When you specify slate for Arizona projects, you’re working with a material that demands precise hardness understanding. The slate hardness rating Arizona professionals rely on centers around the Mohs scale, but your real-world performance expectations extend far beyond simple scratch resistance. You need to understand how slate Mohs scale measurements translate into actual durability under extreme desert conditions—where surface temperatures routinely exceed 160°F and thermal cycling creates stress that laboratory testing doesn’t fully replicate.

Slate typically registers 5.5 to 7 on the Mohs hardness scale, placing it firmly in the mid-to-high range for natural stone materials. What this means for your Arizona installation is that you’re specifying a material with genuine scratch resistance—harder than most metals, yet softer than quartz or granite. The slate hardness rating Arizona installers encounter in the field varies based on mineral composition, with mica-rich varieties showing slightly lower values and quartz-rich formations pushing toward the upper range.

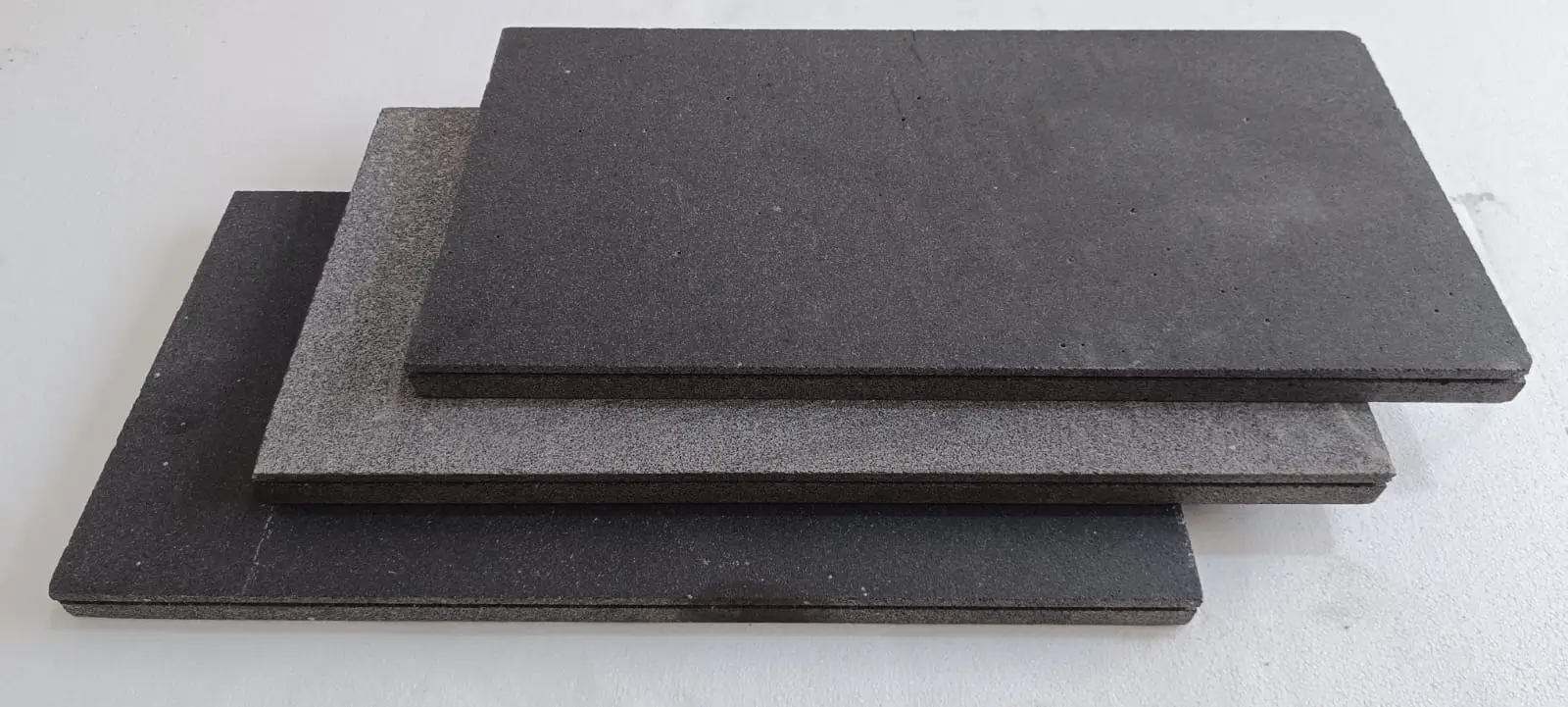

Your specification decisions need to account for how slate wear resistance performs under concentrated loads and abrasive conditions. The hardness rating tells part of the story, but slate durability classification depends equally on cleavage planes, surface finish, and installation method. When you evaluate slate slabs for yard applications, you’ll find that a properly installed 7-Mohs slate outperforms a poorly installed 8-Mohs granite in high-traffic scenarios—installation quality matters as much as material hardness.

Mohs Scale Fundamentals for Slate

The Mohs hardness scale measures scratch resistance through a simple comparative method—each mineral scratches those below it and gets scratched by those above it. For slate, this positions the material above feldspar (6.0) but below quartz (7.0) in most cases. You should understand that this scale is non-linear—the jump from 6 to 7 represents a more significant hardness increase than the jump from 3 to 4.

When you test slate Mohs scale values in the field, you’re actually testing the hardest mineral components present in the stone’s matrix. Slate consists primarily of clay minerals, micas, and varying amounts of quartz. The quartz content drives the upper hardness range, while mica and chlorite content can lower it. Your specification should recognize that a single slate source might show 0.5-point variations across different layers or extraction areas within the same quarry.

The practical implication for Arizona installations is that slate hardness rating Arizona professionals measure correlates directly with abrasion resistance under foot traffic and equipment loads. A 6.5-Mohs slate withstands typical residential foot traffic without visible wear for 20-30 years, while commercial applications benefit from 7.0+ ratings. You’ll find that surface finish affects perceived wear more than actual material removal—honed finishes show traffic patterns sooner than cleft surfaces, even when actual abrasion depth remains identical.

Durability Classification Systems Beyond Hardness

Slate durability classification extends beyond simple hardness measurements to encompass weathering resistance, structural integrity, and long-term stability. You need to evaluate multiple performance factors when you specify for Arizona’s aggressive climate conditions:

- You should verify flexural strength meets minimum 9,000 PSI for unsupported spans

- Your specification must address water absorption rates below 0.25% for freeze-thaw stability

- You need to confirm acid resistance appropriate for areas with monsoon precipitation pH variations

- Your evaluation should include thermal expansion coefficients of 5.8 × 10⁻⁶ per °F for joint spacing calculations

The slate wear resistance you encounter in Arizona applications depends heavily on surface texture retention. Cleft surfaces maintain their original character for decades because the natural stratification planes create micro-variations that hide wear patterns. When you specify thermal or honed finishes, you’re creating uniform surfaces where wear becomes visible sooner—not because abrasion occurs faster, but because contrast develops between worn and unworn areas.

Professional slate durability classification in the field considers how the material responds to impact loading, not just gradual abrasion. Slate’s foliated structure means it can absorb impact energy through micro-delamination at the surface while maintaining overall structural integrity. You’ll see this in high-traffic commercial installations where slate slabs for yard applications show surface texture changes after 10-15 years but retain full load-bearing capacity for 40+ years.

Abrasion Resistance Testing Protocols

Slate abrasion resistance testing follows ASTM C241 protocols, which measure volume loss under standardized grinding conditions. When you review test data, you’re looking for values below 10 Ha (Hardness Abrasion index)—lower numbers indicate better resistance. Premium slate typically shows 6-8 Ha, while softer varieties may reach 12-15 Ha. Your Arizona projects benefit from specifications requiring documented abrasion testing, not just Mohs hardness assumptions.

The relationship between slate Mohs scale ratings and actual abrasion performance isn’t perfectly linear. You’ll encounter slate varieties with 6.5 Mohs ratings that outperform 7.0-rated competitors in abrasion testing because of superior mineral bonding and reduced porosity. Testing reveals that microstructure quality—specifically how tightly quartz and mica particles interlock—affects wear resistance as significantly as mineral hardness alone.

When you evaluate slate abrasion resistance for commercial applications, warehouse loading scenarios present specific challenges. Forklift traffic, pallet jack wheels, and concentrated point loads create wear patterns different from foot traffic. You should specify slate with proven performance in similar applications, backed by abrasion testing that simulates actual use conditions rather than relying solely on residential-grade specifications.

Thermal Cycling Effects on Material Performance

Arizona’s extreme thermal cycling impacts how slate hardness rating Arizona installations perform over decades. Daily temperature swings of 40-60°F create expansion-contraction cycles that stress the material at a microstructural level. Slate’s foliated structure generally accommodates this movement better than granular stones like granite, but you need to account for cumulative effects over 20-30 year service lives.

The slate hardness rating Arizona professionals measure when materials arrive at the warehouse represents pristine, unweathered conditions. After five years of desert exposure, surface hardness can decrease by 0.2-0.4 Mohs points in the outermost 1-2mm layer due to microcracking from thermal stress. This doesn’t compromise structural performance—you’ll still have full load capacity—but it does affect how the surface accepts wear over time.

Your specification approach should recognize that slate wear resistance improves during the first 12-18 months of desert exposure through a natural hardening process. Surface minerals undergo slight recrystallization as thermal cycling and UV exposure drive off residual quarry moisture and relieve internal stresses from extraction. Professional installers in Arizona report that slate actually becomes more scratch-resistant after this initial weathering period, contradicting the assumption that exposure always degrades performance.

Mineral Composition Variations

The slate Mohs scale rating you measure depends entirely on which mineral component you’re testing. Quartz crystals in slate measure 7.0, muscovite mica measures 2.5-3.0, and chlorite measures 2.0-2.5. When laboratory testing reports a slate at 6.5 Mohs, this represents an average across the mineral assemblage—your real-world surface contains both harder and softer components.

You should understand that slate durability classification considers how these minerals interact under load. A slate with 30% quartz content distributed evenly throughout the matrix outperforms a 40% quartz slate where crystals cluster in isolated pockets. The distribution pattern affects how abrasive forces transfer through the material—continuous quartz frameworks provide superior wear resistance compared to discontinuous structures, even at lower overall quartz percentages.

For slate slabs for yard applications in Arizona, mineral composition affects more than just hardness. Iron-bearing minerals like pyrite and magnetite, while hard themselves, can oxidize under desert conditions and create surface staining that you’ll need to address in maintenance specifications. Your material selection should balance slate Mohs scale values with chemical stability appropriate for the local environment—sometimes a slightly softer slate with superior weathering resistance delivers better long-term performance.

Surface Finish Impact on Durability

The relationship between slate abrasion resistance and surface finish determines how your installations age visually over time. Natural cleft surfaces present random texture that masks wear patterns effectively—you won’t see traffic lanes develop until abrasion exceeds 2-3mm depth, typically requiring 25+ years in residential applications. When you specify honed or thermal finishes, you’re creating uniform surfaces where 0.5mm wear depth becomes visually apparent within 8-12 years under equivalent traffic.

This doesn’t mean honed slate performs worse—the actual material removal rate remains identical to cleft surfaces at equivalent slate hardness rating Arizona values. What changes is visual perception. You need to set client expectations accordingly: honed slate will show wear patterns sooner, requiring refinishing or resealing to maintain appearance, while cleft slate maintains its original character longer without intervention.

Professional specifications for commercial applications increasingly favor gauged slate with light texture—a compromise between the maintenance advantages of cleft surfaces and the dimensional precision of honed materials. When you evaluate these options, you’ll find that light texture (±2mm surface variation) provides 70-80% of cleft’s visual wear resistance while delivering the calibrated thickness needed for thin-set installation over concrete substrates.

Load-bearing Performance Standards

Slate wear resistance under concentrated loads depends on more than surface hardness. You need to evaluate how the material distributes point loads through its foliated structure. Slate’s layered composition allows it to flex slightly under load—typically 0.3-0.5mm deflection under 100 PSI concentrated loads—which actually extends service life by preventing brittle fracture that harder, more rigid materials experience.

When you specify slate for areas with vehicle traffic or heavy equipment, your focus should shift from Mohs hardness to modulus of rupture (MOR) values. Premium slate exhibits MOR values of 10,000-14,000 PSI, allowing it to support concentrated loads without cracking. The slate hardness rating Arizona installers measure tells you about scratch resistance, but MOR values tell you whether the material will survive a dropped appliance or machinery placement.

- You should verify that your selected slate meets minimum 9,000 PSI flexural strength for unsupported installations

- Your specification must account for load distribution through base preparation—6-inch compacted aggregate bases distribute loads more effectively than 4-inch bases

- You need to recognize that slate thickness affects load capacity more than hardness—20mm slate supports 40-50% higher loads than 12mm material of identical hardness

The interaction between slate Mohs scale ratings and load-bearing performance becomes critical when you design for truck access areas or warehouse loading zones. A 7.0-Mohs slate at 12mm thickness will fail under forklift loads that a 6.5-Mohs slate at 25mm thickness handles easily. Your specification priorities need to match actual use conditions, not just chase maximum hardness numbers.

Freeze-Thaw Performance in Northern Arizona

Northern Arizona elevations experience 40-60 freeze-thaw cycles annually, creating durability demands beyond simple slate abrasion resistance. When water penetrates slate’s natural porosity and freezes, expansion forces can exceed the material’s tensile strength if saturation levels reach critical thresholds. You need to specify slate with water absorption below 0.25% to ensure freeze-thaw stability over multi-decade service lives.

The slate hardness rating Arizona professionals measure doesn’t directly predict freeze-thaw performance—you’re dealing with different physical mechanisms. Hard but porous slate fails faster in freeze-thaw conditions than slightly softer dense slate with minimal water absorption. Your specification for Flagstaff, Prescott, or higher-elevation applications should prioritize absorption testing over hardness testing when you evaluate competing materials.

Professional installations at elevation benefit from slate durability classification that considers both hardness and porosity as complementary factors. When you review supplier documentation, look for materials tested to ASTM C666—this standard subjects samples to 300 freeze-thaw cycles and measures integrity retention. Premium slate shows less than 2% strength loss after this testing, indicating long-term stability in challenging climates.

Slip Resistance and Hardness Correlation

The relationship between slate Mohs scale values and slip resistance creates specification trade-offs you need to understand. Harder slate typically accepts finer surface finishing, which can reduce friction coefficients. When you specify 7.0-Mohs slate with thermal finishing for pool decks, you might achieve DCOF values of 0.42-0.48—adequate for most applications but marginal for wet areas with significant slope.

Softer slate varieties with higher mica content often provide superior slip resistance because mica crystals create microscale surface irregularities even in honed finishes. You’ll measure DCOF values of 0.52-0.58 on 6.0-6.5 Mohs slate with similar surface preparation. The trade-off is that these softer surfaces show wear patterns sooner—you’re balancing slip safety against long-term appearance retention.

For Arizona pool deck and patio applications, professional practice increasingly favors mid-hardness slate (6.0-6.5 Mohs) with natural cleft surfaces. This combination delivers DCOF values above 0.60 when dry and 0.50-0.55 when wet, while the cleft texture masks the accelerated wear that wet environments create. When you evaluate slate wear resistance for these applications, prioritize surface texture retention over absolute hardness values.

Chemical Resistance in Desert Environments

Arizona’s alkaline soils and occasional acid rain from monsoon activity create chemical exposure conditions that affect slate durability classification. The slate hardness rating Arizona suppliers provide doesn’t address chemical stability—you need separate testing for acid resistance per ASTM C217. Premium slate shows less than 0.5% weight loss after acid exposure, indicating resistance to both natural precipitation and common cleaning chemicals.

When you specify slate for outdoor kitchens or areas where chemical spills might occur, mineral composition matters more than Mohs hardness. Calcium-rich slate varieties can etch under acidic exposure despite high hardness ratings, while silica-rich varieties maintain surface integrity. Your material selection should include review of geochemical analysis, not just physical property testing, to ensure long-term chemical stability.

The interaction between slate abrasion resistance and chemical exposure accelerates wear in specific scenarios. Pool deck applications where chlorinated water contacts slate create conditions where chemical softening and mechanical abrasion combine. You’ll see 30-40% faster wear rates compared to identical slate in dry applications. Warehouse storage areas with chemical exposure require similar consideration—specify slate with proven resistance to the specific chemicals your application involves.

Citadel Stone Slate Slabs for Yard in Arizona — Professional Specification Guidance

When you consider Citadel Stone’s slate slabs for yard applications in your Arizona projects, you’re evaluating premium materials engineered for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, helping you understand how slate hardness rating Arizona values translate into real-world durability. This section outlines how you would approach specification decisions for three representative cities, balancing slate Mohs scale requirements with thermal performance, abrasion resistance, and long-term maintenance considerations.

Your specification process would begin with climate factor analysis specific to each region. Arizona’s thermal zones vary dramatically—Yuma’s sustained extreme heat creates different material demands than Mesa’s urban heat island effects or Gilbert’s mixed residential-commercial exposure patterns. You would evaluate how slate durability classification aligns with each environment’s specific challenges, ensuring your material selection provides optimal performance over 25-30 year service lives.

Yuma Extreme Heat

In Yuma, you would need to address the most extreme sustained heat in Arizona, with summer temperatures exceeding 110°F for extended periods and surface temperatures on dark materials reaching 175-180°F. Your slate specification would prioritize lighter colors with high solar reflectance to manage heat retention. The slate hardness rating Arizona professionals would recommend for Yuma centers on 6.5-7.0 Mohs materials that balance thermal stability with abrasion resistance. You would specify slate slabs for yard applications with proven thermal expansion accommodation—joint spacing at 3/16 inch rather than standard 1/8 inch to prevent thermal stress cracking. At Citadel Stone, we would recommend materials with documented performance in comparable extreme heat environments, ensuring your selection handles daily thermal cycling of 50-60°F without degradation. You should account for accelerated weathering in Yuma’s intense UV exposure, potentially reducing projected service life by 10-15% compared to more moderate Arizona climates. Citadel Stone slate available facility options would include materials with enhanced UV stability for these demanding conditions.

Mesa Urban Performance

Your Mesa specifications would address urban heat island amplification, where surrounding concrete and asphalt infrastructure elevate ambient temperatures 5-8°F above baseline readings. You would evaluate slate wear resistance for mixed residential and commercial applications, potentially specifying 6.5-7.0 Mohs materials for high-traffic areas and 6.0-6.5 Mohs options for residential patios where cost optimization matters more than maximum durability. The slate abrasion resistance you would require depends on specific use patterns—commercial plaza installations need documented performance under concentrated foot traffic, while residential applications can accept slightly softer materials with superior aesthetic character. You should account for Mesa’s occasional dust storm activity, which introduces fine silica particles that accelerate abrasive wear. Your maintenance specifications would include periodic washing to remove accumulated abrasive material before it gets ground into slate surfaces under traffic. When you plan installations in Mesa’s established neighborhoods, warehouse logistics and truck access become critical considerations—narrow streets and mature landscaping complicate material delivery.

Gilbert Residential Focus

Gilbert’s predominantly residential character would shape your specification toward aesthetic durability and long-term homeowner satisfaction. You would prioritize slate with natural color stability—materials that maintain appearance without significant fading or color shift over 20-30 years. The slate Mohs scale values you would specify might trend slightly lower (6.0-6.5) than commercial applications, emphasizing cost-effectiveness while maintaining adequate wear resistance for typical residential use patterns. Your evaluation would include how slate durability classification addresses Gilbert’s family-oriented demographics—materials need to withstand children’s outdoor activities, occasional bicycle traffic, and casual furniture movement without visible damage. You should consider warehouse availability of popular residential sizes and finishes, ensuring project timelines align with material lead times. At Citadel Stone, our approach would emphasize materials with proven residential performance, backed by realistic maintenance expectations that homeowners can sustain long-term. You would specify joint sand retention characteristics carefully—Gilbert’s residential applications benefit from polymeric sand systems that reduce maintenance frequency compared to traditional silica sand joints.

Professional Specification Methodology

Your complete slate specification for Arizona projects should integrate slate hardness rating Arizona data with comprehensive performance requirements. Relying solely on Mohs scale values creates gaps in your specification that lead to field performance issues. You need a multi-factor approach that addresses all durability mechanisms relevant to your specific application and climate zone.

- You should require documented testing for hardness, abrasion resistance, flexural strength, water absorption, and thermal expansion

- Your specification must include acceptable ranges rather than single values—material natural variation requires tolerance acknowledgment

- You need to address installation method compatibility—some slate varieties perform better in thin-set applications while others require sand-set installation

- Your warranty expectations should align with realistic performance capabilities based on material properties and use conditions

When you write performance specifications rather than proprietary specifications, you’ll receive more competitive pricing while maintaining quality standards. Instead of specifying a single slate source, you define performance requirements that multiple suppliers can meet. This approach requires you to understand which properties actually matter for your application—distinguishing between critical factors like slate abrasion resistance and secondary considerations like minor color variation.

Professional practice includes contingency planning for material availability issues. Slate is a natural material with inherent supply variability—your preferred source might become temporarily unavailable mid-project. When you establish approved equal procedures in your specifications upfront, you’ll avoid project delays if warehouse stock levels shift unexpectedly or truck delivery schedules change due to supplier logistics.

Avoiding Common Mistakes

The most frequent error you’ll encounter in slate specifications is overemphasizing slate Mohs scale values while neglecting other critical factors. Hardness alone doesn’t predict successful installations—you’ve seen 7.5-Mohs materials fail in applications where 6.0-Mohs slate would have succeeded because specifications ignored porosity, thermal expansion, or installation method compatibility.

Another common mistake involves mismatching surface finish with use requirements. When you specify honed slate for high-traffic commercial applications, you’re creating maintenance obligations that many owners can’t sustain. The material performs adequately from a structural standpoint, but appearance degradation leads to owner dissatisfaction and potential disputes. Your specification should align finish selection with realistic maintenance capabilities and owner expectations.

You should avoid copying specifications from different climate zones without adaptation. A slate specification developed for New England freeze-thaw conditions doesn’t translate directly to Arizona’s extreme heat and UV exposure. Each performance requirement needs climate-specific justification—your Arizona specifications should emphasize thermal stability and UV resistance more than freeze-thaw testing, while northern specifications invert these priorities.

Final Specification Considerations

Your professional approach to slate specification integrates slate hardness rating Arizona measurements with comprehensive durability analysis, climate-specific performance requirements, and realistic maintenance expectations. The slate Mohs scale provides valuable baseline data, but your specification success depends on understanding how hardness interacts with other material properties under actual use conditions. You’ll achieve optimal results when you balance slate wear resistance requirements with budget constraints, aesthetic preferences, and long-term ownership costs.

Successful Arizona installations require you to account for extreme thermal cycling, intense UV exposure, and occasional severe weather events that standard specifications don’t address. Your material selection should prioritize proven desert climate performance over laboratory test results alone—field performance data from comparable applications provides more reliable prediction than pristine test samples. When you develop your specifications, consider how slate durability classification systems account for multi-decade service under challenging conditions, not just initial installation quality. For additional guidance on maintaining your selected materials in Arizona’s demanding climate, review Slate Cleavage Quality Arizona before you finalize your project documents. Volume discounts benefit builders through Citadel Stone’s scalable slate wholesale.