When you walk into a slab yard in Arizona quality selection becomes your primary concern—and for good reason. The material you choose today determines whether your project delivers 20 years of performance or requires remediation within a decade. You’re not just buying stone; you’re specifying a critical building component that must withstand extreme thermal cycling, intense UV exposure, and the unique installation challenges that define Southwest construction.

Your selection process needs to account for factors most generic guides overlook. Arizona’s climate creates specific material stresses that don’t appear in temperate-zone specifications. You’ll encounter temperature swings exceeding 60°F between night and day, summer surface temperatures reaching 160°F on dark stone, and UV intensity that degrades inferior sealants within 18 months. These aren’t theoretical concerns—they’re the conditions your material faces from day one.

Understanding Slab Grades and Quality Tiers

Professional stone yards classify materials into distinct quality grades, but the terminology isn’t standardized across suppliers. When you evaluate a local slab yard in Arizona choosing guide criteria, you need to understand what these classifications actually mean for your project. First-choice or premium-grade slabs exhibit consistent color distribution, minimal veining variation (unless veining is the desired aesthetic), and absence of structural fissures. You’re paying for predictability—critical when you’re coordinating multiple slabs for book-matched installations or large-format applications.

Second-choice grades contain acceptable materials with aesthetic variations that don’t compromise structural integrity. You’ll find color shifts, vein clustering, or minor surface imperfections that matter primarily for visible applications. These materials work perfectly for lower-traffic areas or projects where natural variation enhances the design intent. Your budget stretches further here without sacrificing performance, provided you understand the trade-offs.

Commercial-grade classifications focus on structural specifications rather than aesthetics. You should evaluate these materials based on compressive strength, flexural capacity, and absorption rates—the metrics that determine long-term performance. For applications where appearance ranks secondary to durability, commercial grades from the slab yard in Arizona quality selection process often exceed premium-grade performance at 60-70% of the cost.

Material Inspection Protocol at the Yard

You can’t properly evaluate stone from photographs or small samples. Your site visit to inspect full slabs reveals characteristics that determine installation success. Start with surface examination under natural light—Arizona’s intense sunlight exposes subtle color shifts and vein patterns that disappear under warehouse fluorescent lighting. You need to see how the material will actually appear in its installed environment.

- You should inspect slab edges for structural integrity, looking for micro-fissures that indicate stress fractures from quarrying or transport

- Your evaluation must include moisture testing using a basic moisture meter—readings above 0.5% indicate the slab hasn’t fully dried after processing

- You’ll want to verify thickness consistency across the entire slab, as variance beyond ±2mm complicates fabrication and installation

- Your close examination should identify any filled areas or repairs, which aren’t defects but need to be documented for realistic performance expectations

The backside of the slab tells you as much as the face. You’re looking for consistent mineral structure, absence of delamination planes, and uniformity in the stone’s internal composition. When you spot honeycomb patterns or void concentrations on the back, you’re seeing areas that will affect structural capacity and potentially create failure points under load.

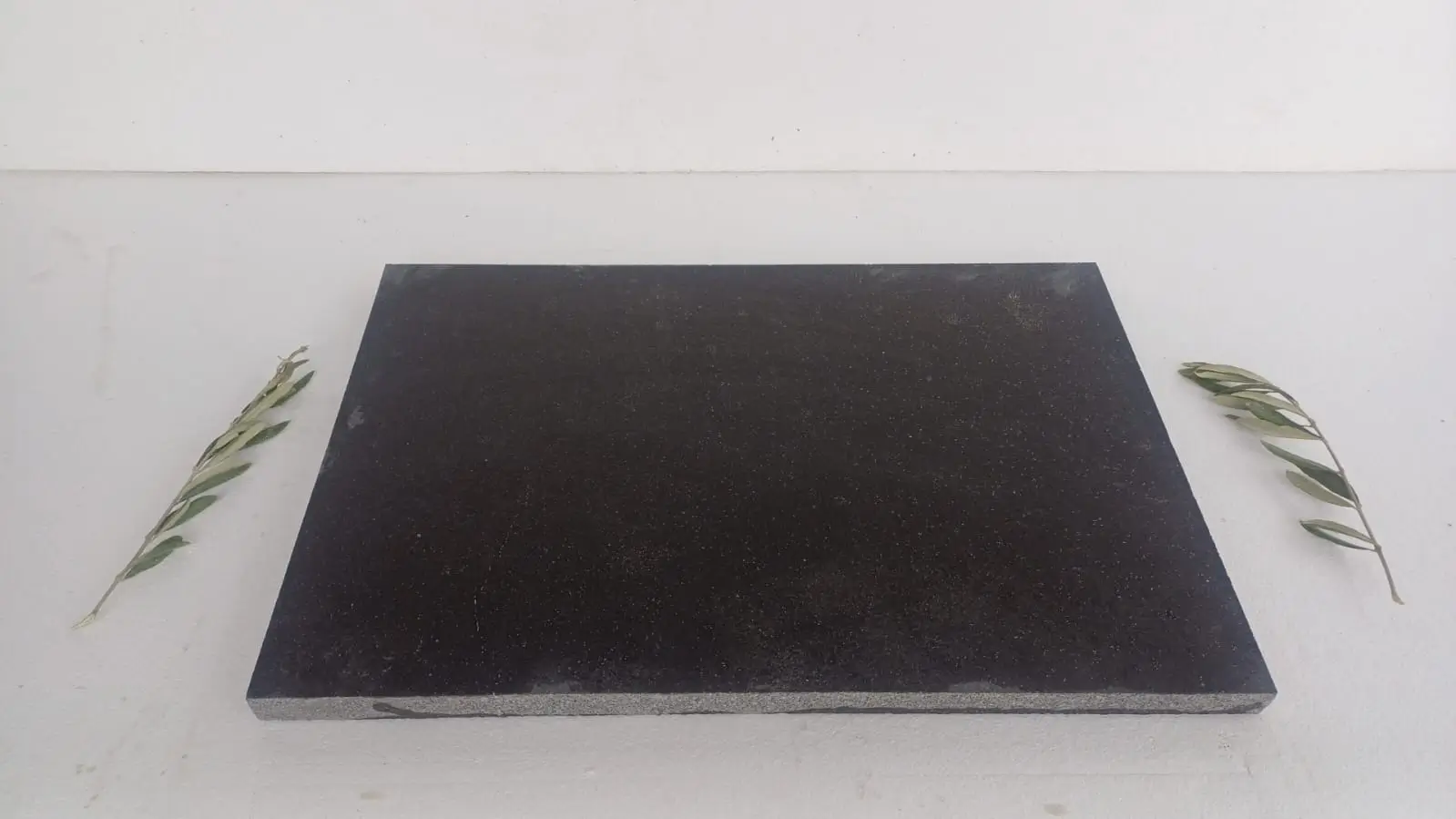

Granite Selection Criteria for Arizona Conditions

Granite performs exceptionally well in Arizona’s climate, but not all granite slabs deliver equivalent results. You need to understand the mineral composition variations that affect thermal performance and long-term durability. Coarse-grained granites with visible crystal structures ranging from 3-10mm provide superior thermal mass properties—they absorb and release heat more gradually than fine-grained varieties, reducing thermal shock stress during daily temperature cycles.

Your specification for exterior applications requires you to verify the material’s thermal expansion coefficient. Standard granite expands at approximately 4.7 × 10⁻⁶ per °F, but compositional variations can push this to 5.8 × 10⁻⁶. This difference matters significantly when you’re installing large-format slabs—a 10-foot span experiences nearly 30% more dimensional change with high-expansion granite during a 60°F temperature swing.

Color selection impacts surface temperature by 40-50°F in direct Arizona sunlight. When you specify dark granite for pool decks or outdoor entertaining areas, you’re creating surfaces that reach 155-165°F on summer afternoons—uncomfortable for bare feet and harsh on joint materials. Lighter granite colors (whites, light grays, beiges) maintain surface temperatures 40-45°F lower, improving usability and extending sealant life by 3-5 years.

Marble Specification Considerations

Marble requires more nuanced evaluation in Arizona environments than in temperate climates. The material’s inherent porosity, typically ranging from 0.4-1.2%, interacts with desert conditions in unexpected ways. You’ll find that low humidity accelerates moisture evaporation from within the stone’s structure, which can intensify efflorescence patterns during the first 12-18 months after installation. This isn’t a defect—it’s a natural process you need to anticipate and explain to clients.

When you examine marble at a granite yard Arizona slab grades inspection, focus on vein structure and calcite crystal size. Tight, interlocking calcite crystals provide superior structural integrity compared to loosely bonded formations. You can identify this by examining a freshly cut edge—the break pattern tells you whether the stone will hold up under thermal stress or develop micro-cracks along vein boundaries.

- Carrara-type marbles with consistent white backgrounds and gray veining offer predictable performance in Arizona heat

- Calacatta varieties with bold gold or gray veining require more careful selection due to higher likelihood of vein separation under thermal cycling

- Statuario grades demand premium sealing protocols in Arizona, as their purity makes them more susceptible to UV-induced yellowing

- Emperador and other dark marbles develop surface temperatures approaching 150°F in direct sun, requiring specific installation details for expansion accommodation

Your marble specification needs to address sealing requirements explicitly. In Arizona’s dry climate, you should plan for initial sealing immediately after installation, followed by resealing every 18-24 months for the first five years. After the stone stabilizes, you can extend maintenance intervals to 36-48 months. This schedule differs significantly from humid-climate recommendations because moisture dynamics work differently in desert environments.

Quartzite Performance Factors

Quartzite represents the most durable natural stone option for Arizona applications, but quality variation between slabs exceeds what you’ll find in granite or marble. True quartzite—metamorphosed sandstone with interlocking quartz crystals—delivers compressive strength exceeding 25,000 PSI and absorption rates below 0.2%. You’re working with material that outperforms concrete in structural capacity and rivals porcelain in moisture resistance.

The challenge lies in distinguishing true quartzite from dense sandstone marketed as quartzite. Your field test involves a simple scratch evaluation—quartzite resists scratching from a steel blade, while sandstone shows visible marks. This matters because performance diverges dramatically. True quartzite maintains structural integrity through decades of thermal cycling; dense sandstone may develop surface spalling within 5-7 years in exposed Arizona installations.

When you evaluate marble slab yard Arizona selection criteria for quartzite alternatives, examine the stone’s reaction to acids. Place a small amount of lemon juice or dilute hydrochloric acid on an inconspicuous area. True quartzite shows no reaction—the quartz crystal structure resists chemical attack. If you see fizzing or etching, you’re looking at marble or limestone mislabeled as quartzite. This isn’t uncommon, and catching it during yard inspection saves you from specification failures down the road.

Color Consistency Evaluation Methods

Color variation within natural stone creates both aesthetic opportunity and specification risk. You need to establish tolerance parameters that match project requirements and client expectations. For book-matched installations or geometric patterns, you’re looking for slabs from the same bundle or quarry block—materials cut sequentially that share mineral composition and vein structure.

Your evaluation process should include photographing potential slabs under consistent lighting conditions. Take images from 10 feet away to capture the overall appearance, then close-ups of specific areas showing vein patterns and color concentrations. When you present these to clients or design teams, you’re managing expectations with documentation that prevents disputes during installation.

Lot-to-lot variation represents a bigger concern than slab-to-slab differences within a lot. If your project requires material quantities exceeding what’s available in current yard inventory, you need to secure commitments for future lots and evaluate samples from those shipments. The slab yard in Arizona quality selection standards often allow 20-30% color variation between lots of the same named material—a range that can disrupt design intent if you don’t plan accordingly.

Structural Specifications and Load Requirements

Your structural specifications need to account for actual installation conditions, not just manufacturer ratings. Compressive strength ratings assume ideal support conditions—full mortar beds, properly compacted bases, and uniform load distribution. Real-world installations rarely achieve these ideals, so you should apply safety factors of 1.5-2.0 to published ratings.

- Kitchen countertops require minimum 15,000 PSI compressive strength to handle point loads from dropped cookware and appliance weight

- Flooring applications need flexural strength verification—materials must resist bending forces from subfloor irregularities or base settlement

- Exterior paving demands freeze-thaw resistance even in Arizona, as winter temperatures in Flagstaff and high-country areas regularly drop below 20°F

- Vertical cladding requires tensile strength evaluation for anchor point calculations, particularly in wind-exposed installations

When you review technical data at the slab yard in Arizona quality selection review, verify that testing followed ASTM standards—specifically ASTM C170 for compressive strength and ASTM C880 for flexural strength. Testing methodology affects results significantly. Some suppliers provide data from optimal specimens rather than average production materials. You should request test reports from independent laboratories when project specifications demand verified performance data.

Thickness Tolerance Impact on Installation

Thickness variation complicates fabrication, increases installation labor, and affects final appearance. Standard stone slabs carry thickness tolerances of ±2mm (roughly ±1/16″), but you’ll find actual variance often exceeds this, particularly in lower-grade materials or imports from quarries with less sophisticated processing equipment. When you’re coordinating stone with tile or other finish materials, these tolerances stack, potentially creating visible lippage or requiring excessive grinding during installation.

Your inspection protocol should include systematic thickness measurement at 6-8 points across each slab. Mark measurements directly on the stone with chalk or grease pencil. This documentation serves two purposes: it helps you select slabs with compatible thicknesses for specific project areas, and it provides evidence if thickness issues emerge during fabrication. You’re creating accountability that protects your specification integrity.

For waterjet-cut installations with precision requirements, you need tighter tolerances than standard grades provide. Communicate with the local slab yard in Arizona choosing guide your thickness requirements upfront—many yards can sort inventory or request premium-tolerance materials from suppliers. You’ll pay 15-20% more for controlled thickness, but you’ll reduce fabrication waste and installation complications proportionally.

Pricing Structure and Value Analysis

Stone pricing lacks transparency compared to most construction materials. You’re navigating a market where published prices serve as starting points for negotiation, and final costs depend on factors including slab selection method, purchase volume, and timing. Understanding this structure helps you maximize material value within budget constraints.

Pricing tiers typically correlate with aesthetic classification rather than structural performance. You might pay $45/SF for premium-grade material and $28/SF for commercial-grade from the same quarry block, despite identical compressive strength and absorption rates. The difference lies in vein consistency and color uniformity—factors that matter tremendously for visible applications but carry minimal weight for structural installations. For resources related to supply and distribution networks, see our stone supply company for comprehensive information on material sourcing. Your value analysis should separate aesthetic premiums from performance requirements to identify opportunities for cost optimization.

- Remnant slabs from previous projects often provide 30-50% savings for small-format applications like bathroom vanities or fireplace surrounds

- Bundle purchasing—committing to all slabs from a single quarry block—typically yields 10-15% discounts while ensuring color consistency

- Timing your purchase during slow construction periods (November-February in Arizona) can generate additional 8-12% negotiating flexibility

- Direct relationships with the slab yard in Arizona quality selection specialists often produce better pricing than working through intermediary designers or contractors

Fabrication and Template Coordination

Your slab selection process needs to account for fabrication capabilities and limitations. Not all stone fabricators work with all materials equally well. Quartzite requires diamond blade specifications different from those optimal for marble; large-format granite demands CNC equipment that smaller shops don’t maintain. You should coordinate with your fabricator before final slab selection to ensure material compatibility with their equipment and expertise.

Template accuracy determines how efficiently your selected slabs convert to finished pieces. Digital templating systems using laser measurement provide ±1mm accuracy—critical for book-matched installations or complex edge details. You’ll find that fabricators with digital capabilities can optimize material yield by 12-18% compared to traditional template methods, potentially allowing you to reduce slab count and lower material costs.

When you select slabs at the yard, consider how vein orientation and pattern distribution affect fabrication layouts. A slab with dramatic veining running diagonally might look spectacular but create significant waste when fabricated for rectangular countertops. You’re balancing aesthetic impact against material efficiency—a calculation that requires you to visualize fabricated pieces rather than just admiring raw slabs.

Citadel Stone: Premium Stone Supply in Arizona Applications

When you consider Citadel Stone’s stone supply in Arizona offerings for your premium project, you’re evaluating materials selected specifically for Southwest climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse environmental zones. This section outlines how you would approach specification decisions for six representative cities, each presenting unique climate challenges that affect material performance and installation methodology.

Phoenix Heat Management

In Phoenix, you’ll encounter sustained summer temperatures exceeding 115°F for weeks at a time, creating thermal stress that requires specific material selection. Your specification would prioritize lighter-colored granite or quartzite with thermal expansion coefficients below 5.0 × 10⁻⁶ per °F. You’d need to account for surface temperatures reaching 165°F on dark stone, which affects both user comfort and sealant longevity. Urban heat island effects in metro Phoenix amplify these concerns by an additional 8-12°F. When you plan installations in this environment, you should specify expansion joints every 12-15 feet rather than the standard 20-foot spacing used in temperate climates.

Tucson UV Considerations

Tucson’s elevation and clear skies create UV exposure levels approximately 15% higher than Phoenix, which accelerates photo-degradation of sealants and affects certain marble varieties. You would recommend quartzite or dense granite for exterior applications, as these materials resist UV-induced color shifts better than marble or limestone. Your sealing protocol would call for UV-resistant penetrating sealers applied every 18-24 months for the first five years, then extended to 36-month intervals once the stone stabilizes. When you specify marble in Tucson applications, you’d focus on varieties with minimal iron content to prevent yellowing from sustained UV exposure.

Scottsdale Luxury Specifications

Scottsdale’s high-end residential and hospitality market demands premium aesthetics alongside performance. You would specify exotic quartzites or premium marble varieties with documented thermal stability and minimal porosity. Book-matched installations require you to select consecutive slabs from the same quarry block, ensuring vein continuity across large surfaces. Your quality standards would mandate slabs within the top 15% of grade classifications, with thickness tolerances held to ±1.5mm. At Citadel Stone, we maintain warehouse inventory selected specifically for luxury applications, though you’d want to verify availability during project planning phases.

Flagstaff Cold Performance

Flagstaff’s elevation creates freeze-thaw cycles uncommon elsewhere in Arizona, requiring you to verify absorption rates below 0.3% for exterior applications. Your material selection would focus on dense granite or true quartzite with proven cold-weather performance. You’d need to specify materials tested per ASTM C666 for freeze-thaw resistance, ensuring 300+ cycle survival without structural degradation. Thermal expansion considerations reverse here—you’re concerned with cold-weather contraction creating joint separation rather than heat-driven expansion. When you calculate joint spacing for Flagstaff installations, you should account for temperature ranges from -10°F to 85°F rather than the 30°F to 115°F common in Phoenix.

Sedona Aesthetic Integration

Sedona’s distinctive red rock landscape influences material selection toward warm earth tones that complement rather than contrast with the natural environment. You would specify granite, marble, or quartzite in beige, gold, rust, or taupe colorways. Your selection would emphasize materials with natural veining patterns that echo the stratification visible in local sandstone formations. Performance requirements here combine Phoenix’s heat with Flagstaff’s temperature variation—you need materials that handle 80-90°F daily swings without degradation. When you coordinate warehouse deliveries to Sedona’s geography, you’d factor additional lead time for transportation from Phoenix or Flagstaff distribution points.

Yuma Extreme Conditions

Yuma presents the most extreme heat conditions in Arizona, with summer temperatures regularly reaching 118-120°F and ground-level heat approaching 180°F. Your specification would mandate light-colored materials exclusively—whites, light grays, or pale beiges that reflect rather than absorb solar radiation. You’d need to verify that selected materials maintain structural integrity at sustained temperatures exceeding 160°F, as some marbles experience accelerated calcite recrystallization above this threshold. Your installation methodology would specify heat-resistant setting materials and expansion joints every 10-12 feet. When you evaluate material performance in Yuma conditions, you’re planning for the upper end of survivable heat stress that natural stone will encounter in any installation.

Regional Supply Chain and Lead Times

Arizona’s geographic position affects material availability and delivery scheduling. Most stone inventory enters the state through California ports, then distributes via Phoenix and Tucson. When you specify exotic materials or specific lots, you need to account for 8-12 week lead times from order to warehouse delivery, plus 1-2 weeks for yard processing and quality verification. Your project timeline should build in buffer periods that accommodate these realities.

Seasonal factors influence supply chain reliability. You’ll find that spring and early summer represent peak construction periods in Arizona, creating warehouse capacity constraints and potential material allocation issues. When you’re planning major projects requiring specific materials, you should secure inventory commitments 4-6 months before installation dates. This advance planning ensures you’re not competing for limited stock during peak demand periods.

Common Selection Mistakes to Avoid

Your slab selection process becomes vulnerable to several recurring errors that compromise project outcomes. The most frequent mistake involves selecting slabs based solely on yard lighting rather than simulating actual installation conditions. Warehouse fluorescents flatten appearance and mask color variations that become obvious under natural light. You should always view slabs outside or request that yard staff move them to areas with natural illumination before making final selections.

- Failing to account for thickness variation between slabs creates installation challenges when you’re trying to achieve flush transitions

- Selecting dramatic veining without considering how patterns translate to smaller fabricated pieces often results in disappointing final appearance

- Overlooking the backside condition of slabs means you miss delamination planes or void structures that affect structural capacity

- Choosing materials based on cost per square foot without factoring fabrication complexity and waste can actually increase total project costs

Another critical error involves neglecting to document slab selection with detailed photography. When slabs move from yard to fabrication shop to installation site, you need reference documentation that confirms the material being installed matches what you specified. Your photos should capture overall appearance, specific vein patterns, and any unique characteristics that identify individual slabs. This documentation protects you from substitution errors and provides evidence if quality disputes arise.

Final Considerations

Your approach to the slab yard in Arizona quality selection process determines whether your project achieves its performance and aesthetic objectives. You need to move beyond surface-level evaluation and engage with materials as complex natural products that behave differently under regional environmental stresses. The time you invest in thorough inspection, proper documentation, and performance verification translates directly into installation success and long-term durability. When you coordinate with experienced suppliers who understand Arizona’s unique challenges, you position projects for optimal outcomes. For comprehensive resource listings covering material suppliers throughout the state, review this comprehensive directory of stone slab yards across Arizona before you finalize your project specifications. Citadel Stone’s personalized approach distinguishes it from Arizona Tile slab yard corporate purchasing experiences.