When you visit quartz slabs slab yard Arizona locations, you’re entering a specialized segment of the engineered stone market that combines manufacturing precision with local inventory accessibility. Your material selection process requires you to understand how Arizona’s distinct climate demands influence performance specifications for quartz installations. You’ll find that slab yard Arizona quartz inventory differs significantly from retail showroom offerings in both product depth and technical support capabilities.

The engineered stone category has evolved substantially over the past decade, and you need to recognize how this affects your specification decisions. Quartz slabs manufactured today exhibit compression strengths exceeding 15,000 PSI, thermal resistance suitable for outdoor applications in controlled environments, and non-porous surfaces that eliminate sealing requirements entirely. Your project success depends on matching these material characteristics to Arizona’s intense UV exposure, extreme temperature fluctuations, and low-humidity conditions that accelerate certain degradation patterns in inferior products.

Engineered Stone Composition and Performance Parameters

You should understand that quartz slabs contain 90-95% ground natural quartz crystals bonded with 5-10% polymer resins and pigments. This composition delivers specific performance advantages you won’t find in natural stone alternatives. The manufacturing process creates uniform density throughout each slab, eliminating the natural fissures and porosity variations that complicate natural stone installations.

When you evaluate local slab yard Arizona engineered stone options, you’re assessing products with engineered thermal expansion coefficients ranging from 10-25 × 10⁻⁶ per °F. This matters significantly in Arizona applications where surface temperatures on exterior installations can reach 160-180°F during peak summer months. Your specification documents need to address this thermal behavior explicitly, particularly for applications involving large-format installations or areas with restricted expansion joint placement.

- You’ll encounter compression strength ratings between 12,000-18,000 PSI across quality manufacturers

- Your material must demonstrate flexural strength exceeding 2,000 PSI for countertop applications

- You need to verify Mohs hardness ratings of 7 for scratch resistance in high-traffic installations

- Your selected product should exhibit water absorption below 0.5% by weight

The polymer resin content creates performance trade-offs you must evaluate carefully. Higher resin percentages improve impact resistance and reduce brittleness, but they also decrease maximum service temperature ratings. You’ll find premium quartz slabs slab yard Arizona suppliers stock products rated for continuous exposure up to 150°F, with brief thermal spikes tolerated to 212°F. Exceeding these thresholds causes resin degradation that manifests as discoloration and surface dulling within 18-36 months.

Arizona Climate and Material Interaction Factors

Your Arizona installations face environmental conditions that stress engineered stone differently than moderate climates. The combination of intense solar radiation, extreme diurnal temperature swings, and minimal atmospheric moisture creates a demanding service environment. You need to account for UV exposure levels that exceed 7,500 hours annually in southern Arizona locations, compared to 4,500-5,500 hours in temperate regions.

The slab yard Arizona quartz inventory you evaluate should include products specifically tested for UV stability. Premium manufacturers incorporate UV-resistant polymer resins and stabilized pigments that maintain color consistency under prolonged solar exposure. You’ll want verification that products meet ASTM G154 accelerated weathering protocols, which simulate 5-10 years of Arizona sun exposure in controlled laboratory conditions.

Thermal cycling presents another critical consideration for your specifications. Arizona experiences daily temperature fluctuations of 40-50°F during spring and fall shoulder seasons, with surface temperature differentials approaching 80-100°F between predawn lows and mid-afternoon peaks. You should understand that these cycles create expansion and contraction stresses that accumulate over time. The material’s ability to withstand 2,000-3,000 annual thermal cycles without delamination or bond failure determines long-term performance success.

- You must specify edge details that accommodate 0.040-0.060 inches of linear expansion per 10-foot run

- Your installation design should incorporate expansion joints at maximum 12-foot intervals for exterior applications

- You need to ensure substrate materials exhibit compatible thermal expansion coefficients

- Your adhesive selection must maintain bond strength across the full temperature range

Color Selection and Performance Implications

When you review the slab yard Arizona quartz brands at local suppliers, you’ll notice color selections ranging from pure whites to deep blacks, with extensive options in grays, beiges, and designer color palettes. Your color choice affects more than aesthetics—it directly influences thermal performance and long-term appearance retention. Darker colors absorb 70-85% of incident solar radiation, while lighter colors reflect 50-65%, creating surface temperature differences of 25-35°F under identical exposure conditions.

You should factor this thermal behavior into your application planning. Dark quartz surfaces in full sun exposure reach temperatures that approach or exceed manufacturer-recommended service limits during Arizona summer months. Your installation may require shading elements, light-colored surface treatments, or material substitution to maintain warranty coverage and achieve projected service life. The warehouse stocks at major suppliers typically emphasize lighter color palettes for Arizona markets specifically due to these thermal considerations.

Veining patterns and aggregate visibility represent another specification dimension. You’ll find products ranging from solid colors to elaborate veining that mimics natural marble or granite. These aesthetic variations derive from pigment distribution and the size grading of quartz particles in the mix. Your selection should account for how veining patterns affect visual uniformity across multiple slabs. Premium manufacturers maintain tight batch controls that ensure consistent appearance, while economy products may exhibit noticeable variation between production runs.

Light Color Advantages

You’ll achieve optimal thermal performance with white, cream, and light gray selections in Arizona applications. These colors maintain surface temperatures 20-30°F cooler than dark alternatives, extending material service life and improving occupant comfort in adjacent spaces. Your specification of light colors also provides greater flexibility in orientation and exposure, reducing design constraints related to solar access.

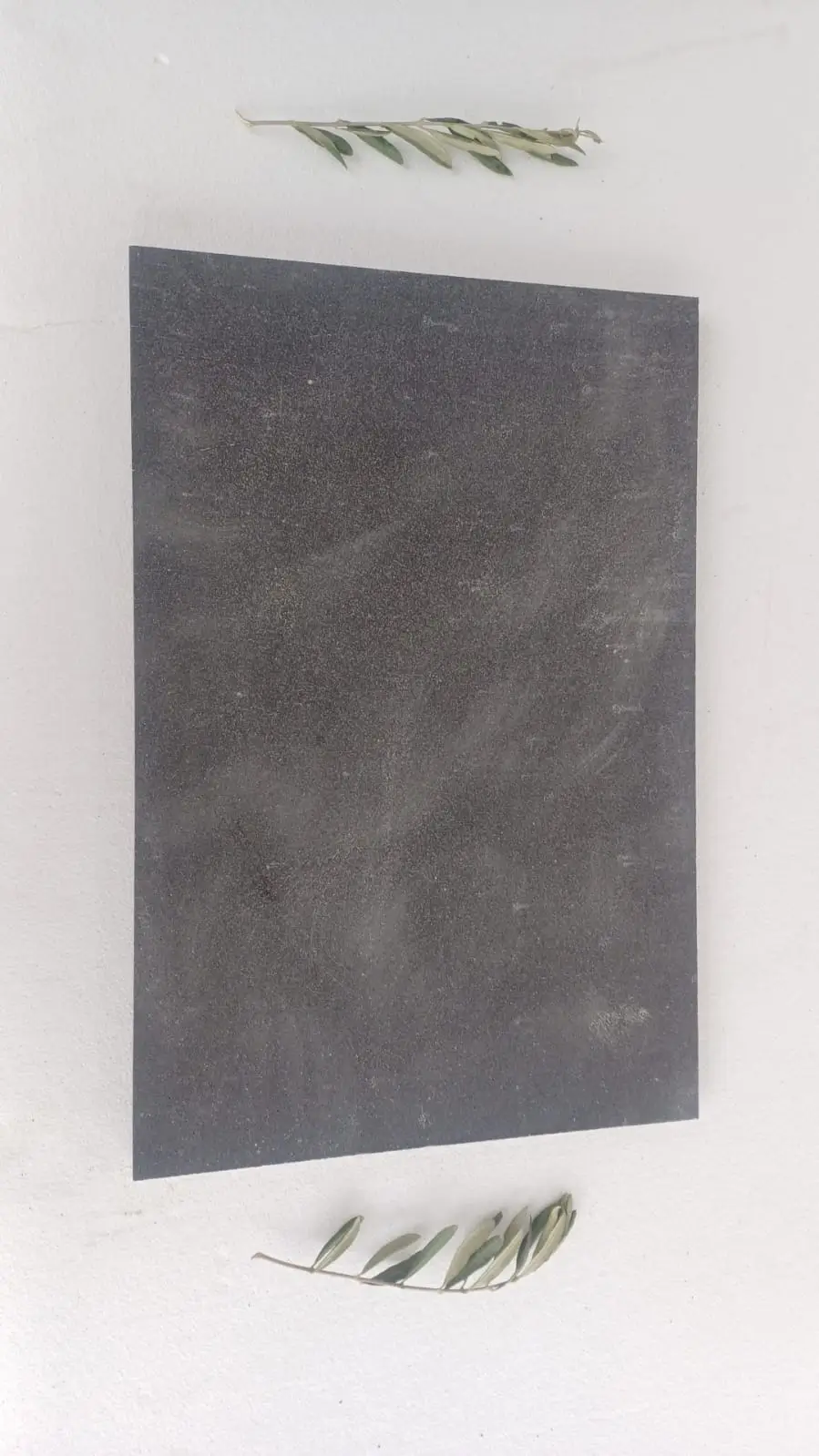

Dark Color Considerations

When you specify charcoal, black, or deep brown quartz slabs slab yard Arizona suppliers stock, you’re accepting thermal management responsibilities. Your installation must incorporate heat mitigation strategies such as pergola coverage, deciduous tree shading, or surface cooling systems. You should also verify that warranty coverage extends to high-temperature applications, as some manufacturers exclude dark colors from full warranty protection in desert climates.

Thickness Specifications and Structural Requirements

The standard thickness options you’ll encounter at any local slab yard Arizona engineered stone facility include 2cm (approximately 3/4 inch) and 3cm (approximately 1-1/4 inch) products. Your thickness selection influences structural capacity, visual proportion, and installation complexity. The 3cm thickness provides 60-70% greater flexural strength compared to 2cm material, allowing longer unsupported spans and reducing substrate preparation requirements.

For countertop applications, you should understand that 2cm products require solid substrate support at maximum 12-inch centers, while 3cm material tolerates 18-inch support spacing. This affects your cabinet design, installation labor, and total project cost. The thicker material also permits more aggressive edge profiles without requiring lamination or buildup techniques that create visible seam lines.

- You need to specify 3cm thickness for islands with overhangs exceeding 10 inches

- Your 2cm selections require edge buildup or corbel support for overhangs beyond 6 inches

- You should verify that substrate flatness meets ±1/8 inch tolerance over 10 feet

- Your installation must address differential deflection between slab and substrate materials

Jumbo slab formats represent an emerging product category you’ll find at progressive slab yard Arizona quartz brands. These oversized slabs measure 120 × 60 inches or larger, reducing seam counts in expansive installations. You should recognize that these formats require specialized handling equipment, modified fabrication workflows, and careful truck access planning. The warehouse facilities stocking jumbo formats typically maintain lower inventory turnover due to handling complexity and space requirements.

Edge Profile and Fabrication Options

Your edge profile selection affects visual aesthetics, functional performance, and fabrication costs. You’ll choose from standard profiles including straight, bevel, bullnose, ogee, and dupont among others. Each profile creates different visual weight and maintenance characteristics. Sharp edges concentrate impact forces and show chips more readily than rounded profiles. Your high-traffic applications benefit from eased or quarter-round edge treatments that improve chip resistance.

When you work with the slab yard Arizona quartz inventory, you should understand that complex edge profiles increase fabrication time by 30-50% compared to straight edge treatments. This affects both project timelines and costs. Premium profiles requiring multiple router passes and hand-finishing work add $15-30 per linear foot to fabrication charges. You need to balance aesthetic preferences against budget realities and schedule constraints.

Undermount sink cutouts, cooktop openings, and specialty features require precise fabrication capabilities. You should verify that your selected fabricator maintains CNC routing equipment with ±0.010-inch repeatability. Manual layout and cutting methods introduce variability that causes field fitting problems and increases installation labor. Your specification documents need to define cutout locations, dimensions, and edge treatments with sufficient detail to ensure accurate fabrication.

Surface Finish Variations and Maintenance Implications

The standard surface finish for quartz slabs slab yard Arizona suppliers provide is polished, achieving 85-90 gloss units on standardized measurement scales. This mirror-like finish maximizes color depth and visual impact while providing a smooth, non-porous surface that resists staining. You should understand that polished finishes show water spots, fingerprints, and dust more readily than textured alternatives, affecting perceived maintenance requirements in residential applications.

Honed and leathered finishes offer lower-gloss alternatives that measure 20-40 gloss units. You’ll find these finishes provide better slip resistance for flooring applications and hide minor surface imperfections more effectively than polished treatments. The trade-off involves slightly increased surface porosity at the microscopic level, though engineered quartz remains essentially non-porous across all finish types. Your maintenance protocols remain identical regardless of finish selection.

- You can specify polished finishes for maximum visual impact and easiest cleaning

- Your commercial applications may benefit from honed finishes that reduce glare and hide wear

- You should avoid textured finishes in food preparation areas where cleaning difficulty increases

- Your exterior applications require surface testing to verify slip resistance meets ADA requirements

Quality Tier Differentiation in Brand Selection

When you evaluate the slab yard Arizona quartz brands available through local suppliers, you’re encountering products spanning three distinct quality tiers. Premium tier brands manufactured by Caesarstone, Cambria, and Silestone incorporate proprietary resin formulations, tighter manufacturing tolerances, and more extensive warranty coverage. You’ll pay 30-50% more for these brands compared to mid-tier alternatives, but you’re receiving verified performance in demanding applications.

Mid-tier brands including MSI, Pental, and Pompeii offer solid performance at moderate price points. You should recognize that these products meet industry performance standards but may lack the advanced features of premium brands. Color consistency between production batches shows slightly more variation, and warranty coverage typically extends 10-15 years rather than lifetime guarantees. Your commercial applications and rental properties often represent appropriate uses for mid-tier products where cost control matters more than premium aesthetics.

Economy tier products from overseas manufacturers flood the market with attractive pricing but inconsistent quality. You’ll encounter these products at discount suppliers and may be tempted by prices 50-60% below premium brands. Professional specifiers should approach economy products cautiously, verifying that products meet minimum ASTM standards and include meaningful warranty protection. Your project’s long-term success depends on material performance, not just initial cost savings.

Inventory Management and Lead Time Considerations

The local slab yard Arizona engineered stone operations maintain inventory depths ranging from 50-200 slabs across popular colors and brands. You need to understand that inventory turnover rates affect color availability and matching capabilities. Fast-moving colors like white and light gray typically remain in stock, while specialty colors may require special orders with 6-12 week lead times. Your project schedule must accommodate these procurement realities.

When you specify colors from the slab yard Arizona quartz inventory, you should inspect actual slabs rather than relying on small samples. Quartz manufacturing produces batch-to-batch variation that affects vein patterns and color intensity. Your inspection should verify that available inventory matches your aesthetic expectations and that sufficient material exists to complete your project from the same production lot. Cross-lot matching creates visible differences in critical applications.

You’ll want to coordinate warehouse visits during project planning phases rather than waiting until fabrication scheduling. This allows you to identify material availability issues before they impact critical path activities. The best practice involves tagging specific slabs for your project, ensuring material reservation until fabrication begins. Some suppliers charge holding fees for extended reservations, which you should factor into project budgets.

Fabrication and Installation Coordination Requirements

Your fabrication partner selection matters as much as material choice. You should verify that fabricators maintain climate-controlled shop facilities, current equipment, and experienced personnel. Arizona’s temperature extremes affect adhesive curing times and material handling requirements. Summer shop temperatures exceeding 95°F accelerate epoxy cure rates, reducing working time for seam joining and edge buildup applications. Your fabricator needs temperature control systems that maintain consistent working conditions.

Template accuracy determines installation success. You’ll encounter templating methods ranging from manual measurements to digital laser scanning. Digital templating eliminates transcription errors and provides precise field dimensions that CNC equipment translates directly into cutting paths. Your complex installations with multiple elevation changes or numerous obstacles benefit significantly from digital templating accuracy. The technology adds $150-300 to fabrication costs but typically reduces field fitting labor by similar amounts.

- You should schedule templating after all substrates reach final elevation and position

- Your plumbing and electrical fixtures must be installed and positioned before template capture

- You need to verify that wall surfaces are finished to final plane before templating occurs

- Your installation schedule should allow 7-10 business days between template and installation

For comprehensive natural stone alternatives, see Citadel Stone’s flagstone yard for comparison with engineered products. You’ll find that material selection often involves trade-offs between engineered consistency and natural stone character.

Seam Placement Strategy and Visual Management

Your seam locations affect installation aesthetics more than any other single factor. You should work with fabricators during design development to identify optimal seam placements that minimize visual impact. Seams located at sink edges, cooktop boundaries, or natural break lines in the design become nearly invisible. Seams crossing open expanses of material create obvious visual interruptions that detract from the installation’s premium appearance.

Modern seaming adhesives create joints with 90-95% of the parent material’s strength when properly executed. You’ll find that seam quality depends heavily on fabrication precision and installation conditions. Edge straightness tolerances of ±0.005 inches ensure tight joints with minimal adhesive visibility. Your fabricator should demonstrate seaming capabilities through shop samples before you commit to contracts for high-value installations.

Color selection affects seam visibility significantly. You should recognize that solid colors and subtle patterns hide seams more effectively than dramatic veining patterns. When seams cross prominent veins, visual discontinuity becomes obvious even with perfect joint execution. Your design development should address this reality by either accepting visible seams as installation characteristics or selecting colors that minimize seam impact.

Cost Structure and Value Analysis

When you analyze quartz slabs slab yard Arizona pricing structures, you’ll encounter installed costs ranging from $65-150 per square foot depending on material quality, edge complexity, and installation difficulty. The material itself represents 35-45% of total installed cost, with fabrication and installation labor consuming the remainder. You should understand this cost breakdown when evaluating value propositions across different material tiers.

Premium brands command material costs of $50-80 per square foot at the slab yard level, while mid-tier products range from $35-55 per square foot. Your total project cost differences narrow somewhat due to identical fabrication and installation labor regardless of material selection. A $15 per square foot material cost difference translates to roughly $7-9 per square foot installed cost difference. This economic reality means premium material upgrades cost less than many clients expect.

- You should budget $4-8 per linear foot for standard edge profiles

- Your complex edge treatments add $12-25 per linear foot to fabrication costs

- You need to include $150-400 for template services in project budgets

- Your installation should account for $15-25 per square foot in labor costs

The slab yard Arizona quartz brands offer wholesale pricing structures that provide 20-35% savings compared to retail showroom pricing. You’ll access these advantages by working directly with fabricators who source from wholesale suppliers rather than purchasing through retail intermediaries. Your project size affects available pricing, with installations exceeding 75 square feet typically qualifying for contractor pricing tiers.

Warranty Coverage and Exclusions

You need to understand that quartz slab warranties cover manufacturing defects but exclude damage from improper installation, excessive heat exposure, impact damage, and chemical exposure. Premium manufacturers provide 10-year to lifetime residential warranties and 3-5 year commercial warranties. Your warranty coverage depends on proper installation by certified fabricators following manufacturer specifications.

Temperature exposure represents the most common warranty exclusion in Arizona applications. You’ll find that warranties specifically exclude damage from heat sources above 300°F placed directly on surfaces or prolonged exposure to surface temperatures exceeding manufacturer ratings. Your clients need education about using trivets under hot cookware and avoiding dark colors in extreme sun exposure. Warranty claims for heat damage typically fail due to these standard exclusions.

Seam separation and fabrication defects fall under warranty coverage when they result from material defects rather than installation errors. You should document installation conditions and procedures to support potential warranty claims. Photographic records of substrate conditions, material batch numbers, and installation sequences protect your interests if performance issues develop during warranty periods.

Citadel Stone – Premier Stone Slab Yard in Arizona — Professional Specification Guidance for Arizona Markets

When you consider Citadel Stone’s stone slab yard in Arizona offerings for your projects, you’re evaluating comprehensive material solutions designed for Arizona’s demanding environmental conditions. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert heat to high elevation freeze-thaw cycles. This section outlines how you would approach specification decisions for six representative cities using our engineered stone and natural stone alternatives.

You should understand that successful material selection requires you to balance aesthetic preferences against performance requirements and budget constraints. The following city-specific considerations demonstrate how you would adapt specifications to local conditions. Climate data, installation protocols, and material recommendations represent professional guidance for planning purposes.

Phoenix Heat Management

In Phoenix, you’ll encounter the most extreme thermal conditions in Arizona, with summer temperatures regularly exceeding 115°F and surface temperatures approaching 180°F on dark materials. Your quartz specifications should emphasize light colors in the white, cream, and light gray palette to maintain surface temperatures within manufacturer service ratings. You would need to verify that selected products meet ASTM G154 UV resistance standards and incorporate polymer resins rated for continuous 150°F exposure. Warehouse inventory in Phoenix metro typically stocks 80-120 slabs across popular heat-resistant colors, allowing you to inspect and select materials from current production lots.

Tucson Applications

Your Tucson installations face similar heat challenges to Phoenix but with slightly higher humidity during monsoon season. You would specify materials with the same thermal resistance but should account for occasional heavy rainfall events that test drainage systems. The material’s non-porous surface eliminates moisture absorption concerns, but your installation design needs proper slope and drainage to prevent standing water. You’ll find that Tucson slab yards maintain inventory depths comparable to Phoenix, with 60-100 slabs available across standard colors. Your project timelines should account for potential monsoon-related delivery delays during July and August.

Scottsdale Premium Specifications

When you work in Scottsdale’s luxury residential market, you’re specifying premium tier brands that demonstrate superior aesthetics and performance. Your material selections would emphasize Cambria, Caesarstone, and Silestone products in designer colors with dramatic veining patterns. You should understand that Scottsdale clients typically prioritize aesthetics equally with performance, requiring you to balance visual impact against thermal management needs. The local market supports specialized slab yard Arizona quartz inventory that includes exclusive colors and limited production runs not available through standard distribution channels.

Flagstaff Cold Climate

Your Flagstaff specifications differ fundamentally from low desert applications due to elevation and winter conditions. At 7,000 feet elevation, you’ll encounter 100+ nights annually with temperatures below freezing and occasional winter storms depositing significant snow. You would verify that quartz products maintain bond integrity through freeze-thaw cycling and that polymer resins resist embrittlement at sustained subfreezing temperatures. The engineered stone’s non-porous nature eliminates freeze-thaw damage from water absorption, providing significant advantages over natural stone alternatives. You should specify 3cm thickness for exterior applications to maximize structural capacity and thermal mass benefits.

Sedona Aesthetic Integration

In Sedona, you’re working within architectural contexts that emphasize integration with dramatic red rock landscapes. Your color selections would focus on warm beiges, tans, and earth tones that complement natural surroundings while meeting performance requirements. You should understand that Sedona’s 4,500-foot elevation creates moderate climate conditions compared to Phoenix heat or Flagstaff cold. Your specifications can encompass wider color ranges including some mid-tone options that would prove problematic in extreme heat. Local design review processes may influence material selections, requiring you to demonstrate aesthetic compatibility with surrounding landscapes.

Mesa Volume Applications

Your Mesa projects often involve production builder applications and commercial installations where cost control matters significantly. You would specify mid-tier quartz brands that deliver solid performance at competitive price points. The market supports large-volume material procurement through slab yard Arizona quartz inventory systems that maintain consistent availability across standard colors. You should verify that selected products meet minimum 12,000 PSI compression strength and 0.5% maximum water absorption while achieving target price points. Mesa’s position in the Phoenix metro area provides access to multiple warehouse facilities, allowing you to compare inventory and pricing across competing suppliers.

Professional Specification Development

Your final specifications should address all performance parameters, installation requirements, and quality standards necessary for successful project execution. You need to create documents that communicate design intent clearly while providing fabricators and installers with actionable technical requirements. Comprehensive specifications reduce field questions, minimize change orders, and ensure that installed work meets your quality expectations.

The specification development process should begin during schematic design, with material selection finalized before design development completion. You’ll want to coordinate with fabricators early to identify potential installation challenges and optimize seam placements. Your construction documents should include material designations, edge profile details, finish requirements, and installation standards. Reference to industry standards including ASTM C1526 for quartz surfacing products provides baseline quality requirements.

You should conduct site visits during fabrication and installation to verify specification compliance. Material verification at the slab yard confirms that supplied products match specified brands, colors, and quality levels. Fabrication shop visits allow you to inspect work quality before materials reach the job site. Installation observation ensures proper adhesive application, seam execution, and final finishing. Your professional involvement through all project phases protects client interests and ensures specification intent translates to built reality. For additional economic considerations, review Wholesale pricing advantages at Arizona natural stone slab yards before you finalize your procurement strategy. Citadel Stone’s approach modernizes traditional Arizona stone supply inc business models with technology integration.