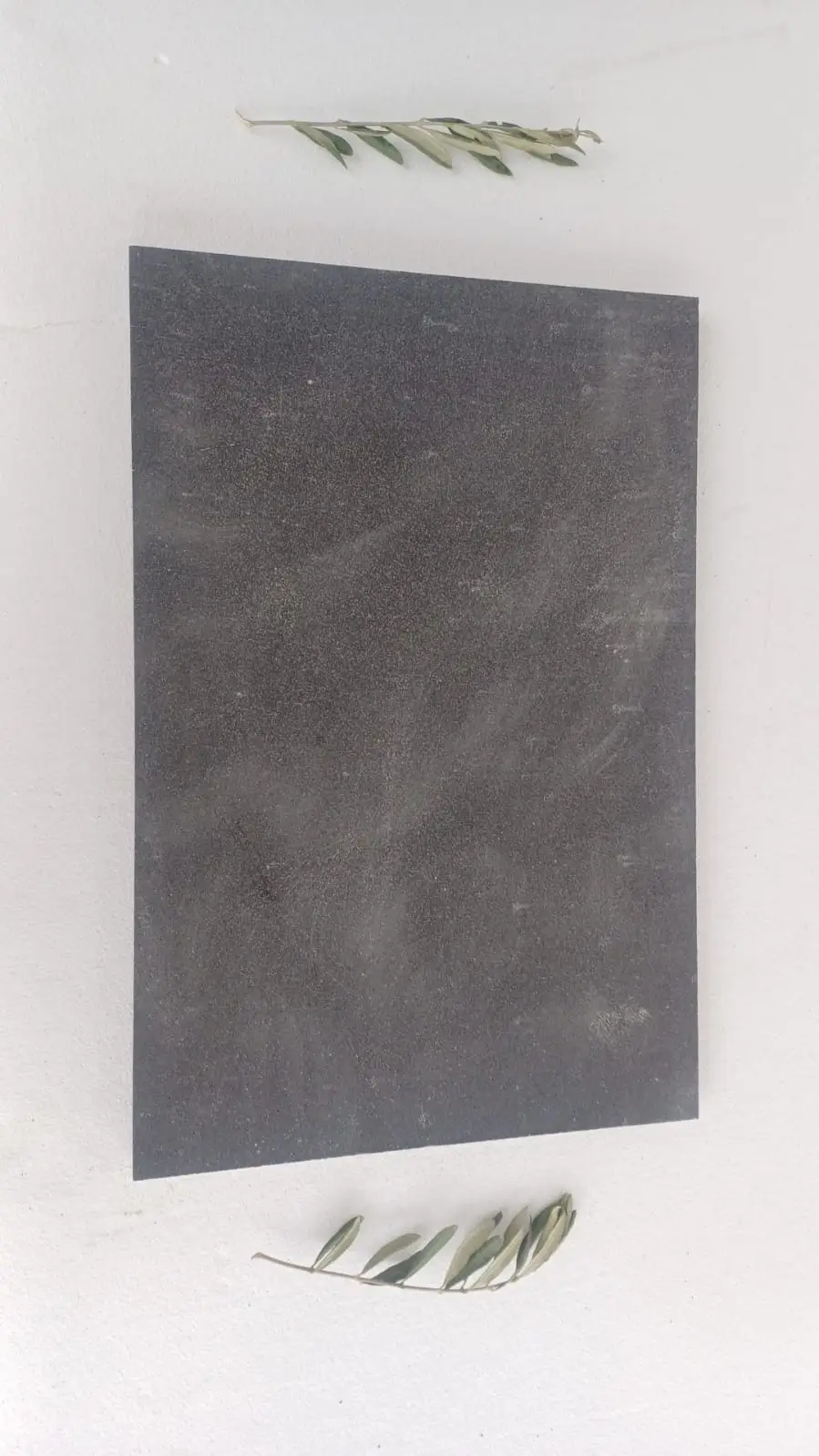

When you evaluate slate mineral streaking Arizona installations, you’re encountering one of the most distinctive visual characteristics that separates natural stone from manufactured alternatives. These mineral-rich veins and color bands form through millions of years of metamorphic pressure, creating patterns that define slate’s architectural appeal. Your material selection depends on understanding how these natural variations perform in Arizona’s extreme climate while meeting aesthetic expectations for commercial and residential projects.

The streaking patterns you see in slate result from mineral deposition during metamorphic transformation. Iron oxides create rust-red and gold tones, while chlorite and carbon compounds produce green and black striations. You need to recognize that no two slabs exhibit identical patterns — this natural variability becomes a specification consideration rather than a quality defect. Your project documentation should address expected variation ranges to prevent field disputes during installation verification.

Mineral Composition Driving Color Variation

The slate color variation you specify originates from specific mineral assemblages present during metamorphic formation. Hematite concentrations create burgundy and rust tones that intensify under Arizona’s intense UV exposure, while magnetite produces blue-gray base colors that remain stable across decades of solar radiation. You should understand that these minerals don’t just affect appearance — they influence thermal absorption, surface hardness, and long-term weathering characteristics.

When you examine slate pattern characteristics, you’re observing the directional alignment of mica minerals that define the stone’s natural cleavage planes. This foliation creates the linear streaking that runs parallel to the original bedding structure. Your installation orientation affects how these patterns appear in the finished application. Horizontal laying emphasizes linear flow, while diagonal installation creates dynamic visual movement that works well in contemporary landscape designs.

- You should verify that chlorite content remains below 15% for high-traffic applications where surface durability becomes critical

- Pyrite inclusions create gold metallic flecks that oxidize in Arizona humidity, shifting from bright gold to darker bronze tones within 18-24 months

- Carbon-rich layers produce true black streaking that maintains color stability better than dyed or treated alternatives

- Your specification must address whether mineral oxidation represents acceptable weathering or requires sealer application to slow color transition

Slate aesthetic features emerge most dramatically when you work with material sourced from single quarry runs. The geological consistency within one extraction area produces related but not identical patterns. For projects requiring 3,000+ square feet, you need to request material from the same quarry bench to minimize pattern disruption across large installations. What catches most specifiers off-guard is how lighting conditions transform slate mineral streaking Arizona appearance — morning grazing light reveals texture depth that disappears under harsh midday sun.

Thermal Performance of Streaked Slate Surfaces

Your thermal management strategy requires understanding how slate natural marking affects heat absorption and retention. Darker mineral streaks absorb 15-20% more solar radiation than lighter base colors, creating localized hot spots that affect barefoot comfort on pool decks and patio surfaces. In Phoenix installations where ambient temperatures exceed 115°F, surface temperatures on heavily streaked slate reach 165-180°F by mid-afternoon.

The slate color variation you specify directly impacts cooling lag time after sunset. Darker mineral-rich sections retain heat 30-45 minutes longer than lighter areas, creating uneven surface cooling that affects evening usability. You need to account for this thermal behavior when positioning slate near outdoor living spaces where occupants expect comfortable surface temperatures for evening entertainment. At Citadel Stone, we recommend light-colored slate varieties for west-facing applications where afternoon solar gain becomes most problematic.

Slate pattern characteristics influence emissivity rates that determine how quickly surfaces release absorbed heat. Smooth, mica-rich streaks exhibit higher emissivity (0.85-0.92) compared to rough, iron-oxide bands (0.78-0.84). This 8-10% difference translates to measurable temperature variations across single slabs. Your thermal comfort analysis should include infrared surface mapping for projects where temperature uniformity affects user experience.

Aesthetic Consistency Versus Natural Variation

When you establish aesthetic standards for slate mineral streaking Arizona projects, you’re balancing natural material authenticity against architectural uniformity requirements. The specification challenge involves defining acceptable variation ranges without eliminating the organic character that justifies slate selection over concrete alternatives. Your project documents need quantifiable metrics rather than subjective descriptors like “similar” or “consistent.”

Professional practice requires you to establish color variation tolerances using standardized comparison methods. The most reliable approach involves selecting representative sample boards that demonstrate minimum and maximum acceptable slate aesthetic features. You should photograph these samples under diffuse daylight conditions and include images in specification packages. This documentation prevents disputes when field-delivered material exhibits natural variation within acceptable industry standards.

- You need to specify whether slate natural marking should appear on 40-60% of surface area or require more uniform distribution

- Define acceptable streak width ranges (typically 2-15mm for commercial applications) to prevent delivery of material with unexpectedly bold or subtle patterns

- Your specifications must address whether color variation should blend within individual slabs or may create contrast between adjacent pieces

- Establish protocols for rejecting material that falls outside documented ranges while recognizing that 3-5% variation from samples represents normal geological diversity

The slate color variation you approve during sample selection may shift slightly when you view full pallets under natural light conditions. Showroom samples often represent ideal examples rather than average production ranges. You should request field samples from actual project inventory before finalizing orders exceeding 2,000 square feet. This verification step prevents costly returns and project delays when delivered material meets technical specifications but fails aesthetic expectations.

Installation Orientation and Pattern Emphasis

Your installation design controls how slate pattern characteristics appear in completed applications. Running bond patterns with 1/3 offset emphasize linear mineral streaking by creating visual flow across multiple courses. When you specify this layout for slate mineral streaking Arizona installations, you’re enhancing the natural directionality inherent in metamorphic foliation. This approach works particularly well for pathways and linear site elements where directional movement guides circulation patterns.

Conversely, you might choose random ashlar patterns to minimize streak emphasis and create more varied visual texture. This layout distributes slate aesthetic features across mixed slab sizes, preventing the eye from tracking individual mineral bands. You should specify random patterns when architectural context demands subdued material presence or when slate serves as background rather than focal element. The installation premium for random layouts typically adds 8-12% to labor costs compared to running bond applications.

Diagonal installation at 45-degree angles transforms how you perceive slate natural marking by creating dynamic visual energy. This orientation works effectively in contemporary designs where material texture provides architectural interest. You need to account for increased waste factors (12-15% versus 7-9% for orthogonal layouts) and verify that your budget accommodates the material premium. Additionally, you should confirm that mineral streaking maintains visual coherence when viewed at diagonal angles rather than parallel to natural foliation.

Sealing Considerations for Mineral Streaking

When you evaluate sealer applications for slate mineral streaking Arizona projects, you’re making decisions that permanently alter surface appearance and performance characteristics. Penetrating sealers darken base colors by 1-2 shades while intensifying mineral streak contrast by 15-20%. This enhancement effect satisfies clients seeking dramatic color depth but may overly emphasize streaking patterns that appeared subtle in unsealed samples.

You should conduct side-by-side sealing tests on project-specific material before committing to full application. Apply three sealer types to sample boards — penetrating, color-enhancing, and natural-finish formulations. Photograph results after 24-hour curing under direct sunlight to document actual appearance shifts. This testing reveals whether sealer application supports or undermines your intended aesthetic outcome for slate color variation.

- Natural-finish sealers maintain original appearance while providing stain protection, preserving subtle slate pattern characteristics without color intensification

- You need to reapply penetrating sealers every 2-3 years in Arizona’s UV-intense environment to maintain stain resistance and color enhancement

- Color-enhancing formulations create permanent darkening that cannot be reversed if results don’t meet expectations

- Your maintenance program must address sealer breakdown patterns that create uneven gloss levels emphasizing some mineral streaks more than others

The long-term appearance of sealed slate depends on Arizona’s extreme temperature cycling. Sealers experience thermal expansion rates different from slate substrate, creating microscopic surface cracks that trap dust and alter slate aesthetic features over time. You should anticipate that sealed surfaces require professional stripping and resealing every 5-7 years to maintain uniform appearance. For guidance on related paving options, see our natural slate stone inventory for comprehensive comparison data across sealer compatibility testing.

Quality Grading Systems for Streaked Slate

You need to understand that slate grading systems evaluate structural integrity rather than aesthetic qualities like mineral streaking intensity. ASTM C629 establishes three grades based on modulus of rupture and water absorption — your specifications should reference these standards while separately addressing slate color variation requirements. Grade S-1 slate exceeds 9,000 PSI flexural strength with less than 0.25% absorption, suitable for Arizona’s freeze-thaw boundary regions despite their rarity.

When you specify slate mineral streaking Arizona material, you’re typically working with S-2 grade slate that provides 7,000-9,000 PSI strength with 0.25-0.45% absorption. This grade offers optimal balance between structural performance and cost efficiency for most commercial and residential applications. The slate natural marking you observe correlates loosely with grade — heavily mineralized streaking sometimes indicates geological conditions that reduce structural uniformity, though this relationship isn’t absolute.

Your quality verification process should include visual inspection for delamination risks along mineral streak boundaries. When iron-rich bands create distinct color transitions, you’re observing potential weakness planes where water infiltration might cause separation during freeze-thaw cycles. You should reject slabs exhibiting visible layering gaps wider than 0.5mm along streak boundaries, even when overall dimensions and surface finish meet specifications. These structural concerns override aesthetic considerations regardless of how attractive the slate pattern characteristics appear.

Comparative Durability Across Streak Intensities

The slate aesthetic features you select influence long-term durability through mineral hardness variations across streaked surfaces. Mica-rich light-colored bands exhibit Mohs hardness of 2.5-3.0, while iron-oxide streaks reach 5.0-5.5 hardness. This differential creates uneven wear patterns in high-traffic applications. You’ll observe that softer mica-rich areas develop subtle depressions after 8-12 years of foot traffic, creating texture that some clients appreciate as patina while others view as degradation.

When you specify slate for commercial plaza applications expecting 5,000+ daily pedestrian crossings, you need to account for accelerated wear along softer mineral bands. The slate color variation that appears subtle during installation becomes more pronounced as traffic polishes harder streaks while abrading softer areas. You should establish client expectations during design development that this differential wear represents natural aging rather than material failure.

- Darker iron-oxide streaking maintains surface texture longer than lighter mica-rich base colors in traffic areas

- You should orient slate so that major mineral streaking runs perpendicular to primary traffic flow, distributing wear across both hard and soft mineral bands

- Salt exposure from winter de-icing accelerates deterioration of iron-bearing streaks through oxidation cycles that don’t affect silicate-rich areas

- Your maintenance specifications need to address whether periodic diamond honing will restore surface uniformity or should be avoided to preserve natural patina development

Arizona’s minimal freeze-thaw cycling reduces durability concerns related to differential expansion across slate mineral streaking Arizona applications. In northern regions, thermal cycling causes separation along mineral boundaries when expansion coefficients differ by more than 2 × 10⁻⁶ per °F. You benefit from specifying this material in Phoenix and Tucson environments where annual freeze events occur fewer than 5 times, essentially eliminating this failure mode from long-term performance projections.

Specification Language for Acceptable Variation

Your specification documents require precise language that defines acceptable slate color variation without eliminating natural characteristics that justify material selection. Vague terminology like “similar appearance” or “consistent coloring” creates disputes during material acceptance. You should establish quantifiable standards using percentage coverage, dimensional limits, and comparative sampling protocols.

Professional specifications might state: “Slate shall exhibit mineral streaking covering 35-55% of surface area, with individual streaks ranging 3-12mm width. Base color shall fall within green-gray range matching approved sample board. Mineral content variation shall not cause surface reflectance to vary by more than 15% when measured under D65 illumination.” This specificity protects both your design intent and supplier’s ability to source conforming material from natural geological deposits.

You need to address how slate pattern characteristics distribute across project quantities. For orders exceeding 3,000 square feet, specify whether material should represent single quarry extraction or may include multiple sources blended to achieve overall project appearance. Single-source material provides tighter aesthetic control but limits supplier flexibility and may extend lead times. Blended sourcing offers faster delivery with slightly broader variation ranges. At Citadel Stone, we recommend single-source specifications for feature applications under 5,000 square feet and blended sourcing for large-format site paving where subtle variation becomes imperceptible.

Lighting Design Interaction with Mineral Patterns

When you coordinate slate mineral streaking Arizona installations with architectural lighting, you’re amplifying or suppressing natural patterns through illumination angle and color temperature. Grazing light at 15-30 degree angles emphasizes texture and mineral banding by creating shadow patterns that enhance three-dimensional surface relief. You should specify this lighting approach for feature walls and vertical applications where slate aesthetic features become focal design elements.

Conversely, diffuse overhead lighting at 60-90 degree angles minimizes slate natural marking visibility by eliminating shadows that reveal surface texture. This approach suits applications where slate provides neutral background rather than visual emphasis. Your lighting specifications should include photometric studies showing how proposed fixtures affect slate appearance under day and night conditions. What most designers overlook is how LED color temperature transforms mineral streak appearance — 3000K warm white emphasizes rust and gold tones while suppressing gray-green base colors, while 5000K cool white reverses this effect.

You need to account for reflected glare from polished or honed slate surfaces in Arizona’s intense sunlight. Smooth mica-rich streaks create specular reflections that become uncomfortable at certain sun angles. Your site orientation analysis should identify times when solar altitude creates problematic reflections and adjust slate finish specifications accordingly. Thermal finishing or flaming creates rougher surfaces that diffuse light, reducing glare while emphasizing slate color variation through texture contrast rather than mineral streak visibility.

Cost Implications of Pattern Selectivity

Your budget management requires understanding how aesthetic selectivity for slate pattern characteristics affects material costs. Standard production slate with naturally occurring mineral variation typically costs $8-14 per square foot FOB quarry. When you specify narrow aesthetic tolerances requiring selection of particular streak intensities or color ranges, you’re imposing culling requirements that increase costs by 20-35%.

This premium reflects the supplier’s need to sort through larger material volumes to identify slabs meeting restricted criteria. You should evaluate whether visual uniformity justifies this cost increase or whether natural variation provides acceptable results at standard pricing. For most Arizona landscape applications, the geological diversity inherent in slate mineral streaking Arizona material enhances rather than detracts from design intent. Your value engineering analysis should question aesthetic restrictions that add cost without proportional performance or visual benefits.

- You can reduce material costs by 15-20% by accepting broader variation ranges that allow suppliers to ship consecutive quarry runs without selective culling

- Premium pricing applies when you restrict mineral streaking to specific areas of each slab or require matched patterns across adjacent pieces

- Your project budget should include 5-8% contingency for replacing pieces that arrive within specification ranges but don’t satisfy subjective aesthetic expectations

- Warehouse inventory of pre-selected slate typically commands 25-30% premium versus custom orders with 8-12 week lead times

Best Slate Stone Suppliers Arizona — Citadel Stone Guidance

When you consider Citadel Stone’s slate stone suppliers for your Arizona project, you’re evaluating premium materials designed for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions. This section outlines how you would approach specification decisions for three representative cities where slate mineral streaking Arizona installations demonstrate distinct performance considerations.

Your material selection process should account for regional climate variations that affect slate color variation stability and thermal performance. The guidance below represents professional approaches for hypothetical projects in different Arizona climate zones. You would adapt these recommendations based on specific site conditions, client aesthetic preferences, and budget parameters for actual installations.

San Tan Valley Residential Guidance

In San Tan Valley’s transitional climate zone, you would specify slate with moderate mineral streaking (40-50% coverage) that balances thermal absorption with aesthetic interest. Your residential courtyard applications would benefit from slate pattern characteristics that create visual texture without excessive heat retention. You should recommend light base colors with subtle iron-oxide streaking to maintain barefoot comfort during extended outdoor season. The region’s minimal freeze risk allows you to prioritize aesthetic considerations over extreme durability requirements, though you would still specify S-2 grade material for structural reliability. Your installation guidance would address thermal expansion in 110°F+ summer conditions by requiring 3/16-inch joints with polymeric sand stabilization.

Yuma Commercial Applications

For Yuma’s extreme desert environment, you would recommend slate with minimal dark mineral streaking to control surface temperatures in commercial plaza settings. The city’s 4,000+ annual sunshine hours demand that your specifications prioritize reflective base colors over dramatic slate aesthetic features. You would specify material with less than 35% streak coverage, focusing on green-gray base tones that maintain lower thermal mass. Your technical guidance would address UV stability for slate natural marking, recommending penetrating sealers with UV inhibitors applied every 18-24 months. Commercial traffic patterns would require you to specify thicker 30mm material versus standard 20mm residential gauges, accounting for accelerated wear in public access areas.

Avondale Pool Deck Scenarios

In Avondale pool deck applications, you would balance slate color variation aesthetic appeal against safety requirements for wet surface traction. Your specifications would require thermal-finished surfaces that emphasize natural texture while maintaining DCOF ratings above 0.60 when wet. You should recommend slate mineral streaking Arizona material with moderate pattern intensity (45-55% coverage) that conceals water spotting and chemical staining common in pool environments. The chlorine exposure typical in these applications would require you to specify non-reactive sealers that don’t yellow or deteriorate under chemical contact. Your installation details would address drainage slopes of 1.5-2% minimum to prevent standing water that accelerates mineral leaching from streaked areas. At Citadel Stone, we would recommend increasing joint width to 1/4-inch for enhanced drainage performance in this application type.

Long-Term Color Stability Expectations

Your maintenance planning requires realistic expectations for how slate mineral streaking Arizona appearance evolves over decades of UV exposure and weathering. Iron-oxide mineral bands undergo gradual oxidation that shifts bright rust tones toward darker brown-red hues over 10-15 years. This color transition occurs more rapidly on horizontal surfaces receiving direct solar radiation compared to vertical applications with partial shading.

You should inform clients that this color evolution represents natural weathering rather than material degradation. The slate pattern characteristics they observe during installation will shift subtly but remain within the geological variation inherent in natural stone. Some architects prefer this aging process, viewing weathered slate as developing character similar to patinated copper. Others consider color shift undesirable and require maintenance protocols that slow oxidation through regular sealer renewal.

Chlorite-bearing green streaks demonstrate superior UV stability compared to iron-oxide bands, maintaining original color intensity with less than 5% shift over 20+ years. When you specify slate with predominantly chlorite-based slate color variation, you’re providing more predictable long-term appearance. This consideration matters most for projects where color consistency affects architectural cohesion across building facades or large plaza installations where replacement sections must match aged material.

Final Technical Considerations

Your professional specification process requires you to balance multiple factors when evaluating slate mineral streaking Arizona applications. The aesthetic appeal of natural mineral patterns must align with thermal performance requirements, durability expectations, and budget constraints. You need to establish clear acceptance criteria that honor geological variability while preventing delivery of material that fails project intent.

When you document specifications, include representative samples photographed under controlled lighting that demonstrate acceptable variation ranges. Your construction administration responsibilities include field verification that delivered material falls within these documented parameters. You should anticipate that natural stone installations always involve some aesthetic judgment — establishing collaborative client relationships prevents disputes when material exhibits variation within industry-standard ranges.

The long-term success of your slate installations depends on maintenance protocols addressing sealer renewal, joint stabilization, and cleaning methods appropriate for mineralized surfaces. You need to provide clients with realistic performance expectations that account for Arizona’s extreme climate while emphasizing the enduring beauty of natural slate aesthetic features. For additional technical insights, review Metamorphic transformation processes that produce slate rock formations before you finalize your project documents. Fireplace surrounds feature Citadel Stone’s heat-resistant slate stone for sale hearths.