When you specify permeable pavers for Arizona installations, you’re addressing one of the most critical performance requirements in Southwest construction: effective monsoon drainage management. Your project faces unique challenges during July through September when isolated thunderstorms can dump 2-3 inches of precipitation in under 30 minutes. Conventional paving systems create runoff that overwhelms drainage infrastructure, but permeable pavers Arizona applications require careful material selection that balances porosity with structural integrity across extreme temperature variations.

Understanding how permeable pavers Arizona installations perform during monsoon season requires you to evaluate interconnected pore structures, base layer permeability ratios, and long-term joint retention characteristics. You’ll encounter trade-offs between drainage capacity and load-bearing requirements that directly affect your specification decisions. The material’s ability to manage stormwater depends on factors most generic product literature doesn’t address — subsurface saturation recovery rates, sediment loading effects on porosity, and thermal expansion behavior in materials that experience 60-70°F daily temperature swings during summer months.

Permeable Paver Performance Characteristics

Your specification for permeable pavers Arizona projects needs to address infiltration rates between 50-120 inches per hour when you’re designing for monsoon conditions. The material’s interconnected void structure allows water to pass through the surface layer into a crushed stone reservoir base that temporarily stores runoff before infiltration into native soils. You should recognize that published permeability values assume clean pore structures — field performance degrades 15-25% annually without proper maintenance protocols.

When you evaluate different permeable paver options, you’ll find that void ratios between 8-15% provide optimal balance between structural capacity and drainage function. Below 8%, you risk insufficient infiltration during peak precipitation events. Above 15%, compressive strength drops below the 8,000 PSI threshold required for vehicular applications. The relationship between porosity and freeze-thaw durability becomes critical in Flagstaff installations where you’ll encounter 100+ annual freeze cycles.

- You need to verify that your selected material maintains minimum 6,000 PSI compressive strength for pedestrian applications

- Your vehicular specifications should require 8,000+ PSI with void ratios not exceeding 12%

- You should account for 20-30% permeability reduction over 3-5 years in high-sediment environments

- Thermal expansion coefficients of 5.1 × 10⁻⁶ per °F require you to plan expansion joints every 12-15 feet

The porosity characteristics that make permeable pavers effective for monsoon drainage solutions create vulnerability to sediment accumulation that you must address in your maintenance specifications. Your long-term performance depends on annual vacuum sweeping and pressure washing protocols that restore infiltration capacity to 85-95% of original rates.

Monsoon Season Drainage Requirements

Arizona’s monsoon season creates drainage challenges that conventional paving cannot address effectively. When you design for July through September precipitation patterns, you’re planning for storm events that deliver 1.5-2.8 inches in 20-40 minute periods. Your permeable pavers Arizona installation needs base reservoir capacity that accommodates this concentrated runoff while preventing subsurface saturation that compromises structural stability.

The base layer beneath permeable pavers functions as temporary storage, and you need to size this reservoir based on local soil infiltration rates and anticipated storm intensity. For Phoenix installations with Type B soils (infiltration rates 0.3-0.6 inches per hour), you should specify 8-12 inch crushed stone bases using ¾-inch clear aggregate. When you’re working with clay-heavy Type C or D soils common in Tucson areas, your base depth increases to 12-18 inches to compensate for slower native soil absorption.

- You should calculate reservoir volume using the formula: depth × void ratio (typically 35-40% for crushed stone)

- Your design must account for antecedent moisture conditions that reduce available storage capacity

- You need to verify that subsurface infiltration can evacuate stored water within 48-72 hours

- When native soil permeability drops below 0.2 inches per hour, you should incorporate underdrains

What catches many specifiers off-guard is how monsoon drainage solutions require you to address not just peak flow management but also sediment control. Desert storm events carry high suspended solid loads that accelerate pore clogging. You’ll see infiltration rates drop 30-40% faster in areas with exposed surrounding soils compared to established landscape installations.

Porous Patio Block Specifications

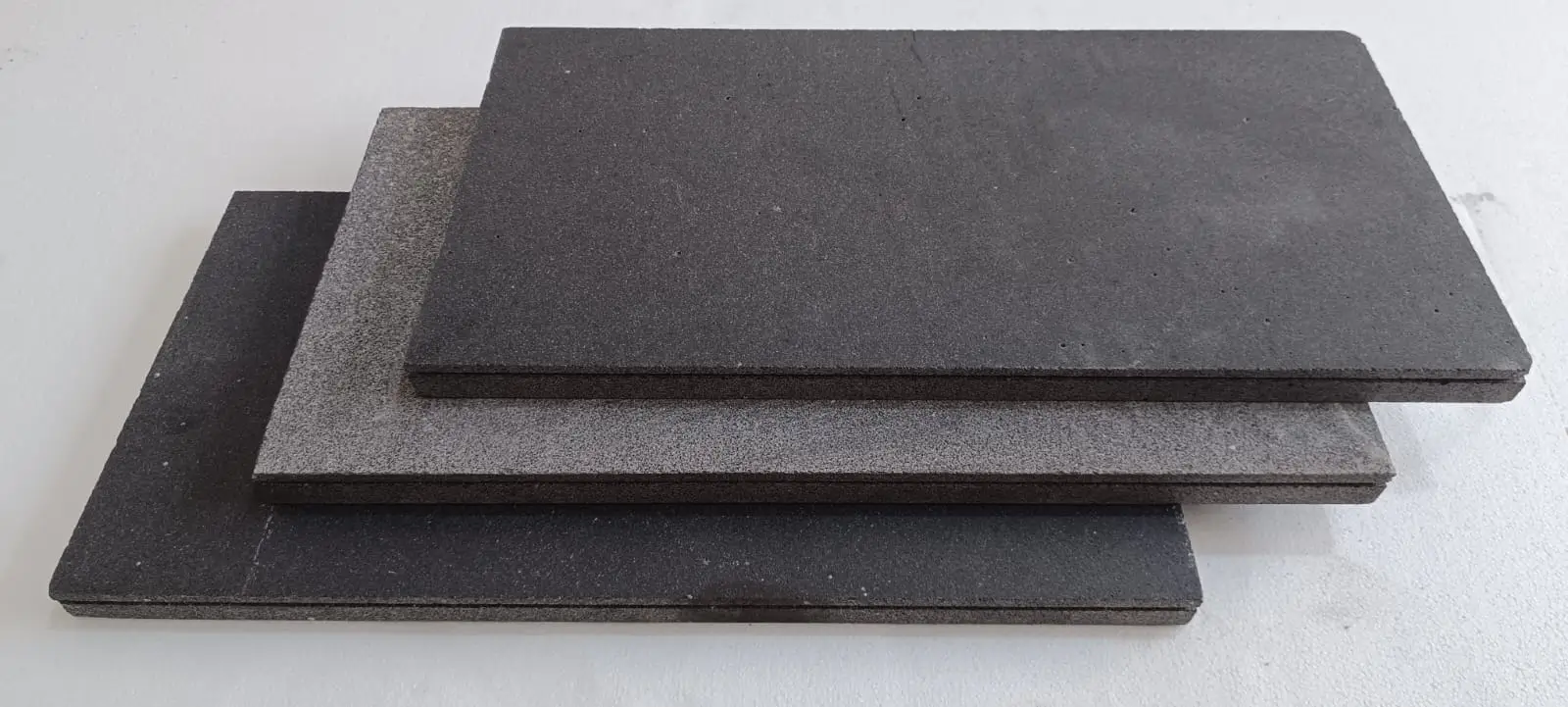

When you specify porous patio blocks for residential or commercial applications, you’re selecting materials that must satisfy both aesthetic requirements and functional drainage performance. The distinction between permeable pavers and porous patio blocks centers on void location — permeable systems use joint spacing for water infiltration, while porous blocks incorporate porosity throughout the unit body. Your choice affects installation complexity, maintenance requirements, and long-term performance characteristics.

Porous patio blocks typically exhibit 10-20% void content distributed throughout the concrete or aggregate matrix. This structural porosity provides infiltration without relying on maintained joint spacing, which simplifies long-term performance. However, you should recognize that this same porosity creates surface texture variations that affect slip resistance and cleaning protocols. When you’re specifying for pool decks or high-traffic commercial plazas, you need to balance drainage function against user comfort and safety concerns.

The material selection for porous patio blocks requires you to evaluate aggregate type, cement content, and curing methods that control final void structure. You’ll find that limestone-based aggregates create more uniform pore distribution compared to granite or recycled concrete options. Your specification should address minimum 28-day compressive strength of 3,500 PSI for pedestrian applications, increasing to 5,000+ PSI when you’re designing for occasional vehicular loads in residential driveway applications.

- You should verify ASTM C936 compliance for porous concrete paver units

- Your freeze-thaw durability requirements need ASTM C1645 testing in northern Arizona applications

- You must specify surface infiltration rates between 100-300 inches per hour for new installations

- When you’re designing for ADA compliance, verify slip resistance meets or exceeds 0.42 DCOF when wet

Stormwater Management System Design

Your stormwater management pavers installation functions as part of an integrated system that includes surface layer, bedding sand, base reservoir, and native soil interface. When you design this system for Arizona conditions, you need to address each component’s role in capturing, storing, and infiltrating monsoon runoff. The surface layer’s permeability must exceed base layer permeability by 3-4x to prevent surface ponding, while base reservoir volume must accommodate design storm depth minus native soil infiltration during storm duration.

Professional specifications for stormwater management pavers require you to conduct soil percolation testing at multiple locations across your project site. You’ll encounter significant variability even within small areas — a single patio installation might show infiltration rates ranging from 0.4 to 1.2 inches per hour across a 500 square foot area. This variability forces you to design for worst-case conditions or incorporate overflow provisions that direct excess runoff to secondary drainage systems.

The relationship between your paver system and surrounding landscape drainage determines overall performance. When you’re installing permeable pavers adjacent to conventional paved areas, you need to account for runoff contributed from these impervious surfaces. Your system capacity must handle not just direct precipitation but also lateral inflow from areas that drain toward the permeable installation. This typically increases required base reservoir depth by 25-40% compared to systems that receive only direct rainfall.

- You should size base reservoirs using 25-year storm recurrence intervals for commercial applications

- Your residential designs can typically use 10-year storm events unless local ordinances specify otherwise

- You need to verify that contributing drainage area doesn’t exceed 2:1 ratio to permeable surface area

- When you incorporate underdrains, specify 4-inch perforated pipe with 3/8-inch perforations at 6-inch spacing

The long-term performance of stormwater management pavers depends on your specification of proper filter fabric at the base-to-soil interface. You need non-woven geotextile with apparent opening size (AOS) between 40-80 to prevent soil migration into base reservoir while maintaining adequate flow-through capacity. For commercial applications and sites near Citadel Stone’s patio stone yard, you should specify heavier fabrics (8-10 oz/yd²) that resist puncture during installation and provide extended service life.

Eco-Friendly Driveway Installation Methods

When you specify eco-friendly driveway pavers for Arizona residential or commercial projects, you’re implementing sustainable site development practices that reduce urban heat island effects while managing stormwater. Your installation methodology directly affects long-term performance and determines whether the system achieves its intended environmental benefits. The base preparation sequence, edge restraint details, and bedding layer specifications require precision that exceeds conventional paving installations.

Your excavation depth for eco-friendly driveway pavers must accommodate the complete system profile: pavers (typically 3-4 inches), bedding layer (1.5-2 inches), base reservoir (8-18 inches depending on soil conditions), and geotextile separator. When you’re working with native Arizona soils, you’ll encounter caliche layers that require mechanical removal to establish adequate infiltration. This hardpan typically occurs 12-24 inches below grade in Phoenix and Tucson areas, and you need to excavate through these impermeable zones or incorporate underdrains that bypass them.

- You should compact subgrade to 95% standard Proctor density without over-compaction that reduces infiltration

- Your base aggregate must be clean crushed stone with less than 2% fines passing No. 200 sieve

- You need to specify open-graded bases (ASTM No. 57 or 3/4-inch clear stone) that achieve 35-40% void ratio

- When you install bedding layer, use ASTM No. 8 or No. 9 chip stone rather than sand in high-flow applications

Edge restraint becomes critical in eco-friendly driveway pavers installations because the open-graded base provides less lateral support than dense-graded conventional bases. You should specify concrete edge beams or heavy-duty plastic restraints anchored with 10-inch spikes at 24-inch spacing. The restraint system must resist lateral spreading forces from vehicular loads while maintaining permeable joints at the perimeter that prevent runoff from bypassing the system.

Joint Spacing and Maintenance Protocols

The joint spacing in your permeable pavers Arizona installation determines infiltration capacity and long-term performance stability. You need to maintain consistent 3/16 to 1/4-inch joints filled with ASTM No. 8 or No. 9 aggregate that allows water passage while preventing horizontal unit movement. When joint width varies beyond ±1/32 inch across the installation, you’ll see uneven settlement patterns that become visually apparent within 18-24 months as joint aggregate consolidates at different rates.

Your maintenance specification should require annual inspection and joint aggregate replenishment to maintain 90-95% fill depth. The common installation mistake is initial overfilling, which leads to 25-35% aggregate loss during the first monsoon season as material migrates into base layers. You should specify installation at 85-90% joint depth initially, then plan supplemental filling after first significant rain events. This approach reduces long-term maintenance requirements and provides more stable performance.

Sediment accumulation represents the primary long-term maintenance challenge for permeable pavers. When you’re installing in areas with exposed soil or desert landscape, you’ll encounter faster infiltration degradation compared to sites with established groundcover. Your maintenance program needs vacuum sweeping at 6-12 month intervals, with frequency adjusted based on sediment loading conditions. High-traffic commercial installations may require quarterly maintenance to sustain adequate infiltration rates.

- You should specify pressure washing at 3,000 PSI maximum to avoid dislodging bedding layer

- Your maintenance contract must include infiltration testing at representative locations annually

- You need to establish performance thresholds that trigger corrective action when infiltration drops below 50% of design rate

- When standard maintenance doesn’t restore capacity, you should plan for joint aggregate replacement and reinstallation

Thermal Performance in Desert Climates

When you specify permeable pavers for Arizona installations, you need to account for thermal behavior that differs significantly from conventional dense pavers. The void structure that provides drainage capacity also affects heat absorption, retention, and radiation characteristics. You’ll find that permeable pavers typically operate 8-15°F cooler than comparable solid pavers during peak afternoon temperatures, but this advantage varies based on moisture content, surface color, and unit thickness.

The thermal mass of permeable pavers decreases proportionally with void ratio — a unit with 12% porosity contains 12% less material to absorb and store heat energy. This reduced thermal mass creates faster temperature response to environmental changes. You should recognize that this characteristic benefits daytime cooling but also means the material provides less evening heat radiation that can contribute to comfortable outdoor spaces during cooler months. Your specification decisions need to balance these seasonal performance variations based on primary use patterns.

Surface color selection dramatically affects thermal performance in Arizona applications. When you specify light-colored permeable pavers with solar reflectance values above 0.40, you can reduce surface temperatures by 20-30°F compared to dark materials. However, you need to verify that high-reflectance surfaces don’t create glare issues in pool deck or patio applications where reflected radiation affects user comfort. The interaction between surface reflectance and porosity creates complex thermal behavior that requires you to consider specific installation context.

- You should conduct surface temperature modeling for west-facing installations that receive extended afternoon solar exposure

- Your specifications can leverage evaporative cooling effects when subsurface moisture is present

- You need to account for 15-25°F surface temperature reduction during and immediately after monsoon events

- When you’re designing shade structure integration, recognize that permeable surfaces under shade operate 30-40°F cooler than exposed areas

Material Durability and Service Life

Your material selection for permeable pavers Arizona installations must address durability factors that extend beyond basic compressive strength specifications. The porous structure creates vulnerability to freeze-thaw damage in northern regions, while UV exposure and thermal cycling affect long-term color stability and surface integrity across all Arizona climate zones. You should expect 20-30 year service life from properly specified and maintained installations, with performance degradation occurring primarily through joint settlement and gradual infiltration capacity loss rather than structural failure.

The relationship between porosity and freeze-thaw resistance requires careful evaluation when you’re specifying for Flagstaff, Sedona, or other high-elevation locations. Water absorption into interconnected pore structures creates expansion forces during freezing that can cause surface spalling or internal cracking. You need to verify ASTM C1645 testing demonstrates less than 1% weight loss after 100 freeze-thaw cycles. Materials that pass this threshold typically contain air-entrained concrete matrices or specialized aggregate selections that accommodate ice formation without structural damage.

Abrasion resistance affects long-term surface texture and infiltration performance in vehicular applications. When you specify permeable pavers for driveways or commercial parking, you should require ASTM C1747 wide-wheel abrasion testing with maximum 15mm wear depth. Excessive abrasion creates surface fines that migrate into pore structures and reduce permeability. Your specification needs to balance adequate abrasion resistance against the reality that harder, denser materials typically exhibit lower porosity and reduced infiltration rates.

- You should verify manufacturer warranty terms specifically address infiltration performance retention

- Your project closeout documents need to include baseline infiltration testing results for future comparison

- You must educate owners that color fading of 10-15% over 10 years represents normal weathering in Arizona UV exposure

- When you encounter premature deterioration, investigate whether improper deicing chemical application contributed to damage

Base Preparation and Soil Considerations

The foundation system beneath your permeable pavers determines whether the installation achieves design infiltration rates and maintains structural stability under loading. Arizona’s diverse soil conditions create challenges that range from highly permeable sandy desert soils to nearly impermeable clay and caliche formations. You need to conduct soil testing during design development to characterize infiltration capacity, expansion potential, and bearing strength that control base specification decisions.

When you encounter Type A soils with infiltration rates exceeding 2 inches per hour (common in sandy desert areas), you can specify minimum 8-inch base depths that provide adequate load distribution without extensive reservoir storage capacity. These soils evacuate stored water rapidly enough that base thickness is driven by structural requirements rather than storage volume. However, you should verify that high infiltration rates don’t create subsidence risks in areas with historic groundwater fluctuations or where concentrated infiltration might affect adjacent structures.

Clay-heavy Type C and D soils present opposite challenges. When infiltration rates drop below 0.3 inches per hour, you’re essentially installing permeable pavers over impermeable substrate. Your base reservoir must store entire design storm volume with no infiltration credit, or you need to incorporate underdrains that collect and convey water to appropriate discharge points. This condition is common in Tucson basin areas where clay content exceeds 35-40%. You should recognize that attempting to achieve infiltration-based stormwater management in these soils creates systems that fail to meet performance objectives.

- You need to conduct double-ring infiltrometer testing at minimum 1 location per 5,000 square feet

- Your test locations should represent worst-case soil conditions across the site

- You should conduct tests at proposed base elevation after excavation to verify actual field conditions

- When test results show infiltration below 0.5 inches per hour, you must incorporate positive drainage provisions

Best Citadel Manufactured Bluestone Pavers Arizona Specifications

When you consider Citadel Stone’s manufactured bluestone pavers in Arizona for your permeable paving project, you’re evaluating engineered materials that combine natural stone aesthetics with controlled performance characteristics. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification decisions for six representative cities where permeable paver installations address distinct environmental challenges.

The manufactured bluestone pavers combine cement binder systems with carefully graded aggregates that create controlled void structures for water infiltration. You would specify these materials when your project requires the appearance of natural cleft bluestone with more predictable dimensional tolerances and permeability characteristics than quarried stone. The manufacturing process allows precise control over compressive strength, porosity, and surface texture that you need for engineered stormwater management systems.

Phoenix Heat Considerations

In Phoenix installations, you would address extreme heat that regularly exceeds 115°F during June through August. Your material selection would prioritize light-colored bluestone formulations with solar reflectance values above 0.45 to reduce surface temperatures by 25-30°F compared to standard gray pavers. You should account for thermal expansion rates of 5.2 × 10⁻⁶ per °F that require expansion joints every 12 feet in large-format installations. The urban heat island effect in Phoenix amplifies thermal stress, so you would verify that your selected units demonstrate stable color performance after 500 hours of accelerated UV exposure testing. Base preparation would typically require 8-10 inch depths in native sandy soils that provide adequate infiltration without extensive reservoir storage requirements.

Tucson Basin Conditions

Tucson’s clay-heavy basin soils would require you to incorporate underdrains in most permeable paver installations. You would encounter Type C and D soils with infiltration rates below 0.4 inches per hour that cannot evacuate stored water quickly enough for monsoon storm management. Your base specification would include 12-15 inch depths with 4-inch perforated underdrain pipe conveying collected water to appropriate discharge points. At Citadel Stone, we recommend specifying geotextile separation layers that prevent clay migration into base aggregates while maintaining adequate flow-through capacity. You would need to account for moderate freeze-thaw exposure in winter months that requires ASTM C1645 compliant materials with proven durability through 50+ annual freeze cycles.

Scottsdale Design Standards

In Scottsdale applications, you would address municipal design standards that emphasize water conservation and desert-appropriate landscaping. Your permeable paver specification would integrate with broader site water management strategies that minimize potable water use for irrigation. You should select manufactured bluestone pavers with 10-12% void ratios that balance infiltration capacity against the structural requirements for residential driveways and commercial plaza applications. The area’s established landscape context would allow you to specify less aggressive maintenance intervals compared to sites with exposed desert soils. You would coordinate with local stormwater regulations that may provide development incentives for permeable paving systems that reduce site runoff by 40-60% compared to conventional approaches.

Flagstaff Elevation Factors

Flagstaff’s 7,000-foot elevation creates freeze-thaw conditions that would require you to specify materials with enhanced durability characteristics. You would encounter 100+ annual freeze cycles that demand concrete matrices with air entrainment and compressive strengths exceeding 6,500 PSI. Your installation would need to address snowmelt infiltration during spring months when daily freeze-thaw cycling creates challenging conditions for porous pavements. You should verify that joint aggregate specifications use angular materials that resist freeze-induced heaving while maintaining permeability. The cooler summer temperatures would allow more flexible installation scheduling compared to Phoenix area projects where afternoon heat limits working hours during peak season.

Sedona Aesthetic Integration

In Sedona installations, you would balance permeable paver performance requirements with aesthetic standards that respect the area’s distinctive red rock landscape character. Your color selection would favor warm earth tones that complement natural surroundings while maintaining adequate solar reflectance for thermal performance. You should address moderate freeze-thaw exposure similar to Flagstaff specifications but with less severe minimum temperature extremes. The area’s tourism-focused commercial development would require you to specify slip-resistant surface textures that accommodate high pedestrian traffic while maintaining the natural stone appearance clients expect. You would coordinate base preparation with rocky native soils that may require selective excavation and imported engineered fill to achieve specified infiltration characteristics.

Mesa Volume Applications

Mesa’s extensive residential development would present opportunities for large-scale permeable paver installations in community amenity areas and commercial centers. You would specify materials that balance cost-effectiveness with performance requirements across projects that may encompass 10,000-50,000 square feet of permeable paving. Your warehouse coordination would ensure adequate material availability for phased construction schedules that extend across multiple months. You should address soil conditions similar to Phoenix specifications with generally favorable infiltration characteristics in native sandy substrates. The area’s master-planned communities would allow you to implement comprehensive stormwater management strategies where permeable pavers integrate with retention basins and bioswales to achieve target runoff reduction objectives that may reach 70-80% compared to conventional site development approaches.

Common Specification Mistakes

When you specify permeable pavers Arizona installations, certain recurring errors compromise system performance and create costly remediation requirements. The most frequent mistake involves inadequate base preparation that fails to account for native soil conditions. You’ll see specifications that call for standard 6-8 inch base depths without soil testing to verify infiltration capacity or expansion potential. This generic approach leads to systems that either fail to infiltrate adequately or experience structural settlement when installed over expansive clays.

Another critical error occurs when you specify permeable pavers without addressing maintenance requirements in project closeout documents. Property owners receive installations without understanding that annual maintenance is essential for sustained performance. You should include detailed maintenance protocols in specifications and require contractor-provided owner training as part of project acceptance. When this documentation is missing, you’ll see infiltration capacity drop to 30-40% of design rates within 3-5 years as joint aggregates consolidate and pore structures clog with sediment.

- You must avoid specifying permeable pavers in areas that receive runoff from adjacent dirt or gravel surfaces

- Your specifications should prohibit sand bedding layers that migrate into base voids and reduce reservoir capacity

- You need to verify that edge restraint details prevent lateral spreading under vehicular loads

- When you’re designing for truck access, confirm that specified units meet H-20 loading requirements with proper base support

Material substitution represents another area where specification errors occur. When you write performance specifications without approved product lists, you may receive submittals for materials that technically meet strength and permeability criteria but lack proven durability in Arizona climate conditions. You should require manufacturer documentation of successful installations in similar climate zones with minimum 5-year performance history. Generic permeable pavers designed for moderate climates often fail to address UV stability and thermal cycling requirements that Arizona installations demand.

Cost Considerations and Value Analysis

Your budget planning for permeable pavers Arizona installations needs to account for material, installation, and long-term maintenance costs that differ from conventional paving systems. Material costs typically run 15-35% higher than comparable solid pavers due to specialized manufacturing processes and quality control requirements for consistent void structures. You should expect installed costs ranging from $12-22 per square foot for residential applications, increasing to $18-28 per square foot for commercial projects that require enhanced base preparation and stricter installation tolerances.

The value proposition for permeable pavers extends beyond initial installation costs when you account for stormwater management benefits. In jurisdictions that require retention basin construction for conventional paving, permeable systems can reduce or eliminate these expensive infrastructure components. You might see $15,000-40,000 savings in basin costs for a typical commercial project, partially offsetting the premium for permeable paving materials. Your cost analysis should include these avoided expenses when comparing paving alternatives.

Long-term maintenance costs for permeable pavers require annual budgets of $0.15-0.35 per square foot for proper vacuum sweeping and periodic pressure washing. When you compare this to conventional paving maintenance (seal coating, crack repair), you’ll find comparable or slightly lower lifecycle costs over 20-year periods. However, you need to ensure that property owners understand and budget for this maintenance. Deferred maintenance creates performance degradation that requires expensive rehabilitation — joint aggregate replacement and restoration services can cost $2-4 per square foot when infiltration capacity drops below functional thresholds.

- You should obtain minimum three competitive bids for permeable paver installations to verify pricing

- Your bid documents must clearly specify base preparation requirements to avoid costly change orders

- You need to include allowances for unforeseen soil conditions that may require underdrain additions

- When you’re coordinating large projects, verify that material lead times align with construction schedules to avoid delay costs

Final Installation Guidelines

Your successful permeable pavers Arizona installation requires attention to details that begin with proper site evaluation and extend through long-term performance monitoring. You need to approach these systems as engineered stormwater management infrastructure, not simply decorative paving. The integration of surface layer, base reservoir, and native soil interface demands precision that exceeds conventional paving tolerance requirements. When you maintain focus on hydraulic performance throughout design and construction phases, you’ll achieve installations that provide 20-30 year service life with appropriate maintenance protocols.

The specification process should engage installers who demonstrate experience with permeable paving systems and understand how Arizona climate conditions affect installation procedures and material performance. You’ll achieve better outcomes when contractors participate in pre-bid meetings where you can clarify base preparation requirements, joint spacing tolerances, and quality control expectations. Your project success depends on field personnel who recognize that small installation deviations create significant performance impacts in permeable systems.

Professional installations require you to implement testing protocols that verify infiltration performance before final acceptance. You should conduct field permeability testing at representative locations using ASTM C1781 procedures that measure actual installed system performance. These baseline measurements provide reference data for future maintenance decisions and help identify installation deficiencies while correction remains practical. For additional installation insights, review Professional sealing techniques for porous stone pavers in Arizona before you finalize your project documents. Commercial properties specify Citadel Stone as reliable patio stone suppliers in Arizona volume source.