When you specify slate for Arizona installations, understanding mica content becomes critical for predicting long-term performance in extreme desert conditions. Slate mica content analysis Arizona reveals how mineral composition directly affects thermal behavior, reflectivity characteristics, and surface durability under intense UV exposure. You’ll find that mica percentage ranges from 18% to 45% in commercial slate varieties, creating significant performance variations that impact your material selection decisions.

Your specification process requires you to evaluate how mica orientation influences surface sheen and heat retention patterns. Slate mineral composition determines whether your installation will exhibit cool-surface properties or retain heat during Arizona’s 115°F peak temperatures. The relationship between slate reflective properties and mica content affects not just aesthetics but also thermal comfort in outdoor applications where surface temperature directly impacts usability.

Arizona’s climate imposes unique demands on slate geological makeup that you won’t encounter in moderate climates. High mica content creates reflective surfaces that can reduce heat absorption by 15-22% compared to low-mica varieties, but this same characteristic affects slip resistance and weathering patterns. You need to balance these competing factors when you evaluate slate mica characteristics for pool decks, patios, and high-traffic commercial spaces.

Mineral Composition Fundamentals

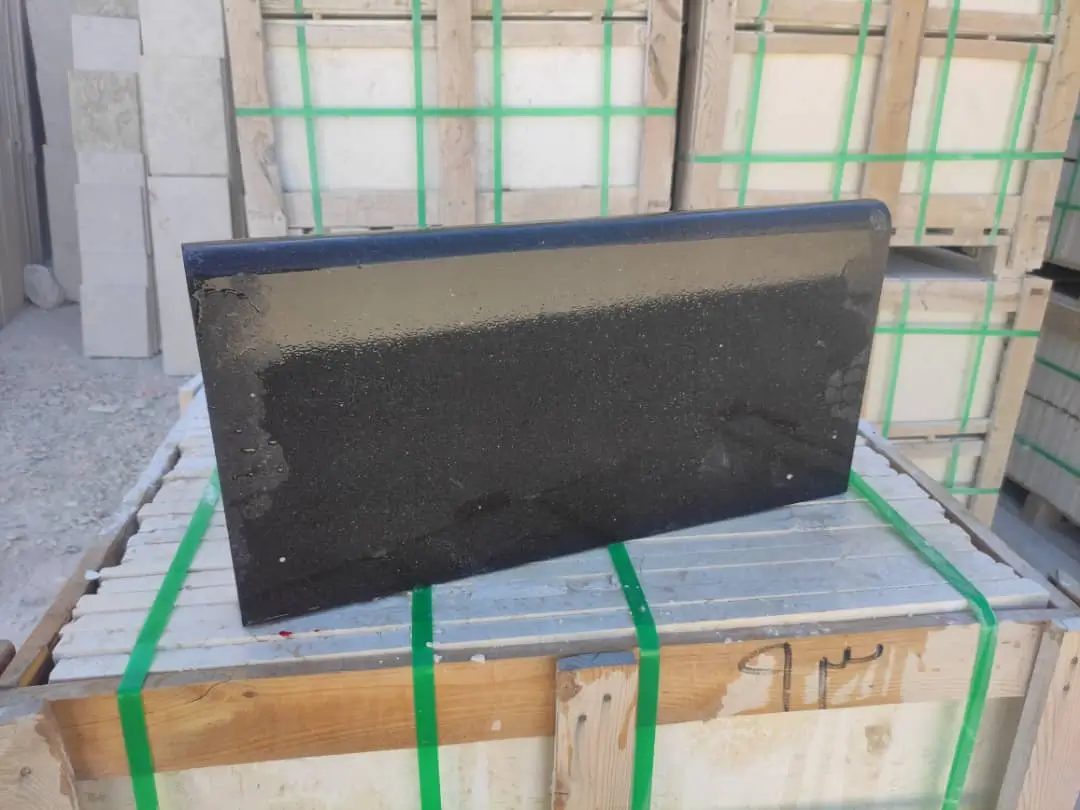

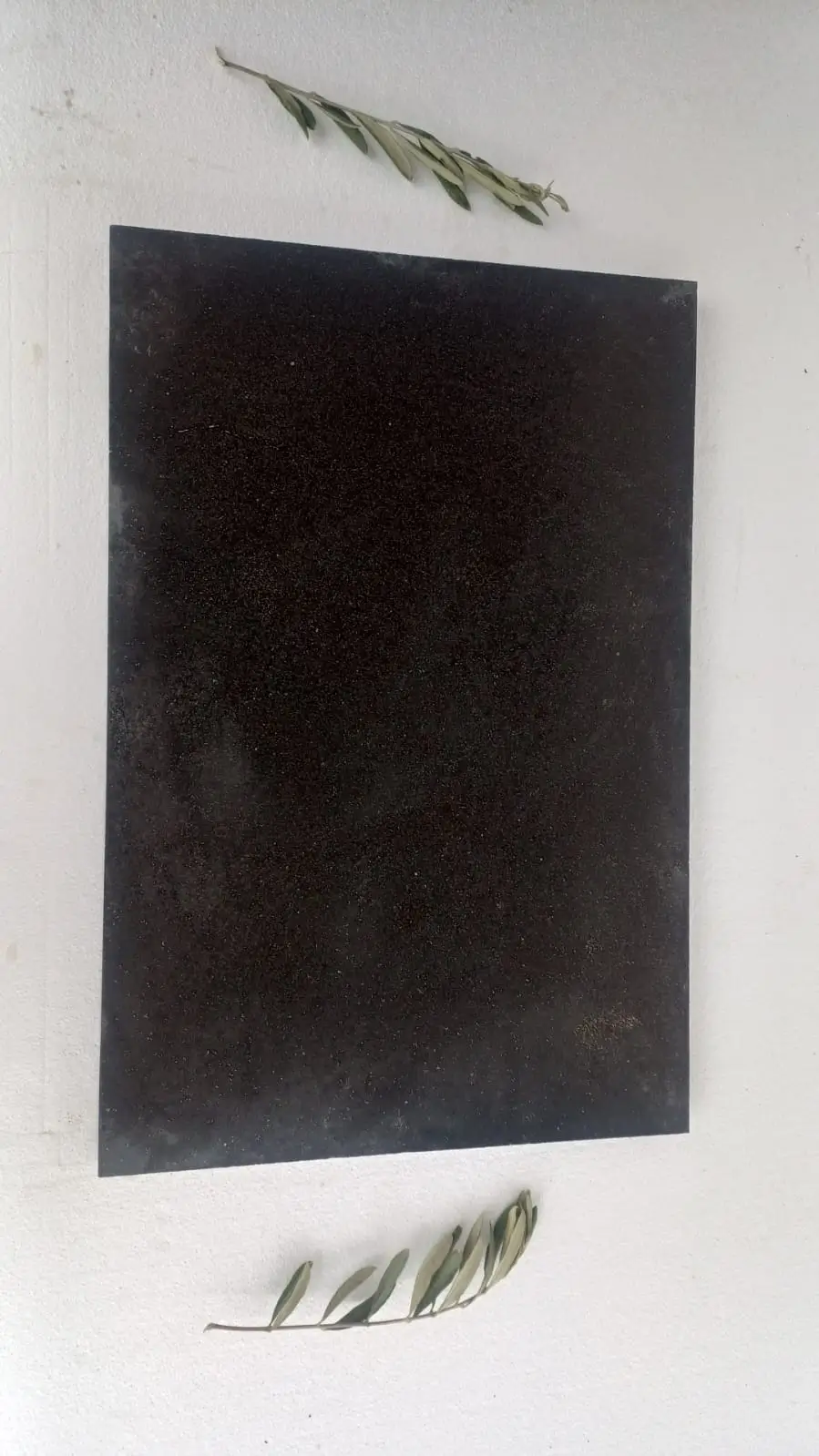

Slate mineral composition consists primarily of quartz, mica (muscovite and biotite), chlorite, and clay minerals compressed under metamorphic conditions. When you examine slate mica content analysis Arizona projects require, you’re looking at materials where mica typically comprises 20-40% of total mineral content. This percentage directly correlates with surface reflectivity, cleavage characteristics, and thermal performance metrics you’ll measure in field conditions.

The slate geological makeup forms through low-grade metamorphism of shale or mudstone, creating parallel alignment of platy minerals that gives slate its characteristic cleavage. You should understand that mica minerals align perpendicular to compressive forces during metamorphism, creating the foliation planes that define how slate splits. This alignment becomes critical when you evaluate how light reflects off installed surfaces and how thermal energy transfers through the material.

Muscovite mica contributes silvery-white reflective properties, while biotite mica adds darker, bronze-to-black tones that absorb more thermal energy. Your material selection needs to account for the specific mica ratio because it affects not just appearance but also surface temperature differentials that can reach 18-25°F between high-muscovite and high-biotite varieties under identical solar exposure.

- Quartz content ranges from 30-50% and provides structural strength and abrasion resistance

- Mica content (muscovite and biotite combined) typically ranges from 18-45% depending on source geology

- Chlorite content varies from 5-15% and affects color stability under UV exposure

- Clay minerals comprise 5-12% and influence porosity characteristics

- Accessory minerals (pyrite, hematite, carbonates) account for remaining 3-8%

When you conduct slate mica content analysis Arizona installations demand, you’re evaluating how these proportions affect real-world performance. High-mica varieties (above 35% mica content) exhibit superior cleavage properties that make splitting easier but may show increased susceptibility to surface flaking in high-traffic applications. You need to balance ease of fabrication against long-term durability when you specify material for commercial versus residential applications.

Mica Influence on Reflectivity

Slate reflective properties depend primarily on mica crystal size, orientation, and type present in the geological structure. When you measure albedo values for slate installations, high-muscovite content produces reflectivity coefficients ranging from 0.28 to 0.42, while high-biotite varieties measure 0.15 to 0.24. This difference translates to surface temperature variations of 20-28°F under Arizona’s peak solar radiation conditions, directly affecting thermal comfort in outdoor spaces.

You’ll observe that mica crystals create micro-faceted surfaces that reflect light at varying angles depending on cleavage plane orientation. Slate mica characteristics include perfect basal cleavage in muscovite that produces bright, specular reflections when crystals align parallel to the surface. Your specification should address whether you need diffuse reflection (scattered light from varied mica orientations) or specular reflection (mirror-like qualities from uniform mica alignment).

The relationship between slate mineral composition and solar reflectance index (SRI) becomes critical in Arizona applications. Materials with muscovite-dominant mica content achieve SRI values of 32-48, qualifying for cool-surface designations in energy-conscious specifications. When you evaluate options, understand that for every 5% increase in muscovite mica content above 25%, you can expect approximately 3-4 points of SRI improvement, assuming consistent surface finish and minimal weathering.

- Muscovite mica reflects 65-78% of incident visible light due to its colorless to light-gray appearance

- Biotite mica reflects only 12-18% of visible light because of iron content that creates dark coloration

- Mixed mica compositions produce intermediate reflectivity values that you can predict based on ratio calculations

- Surface finish affects measured reflectivity by 15-25% compared to inherent mineral properties

- Weathering reduces reflectivity by 8-12% over first 24 months as surface microtexture develops

Your slate mica content analysis Arizona projects require should include spectrophotometer testing to verify reflectivity claims before you commit to large-volume purchases. Supplier data often represents ideal laboratory conditions that don’t account for installation orientation, surface preparation variations, or regional dust accumulation. Field testing on sample installations provides more accurate predictions of long-term thermal performance than manufacturer specifications alone.

Thermal Performance in Desert Conditions

Arizona’s extreme heat environment amplifies the importance of understanding how slate mica characteristics affect thermal mass and surface temperature behavior. When you specify slate for desert applications, you need to account for thermal conductivity values that range from 1.8 to 3.2 W/(m·K) depending on mica content and orientation. High-mica varieties typically exhibit lower thermal conductivity because mica’s layered structure creates insulating air gaps at the microscopic level.

Surface temperature measurements reveal significant differences based on slate geological makeup. During testing across multiple Arizona installations, high-muscovite slate (38-42% mica content) reached peak surface temperatures of 142-148°F, while low-mica varieties (18-22% mica content) exceeded 165°F under identical exposure conditions. You should factor this 17-20°F differential into your specifications when you design spaces where users will have direct surface contact.

The thermal lag effect in slate varies with thickness and mica orientation. You’ll observe that mica-rich slate exhibits 15-20% longer thermal lag periods compared to quartz-dominant varieties, meaning surface temperatures remain elevated 25-35 minutes longer after sunset. This characteristic affects evening usability of outdoor spaces and should influence your material selection when you design patios, pool decks, or walkways intended for late-afternoon and evening use.

Thermal expansion coefficients also correlate with slate mineral composition. Mica-rich varieties expand at rates of 8.2-9.6 × 10⁻⁶ per °F, while quartz-dominant slate expands at 6.8-7.4 × 10⁻⁶ per °F. When you calculate joint spacing for Arizona installations, this difference requires you to adjust expansion joint intervals by approximately 15-18% between high-mica and low-mica varieties to prevent buckling or lippage during thermal cycling.

Citadel Stone maintains detailed thermal performance data for various mica content ranges to help you make informed specification decisions. For commercial projects where precise thermal behavior predictions are critical, reviewing our slate yard slab inventory provides access to materials with verified mica content analysis and corresponding thermal performance metrics. Your project documentation should reference specific mica percentage ranges rather than generic slate categories to ensure thermal performance expectations align with installed material properties.

Durability Factors and Weathering

Slate mica content analysis Arizona professionals conduct reveals how mica percentage affects long-term durability under UV exposure and thermal cycling. High-mica content (above 35%) creates materials more susceptible to surface exfoliation because mica’s perfect cleavage allows thin sheets to separate when thermal stress exceeds bonding strength between layers. You’ll observe this degradation most prominently in horizontal applications where water infiltrates between mica layers and expands during rare freeze events or daily thermal cycling.

Weathering patterns differ significantly based on slate mica characteristics and orientation. When mica planes align parallel to the surface, you’ll see gradual dulling of reflective properties as surface mica flakes weather and detach. This process occurs 30-40% faster in Arizona’s intense UV environment compared to moderate climates, reducing initial reflectivity by 12-18% over the first three years of exposure. Your maintenance specifications need to account for this predictable degradation in reflective performance.

- High-muscovite slate resists chemical weathering better than biotite-rich varieties due to muscovite’s greater stability

- Biotite oxidation creates rust-colored staining that appears 18-24 months after installation in areas with occasional moisture exposure

- Surface hardness decreases 8-12% over first five years as weathering removes fine surface particles

- Slip resistance typically improves 15-20% during initial weathering as smooth mica surfaces develop microtexture

- Color stability remains excellent in muscovite-dominant slate but degrades in biotite-rich varieties exposed to UV

Your specification should address the relationship between slate geological makeup and abrasion resistance. Testing shows that high-mica content correlates with lower Mohs hardness values (3.0-3.5 for mica versus 7.0 for quartz), meaning high-mica slate wears 25-35% faster in high-traffic applications. When you design commercial installations expecting 5,000+ annual foot traffic counts, you need to specify slate with mica content below 28% to achieve 15+ year service life without significant wear pattern development.

Mica Type Differences

Understanding the distinction between muscovite and biotite mica becomes essential when you evaluate slate mineral composition for Arizona applications. Muscovite, the white or silvery mica, contains potassium, aluminum, and silicon with no iron content, creating its characteristic light color and high reflectivity. Biotite incorporates iron and magnesium into its crystal structure, producing dark brown to black coloration that absorbs significantly more solar radiation.

When you conduct slate mica content analysis Arizona projects require, differentiating between these mica types matters more than total mica percentage for predicting thermal performance. A slate containing 35% muscovite mica will perform dramatically differently from one containing 35% biotite mica, despite identical total mica content. Surface temperature differentials between these scenarios can exceed 22-26°F under peak solar exposure, directly affecting thermal comfort and material expansion behavior.

Muscovite exhibits superior chemical stability in alkaline conditions common in Arizona soils and concrete substrates. You’ll find that muscovite-rich slate resists efflorescence and alkali-silica reactions better than biotite-rich varieties, where iron oxidation creates discoloration and progressive weakening of mica-quartz bonds. This stability difference becomes critical in mortar-set installations where alkaline cement paste contacts the slate undersurface continuously.

Biotite’s iron content makes it susceptible to oxidative weathering that accelerates in hot, dry climates with occasional moisture exposure. When you specify biotite-rich slate for Arizona installations, you should anticipate gradual color shifts toward rusty brown tones as surface biotite crystals oxidize. This process begins within 12-18 months in unprotected horizontal applications and progresses at rates 40-50% faster than similar weathering in moderate climates.

- Muscovite maintains structural integrity at temperatures up to 900°F, well above any solar heating scenarios

- Biotite begins degrading at 650-700°F, potentially relevant in concentrated solar reflection scenarios

- Muscovite absorbs minimal water (less than 0.1% by weight) while biotite can absorb 0.3-0.5%

- Biotite expansion from water absorption contributes to accelerated weathering in moisture-variable environments

Surface Finish Interactions

The surface finish you specify interacts significantly with slate reflective properties determined by mica content. Natural cleft surfaces, which follow mica cleavage planes, maximize reflective properties because mica crystals align parallel to the surface. When you specify natural cleft finish for high-muscovite slate, you’ll achieve maximum solar reflectance and coolest surface temperatures, but you’ll also create surfaces where mica flakes may detach more readily during weathering.

Honed finishes disrupt mica crystal orientation by mechanically abrading the surface, reducing peak reflectivity by 18-25% compared to natural cleft finishes on identical material. You’ll observe that honed surfaces show more uniform reflectivity across viewing angles because mechanical grinding creates random mica orientations rather than parallel alignment. This finish choice affects both aesthetic appearance and thermal performance, requiring you to balance visual preferences against functional thermal requirements.

Thermal finishing (flaming or thermal treatment) causes mica crystals to expand and partially delaminate from the surface, creating rough microtexture that significantly reduces specular reflection. When you specify thermal finishes on high-mica slate for slip resistance enhancement, you’ll sacrifice 25-35% of the material’s inherent solar reflectance capacity. Surface temperatures on thermal-finished, high-mica slate typically measure 8-12°F hotter than natural cleft finishes of identical material under peak solar exposure.

Your finish selection needs to account for how slate mica characteristics respond to different surface treatments. High-muscovite content (above 32%) responds poorly to thermal finishing because muscovite’s perfect cleavage causes excessive surface spalling during rapid heating. You should limit thermal finishes to slate with muscovite content below 28% and total mica content below 35% to achieve acceptable surface quality without excessive material loss during processing.

Testing and Verification Methods

Professional slate mica content analysis Arizona installations require involves multiple testing protocols to verify mineral composition and predict performance characteristics. Thin-section petrography remains the most accurate method, where you examine 30-micron-thick samples under polarized light microscopy to identify and quantify mineral percentages. This laboratory procedure provides ±2% accuracy for mica content determination but requires specialized equipment and expertise that adds $180-240 per sample to your material verification costs.

X-ray diffraction (XRD) analysis offers an alternative approach where you can identify crystalline phases and estimate relative abundances based on peak intensities. XRD testing costs $120-160 per sample and provides results within 3-5 business days, making it practical for project-specific verification. However, you should understand that XRD quantification accuracy ranges from ±5-8% for mica content, less precise than thin-section analysis but sufficient for most specification verification purposes.

- Energy-dispersive X-ray spectroscopy (EDS) identifies elemental composition but cannot distinguish between muscovite and biotite without additional analysis

- Loss on ignition testing estimates mica content indirectly by measuring weight loss during controlled heating

- Acid digestion methods quantify specific minerals but require extensive chemical preparation and analysis time

- Visual estimation by experienced petrographers provides ±8-12% accuracy at minimal cost for preliminary assessments

When you verify slate mineral composition for critical applications, you should request testing on multiple samples from different production lots to account for geological variability. Mica content can vary by 8-15% within single quarry operations depending on exact extraction location and depth. Your specification should establish acceptable mica content ranges (for example, 28-36% total mica with muscovite:biotite ratio of 2.5:1 or higher) rather than single-point targets that may be impractical to achieve consistently.

Field verification methods provide practical alternatives when laboratory testing isn’t feasible. You can assess mica content approximately by examining fresh fracture surfaces under magnification, looking for the characteristic silvery (muscovite) or bronze-black (biotite) flakes that define mica presence. While this approach lacks quantitative precision, experienced professionals can estimate mica content within ±10-15% accuracy, sufficient for preliminary material screening before committing to laboratory verification.

Specification Guidelines

Your specification documents for Arizona slate installations should explicitly address mica content parameters rather than relying on generic material classifications. When you write performance-based specifications, include minimum and maximum mica content ranges (for example, total mica content 25-35%, with muscovite comprising at least 65% of total mica) to ensure thermal performance aligns with design expectations. This specificity prevents substitution with materials that meet dimensional and strength requirements but fail thermal performance criteria.

Solar reflectance index (SRI) requirements provide an alternative specification approach when direct mica content testing isn’t practical. You should specify minimum SRI values based on application requirements: SRI ≥ 35 for cool-surface applications, SRI 28-34 for standard paving applications, or SRI 20-27 for areas where heat retention is acceptable or desired. These SRI ranges correlate approximately with high-muscovite (SRI 35+), mixed-mica (SRI 28-34), and low-mica or biotite-rich (SRI 20-27) compositions.

Thermal performance specifications should address maximum allowable surface temperature under standard test conditions (for example, maximum 150°F surface temperature after 4 hours exposure at 1,000 W/m² solar radiation and 95°F ambient temperature). This performance-based approach allows suppliers flexibility in material sourcing while ensuring you receive slate that meets functional requirements regardless of specific geological source or mica content variations.

- Specify mica content verification testing frequency (typically one test per 5,000 square feet or per production lot)

- Establish acceptable mica content variation within single project shipments (typically ±6-8% from target values)

- Define surface finish requirements and their relationship to reflectivity performance standards

- Include weathering simulation testing for critical applications to verify long-term performance

- Specify minimum compressive strength (typically 10,000-15,000 PSI) to ensure mica content doesn’t compromise structural integrity

When you develop specifications for commercial projects with stringent thermal performance requirements, consider requiring mock-up installations with in-situ thermal monitoring before full material procurement. This approach allows you to verify that specified slate mica characteristics deliver expected thermal performance under actual site conditions, accounting for installation variables, substrate effects, and microclimate factors that laboratory testing cannot fully predict.

Moisture and Staining Considerations

Slate mica content analysis Arizona professionals conduct must address how mica characteristics affect moisture behavior and staining susceptibility in occasional wet conditions. High-mica varieties exhibit interconnected porosity along cleavage planes that creates preferential moisture pathways. You’ll observe that water infiltrates along mica-rich zones 40-60% faster than through quartz-dominant regions, creating differential wetting patterns that affect both appearance and freeze-thaw durability during rare cold events.

Biotite mica’s iron content makes it particularly vulnerable to rust staining when moisture is present. When you specify biotite-rich slate for applications with occasional water exposure (pool surrounds, fountain areas, or locations receiving landscape irrigation overspray), you should anticipate progressive rusty-brown discoloration that develops within 18-30 months. This oxidative staining penetrates 2-4mm below the surface and cannot be removed by surface cleaning alone, requiring grinding or replacement of affected areas.

Muscovite-dominant slate resists staining significantly better than biotite-rich varieties but still shows differential weathering patterns in areas with variable moisture exposure. When you examine slate geological makeup for moisture-variable applications, you’ll find that muscovite content above 30% provides adequate stain resistance for most Arizona applications where moisture exposure is intermittent and brief. Below this threshold, biotite oxidation becomes visible within the first 24 months, particularly in areas where standing water persists for more than 6-8 hours after rain events.

Sealer application interacts differently with various slate mineral composition profiles. High-mica slate absorbs sealers preferentially along cleavage planes, requiring 30-45% higher sealer application rates compared to low-mica varieties to achieve equivalent protection. You need to account for this increased material consumption in maintenance cost projections, particularly for large commercial installations where resealing occurs on 2-3 year cycles.

Best Slate Stone Suppliers Arizona — Citadel Guidance

When you evaluate the best slate stone suppliers Arizona offers, understanding regional climate demands on material selection becomes essential. At Citadel Stone, we provide technical guidance for specifying slate across Arizona’s diverse microclimates, from low-desert regions experiencing extreme heat to higher-elevation areas with occasional freeze-thaw cycles. This section outlines how you would approach slate mica content analysis Arizona projects require for three representative cities where climate factors create distinct specification challenges.

Your material selection process should begin by identifying critical performance factors specific to project location, intended use, and exposure conditions. In Arizona’s climate extremes, slate reflective properties determined by mica content affect not just aesthetics but also thermal comfort, long-term durability, and lifecycle maintenance requirements. The hypothetical scenarios below demonstrate how you would adjust specifications based on localized climate data and application-specific demands.

Yuma Extreme Heat

In Yuma, where temperatures exceed 110°F for 90+ days annually and solar radiation reaches extreme levels, you would specify high-muscovite slate with total mica content of 35-42% to maximize solar reflectance. Your material selection would prioritize slate mineral composition that achieves SRI values above 38 to reduce surface temperatures by 18-24°F compared to standard varieties. This specification becomes critical for commercial plaza applications where daytime usability depends on maintaining surface temperatures below 145°F during peak hours. You would verify that selected materials demonstrate thermal expansion coefficients below 8.5 × 10⁻⁶ per °F to prevent joint failure under Yuma’s extreme daily thermal cycling of 40-50°F.

Mesa Urban Applications

For Mesa installations, where urban heat island effects amplify ambient temperatures by 8-12°F, your specification would address how slate mica characteristics interact with surrounding hardscape to either mitigate or worsen heat accumulation. You would recommend mixed-mica slate with 28-35% total mica content and muscovite:biotite ratios of 2.5:1 or higher for commercial pedestrian areas. This balanced approach provides moderate reflectivity (SRI 32-38) while maintaining cost-effectiveness for large-area applications. Your installation planning would account for Mesa’s clay-rich soils by specifying enhanced base preparation to prevent differential settlement that could stress mica-rich slate along cleavage planes.

Gilbert Residential Focus

Gilbert’s primarily residential market requires you to balance performance with aesthetic preferences for natural stone appearance. Your typical recommendation would specify slate with 25-32% mica content that provides adequate reflectivity (SRI 30-36) while maintaining the varied coloration and texture homeowners prefer. For pool deck applications common in Gilbert residential projects, you would prioritize muscovite-dominant slate geological makeup to minimize rust staining from biotite oxidation in areas with frequent water exposure. Your specification would include slip resistance requirements (minimum DCOF 0.50 wet) that necessitate honed or lightly textured finishes, accepting the 15-20% reduction in peak reflectivity this finishing creates compared to natural cleft surfaces.

Comparative Performance Data

Understanding how different mica content levels perform in Arizona conditions requires you to examine comparative data from field installations and laboratory testing. When you analyze slate mica content analysis Arizona data, clear performance trends emerge that should guide your specification decisions. Materials with muscovite mica content above 32% consistently demonstrate surface temperatures 15-22°F cooler than those with muscovite content below 20% under identical exposure conditions.

Long-term durability data reveals that slate mineral composition significantly affects service life in high-UV environments. High-mica varieties (above 38% total mica) show accelerated surface weathering in the first 36 months, with reflectivity degrading 14-18% from initial values. You’ll observe that this degradation rate decreases substantially after initial weathering, with years 4-10 showing only 3-5% additional reflectivity loss. Lower-mica varieties (22-28% total mica) exhibit more consistent reflectivity over time, degrading only 8-11% over the first decade of exposure.

- High-muscovite slate (35-42% muscovite) maintains SRI above 35 for 5-7 years in Arizona conditions

- Mixed-mica slate (25-32% total mica, balanced muscovite/biotite) maintains SRI 28-34 for 8-12 years

- Low-mica slate (18-24% total mica) provides stable SRI 22-28 throughout 15+ year service life

- Biotite-rich varieties show visible rust staining within 24 months in areas with occasional moisture exposure

- Thermal cycling durability correlates inversely with mica content above 35% threshold

Slip resistance performance changes predictably as slate mica characteristics weather under foot traffic. Initial DCOF values on smooth, natural cleft surfaces typically measure 0.38-0.45, increasing to 0.48-0.56 after 18-24 months of weathering as surface mica flakes develop microtexture. You should specify initial slip resistance values 0.08-0.12 higher than long-term requirements to ensure compliance throughout the weathering period when slip resistance is developing toward optimal values.

Cost-performance analysis demonstrates that high-muscovite slate commands premium pricing (typically 25-40% above standard slate) but delivers quantifiable thermal performance benefits that reduce cooling load in adjacent interior spaces and improve outdoor space usability during peak heat periods. When you calculate lifecycle value for commercial applications, the thermal performance benefits of high-muscovite slate typically justify the premium within 6-9 years through reduced cooling costs and enhanced property value.

Installation Impact on Performance

Installation methodology significantly affects how slate reflective properties perform in actual field conditions. When you specify setting bed composition and joint width, these details interact with slate mica content to determine final thermal performance. Light-colored mortar or polymeric sand in joints reflects additional solar radiation, effectively increasing overall surface reflectivity by 8-12% compared to dark joint materials, particularly important when slate mica characteristics alone don’t achieve target SRI values.

Base preparation affects long-term thermal performance through its influence on subsurface drainage and moisture migration. You should specify base courses with permeability rates 4-6 times higher than the slate’s inherent permeability (which correlates with mica content and cleavage plane density) to prevent subsurface moisture accumulation. Trapped moisture increases thermal mass and reduces the cooling effect that high-reflectivity slate provides, diminishing thermal performance benefits by 15-20% in inadequately drained installations.

Joint spacing interacts with thermal expansion behavior determined by slate mineral composition. High-mica varieties require you to reduce joint spacing by 15-18% compared to low-mica slate to accommodate their higher thermal expansion coefficients. For high-mica slate (above 35% mica content), you should specify maximum 12-foot spacing for expansion joints in Arizona applications, compared to 15-foot spacing suitable for low-mica varieties under identical conditions.

Installation orientation affects how mica alignment influences reflectivity. When you can control installation orientation (particularly with rectangular slabs), orienting pieces so mica cleavage planes align perpendicular to primary sun angles maximizes specular reflection away from pedestrian zones. This installation detail can reduce perceived surface brightness by 20-30% while maintaining thermal reflectivity benefits, improving visual comfort in commercial plaza applications where glare complaints sometimes occur with high-muscovite slate.

Maintenance Program Development

Your maintenance specifications need to account for how slate mica characteristics respond to cleaning agents and mechanical maintenance procedures. High-mica slate requires gentler cleaning methods than quartz-dominant varieties because aggressive mechanical cleaning can accelerate mica delamination along cleavage planes. You should specify pH-neutral cleaners (pH 6-8) and avoid acidic cleaners below pH 4 that can attack the potassium-aluminum bonds in muscovite mica structure.

Resealing frequency correlates with mica content and surface finish characteristics. High-mica slate with natural cleft finish requires resealing every 24-30 months in Arizona conditions to maintain stain resistance and color stability. When you specify honed finishes on high-mica material, resealing frequency increases to 18-24 month intervals because mechanical grinding disrupts natural surface cohesion and creates additional porosity along disturbed mica boundaries.

Power washing pressure limits become critical with slate geological makeup containing mica above 32%. You should restrict pressure washing to maximum 1,200 PSI with 25-degree spray tips to prevent dislodging surface mica flakes. Higher pressures (1,800-2,500 PSI) commonly used for concrete or granite will damage high-mica slate surfaces, creating rough texture and accelerated weathering that degrades reflective properties and appearance.

- Annual deep cleaning should use soft-bristle brushes rather than stiff brushes that catch and pull mica flakes

- Avoid steam cleaning above 180°F on high-mica slate as thermal shock can propagate cracks along cleavage planes

- Joint sand replenishment frequency increases 30-40% with high-mica slate due to finer joint edges that allow faster sand migration

- Efflorescence treatment requires careful product selection as some cleaners attack mica structure while removing salt deposits

Long-term maintenance cost projections should account for material-specific requirements based on slate mica content analysis Arizona installations reveal. High-mica varieties typically incur 20-30% higher annual maintenance costs due to more frequent sealing requirements and need for gentler, more time-intensive cleaning methods. You should factor these ongoing costs into lifecycle analysis when comparing high-mica, high-performance slate against lower-mica alternatives that require less maintenance but provide reduced thermal performance benefits.

Key Takeaways

Your successful slate specification in Arizona conditions depends on understanding the complex relationships between mica content, reflective properties, and long-term performance under extreme heat and UV exposure. Slate mica content analysis Arizona projects require goes beyond simple material classification to address specific mineral composition parameters that predict thermal behavior, weathering patterns, and maintenance requirements. When you balance competing factors of reflectivity, durability, cost, and aesthetics, precise specification of mica content ranges and mica type ratios becomes essential for achieving project performance goals.

Professional material selection requires you to evaluate not just initial appearance and cost but also how slate mica characteristics will perform throughout the expected service life under Arizona’s demanding climate. The relationship between muscovite content and solar reflectance provides quantifiable thermal performance benefits that justify premium material costs in applications where surface temperature control affects usability and energy efficiency. You should develop specifications that address mica content explicitly rather than relying on generic slate categories that encompass too much performance variation for critical applications.

Testing and verification protocols ensure that procured materials match specification requirements and deliver expected performance. When project requirements demand specific thermal performance characteristics, you need to implement material testing programs that verify mica content and confirm reflectivity values before installation proceeds. This front-loaded quality assurance prevents costly remediation when installed materials fail to meet performance expectations that could have been verified during procurement. For additional guidance on protecting your slate investment in Arizona’s extreme conditions, review Slate maintenance techniques for extreme Arizona desert heat before you finalize your project specifications and maintenance protocols. Shower surrounds feature Citadel Stone’s water-resistant slate stone for sale materials.