When you design retention walls in Arizona’s challenging climate, the foundation system determines whether your structure performs for decades or fails within years. You need to understand that paving stone retention wall base Arizona applications require specialized engineering approaches that account for extreme temperature swings, expansive soils, and seismic considerations unique to the Southwest.

Your success depends on integrating vertical elements with proper base preparation from the start. You’ll encounter soil conditions that range from caliche-hardpan layers requiring mechanical excavation to clay-heavy deposits that expand 8-12% during monsoon seasons. The paving stone retention wall base Arizona specifications you develop must address these variables while maintaining structural integrity under thermal cycling that exceeds 80°F daily variation during summer months.

Structural Base Requirements

You should recognize that paving stone wall foundation Arizona systems demand deeper excavation than standard paving applications. Your structural base needs to extend below frost line depth—which varies from 12 inches in Phoenix to 36 inches in Flagstaff—and account for soil bearing capacity that typically ranges from 1,500 to 3,000 PSF across Arizona’s diverse geology.

The compacted aggregate base for retention walls requires 95% modified Proctor density, not the 92% acceptable for pedestrian paving. You’ll need to specify crushed angular aggregate in 3/4-inch minus gradation, compacted in 4-inch lifts. When you encounter native soils with expansion indices above 50, your base preparation must include geogrid reinforcement every 8-12 inches vertically, tied back into the retained soil mass at depths calculated by licensed engineers.

- You must verify soil bearing capacity through geotechnical testing before finalizing base depth specifications

- Your compaction equipment needs to achieve consistent density across the full base width, not just accessible edges

- You should plan for drainage aggregate zones behind vertical elements to prevent hydrostatic pressure buildup

- Your specification must address capillary break layers between native soil and structural base materials

The interaction between base materials and paving stone units creates composite behavior that differs significantly from monolithic concrete walls. You need to understand that the paving stone retention wall base Arizona systems rely on friction and mechanical interlock rather than tensile reinforcement alone. This affects how you calculate setback ratios, which typically range from 1:12 to 1:6 depending on wall height and surcharge loads.

Thermal Mass Integration

Your vertical paving stone elements experience thermal exposure patterns completely different from horizontal surfaces. When you design paving stone structural base Arizona systems for walls, you’re dealing with materials that absorb solar radiation through vertical faces while dissipating heat through conduction into surrounding soil. This creates temperature gradients that affect dimensional stability and long-term performance.

The thermal expansion coefficient for natural stone units ranges from 4.8 to 6.2 × 10⁻⁶ per °F, which translates to approximately 0.06 inches per 10 feet of wall length over a 100°F temperature swing. You’ll see these movements occur daily in Phoenix and Yuma during summer months when wall surfaces reach 145-160°F by mid-afternoon. Your base system needs to accommodate this movement without creating structural distress or visual displacement.

What catches most designers unprepared is how thermal cycling affects base material behavior below grade. The first 18 inches of aggregate base experiences temperature variations of 30-40°F seasonally, causing volumetric changes that create settlement if not properly compacted. You should specify moisture conditioning of base aggregates to within 2% of optimum moisture content during compaction to minimize future consolidation.

Drainage System Integration

You need to design three-dimensional drainage systems for paving stone wall foundation Arizona applications, not just the two-dimensional solutions adequate for flatwork. Your drainage must address surface runoff, subsurface infiltration through wall faces, and groundwater migration from retained soil masses. This requires coordination between base preparation, core drainage zones, and outlet systems that function during intense monsoon events.

The typical Arizona monsoon delivers 1.5 to 2.5 inches of precipitation in 60-90 minute events, creating runoff conditions that exceed most municipal storm sewer design parameters. When you specify paving stone wall support systems Arizona requirements, your drainage capacity must handle these peak flows while preventing erosion of base materials. This means installing perforated collector pipes within drainage aggregate zones, connected to positive outlets that prevent ponding behind walls.

- You should position drainage aggregate zones at minimum 12 inches wide behind paving stone units, extending full wall height

- Your collector pipe diameter needs to be sized for wall length and tributary drainage area, typically 4-6 inches for residential walls

- You must provide cleanout access at pipe low points and every 40 feet horizontally for maintenance access

- Your specification should require filter fabric between drainage aggregate and native soil to prevent contamination

The permeability coefficient of your drainage aggregate must exceed 100 times that of retained soil to function effectively. You’ll achieve this with clean crushed stone in 3/4-inch to 1.5-inch sizes, installed to match or exceed hydraulic conductivity rates of 50 inches per hour. For large-scale projects, consider working with trade paver distribution networks that can coordinate delivery schedules with construction phasing.

Soil Stabilization Protocols

When you encounter expansive clay soils—present across 40% of Arizona development areas—your paving stone structural base Arizona design requires specialized stabilization treatments. These soils exhibit plasticity indices above 25 and cause vertical heave forces exceeding 3,000 PSF when moisture content increases during seasonal precipitation. You can’t simply excavate and replace without addressing the underlying soil chemistry that creates expansion behavior.

Lime stabilization provides the most cost-effective treatment for moderately expansive soils with plasticity indices between 25 and 40. You’ll need to incorporate hydrated lime at 4-8% by dry weight of soil, mixed to depths of 12-18 inches below your structural base. This chemical modification reduces plasticity index by 40-60% and increases soil bearing capacity to 2,500-4,000 PSF within 7-14 days of application. Your construction schedule must account for this curing period before placing aggregate base materials.

For highly expansive soils with PI values exceeding 40—common in areas with montmorillonite clay content—you should specify cement stabilization or complete removal to depths determined by geotechnical investigation. Cement treatment at 6-10% by weight creates a semi-rigid platform that resists expansion forces, but you must consider how this affects wall flexibility and movement accommodation. Your engineering analysis needs to evaluate whether rigid or flexible foundation systems better suit project-specific conditions.

Geogrid Reinforcement Design

You’ll integrate geogrid reinforcement into paving stone retention wall base Arizona systems when wall heights exceed 3 feet or when surcharge loads from slopes, structures, or traffic require additional stability. The geogrid selection process involves matching polymer tensile strength, junction efficiency, and soil interaction properties to calculated design loads. This isn’t a generic specification—you need to perform engineering calculations specific to each project’s geometric and loading conditions.

Typical geogrid installations for residential-scale walls use biaxial products with ultimate tensile strengths of 3,500 to 5,500 pounds per foot, reduced by factors addressing installation damage, creep, and chemical degradation. You should specify geogrid embedment lengths that extend into retained soil at minimum 60% of wall height or calculated active wedge dimensions, whichever is greater. Connection to paving stone units occurs through friction and confinement, not mechanical fasteners that create stress concentrations.

- You must position geogrid layers at vertical spacing calculated by wall height and batter angle, typically 16-24 inches on center

- Your installation sequence requires placing geogrid on compacted aggregate lifts before adding soil fill, maintaining proper tension without overstressing

- You need to verify that geogrid extends beyond potential failure planes in retained soil, usually 4-6 feet behind wall face

- Your specification should address geogrid overlap requirements at longitudinal seams, typically 24-36 inches minimum

The soil-geogrid interface develops friction through particle interlock with grid apertures. You’ll achieve optimal performance when retained soil contains less than 15% fines passing #200 sieve, with angular particle shapes that mechanically engage grid structure. When native soils don’t meet these criteria, you should specify select granular backfill in the reinforced zone extending 12 inches behind geogrid termination points.

Seismic Design Considerations

Arizona’s seismic design requirements vary significantly by location, with peak ground acceleration values ranging from 0.05g in southeastern regions to 0.15g near Flagstaff. When you develop paving stone wall support systems Arizona specifications for areas with PGA exceeding 0.10g, your structural analysis must address dynamic loading conditions that create temporary increases in lateral earth pressure. These seismic increments add 20-40% to static design loads during ground motion events.

The flexibility inherent in segmental paving stone systems provides advantages over rigid concrete walls during seismic events. You’re designing structures that can accommodate differential movement and recover from temporary deformation without catastrophic failure. However, this requires proper base preparation that prevents rotation or sliding at the wall foundation interface. Your design must satisfy both static factor of safety requirements—typically 1.5 for sliding and 2.0 for overturning—and seismic stability criteria defined by local building codes.

You should consider how wall batter angle affects seismic performance. Walls constructed with 6-12 degree setback from vertical develop passive resistance that helps counteract dynamic loads. This setback also shifts the center of gravity toward the retained soil mass, improving overturning resistance. Your calculations need to account for vertical ground motion components that can temporarily reduce effective soil weight and friction capacity by 15-25% during peak acceleration phases.

Installation Sequencing Protocols

Your construction phasing for paving stone vertical integration Arizona projects determines whether design assumptions translate to field performance. You need to establish installation sequences that maintain proper alignment, achieve specified compaction, and integrate drainage components without creating weak planes or uncompacted zones. This requires detailed coordination between excavation, base placement, unit installation, and backfill operations.

The critical mistake occurs when contractors rush backfill operations, placing material faster than compaction equipment can properly densify. You should specify maximum lift thickness of 8 inches loose measurement for mechanical compaction, reduced to 6 inches within 3 feet of wall backs where equipment access becomes restricted. Each lift requires minimum 4 passes with plate compactors rated 3,000-5,000 pounds centrifugal force, or roller compactors appropriate for confined space operations.

- You must establish base elevation benchmarks at 25-foot intervals along wall alignment before beginning aggregate placement

- Your inspection protocol needs to verify compaction density through nuclear density testing or equivalent methods every 500 square feet

- You should require proof rolling of completed base sections with loaded trucks or vibratory rollers before accepting base preparation

- Your schedule must prevent base material degradation during extended exposure to weather before wall construction proceeds

Temperature constraints affect installation windows throughout Arizona. You’ll encounter ambient conditions exceeding 105°F during summer months in lower elevation cities, creating handling difficulties and accelerated moisture loss from base materials. Your specification should restrict installation operations when temperatures exceed 110°F, requiring early morning or evening work schedules that maintain material workability and installer safety. Warehouse coordination becomes critical for managing material deliveries that match adjusted construction schedules.

Material Durability Factors

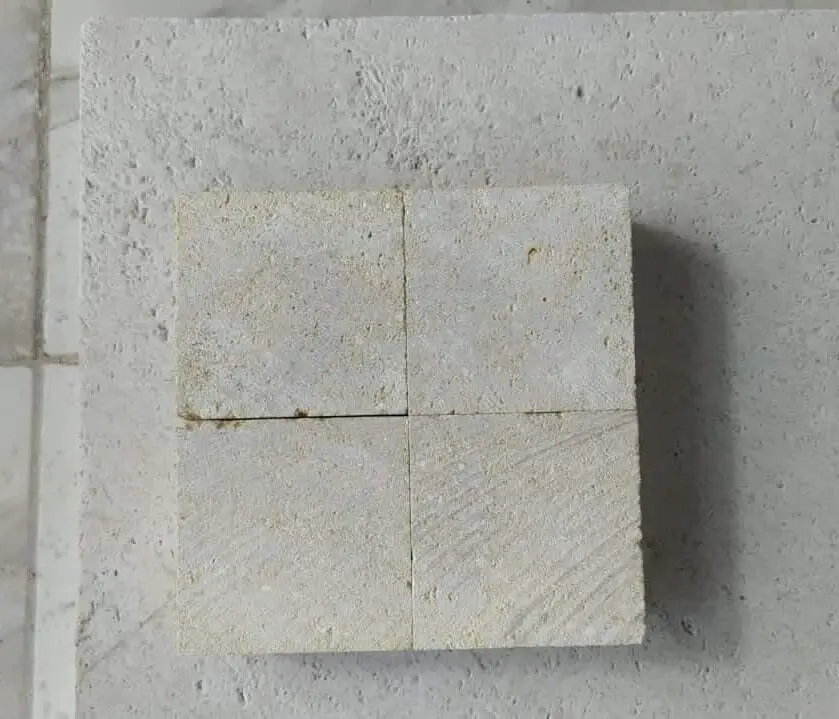

When you select paving stone units for vertical applications in Arizona, you’re evaluating different performance criteria than horizontal installations. Your materials face continuous UV exposure on wall faces, thermal cycling through full thickness dimensions, and moisture penetration through joints that lack the confined compaction present in pedestrian surfaces. The absorption rate specification becomes particularly critical, as units with porosity exceeding 6% experience freeze-thaw damage in northern Arizona locations.

Compressive strength requirements for retention wall units typically range from 8,000 to 10,000 PSI minimum, higher than the 6,000 PSI adequate for paving applications. You need this additional capacity because vertical elements experience concentrated bearing stresses at unit-to-unit interfaces, without the distributed support provided by continuous bedding layers. Your material specification should also address dimensional tolerances of ±1/8 inch maximum variation, as cumulative tolerances over wall height create alignment problems visible in finished installations.

The coefficient of thermal expansion becomes significant when you specify materials for walls with continuous runs exceeding 20 feet without control joints. Natural stone products exhibit coefficients ranging from 4.0 to 7.0 × 10⁻⁶ per °F depending on mineralogy, while concrete units typically measure 5.0 to 6.0 × 10⁻⁶ per °F. You should calculate expected thermal movement and provide control joints at spacing that prevents stress accumulation from causing joint opening or unit cracking.

Quality Control Verification

Your inspection program for paving stone retention wall base Arizona installations needs to verify compliance at multiple construction stages, not just final completion. You should establish hold points for base elevation confirmation, compaction testing, drainage system installation, and geogrid placement before allowing work to proceed. This phased verification prevents problems from becoming buried and inaccessible for correction.

Base elevation accuracy directly affects wall alignment and batter angle consistency. You’ll need to verify that excavated subgrade and compacted base surfaces match design grades within ±1/2 inch over 10-foot spans. This requires systematic surveying using laser levels or total station instruments, with documentation at grid intersections spaced maximum 10 feet apart. When you discover elevation deficiencies, correction must occur through additional compacted lifts, not by adjusting subsequent wall course heights which compromise structural performance.

- You should conduct nuclear density testing or sand cone testing at minimum three locations per 500 square feet of base area

- Your drainage system inspection needs to verify pipe grades, outlet function, and aggregate zone dimensions before backfill placement

- You must document geogrid installation with photographs showing proper embedment, spacing, and overlap details

- Your final inspection should include survey verification of completed wall alignment, batter angle, and top-of-wall elevations

The compaction verification process requires understanding moisture-density relationships for specified aggregate materials. You’ll find that many crushed stone products achieve maximum density at 4-6% moisture content, requiring field adjustment through water addition during hot, dry conditions typical of Arizona summers. Your specification should require contractors to demonstrate through test strips that equipment and methods can achieve 95% modified Proctor density before beginning production work.

Citadel Stone — Paver Stone Supply in Arizona Regional Guidance

When you evaluate Citadel Stone’s paver stone supply in Arizona for your retention wall projects, you’re considering materials engineered specifically for Southwest climate extremes and vertical application demands. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse geographic zones, from low desert valleys to high plateau regions. This section outlines how you would approach material selection and specification decisions for six representative cities, addressing climate variables that affect paving stone wall foundation Arizona performance.

Your material selection process should account for elevation-dependent temperature ranges, precipitation patterns, soil conditions, and seismic design requirements specific to each project location. The paving stone structural base Arizona requirements vary significantly between Phoenix’s low desert environment and Flagstaff’s high-elevation conditions, requiring you to adjust specifications for local geology and climate exposure. You would need to coordinate with geotechnical engineers familiar with regional soil behaviors and structural engineers licensed in Arizona for projects exceeding basic residential-scale applications.

Phoenix Heat Management

In Phoenix, you would encounter extreme thermal conditions with summer temperatures regularly exceeding 115°F and wall surface temperatures reaching 155-165°F during peak afternoon exposure. Your paving stone retention wall base Arizona specification would need to address thermal expansion movement of 0.08-0.10 inches per 10 feet of wall length over daily temperature cycles. You should specify control joints every 15-20 feet horizontally and select materials with proven performance in continuous high-heat exposure. The caliche-cemented soil layers common throughout Phoenix require mechanical excavation equipment and affect drainage design, as these layers create perched water conditions during monsoon events. You would coordinate material deliveries during early morning hours when ambient temperatures allow proper handling and installation procedures.

Tucson Soil Considerations

Your Tucson applications would address expansive clay soils prevalent across the metropolitan area, requiring specialized base preparation including lime or cement stabilization. You should specify geotechnical investigation to depths of 8-10 feet below wall foundations to identify expansion potential and recommend treatment protocols. The paving stone wall support systems Arizona requirements in Tucson include deeper embedment for taller walls due to lower soil bearing capacities in untreated native materials. You would need to account for monsoon precipitation patterns that deliver 6-8 inches of rainfall in July-September period, designing drainage systems with capacity for 2-inch hourly intensities. Material selection should favor units with absorption rates below 4% to minimize moisture-related dimensional changes in clay-bearing soils.

Scottsdale Design Integration

When you plan Scottsdale installations, you’re typically working within high-end residential and commercial contexts requiring superior aesthetic finishes and long-term performance. Your paving stone vertical integration Arizona specifications would emphasize dimensional precision, color consistency, and detailed drainage system integration that prevents efflorescence and staining on wall faces. You should coordinate with landscape architects early in design development to establish wall alignments, batter angles, and cap details that integrate with overall site design intent. The predominantly decomposed granite soils in Scottsdale areas provide good bearing capacity but require proper compaction verification to prevent long-term settlement. You would specify materials that maintain color stability under intense UV exposure typical of desert environments, verifying fade resistance through accelerated weathering test data.

Flagstaff Freeze-Thaw Design

Your Flagstaff projects would address freeze-thaw cycling that occurs 80-120 times annually, requiring materials with absorption rates below 3% and verified resistance to ASTM C1262 testing protocols. You should specify paving stone wall foundation Arizona systems with frost footings extending 36-42 inches below finish grade, deeper than lower elevation locations. The volcanic soils common in Flagstaff areas provide excellent drainage characteristics but require proper gradation analysis to ensure compatibility with specified aggregate base materials. You would need to design drainage systems that prevent ice lens formation behind wall faces during winter months when temperatures drop below 20°F for extended periods. Material selection should emphasize dense, low-porosity units with proven performance in severe freeze-thaw environments, coordinating specifications with manufacturers who provide technical data specific to ASTM standards.

Sedona Aesthetic Requirements

In Sedona, you would navigate strict design review requirements that emphasize natural material integration and color compatibility with red rock landscapes. Your paving stone structural base Arizona specifications would need to address sloped site conditions typical of Sedona terrain, requiring stepped wall configurations and enhanced drainage systems. You should select materials with earth-tone colorations and textured finishes that satisfy community design guidelines while meeting structural performance requirements. The rocky substrate conditions in many Sedona locations require careful excavation planning to achieve proper base preparation without excessive blasting or removal costs. You would coordinate closely with local building departments regarding height restrictions, setback requirements, and retaining wall permit procedures specific to Sedona’s hillside development regulations.

Yuma Extreme Conditions

Your Yuma applications would address the most extreme heat conditions in Arizona, with summer temperatures exceeding 120°F and minimal annual precipitation of 3-4 inches. You should specify paving stone retention wall base Arizona systems with enhanced thermal movement accommodation, including control joints every 12-15 feet and materials selected for dimensional stability under continuous high-temperature exposure. The sandy soils prevalent in Yuma areas provide excellent drainage but limited bearing capacity, requiring you to specify larger base footprints or mechanical stabilization for walls exceeding 4 feet in height. You would need to address dust control during construction operations and coordinate material storage to prevent sun damage to polymer-based components. The low humidity environment creates rapid moisture loss from freshly placed materials, requiring you to specify fog misting during installation and curing periods.

Long-Term Maintenance Planning

When you design paving stone wall support systems Arizona installations, your responsibility extends beyond construction completion to include maintenance program development. You should provide owners with clear guidance regarding inspection frequencies, cleaning protocols, drainage system maintenance, and joint repair procedures that preserve structural performance over design service life. The typical retention wall requires annual inspection of drainage outlets, joint condition, and alignment verification to identify problems before they compromise stability.

Your maintenance specification should address joint sand replenishment for installations using polymeric or conventional sand products. You’ll find that Arizona’s intense UV exposure and wind erosion remove approximately 5-10% of joint material annually in exposed locations, requiring periodic reapplication to maintain interlock and prevent unit movement. The procedure involves cleaning joints to 1-inch depth, installing replacement material, and compacting with appropriate tools that don’t damage paving stone surfaces.

Drainage system maintenance becomes critical for long-term performance in paving stone retention wall base Arizona applications. You need to establish inspection protocols that verify collector pipe function, cleanout access, and outlet discharge capacity before each monsoon season. When drainage systems fail due to sediment accumulation or root intrusion, hydrostatic pressure develops behind walls within hours during storm events, creating lateral loads exceeding design capacity. Your maintenance program should include provisions for video inspection of drainage pipes every 5 years and cleanout procedures using water jetting equipment.

Cost Optimization Strategies

You can reduce project costs without compromising performance by optimizing wall geometry, material selection, and construction sequencing. Your design decisions regarding wall height, batter angle, and geogrid reinforcement create cost implications that vary by 30-50% between conservative and optimized approaches. When you work with geotechnical and structural engineers during design development rather than after design completion, you’ll identify opportunities for value engineering that maintain safety factors while reducing material quantities.

The base material specification represents 25-35% of total wall system cost for typical installations. You should evaluate local aggregate sources for crushed stone meeting gradation and durability requirements at competitive pricing. Transportation costs often exceed material costs when you specify products from distant quarries, making local sourcing evaluation an important cost control measure. Your specification should allow approved equal substitutions that meet performance criteria rather than limiting bidding to single-source suppliers without engineering justification.

- You can reduce excavation costs by 15-25% through accurate surveying that minimizes over-excavation and waste disposal

- Your geogrid selection should match calculated design loads rather than defaulting to maximum strength products that exceed requirements

- You should coordinate drainage system installation with wall construction to minimize mobilization costs for specialized crews

- Your construction schedule optimization reduces financing costs and accelerates project completion for earlier beneficial use

Material waste management affects both cost and environmental impact of paving stone vertical integration Arizona projects. You’ll typically experience 3-5% breakage and cutting waste during installation, increasing to 8-12% for complex geometries with frequent direction changes or radius walls. Your quantity calculations should include appropriate waste factors while establishing protocols for salvaging usable cut pieces and recycling broken units. Many suppliers accept clean concrete product returns for aggregate recycling, reducing disposal costs and landfill impacts.

Final Considerations

Your professional specification process for paving stone wall foundation Arizona systems requires integrating multiple technical disciplines including geotechnical engineering, structural design, drainage analysis, and material science. You need to recognize that successful installations result from coordinated design efforts that address site-specific conditions rather than applying generic details without engineering analysis. The complexity increases with wall height, surcharge loads, and challenging soil conditions that demand specialized expertise beyond basic residential applications.

When you prepare contract documents, your specifications should clearly establish performance requirements, material standards, installation procedures, and quality control protocols that contractors must satisfy. This documentation protects all parties by defining measurable acceptance criteria and eliminating ambiguity regarding design intent. You should require pre-construction meetings that review critical installation sequences, verify material submittals, and confirm that contractors understand specialized procedures unique to paving stone retention wall base Arizona construction. For detailed installation insights on related applications, review Durable paving stone materials for residential gate entry designs before finalizing your project documents. Permeable options come from Citadel Stone’s eco-friendly synthetic stone pavers in Arizona systems.