When you’re planning a sustainable landscape project in Arizona, permeable paving slabs deliver measurable stormwater management benefits while reducing urban heat island effects. You need to understand how these materials perform in desert conditions — where summer temperatures exceed 115°F and monsoon rains deliver intense precipitation in concentrated bursts. Your specification decisions affect long-term performance, maintenance requirements, and compliance with increasingly strict municipal stormwater regulations.

Arizona’s climate creates unique challenges for permeable paving slabs Arizona installations. You’ll encounter thermal expansion coefficients that require adjusted joint spacing, porosity characteristics that must balance drainage with structural integrity, and surface treatments that need to withstand extreme UV exposure without degrading permeability. The material selection process involves trade-offs between infiltration rates, compressive strength, and aesthetic requirements that vary significantly across residential, commercial, and municipal applications.

Understanding Permeable Paving Performance in Desert Climates

Permeable paving systems in Arizona must accommodate soil conditions that range from expansive clays in Phoenix metro areas to caliche-laden substrates in Tucson. When you design base layers for permeable paving slabs Arizona projects, you’re working with infiltration rates that need verification through field testing — laboratory data rarely accounts for regional soil compaction and existing drainage patterns. Your base aggregate specification should ensure permeability exceeds surface material permeability by 4-5x to prevent subsurface saturation during monsoon events.

The interconnected void structure in quality permeable paving slabs maintains infiltration rates between 120-200 inches per hour when properly installed and maintained. You should verify that your selected material meets ASTM C1701 testing protocols, but recognize these measurements represent optimal conditions. In practice, you’ll see infiltration rates decrease 15-25% over the first two years as fine particles accumulate in surface voids — this is normal and manageable through appropriate maintenance protocols.

- You need base layer depth of 8-12 inches minimum for Arizona installations

- Your aggregate gradation should follow ASTM No. 57 or similar open-graded specifications

- Subsurface investigation must identify seasonal water table elevation and soil infiltration capacity

- You should plan for geotextile separation fabric between base and native soil in clay-heavy locations

- Edge restraint systems require enhanced anchorage in expansive soil conditions

Your drainage design needs to account for Arizona’s bimodal precipitation pattern — winter frontal systems deliver steady, low-intensity rainfall while summer monsoons produce 1-2 inch events in under 30 minutes. When you’re working with eco friendly paving Phoenix installations, this intensity creates hydraulic loading conditions that exceed most manufacturer test data. Professional specifications include overflow provisions for events exceeding design capacity, typically through strategic placement near existing drainage infrastructure.

Material Specifications for Sustainable Paving Systems

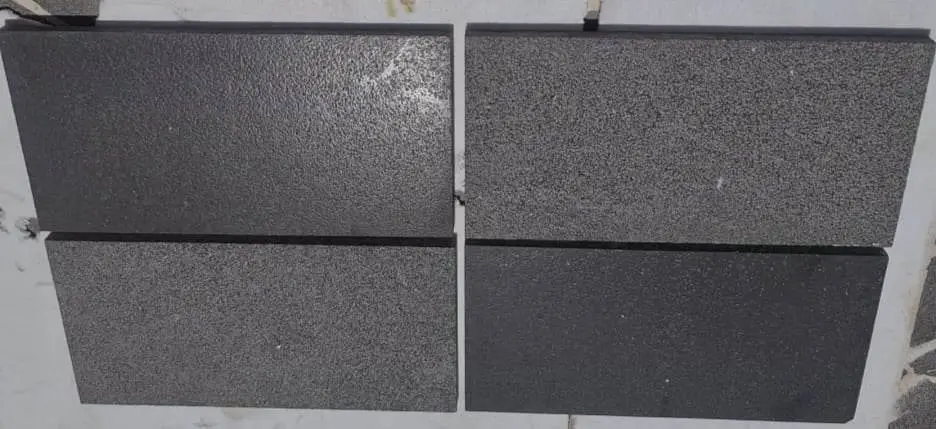

You’ll find permeable paving slabs manufactured from concrete, natural stone, and composite materials — each with distinct performance characteristics in Arizona conditions. Concrete permeable pavers offer consistent dimensional tolerances and predictable compressive strength, typically 8,000-10,000 PSI, which exceeds requirements for most applications. Natural stone options provide superior thermal mass properties and aesthetic variation but require more careful attention to porosity distribution and thickness consistency.

The void ratio in permeable paving slabs Arizona applications should range between 15-20% for optimal performance. Below 15%, you risk inadequate infiltration during high-intensity events. Above 20%, structural integrity becomes compromised in vehicular applications and freeze-thaw durability decreases in high-elevation installations like Flagstaff. Your specification should define minimum void connectivity — not just total porosity — since isolated voids don’t contribute to drainage performance.

- You should specify minimum compressive strength of 8,000 PSI for pedestrian applications

- Vehicular installations require 10,000 PSI minimum with enhanced edge support

- Thickness ranges from 60mm for pedestrian zones to 80mm for standard vehicle loading

- Your freeze-thaw durability specification must reference ASTM C1645 for northern Arizona projects

- Surface texture should maintain slip resistance coefficient above 0.50 when wet

When you evaluate sustainable paving suppliers Arizona options, you need to verify manufacturing consistency through batch testing documentation. Porosity measurements should show variance under 8% across production runs — higher variation creates inconsistent infiltration patterns that lead to localized ponding. Quality suppliers maintain third-party testing records and provide technical support for base design calculations specific to your site conditions.

Drainage Paving Installation Requirements and Base Preparation

Your installation success depends on base preparation that addresses both structural support and infiltration capacity. You’ll need to verify subgrade infiltration rates through field percolation testing — don’t rely on soil classification alone. When native soil infiltration rates fall below 0.5 inches per hour, you’re looking at modified detention systems with underdrains rather than true infiltration applications. This distinction affects permitting, long-term maintenance, and realistic performance expectations.

The compaction requirements for permeable paving base layers differ from conventional paving. You’re targeting 92-95% standard Proctor density rather than 95-98% — over-compaction reduces void space and compromises drainage performance. When you work with drainage paving slabs near me suppliers who understand local conditions, they’ll guide you toward aggregate sources that maintain permeability after compaction. Crushed angular aggregate performs better than rounded river rock in maintaining long-term void structure.

- You need to slope subgrade 1-2% away from structures even with permeable systems

- Your edge restraint must extend below base layer for structural stability

- Joint spacing between permeable paving slabs should maintain 1/4-3/8 inch consistency

- You should use open-graded joint fill material, typically 1/8-1/4 inch angular aggregate

- Surface elevation must account for 1/4-1/2 inch settling over first year

Installation timing in Arizona affects setting time and initial material handling. You’ll achieve best results when ambient temperatures stay between 50-85°F — avoid installation during peak summer heat when surface temperatures exceed material handling specifications. Your crew needs to maintain consistent joint spacing across the entire installation; variance beyond 1/8 inch creates visual irregularities and affects long-term structural performance as seasonal movement occurs.

Thermal Performance and Urban Heat Management

Permeable paving slabs Arizona installations demonstrate measurable cooling benefits compared to conventional impervious surfaces. You’ll see surface temperature reductions of 10-15°F during peak afternoon hours due to evaporative cooling from moisture retained in the base layer. This thermal behavior creates more comfortable outdoor spaces and reduces heat transfer to adjacent structures, contributing to lower cooling loads in nearby buildings.

The albedo rating of your selected material affects long-term thermal performance. Light-colored permeable paving surfaces reflect 35-45% of solar radiation, while dark materials absorb 75-85%. When you’re specifying green paving solutions dealers materials for Arizona projects, you need to balance aesthetic preferences against thermal management goals. Light-colored surfaces show soiling more readily but maintain lower temperatures — a trade-off that affects user comfort in pedestrian applications.

Subsurface moisture retention in properly functioning permeable paving systems extends thermal benefits beyond the immediate surface. You’ll find that base layer moisture creates a thermal mass effect that moderates temperature swings throughout the diurnal cycle. This behavior becomes particularly valuable in urban plaza applications where you’re trying to extend usable hours into evening periods. For comprehensive material comparisons, see Arizona sorted paving varieties for performance data across different stone types and surface treatments.

- Your specification should consider solar reflectance index values above 29 for heat island mitigation

- Surface temperature measurements should guide material selection for high-use pedestrian areas

- You need to account for thermal expansion coefficients in joint spacing calculations

- Moisture retention capacity affects evaporative cooling performance during dry periods

Maintenance Protocols for Long-Term Infiltration Performance

You should establish maintenance protocols before installation completion — permeable paving slabs require different care than conventional paving systems. The primary maintenance concern involves preventing surface void clogging from fine sediment accumulation. In Arizona landscapes, wind-blown dust and decomposed granite from adjacent areas represent the most significant maintenance challenge. Your maintenance plan needs to address quarterly vacuum sweeping using equipment specifically designed for permeable surfaces.

Infiltration testing should occur annually using ASTM C1701 procedures modified for field conditions. When you document infiltration rates below 75% of original capacity, you’re approaching the threshold for restoration maintenance. Vacuum cleaning typically restores 80-90% of original infiltration capacity when performed before heavy clogging occurs. Delayed maintenance leads to subsurface sediment penetration that requires more aggressive intervention.

- You need to schedule vacuum sweeping quarterly in high-dust environments

- Your maintenance specifications should prohibit pressure washing, which drives sediment deeper

- Joint aggregate requires replenishment every 2-3 years as material migrates into base layer

- You should avoid salt-based de-icing products in northern Arizona applications

- Vegetation control in joints requires manual removal or appropriate herbicides that don’t affect permeability

Snow removal in elevated Arizona locations requires modified procedures for permeable paving slabs Arizona installations. You’ll need to specify plastic or rubber-edged plows rather than metal blades that can damage surface texture. Sand application for traction creates maintenance complications — the fine particles accelerate void clogging and require immediate spring removal. Your winter maintenance plan should emphasize mechanical snow removal with minimal sand application.

Municipal Stormwater Compliance and Permitting Considerations

Arizona municipalities increasingly mandate low-impact development practices for commercial and multi-family projects. When you incorporate permeable paving into your stormwater management strategy, you’re addressing retention requirements while reducing conventional detention infrastructure costs. Phoenix and Tucson have specific ordinances that provide stormwater credit for permeable paving installations — understanding these regulations affects your cost-benefit analysis and site planning approach.

Your permitting submittal needs to include design calculations demonstrating infiltration capacity, base layer storage volume, and overflow provisions. Most jurisdictions require you to show that the system can handle a 2-year, 1-hour storm event through infiltration alone, with safe overflow routing for larger events. You should verify local design storm criteria — they vary significantly between northern and southern Arizona due to different precipitation patterns.

- You need as-built documentation showing actual base depth and aggregate gradation

- Your maintenance agreement must specify responsible party and required inspection frequency

- Performance monitoring may be required for first two years post-installation

- You should verify that local jurisdiction recognizes your selected material for stormwater credit

When you work with sustainable paving suppliers Arizona who understand local permitting requirements, they’ll provide technical documentation that streamlines approval processes. This includes third-party testing verification, installation guidelines that meet jurisdiction standards, and maintenance protocols that satisfy long-term performance requirements. The permitting timeline can affect your project schedule by 4-8 weeks if documentation isn’t properly prepared.

Cost Analysis and Value Engineering for Permeable Systems

Your initial cost for permeable paving slabs Arizona installations typically runs 15-30% higher than conventional paving materials. This premium reflects specialized manufacturing, enhanced base preparation requirements, and installation expertise needed for proper performance. You need to conduct lifecycle cost analysis rather than focusing solely on first cost — the value proposition becomes clear when you account for reduced stormwater infrastructure and long-term site benefits.

The cost offset from eliminated or reduced detention facilities often exceeds the permeable paving premium in constrained urban sites. When you calculate the land area saved by reducing surface detention basins, the economic equation shifts favorably. You’re recovering developable area while meeting regulatory requirements — a dual benefit that affects overall project feasibility. Your cost analysis should include reduced site grading, elimination of underground detention structures, and simplified drainage pipe networks.

- You should expect material costs between eighteen and thirty-two dollars per square foot installed

- Your base preparation costs increase 20-35% due to specialized aggregate and placement requirements

- Maintenance costs run 40-60% lower than conventional systems when protocols are followed

- You need to factor reduced irrigation requirements from improved soil moisture in adjacent landscaping

When you coordinate warehouse deliveries for large commercial projects, lead times typically range from 2-4 weeks depending on material selection and current inventory levels. You should verify stock availability early in your procurement process — specialty colors and textures may require extended lead times. Your project schedule needs to accommodate material delivery coordination with site preparation completion to avoid storage complications.

Vehicular Applications and Structural Design Considerations

Permeable paving slabs designed for vehicular loading require enhanced structural specifications beyond pedestrian applications. You’ll need increased thickness, typically 80-100mm depending on traffic loading projections, and compressive strength exceeding 10,000 PSI. The base layer depth increases to 12-18 inches with more stringent compaction requirements to prevent rutting and surface deformation under repeated loading.

Your pavement design should follow modified AASHTO procedures adapted for permeable systems. The structural number calculation accounts for reduced layer coefficients in open-graded base materials. When you’re designing parking areas and access drives, you need to consider edge support conditions carefully — unsupported edges fail prematurely under vehicular loading. Your detail drawings should show thickened edge sections or concrete edge beams that extend below the base layer.

- You need to specify minimum 80mm thickness for passenger vehicle loading

- Your design should account for reduced structural coefficient in permeable base layers

- Edge restraint systems require anchoring every 24-30 inches in vehicular applications

- You should evaluate soil bearing capacity under saturated conditions for structural design

Truck access for delivery and service vehicles requires additional design consideration. You’ll need to identify truck routes and specify enhanced structural sections in these areas. When you plan loading zones and service areas, your pavement thickness may increase to 100mm with reinforced base preparation. The alternative involves limiting permeable paving to passenger vehicle areas and using conventional paving in truck zones — a hybrid approach that still provides significant stormwater management benefits.

Aesthetic Integration and Landscape Design Applications

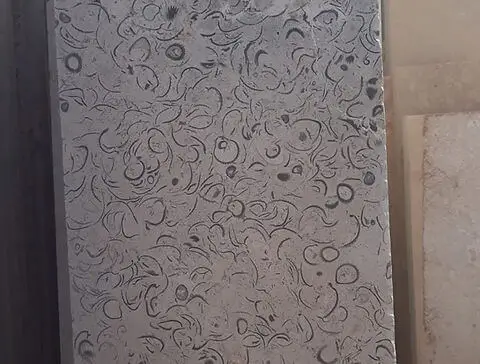

You can achieve diverse aesthetic outcomes with permeable paving slabs Arizona through careful attention to color, texture, and pattern selection. Natural stone options provide variation that complements desert landscape palettes, while manufactured concrete units offer consistent color matching for contemporary design schemes. Your material selection should consider how appearance changes when surfaces are wet — some materials darken significantly, affecting the visual composition.

The joint pattern and spacing affect both structural performance and visual impact. You’ll find that tighter joint spacing creates a more refined appearance but requires more precise installation. Your pattern selection should account for site geometry and desired visual flow — running bond patterns emphasize directional movement while herringbone creates more static compositions. When you work with experienced green paving solutions dealers, they’ll provide pattern layouts that optimize both aesthetics and structural performance.

- You should consider how material color affects thermal performance in high-exposure areas

- Your joint width affects both infiltration capacity and visual scale of the installation

- Texture selection must balance slip resistance requirements with desired aesthetic refinement

- You need to account for color variation in natural stone materials during procurement

Edge transitions between permeable paving and adjacent landscape areas require careful detailing. You’ll need to maintain elevation coordination while providing structural support at material changes. Your transition details should prevent sediment migration from landscaped areas onto paving surfaces — this involves edge restraints, filter fabric installation, and appropriate grading. When transitions aren’t properly detailed, you’ll see accelerated maintenance requirements from sediment loading.

Eco-Friendly Material Sourcing and Supply Chain Considerations

When you evaluate eco friendly paving Phoenix suppliers, you need to understand the complete environmental profile beyond just the permeability feature. Transportation distance significantly affects embodied carbon — locally sourced materials reduce environmental impact compared to products shipped from distant manufacturing facilities. You should request environmental product declarations that document lifecycle impacts including raw material extraction, manufacturing energy, and transportation emissions.

Recycled content in permeable paving slabs varies widely by manufacturer and product line. Some concrete units incorporate 20-40% recycled aggregate or supplementary cementitious materials that reduce portland cement content. When you’re pursuing LEED certification or similar rating systems, you need documentation of recycled content percentages and regional material qualifications. Your specification should define minimum acceptable recycled content levels if this contributes to project sustainability goals.

- You should verify regional material qualification within 500 miles for LEED credits

- Your supplier documentation needs to include recycled content percentages by weight

- Manufacturing energy consumption affects overall environmental profile significantly

- You need to consider end-of-life recyclability in material selection decisions

Supply chain transparency helps you verify environmental claims and ethical sourcing practices. When you work with sustainable paving suppliers Arizona who maintain detailed documentation, you’ll have confidence in specification compliance. This includes quarry certifications for natural stone, manufacturing facility environmental permits, and third-party verification of recycled content claims. Your procurement process should include requests for this documentation early in material selection.

Common Specification Mistakes and How to Avoid Them

You’ll encounter several recurring specification errors that compromise permeable paving performance in Arizona projects. The most significant mistake involves inadequate base design for site-specific soil conditions. When you specify generic base sections without field verification of infiltration capacity, you’re risking system failure or underperformance. Your design process must include subsurface investigation and percolation testing that informs base depth, underdrain requirements, and realistic infiltration expectations.

Another common error involves specifying permeable paving slabs Arizona without addressing maintenance requirements in contract documents. You need to include detailed maintenance specifications, identify responsible parties, and establish performance monitoring protocols. When maintenance isn’t properly specified, system performance degrades rapidly and owners face unexpected restoration costs. Your specifications should include maintenance equipment requirements, scheduling recommendations, and performance thresholds that trigger intervention.

- You should never specify permeable paving without site-specific infiltration testing

- Your base design must account for actual soil conditions, not assumed values

- Joint spacing specifications need to address installation tolerance expectations clearly

- You need to specify appropriate joint fill material, not generic sand products

- Edge restraint requirements must be detailed for all perimeter conditions

Inadequate attention to edge conditions represents another frequent specification gap. You’ll see premature failures when edge restraint systems don’t extend below the base layer or when anchorage spacing exceeds structural requirements. Your detail drawings need to show specific edge conditions for all transitions, including building interfaces, landscape borders, and material changes. Generic edge details lead to field interpretation that often compromises structural integrity.

Citadel Stone Premium Paving Slabs — How We Specify for Arizona’s Diverse Climate Zones

When you consider Citadel Stone’s paving slabs for your Arizona project, you’re evaluating premium materials engineered for extreme desert climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regional conditions, from low desert heat to high country freeze-thaw cycles. This section outlines how you would approach specification decisions for six representative cities, demonstrating the climate-specific considerations that affect material selection and installation planning.

Your specification approach needs to account for Arizona’s remarkable climate diversity — conditions in Yuma differ dramatically from Flagstaff requirements. You would adjust base depth, joint spacing, surface treatment, and maintenance protocols based on local temperature ranges, precipitation patterns, and soil characteristics. The following city-specific guidance demonstrates how professional specifications adapt to regional performance requirements.

Phoenix Heat Specifications

In Phoenix applications, you would prioritize thermal performance in material selection for permeable paving slabs Arizona installations. Your specifications should address surface temperatures that regularly exceed 160°F on dark-colored materials during summer months. You would recommend light-colored options with high solar reflectance to maintain pedestrian comfort in commercial plazas and walkways. The base layer design would account for infrequent but intense monsoon precipitation, requiring infiltration capacity of 150+ inches per hour to handle typical storm events. Your installation timeline should avoid June through August when surface temperatures complicate material handling and setting procedures.

Tucson Caliche Considerations

When you specify for Tucson projects, you would address caliche layers that commonly occur 18-36 inches below grade. Your subsurface investigation would need to identify caliche depth and determine whether excavation through this layer is feasible or if modified detention systems with underdrains are required. You would recommend base depths of 10-14 inches with potential underdrain integration depending on native soil infiltration testing results. The specification would include provisions for dealing with excavated caliche material and verifying adequate infiltration capacity below the restrictive layer. You would coordinate warehouse delivery timing with excavation completion to ensure proper material storage on site.

Scottsdale Upscale Applications

In Scottsdale’s high-end residential and commercial contexts, you would emphasize aesthetic refinement while maintaining drainage functionality. Your material selection would likely favor natural stone permeable paving options that provide color variation and premium appearance. You would specify tighter joint spacing, typically 1/4 inch, and recommend enhanced edge details that create refined transitions between paving and landscape areas. The specifications would address integration with existing hardscape materials commonly found in luxury developments. You would coordinate with landscape architects to ensure paving color and texture complement overall design intent while meeting technical performance requirements for infiltration and structural durability.

Flagstaff Freeze-Thaw Requirements

For Flagstaff installations at 7,000 feet elevation, you would specify freeze-thaw durable materials meeting ASTM C1645 testing protocols. Your material selection would emphasize low absorption rates, typically under 5%, to minimize freeze-thaw damage potential. You would recommend increased base depth, 14-18 inches, to provide adequate storage capacity during spring snowmelt periods when infiltration into frozen subgrade is limited. The specification would address winter maintenance protocols, prohibiting metal plow blades and limiting sand application that accelerates void clogging. You would verify that your selected permeable paving slabs Arizona materials demonstrate 300+ freeze-thaw cycle durability in independent testing documentation.

Sedona Aesthetic Context

In Sedona’s unique visual environment, you would coordinate permeable paving color selection with the iconic red rock landscape context. Your specifications would favor earth-tone materials that complement rather than compete with natural surroundings. You would address moderate freeze-thaw exposure, requiring materials with proven durability in transitional climate zones that experience 40-60 annual freeze-thaw cycles. The base design would account for well-draining native soils common in Sedona’s geology, potentially allowing reduced base depths of 8-10 inches where infiltration testing supports this approach. You would specify installation details that minimize visual impact and maintain the naturalistic character valued in Sedona developments.

Mesa Municipal Applications

When you specify for Mesa’s municipal and commercial projects, you would address large-area installations requiring cost-effective solutions and straightforward maintenance protocols. Your specifications would emphasize durability and consistent performance over premium aesthetics, favoring manufactured concrete permeable units with proven track records. You would detail maintenance requirements clearly, including equipment specifications and scheduling recommendations for quarterly vacuum sweeping. The design would incorporate permeable paving in strategic locations such as parking lot perimeter rows and pedestrian pathways, creating hybrid systems that balance stormwater management benefits with budget constraints. You would coordinate with municipal engineering staff to verify compliance with local stormwater ordinances and ensure proper integration with existing drainage infrastructure.

Professional Specification Development and Project Documentation

Your specification writing process for permeable paving projects should follow CSI MasterFormat division structure, typically under Division 32 – Exterior Improvements. You need to include detailed technical requirements that address materials, installation procedures, quality control, and maintenance. Generic specifications create ambiguity that leads to substitution requests and field interpretation issues. Your documents should reference specific ASTM standards, define acceptable manufacturers, and establish clear performance criteria.

The specification should address submittal requirements that verify material compliance before installation begins. You’ll need manufacturer technical data, third-party testing documentation, sample approval procedures, and installation plan review. When you require pre-installation meetings, you create opportunities to address questions and clarify expectations before field work begins. Your quality control provisions should include field density testing of base layers, infiltration rate verification, and dimensional inspection of completed work.

- You should reference ASTM C1701 for infiltration rate testing and acceptance criteria

- Your specifications need to define joint spacing tolerances, typically ±1/8 inch

- Material submittals should include compressive strength, absorption rate, and freeze-thaw data

- You need to specify warranty requirements for both materials and installation workmanship

Installation quality directly affects long-term performance of permeable paving slabs Arizona systems. You should require qualified installers with demonstrated experience in permeable paving installation — this isn’t conventional paving work. Your specification can include installer certification requirements or previous project references. When installation quality is properly addressed in contract documents, you reduce risk of performance failures and associated remediation costs.

Emerging Technologies and Future Considerations

You’re seeing innovation in permeable paving technology that addresses traditional limitations and expands application possibilities. Enhanced polymer-modified materials demonstrate improved freeze-thaw durability while maintaining high infiltration rates. Some manufacturers now incorporate photocatalytic surface treatments that break down pollutants in stormwater, adding water quality benefits to quantity management. When you specify emerging technologies, you need additional documentation verifying long-term performance since field track records may be limited.

Smart monitoring systems integrated into permeable paving installations provide real-time performance data on infiltration rates and subsurface moisture levels. These systems help you optimize maintenance scheduling and verify continued regulatory compliance. The technology remains relatively expensive but becomes cost-effective in high-value installations or projects with stringent performance documentation requirements. Your specification should address data collection protocols and responsible party identification when monitoring systems are incorporated.

- You should evaluate new technologies based on independent testing rather than manufacturer claims alone

- Your adoption of emerging products needs to consider long-term replacement part availability

- Performance monitoring technology provides valuable data but requires ongoing maintenance and calibration

Climate adaptation strategies increasingly incorporate permeable paving as cities address intensifying precipitation events and heat island effects. You’ll see permeable paving slabs specified more frequently in municipal master plans and development ordinances. Your familiarity with these systems positions you to take advantage of expanding market opportunities while helping clients meet evolving regulatory requirements. The technology continues maturing with improved materials, refined installation practices, and growing installer expertise.

Selection Framework for Project Success

Your decision-making process for permeable paving system selection should follow a structured evaluation framework that weighs multiple performance factors. You need to assess site-specific constraints including soil infiltration capacity, space limitations, budget parameters, aesthetic requirements, and maintenance capabilities. No single solution works optimally for all applications — your expertise involves matching system characteristics to project-specific priorities.

When you develop your evaluation matrix, you should weight factors according to project-specific importance. A high-profile commercial plaza emphasizes aesthetics and user experience, while a municipal parking lot prioritizes durability and maintenance efficiency. You’ll find that making these priority decisions explicit early in design development streamlines subsequent specification decisions and reduces later conflicts between competing objectives. For additional guidance on large-format options suitable for commercial applications, review Suppliers of oversized outdoor paving slabs in Arizona before you finalize your project approach.

- You should create project-specific decision matrices that weight evaluation criteria appropriately

- Your selection process needs to involve stakeholder input on maintenance capabilities and budget constraints

- Life-cycle cost analysis provides more accurate value assessment than first-cost comparison alone

- You need to verify that your selected system meets local regulatory requirements before detailed design

Professional practice requires you to document your selection rationale clearly in project records. This documentation supports future decision-making if modifications become necessary and provides valuable reference for similar projects. Your specification approach continues evolving as you gain experience with different systems, climates, and applications — maintaining detailed records of performance outcomes improves your future recommendation quality and builds your professional expertise in this specialized area. Citadel Stone manufactures premium cladding-grade paving slabs and distributes them across Arizona for facades and plazas.