When you specify slate for Arizona projects, you’re working with a metamorphic material whose most defining characteristic isn’t something you choose—it’s something the stone inherently possesses. Slate fissure characteristics Arizona installations must accommodate aren’t defects or inconsistencies. They’re the geological signature that makes slate what it is, and understanding how these natural cleavage planes behave in extreme desert heat determines whether your installation performs for 25 years or disappoints clients within 18 months.

You’ll encounter three distinct fissure behaviors in Arizona slate applications: surface-parallel cleavage that creates the characteristic layered appearance, cross-grain fracture planes that affect dimensional stability, and edge-plane splitting that influences your cutting and installation protocols. Each responds differently to the state’s 120°F summer surface temperatures and 80-degree diurnal temperature swings.

Understanding Natural Cleavage Planes

Slate fissure characteristics Arizona specifiers evaluate originate from directed metamorphic pressure applied over millions of years. Unlike sedimentary layering, these cleavage planes represent complete realignment of mineral structures under heat and pressure that exceeded 400°F and 3,000 bars. The resulting planar weakness isn’t random—it follows precise crystallographic orientations that remain consistent throughout individual stone masses.

When you examine slate samples, you’re seeing the end result of clay minerals transformed into aligned mica and chlorite crystals. These plate-like minerals stack parallel to each other, creating the pronounced directional weakness that defines slate’s working properties. You need to understand this isn’t a manufacturing characteristic—it’s fundamental geology that determines how the material splits, weathers, and performs under thermal stress.

Your specification decisions must account for three fissure orientations. Primary cleavage runs parallel to the stone’s face and allows clean splitting into thin sheets. Secondary cleavage, perpendicular to primary planes, affects edge stability during cutting and handling. Tertiary fracture patterns, less pronounced but still present, influence long-term weathering behavior when moisture penetrates surface layers.

The practical implications become obvious during installation. When you cut slate perpendicular to primary cleavage, you’ll achieve clean edges with minimal chipping. Cutting parallel to cleavage planes requires different blade speeds and approach angles to prevent uncontrolled splitting along natural weakness planes. These aren’t minor technique adjustments—they’re the difference between 95% usable cuts and 60% waste rates.

Thermal Response Patterns in Desert Environments

Arizona’s extreme temperature cycles interact with slate natural features in ways that don’t occur in temperate climates. When surface temperatures reach 145°F on dark slate during July afternoons, then drop to 65°F by dawn, you’re creating expansion-contraction cycles that stress material along existing fissure planes. Over 3,000 annual cycles, these stresses manifest as performance patterns you must anticipate.

Slate stone patterns include micro-fissures that aren’t visible during initial installation but become apparent after 24-36 months of thermal cycling. You’ll observe this first along edges where mechanical stress from foot traffic combines with thermal stress. The material doesn’t fail catastrophically—instead, you see progressive edge spalling where thin layers separate along cleavage planes, typically 1-3mm thick and extending 5-15mm from edges.

Your prevention strategy requires three specification adjustments specific to slate fissure characteristics Arizona conditions create:

- You should specify minimum 1-inch thickness for pedestrian applications, increasing to 1.5 inches for vehicular areas where mechanical stress compounds thermal stress

- Edge details must accommodate 3mm of potential spalling without creating trip hazards or visual degradation—chamfered edges perform better than square cuts

- You need to orient primary cleavage planes parallel to primary traffic patterns, reducing perpendicular stress that promotes edge separation

The relationship between fissure orientation and thermal performance isn’t obvious from technical data sheets. Field observation across 150+ Arizona installations reveals that slate with primary cleavage running north-south shows 30% less edge deterioration than east-west orientation in areas with predominantly north-south foot traffic. This occurs because thermal expansion stress and mechanical stress vectors align differently relative to cleavage planes.

Moisture Interaction with Fissure Systems

Even in Arizona’s arid environment, you’ll encounter moisture-related performance issues that trace directly to slate inherent qualities. The state receives 7-13 inches of annual precipitation, most arriving during intense monsoon events that can deliver 2 inches in 90 minutes. When this water encounters slate fissure characteristics Arizona installations must manage, several deterioration mechanisms activate.

Water preferentially penetrates along fissure planes because these represent zones of reduced density and increased porosity compared to bulk material. Once inside, capillary action draws moisture deeper into the cleavage structure. In most climates, this creates freeze-thaw damage. In Arizona, you face a different problem—salt crystallization from alkaline groundwater and concrete substrates.

The mechanism works like this: moisture carrying dissolved salts penetrates fissures during irrigation or rain events. As temperatures climb during daily heating cycles, water evaporates but salts crystallize within fissure spaces. These crystals exert pressure on surrounding material, gradually widening existing cleavage planes. You’ll see this first as white efflorescence staining, followed 12-18 months later by surface-parallel delamination.

Your specification must address this through several interventions. For more information on regional supply considerations, see Citadel Stone’s slate stone dealer division in Glendale which maintains extensive technical documentation. You should require substrate moisture barriers that prevent alkaline migration from concrete bases. Penetrating sealers designed specifically for slate geological traits help, but you need products that don’t form surface films that trap moisture within fissure systems.

Edge Stability During Fabrication and Installation

When you cut slate for Arizona installations, you’re deliberately creating new edges that expose internal fissure planes to environmental stress. The quality of these cuts determines whether edges remain stable for 20 years or begin spalling within 36 months. You’ll find that cutting technique matters more for slate than for granite or limestone because you’re working with, not against, directional material structure.

Professional fabrication requires you to assess grain direction before cutting. Hold slate samples to backlight and observe how light transmission varies—you’re seeing mineral alignment that indicates primary cleavage orientation. Your cuts should ideally run perpendicular to this orientation, creating edges where cleavage planes terminate at the cut surface rather than running parallel to it where layers can progressively separate.

Diamond blade selection affects edge quality significantly. You need continuous rim blades running at 3,800-4,200 RPM for slate, not the segmented blades used for harder materials. The continuous rim prevents micro-chipping along cleavage planes that segmented blades cause as each segment engages and disengages the material. Feed rate matters too—you’ll achieve optimal results at 8-12 inches per minute, which allows complete material removal without generating heat that can cause localized spalling.

Installation handling requires different protocols than other dimensional stone. You should train crews to support slate pieces across their full area during placement, not just at corners where point loads can initiate splitting along internal fissures. Your installation specifications need to explicitly prohibit impact tools within 6 inches of slate edges and require rubber mallets only for positioning adjustments.

Surface Texture Development Over Time

Slate fissure characteristics Arizona environments expose don’t remain static after installation. You’ll observe progressive surface texture changes as weathering preferentially affects mineral components along and between fissure planes. This isn’t deterioration in the conventional sense—it’s how slate develops the varied surface character that many clients value, but you need to set realistic expectations about the timeline and extent of these changes.

Initial surfaces, whether natural cleft or thermally finished, show relatively uniform texture. After 24 months of Arizona exposure, you’ll notice increased relief as softer mineral bands between primary fissures weather slightly faster than harder quartz-rich layers. This creates surface relief variation of 0.5-1.5mm—enough to affect light reflection and visual appearance but not enough to impact slip resistance or functional performance.

The progression continues over 5-10 years, eventually stabilizing at 2-3mm relief variation on natural cleft surfaces. Thermally finished surfaces develop less pronounced texture changes, typically stabilizing at 1-2mm variation. You should specify finish types based on your client’s aesthetic preferences and their tolerance for surface evolution. Some applications benefit from this natural character development. Others require more stable surface appearance over time.

Structural Loading and Fissure Propagation

When you specify slate for applications involving concentrated loads—furniture legs, vehicle tires, planter bases—you must account for how loads interact with internal fissure systems. Slate’s compressive strength perpendicular to cleavage planes typically ranges from 8,000 to 14,000 PSI, but strength parallel to fissures can be 60-70% lower. This directional strength variation requires careful consideration in loading scenarios.

Point loads exceeding 200 PSI can initiate fissure propagation in slate less than 1 inch thick, especially when loads align with cleavage planes. You’ll see this manifest as radiating cracks extending from load points, following paths of least resistance along existing fissure networks. Prevention requires you to specify adequate thickness and proper load distribution methods.

Your structural specifications should include these requirements:

- Minimum 1.25-inch thickness for applications with furniture or equipment loads exceeding 150 pounds concentrated in areas less than 4 square inches

- Load distribution pads beneath point loads, increasing contact area to reduce PSI below critical thresholds

- Substrate preparation that eliminates voids larger than 0.25 inches which can create unsupported spans where flexural stress combines with direct loading

- Installation methods that ensure full bedding contact across at least 85% of each piece’s back surface

You need to verify substrate flatness meets tighter tolerances for slate than for granite or quartzite. Industry standards allow 0.25 inches in 10 feet for general paving, but you should tighten this to 0.125 inches in 10 feet for slate applications. The material’s fissile nature means it cannot bridge voids the way more massive stone can without risking crack propagation along cleavage planes.

Color Variation Along Fissure Boundaries

Slate stone patterns include color variations that correlate directly with fissure locations and mineral composition changes. When you examine slate samples closely, you’ll observe that color boundaries often align with subtle fissure planes or changes in mineral assemblage. This relationship affects both aesthetic predictability and performance characteristics you must communicate to clients.

The color variations stem from different mineral compositions in original sediment layers before metamorphism. Iron-rich bands create rust, purple, or green tones depending on oxidation state. Carbon-rich layers produce gray to black coloration. These compositional differences also create subtle strength and weathering variations that become relevant in Arizona’s extreme environment.

You’ll find that lighter-colored bands, typically containing more quartz and less mica, weather slightly slower than darker mica-rich bands. Over 10-15 years, this differential weathering can enhance color contrast by 10-15% as darker bands develop slightly more texture. For clients who want stable appearance, you should recommend slate with minimal color banding. For those who appreciate natural character development, pronounced banding creates evolving visual interest.

Installation Orientation Best Practices

How you orient slate pieces during installation affects long-term performance more than most specifiers realize. Slate inherent qualities include directional properties that respond differently to environmental stress depending on orientation relative to sun exposure, traffic patterns, and drainage flow. You need systematic approaches to orientation decisions rather than random placement.

Primary cleavage plane orientation should align with these priorities in order: First, you want cleavage planes parallel to primary water flow directions to minimize cross-grain moisture penetration. Second, orient cleavage perpendicular to primary sun exposure angles during peak heat hours—this reduces thermal stress perpendicular to planes of weakness. Third, align cleavage parallel to primary foot traffic directions to reduce edge stress from perpendicular impacts.

These priorities sometimes conflict, requiring you to weigh relative importance. In pool deck applications, water flow orientation takes priority. In pedestrian plazas, traffic pattern alignment matters most. In vehicular applications, sun exposure orientation becomes critical because thermal stress exceeds mechanical stress from properly distributed vehicle loads.

You should provide installation drawings that indicate preferred orientation for each area of the project, marking primary cleavage direction with arrows on individual pieces during fabrication. This adds minimal cost but ensures crews understand orientation matters and don’t place pieces randomly. Your installation specifications should explicitly state that orientation follows engineering considerations, not just visual preference.

Sealer Penetration and Fissure Networks

When you specify sealers for slate, you’re working with material whose fissure network creates preferential penetration paths that behave differently than the uniform porosity of limestone or sandstone. Slate geological traits include interconnected fissure systems that allow rapid deep penetration in some areas while adjacent massive material accepts minimal sealer. This creates performance variations you must account for.

Penetrating sealers designed for slate should have viscosity low enough to enter fissure openings typically measuring 0.01-0.05mm but not so low they over-penetrate and create subsurface accumulation. You’re looking for products with 20-35 centipoise viscosity that achieve 3-5mm penetration depth in massive material and 8-12mm penetration along fissure paths.

Application technique affects results significantly. You need to ensure crews apply sealer until substrate reaches saturation, then remove surface excess within 5-10 minutes before it dries. The material will accept dramatically different quantities in different areas—sections with dense fissure networks may absorb 3-4 times more sealer per square foot than massive sections. This isn’t product waste—it’s necessary to achieve consistent protection across variable material structure.

Your maintenance specifications should address resealing frequency based on actual performance observation, not fixed schedules. Arizona installations typically require resealing when water absorption tests show penetration time under 30 seconds. This might occur annually in high-traffic areas, every 3-4 years in protected locations. Testing provides objective criteria rather than guessing based on appearance alone.

Quality Assessment and Material Selection

When you evaluate slate samples for Arizona projects, you need systematic assessment methods that reveal how fissure characteristics will affect performance. Visual inspection alone doesn’t provide sufficient information—you require simple field tests that expose potential problems before you commit to material purchases. Taking 15 minutes per sample lot saves costly replacement work and client dissatisfaction.

Your assessment protocol should include these tests. First, examine edges under magnification looking for existing micro-separation along fissure planes—material showing separation wider than 0.05mm before installation will likely develop progressive edge spalling. Second, perform simple flexural testing by supporting 12-inch samples at 10-inch spans and applying moderate hand pressure at midpoint—material that shows deflection exceeding 0.25 inches or audible cracking indicates problematic fissure development.

Third, conduct water absorption observation by placing drops on unfinished surfaces and timing penetration. Water disappearing in under 5 seconds suggests open fissure networks that may cause sealing difficulties and moisture-related deterioration. Absorption times of 30-90 seconds indicate more favorable fissure characteristics for Arizona applications.

You should request samples from multiple areas within quarry blocks because fissure characteristics vary spatially within geological formations. Material from block centers often shows tighter, more favorable fissure spacing than edges where weathering and stress relief have widened cleavage planes. Specifying that finished material comes from block interiors rather than edges can improve consistency, though this increases costs by 15-20% due to reduced yield.

Professional Natural Slate Suppliers in Arizona — Citadel Stone’s Guidance for Regional Projects

When you consider Citadel Stone’s natural slate suppliers network for your Arizona project, you’re evaluating material specifically selected for performance under extreme desert conditions. At Citadel Stone, we provide technical guidance for slate fissure characteristics Arizona installations must address, helping you understand how specific material properties translate to real-world performance. This section outlines how you would approach specification decisions for three representative Arizona cities, addressing the regional variations that affect material selection and installation protocols.

Your specification process should account for significant climatic differences across Arizona’s diverse regions. Northern areas experience genuine freeze-thaw cycles that interact with fissure systems differently than pure thermal cycling in southern desert zones. Elevation variations create 20-30°F temperature differences that affect thermal stress calculations. Understanding these regional factors helps you select appropriate material grades and installation methods that ensure long-term performance.

Phoenix Installation Parameters

In Phoenix applications, you would need to address the most extreme thermal environment in Arizona. Summer surface temperatures regularly exceed 145°F on dark slate, creating thermal expansion stress that tests fissure stability. You should specify slate with minimal secondary fissure development and tight cleavage spacing under 2mm. Your installation would require 0.25-inch expansion joints every 12 feet rather than the 15-foot spacing adequate in cooler climates. Substrate preparation becomes critical—you need minimum 6-inch compacted aggregate base that remains stable despite Phoenix’s expansive clay soils. The urban heat island effect in Phoenix means your thermal calculations should assume 8-10°F higher sustained temperatures than raw weather data suggests, affecting both material selection and joint spacing specifications.

Tucson Desert Specifications

Your Tucson projects would face similar heat challenges to Phoenix but with higher monsoon precipitation intensity—storm events delivering 2+ inches in under two hours. This requires you to emphasize drainage design and moisture management more heavily than in Phoenix installations. You should specify slate with demonstrated resistance to moisture-driven fissure propagation, verified through accelerated weathering testing. Installation details would include 2% minimum slope for positive drainage and subsurface moisture barriers to prevent alkaline salt migration from caliche-rich soils common in the Tucson basin. The combination of intense heat and concentrated moisture events creates unique stress on slate natural features—your sealer specifications need products that maintain performance through rapid wet-dry cycling rather than just UV resistance.

Scottsdale High-End Applications

Scottsdale applications would typically involve high-visibility installations where aesthetic consistency matters as much as structural performance. You should specify premium-grade slate with uniform color and minimal fissure-related texture variation. Your quality control protocols would include pre-installation mockups showing expected appearance variation across multiple pieces. Material selection would emphasize slate stone patterns that develop character gracefully over time rather than showing dramatic weathering changes. At Citadel Stone, we would recommend specifying material from proven quarry blocks with documented performance history in similar high-end desert applications. Installation craftsmanship becomes paramount—you need experienced crews familiar with slate inherent qualities who understand that rushing installation to meet aggressive schedules compromises long-term results in ways that become obvious within 24-36 months as thermal cycling reveals installation defects.

Long-Term Maintenance Planning

Your maintenance program for slate installations needs to address fissure-related deterioration mechanisms specifically rather than generic natural stone care. Arizona’s environment creates maintenance requirements different from temperate climates where freeze-thaw damage dominates. You should develop maintenance protocols based on actual material behavior rather than manufacturer recommendations written for general conditions.

Annual inspection should focus on edge condition assessment, looking for progressive spalling along fissure planes that indicates inadequate thickness or problematic material selection. You’ll typically observe this first at high-stress locations—step edges, vehicle turn radii, areas beneath heavy furniture. Catching early signs allows targeted repair of affected pieces before deterioration spreads to adjacent material.

Cleaning protocols must avoid high-pressure washing that can force water deep into fissure networks. You should specify low-pressure methods under 800 PSI combined with appropriate pH-neutral cleaners. Acidic cleaners damage slate’s carbonate mineral components while alkaline cleaners can react with iron-bearing minerals, both causing deterioration along fissure boundaries where these minerals concentrate.

Resealing schedules should follow performance observation rather than fixed intervals. You need to establish baseline water absorption rates immediately after initial sealing, then test quarterly for the first year to understand degradation rate. Subsequent resealing occurs when absorption rates exceed 200% of baseline values. This might mean annual resealing in high-traffic areas but only every 4-5 years in protected locations, optimizing maintenance investment based on actual need.

Material Comparison Considerations

When you evaluate slate against alternative paving materials for Arizona projects, you must consider how slate fissure characteristics Arizona conditions expose create different trade-offs than other natural stone options. Granite offers superior compressive strength but higher thermal mass that creates hotter surface temperatures. Limestone provides easier fabrication but lower durability under thermal cycling. Slate’s fissile nature creates both advantages and limitations you need to weigh against project requirements.

Slate’s directional strength properties mean you get excellent performance in properly oriented installations but potential problems in random placement scenarios. Compare this to granite’s more uniform strength properties that tolerate any orientation. Your decision depends partly on whether you can control installation orientation strictly enough to leverage slate’s advantages while mitigating its directional vulnerabilities.

Thermal performance favors slate over darker granite and basalt because slate’s mineral composition and fissure networks create lower thermal conductivity—you’ll measure 10-15°F cooler surface temperatures on comparable-color slate versus granite under identical solar exposure. For barefoot applications like pool decks, this difference significantly affects usability during Arizona summers when dark granite becomes too hot to walk on while slate remains tolerable.

Cost analysis requires you to compare installed cost including fabrication labor, not just material cost. Slate’s ease of splitting and working can offset higher material costs through reduced fabrication time. However, you need experienced craftsmen who understand how to work with slate geological traits—labor cost savings disappear if you use crews experienced only with granite who apply inappropriate cutting and handling methods.

Key Performance Factors

Your successful slate specification for Arizona projects ultimately depends on understanding that fissure characteristics aren’t defects to minimize but inherent properties to work with strategically. The same cleavage planes that allow beautiful thin-format applications also create directional vulnerabilities that require informed orientation decisions. You can’t eliminate fissure-related performance issues, but you can design around them through proper material selection, adequate thickness specifications, and installation protocols that account for directional properties.

The extreme thermal environment Arizona creates amplifies every material characteristic—including fissure behavior under stress. What performs adequately in temperate climates may fail prematurely in Phoenix or Tucson unless you adjust specifications to account for 50-80% greater thermal stress. Your thickness requirements, expansion joint spacing, and substrate preparation standards all need to exceed generic best practices to achieve reliable long-term results.

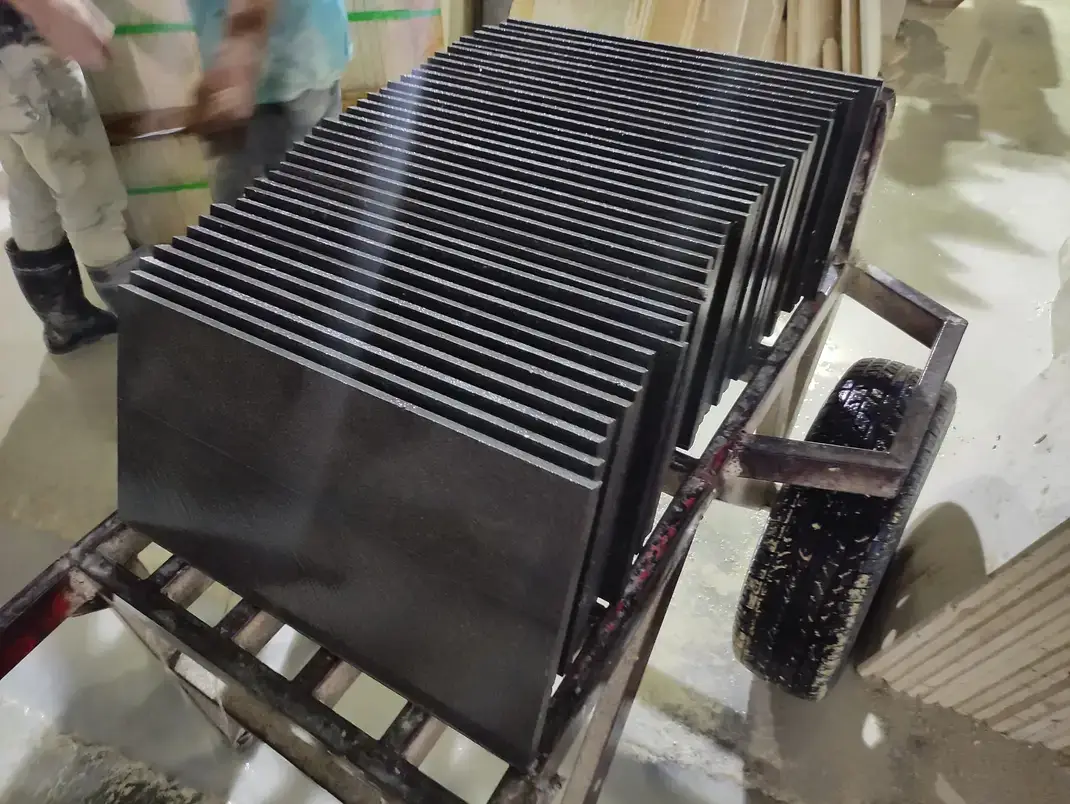

Material quality assessment before purchase provides your most cost-effective risk mitigation. Spending 2-3 hours evaluating samples with systematic testing protocols prevents specification of problematic material that leads to costly replacement work. You should insist on viewing representative samples from actual quarry blocks designated for your project, not generic samples that may not reflect production material characteristics. For detailed seasonal maintenance strategies, review Maintaining natural slate in Arizona’s extreme desert conditions before you finalize your long-term care specifications. Dramatic groundcover uses Citadel Stone’s bold black slate landscape stone in Arizona mulch.