When you manage paving stone installations across Arizona’s climate extremes, you’ll encounter unique repair challenges that demand specialized approaches. Your repair strategy needs to address thermal cycling that exceeds 60°F daily variation, UV exposure that degrades joint materials within 18-24 months, and soil movement patterns that create settlement issues standard leveling methods can’t resolve. Understanding how paving stone repair services Arizona professionals approach these conditions helps you maintain installations that would otherwise fail within 5-7 years.

Arizona’s environment accelerates damage mechanisms you won’t see in temperate climates. You’re dealing with thermal expansion that creates progressive joint degradation, subsurface erosion from monsoon events that undermines base stability, and efflorescence patterns that indicate deeper moisture migration problems. Professional paving stone repair services Arizona teams recognize these aren’t cosmetic issues — they’re symptoms of system-level failures requiring comprehensive intervention.

Crack Repair Protocols Arizona

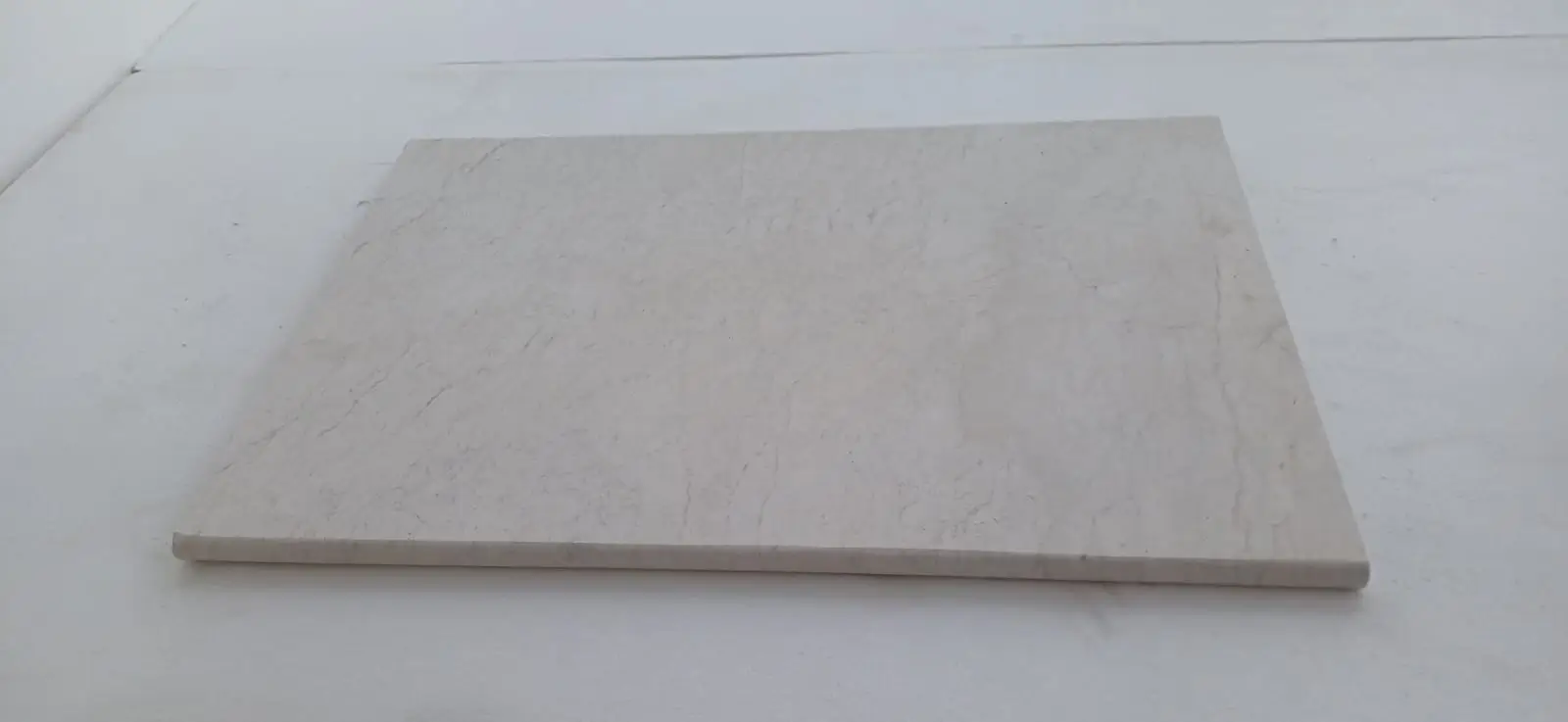

You need to distinguish between structural cracks and surface crazing before you select repair methods. Structural cracks penetrate through the paver thickness and typically originate from base failure or point load concentration. Surface crazing affects only the top 3-8mm and results from freeze-thaw cycling in elevation zones above 4,500 feet or thermal shock from rapid temperature changes. Your repair approach depends entirely on accurate diagnosis.

When you address structural cracks, epoxy-based repair systems designed for outdoor stone applications provide bond strengths exceeding the parent material’s tensile strength. You’ll need products with shore hardness ratings between 75-85D and thermal expansion coefficients matching natural stone at 5.0-5.5 × 10⁻⁶ per °F. Application requires surface preparation that removes all loose material and creates clean substrate contact — moisture content must measure below 4% for proper adhesion.

Your crack filling technique affects long-term performance more than product selection. You should route cracks to minimum 1/4″ width and 1/2″ depth using diamond grinding tools, creating mechanical interlock that supplements chemical bonding. Fill depth needs to reach sound material below the crack terminus. Partial-depth fills inevitably fail within 12-18 months as thermal cycling propagates the original crack pattern beneath the repair.

Surface crazing repair uses different chemistry. You’ll achieve better results with penetrating sealers that contain reactive siliconate or silane compounds rather than film-forming products. These materials penetrate 2-5mm depth and create subsurface consolidation that arrests crack progression. Application timing matters — you need to apply during temperature windows between 60-85°F when stone porosity facilitates maximum penetration.

Leveling Techniques Settlement

Settlement patterns in Arizona installations follow predictable failure modes based on soil type and base construction methods. You’ll encounter three primary scenarios: uniform settlement affecting large areas, differential settlement creating trip hazards at transitions, and edge zone subsidence along boundaries where base confinement fails. Each condition requires specific leveling approaches.

For uniform settlement affecting areas larger than 50 square feet, you need to remove and relay pavers with base reconstruction. Attempting to level by adding sand beneath individual units creates unstable conditions that accelerate future settlement. Your base evaluation should measure both density and moisture content — compaction below 95% Proctor density or moisture variance exceeding ±2% indicates you need full base remediation.

- You should verify base aggregate gradation matches ASTM D448 specifications for size numbers 57 or 67

- Your compaction process requires mechanical plate compactors delivering minimum 5,000 pounds force for 4-6″ lifts

- You need to establish positive drainage gradients of 2% minimum even in areas specified as level

- Edge restraint systems must resist lateral movement under 1,500 pounds per linear foot loading

Differential settlement creating 1/4″ or greater elevation changes demands immediate intervention. These transitions concentrate pedestrian traffic stress and accelerate adjacent unit degradation. Your leveling approach involves removing affected pavers, adding properly graded bedding sand in controlled lifts, and re-establishing screeded elevations. You can’t simply force pavers upward with sand injection — this creates voids that collapse under traffic within weeks.

Edge zone failures require you to address both vertical settlement and horizontal displacement. You’ll often find base material has migrated laterally beyond the edge restraint, leaving voids beneath perimeter pavers. Successful paving stone leveling services Arizona repairs install secondary confinement using buried edge restraints or excavated trenches filled with lean concrete. Standard plastic edging rarely provides sufficient restraint in Arizona’s expansive soil conditions.

Restoration Methodology Weathering

Weathering damage in Arizona manifests differently than coastal or industrial environments. You’re addressing UV degradation that affects pigmented concrete pavers, surface erosion from wind-driven sand abrasion, and chemical alteration from alkaline soil contact. Your restoration strategy needs to reverse visible damage while preventing recurrence through protective treatments.

Surface cleaning precedes all restoration work. You need to remove accumulated salts, organic staining, and weathered surface material without damaging sound substrate. Pressure washing at 1,200-1,800 PSI with 15° fan tips provides adequate cleaning force while avoiding surface erosion. Chemical cleaning agents should target specific contaminants — acidic cleaners for mineral deposits, alkaline cleaners for organic staining. You must neutralize all chemical residues before applying restoration treatments.

When you evaluate color restoration options for faded pavers, you’ll choose between penetrating stains and film-forming coatings. Penetrating systems provide 5-8 year service life with minimal surface build-up but offer limited color correction capacity. Film-forming products deliver superior color enhancement but require reapplication every 3-4 years and create slip resistance concerns. Your selection depends on whether you prioritize longevity or aesthetic improvement.

Surface consolidation treatments address erosion damage affecting concrete and natural stone pavers. You should specify silicate-based consolidants that react with calcium hydroxide in concrete or silane/siloxane blends for natural stone. Application requires flooding the surface to refusal, allowing 24-hour reaction time, and removing excess material before it creates surface glazing. Proper consolidation increases surface hardness by 15-25% as measured by Mohs scratch testing.

Joint Stabilization Requirements

Joint material failure represents the most common maintenance issue you’ll encounter in Arizona paving installations. Standard silica sand experiences 40-60% loss within the first 18 months due to wind scour, irrigation washout, and weed growth displacement. Your joint stabilization approach determines whether you’re performing annual maintenance or achieving 5+ year service intervals.

Traditional polymeric sand products perform inconsistently in Arizona conditions. You need formulations specifically designed for high-UV environments with polymer chemistry that remains flexible across 140°F temperature ranges. Product specifications should confirm polymer content between 8-12% by weight — lower percentages provide insufficient binding, higher percentages create brittle joints that crack during thermal cycling.

Your installation technique affects polymeric sand performance as much as product selection. You must fill joints completely to within 1/8″ of paver surface, compact using plate compactors with protective pads, and activate with precise water application. Underwatering leaves unbound sand at depth that washes out through bottom of joints. Overwatering dilutes polymers and creates surface hazing that requires mechanical removal.

For high-performance applications, you should consider polyurea-based joint stabilization systems. These two-component materials cure through chemical reaction rather than water activation, providing superior bond strength and UV resistance. Application requires specialized equipment and costs 3-4 times more than polymeric sand, but service life extends to 8-12 years in Arizona exposure conditions. You’ll find this approach cost-effective for commercial installations where annual maintenance disrupts business operations.

Base Failure Diagnosis

You can’t effectively repair surface symptoms without addressing underlying base deficiencies. Visual inspection reveals settlement patterns, but you need subsurface investigation to determine failure mechanisms. Your diagnostic process should include test excavations at representative failure locations, base material sampling for gradation analysis, and moisture content measurement at multiple depths.

When you excavate test pits, you’re looking for specific failure indicators. Uniform base material with consistent gradation but poor compaction suggests installation errors. Segregated material with fines accumulated at depth indicates water infiltration and migration. Missing base material with voids beneath pavers confirms erosion from subsurface water movement. Each condition requires different remediation approaches.

Soil conditions beneath the base layer drive long-term performance. Arizona’s expansive clays create cyclical heaving that no base design can completely isolate. You need to determine plasticity index of underlying soils — PI values above 25 indicate high expansion potential requiring soil stabilization or removal and replacement. Standard geogrid reinforcement provides minimal benefit in highly plastic soil conditions.

Your base reconstruction specifications should address the specific failure mechanism identified. For compaction failures, you’ll re-compact existing material in thinner lifts with proper moisture conditioning. For gradation problems, you need to remove contaminated base and install fresh aggregate meeting specification gradation. For erosion damage, you must establish positive drainage and potentially install subsurface drainage systems before reconstructing the base.

Thermal Damage Assessment

Arizona’s extreme thermal cycling creates damage patterns you won’t find in moderate climates. Daily temperature swings from 50°F predawn to 110°F afternoon generate expansion and contraction cycles that stress paver joints, crack weak units, and displace edge restraints. Your damage assessment needs to distinguish between thermal effects and other failure modes.

Joint widening at mid-panel locations with corresponding compression at edges indicates thermal movement exceeding original joint spacing capacity. You’ll measure this by comparing joint widths in early morning versus afternoon — variance exceeding 1/16″ confirms thermal displacement as primary mechanism. Your repair requires either expansion joint installation at 15-foot intervals or complete relay with increased joint spacing.

Crack patterns radiating from paver corners suggest thermal stress concentration. These typically appear in darker colored units that experience greater temperature differentials. Surface temperatures on charcoal pavers regularly reach 160-170°F during summer afternoons, creating thermal gradients through the unit thickness that generate internal stress. You can’t repair these cracks permanently — you need to replace affected units with lighter colors that reduce thermal absorption.

Edge restraint displacement from thermal forces requires upgraded confinement systems. Standard plastic edging provides minimal resistance to the 300-500 pounds per linear foot lateral forces generated during thermal expansion. You should specify concrete edge beams or steel restraints capable of resisting these forces without displacement. Proper installation includes below-grade placement at 8-10″ depth where soil confinement provides additional resistance.

Moisture Related Deterioration

You might assume Arizona’s arid climate minimizes moisture damage, but irrigation systems, monsoon events, and subsurface water create significant deterioration. Your moisture assessment should identify source, migration pathways, and resulting damage mechanisms before you select repair approaches.

Efflorescence appearing as white crystalline deposits indicates water movement through the paver bringing dissolved salts to the surface. You need to determine whether moisture originates from surface infiltration, subsurface wicking, or lateral migration from adjacent landscaping. Surface cleaning removes visible deposits but doesn’t address the underlying moisture problem — efflorescence will reappear within 3-6 months without source control.

- You should verify drainage gradients direct water away from paved areas rather than toward them

- Your irrigation systems need adjustments to eliminate overspray onto paved surfaces

- You must establish vapor barriers between base and subgrade in areas with high water tables

- Edge drainage systems should intercept lateral moisture migration from planted areas

Spalling and surface scaling from freeze-thaw damage affects elevation zones above 5,000 feet. Water absorbed into paver porosity expands upon freezing, creating internal pressure that exceeds tensile strength. You’ll see progressive deterioration where surface layers separate in thin sheets. Your repair options are limited — affected pavers require replacement with lower porosity units rated for freeze-thaw exposure.

Subsurface erosion from water migration beneath the base creates settlement patterns that follow drainage flow paths. You’ll identify these by excavating settlement areas and finding voids aligned with grade direction. Repair requires establishing positive subsurface drainage using perforated pipe in gravel-filled trenches before reconstructing the base and pavers.

Fixing Techniques Field Proven

Professional paving stone fixing techniques Arizona applications rely on methods proven through thousands of square feet of installations rather than manufacturer claims. You’ll achieve reliable results by following protocols that account for material behavior in actual service conditions.

When you reset individual pavers that have cracked or spalled, your success depends on addressing why the original unit failed. Simply replacing the paver without correcting base support, drainage, or load concentration recreates the same failure. Your investigation should determine whether failure resulted from manufacturing defects, improper installation, or service conditions exceeding design parameters.

For crack repairs in natural stone pavers, you need to evaluate whether cracks follow natural veining or cross grain structure. Cracks along veining patterns indicate the stone was improperly oriented during installation — bedding planes should run horizontally, not vertically through the unit thickness. These pavers require replacement with properly oriented units. Cracks crossing grain structure suggest impact damage or point load concentration requiring base correction.

Lippage correction where adjacent pavers show vertical displacement requires more than surface grinding. You need to remove high units, verify base elevation is correct, and reinstall with proper bedding. Grinding paver surfaces to eliminate lippage removes protective surface layer and accelerates weathering. Maximum acceptable grinding depth is 1/16″ — anything greater requires removal and proper releveling.

UV Protection Strategies

Arizona’s intense UV exposure at 3,000-7,000 foot elevations degrades unprotected materials faster than coastal or lower elevation locations. You’re managing UV radiation levels 15-20% higher than sea level, creating accelerated polymer breakdown, color fading, and surface chalking. Your protection strategy needs to account for this enhanced exposure.

Polymeric joint materials require UV stabilizer packages specifically formulated for high-altitude exposure. Standard formulations designed for temperate climates fail within 24-30 months in Arizona conditions. You should specify products with UV stabilizer content exceeding 2% by weight and confirmed field performance in similar exposure conditions. Manufacturer testing data should include ASTM G155 xenon arc exposure results demonstrating minimal color change after 2,000 hours.

When you apply protective sealers to paver surfaces, UV resistance of the sealer itself determines service life. Acrylic-based sealers typically survive 18-24 months before requiring reapplication. Polyurethane formulations extend this to 36-48 months. Fluoropolymer-modified sealers provide 5-7 year performance but cost 4-5 times more than standard acrylics. Your selection balances initial cost against long-term maintenance frequency and disruption.

Color retention in concrete pavers depends on pigment selection and dosage rates. You’ll find iron oxide pigments provide superior UV stability compared to organic colorants. Integral color concrete with pigment dosage rates at 5-7% of cement weight shows minimal fading over 10+ year exposure. Surface-applied color hardeners at lower dosage rates fade noticeably within 3-5 years, requiring restoration treatments to maintain appearance.

Professional Repair Assessment

You need systematic evaluation protocols to determine whether repairs are feasible or replacement is necessary. Your assessment should quantify damage extent, identify failure mechanisms, and evaluate cost-effectiveness of repair versus replacement options.

Damage quantification starts with measuring affected area as percentage of total installation. When damage exceeds 30% of the paved area, replacement typically provides better long-term value than extensive repairs. You should calculate square footage requiring intervention, estimate material and labor costs for repair, and compare against new installation pricing. Include future maintenance costs in your analysis — repaired installations often require more frequent maintenance than complete replacement.

Failure mechanism identification determines whether repairs will provide lasting solutions or temporary fixes. Systemic problems like inadequate base thickness, poor drainage design, or inappropriate material selection for site conditions will continue causing damage regardless of repair quality. You need honest assessment of whether root causes can be corrected within repair scope or whether design deficiencies require complete reconstruction.

When you evaluate repair feasibility for paving stone crack repair Arizona projects, you should consider whether matching replacement materials remain available. Discontinued product lines, color lot variations, and manufacturer changes create matching challenges that affect appearance uniformity. Perfect repairs of individual units within otherwise sound installations make sense. Extensive repairs requiring 40+ units often show visible color and texture variations that diminish overall appearance quality.

Installation Errors Correction

You’ll frequently encounter damage caused by installation errors rather than material deficiencies or environmental factors. Your correction approach needs to address these errors without creating additional problems.

Insufficient bedding sand depth represents the most common installation error. You’ll find this where pavers rock when walked on or where joints have widened irregularly. Proper bedding sand depth should measure 1″ after compaction — installations with 1/2″ or less create point contact between pavers and base rather than uniform support. Correction requires complete removal, proper sand placement at 1-1/4″ loose depth, screeding to uniform elevation, and reinstallation.

- You need to verify bedding sand meets ASTM C33 fine aggregate gradation requirements

- Your sand should contain zero percent passing the #200 sieve to prevent cement formation

- You must confirm sand remains loose and uncompacted before paver placement

- Bedding layer thickness should measure uniform across entire installation area

Improper joint spacing creates both aesthetic and functional problems. Joints narrower than 1/16″ prevent adequate sand interlock and create crack initiation points. Joints wider than 3/16″ allow excessive movement and accelerate sand loss. Your correction involves removing and reinstalling pavers with proper spacing tools — this often requires removing edge restraints and reestablishing proper panel dimensions.

Missing or inadequate edge restraint allows lateral creep that progressively widens joints and creates perimeter displacement. You can’t correct this by simply reinstalling displaced edge pavers. You need to install proper edge restraint systems, remove all affected pavers, re-compact base, and reinstall entire perimeter zone. Half-measures that address only visible displacement leave underlying deficiencies that cause rapid failure recurrence.

Chemical Damage Remediation

Chemical exposure in Arizona comes primarily from pool treatments, landscape fertilizers, and alkaline soil contact rather than industrial sources. You need to identify specific chemical agents before selecting remediation approaches.

Pool chemical damage appears as surface etching, color bleaching, and accelerated weathering in pavers surrounding pools and spas. Chlorine concentrations above 5 ppm aggressively attack concrete and many natural stones. Your remediation starts with eliminating the exposure source through improved drainage, equipment modification, or owner education. Surface damage requires grinding to remove affected material followed by sealing to prevent future exposure.

Fertilizer staining creates brown or rust-colored discoloration from iron compounds in lawn treatments. You’ll encounter this where granular fertilizer contacts wet pavers and dissolves, leaving concentrated chemical contact. Removal requires acidic cleaning agents specifically formulated for rust stain removal — oxalic acid or ammonium bifluoride compounds at 5-10% concentration. You must neutralize acid residues with alkaline rinse before sealing to prevent ongoing stone degradation.

Efflorescence from alkaline soil contact requires source control through moisture management. Surface cleaning removes visible deposits but you need to address water migration that transports dissolved salts. Your remediation includes establishing positive drainage, applying penetrating water repellents to reduce moisture absorption, and potentially installing vapor barriers between soil and pavement system.

Paving Stone Suppliers Arizona: Citadel Specification Guidance

When you consider Citadel Stone’s wholesale paver supply for paving stone restoration Arizona projects, you’re evaluating materials designed for extreme climate performance and repair compatibility. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, helping you understand how material selection affects long-term repair requirements. This section outlines how you would approach specification decisions for six representative cities, considering climate factors that impact paving stone repair services Arizona professionals encounter daily.

Your material selection directly affects future repair frequency and complexity. Dense, low-porosity pavers resist moisture-related deterioration but concentrate thermal stress. Higher porosity units accommodate thermal movement better but increase freeze-thaw vulnerability at elevation. You need to balance these competing factors based on specific site conditions rather than applying generic specifications across all locations.

Phoenix Extreme Heat

In Phoenix, you would encounter the most severe thermal conditions in Arizona, with pavement surface temperatures reaching 170°F during summer months. Your material specifications should prioritize light colors that reduce solar absorption by 35-40% compared to charcoal tones. You need to plan for thermal expansion joints every 12-15 feet to accommodate the 0.18″ linear expansion occurring across 20-foot panels during peak heating cycles. Repair services in this environment would focus heavily on joint material replacement every 24-30 months and thermal crack repair in darker colored installations.

Tucson Desert Performance

Tucson’s slightly lower elevation and monsoon moisture patterns create different repair challenges. You would specify materials with porosity ratings between 3-5% to balance drainage requirements against efflorescence potential. Your installation design should incorporate positive drainage gradients of 2.5% minimum to handle intense short-duration rainfall events that deliver 1-2 inches within 30 minutes. Typical paving stone leveling services Arizona applications in this region would address settlement from base erosion where drainage design proves inadequate, requiring subsurface drainage installation during repair.

Scottsdale Premium Installations

Your Scottsdale specifications would emphasize aesthetic durability for high-end residential and resort applications. You should select materials with demonstrated color retention over 10+ year exposure, requiring UV stabilizer packages in both pavers and joint materials. Edge restraint systems would need architectural integration while providing lateral resistance exceeding 2,000 pounds per linear foot. Restoration services in this market would focus on maintaining like-new appearance through periodic sealing, joint material refresh, and individual unit replacement to address any visible imperfections.

Flagstaff Freeze-Thaw

At 7,000 feet elevation, you would encounter freeze-thaw cycling that requires completely different material specifications. Your paver selection must verify ASTM C1645 compliance with absorption rates below 3% and successful completion of 50 freeze-thaw cycles without degradation. You need to specify polymeric joint materials formulated for freeze-thaw resistance with laboratory testing confirming flexibility at -10°F. Repair protocols would include spring assessment for spalling damage and proactive replacement of units showing surface scaling before deterioration progresses through full thickness.

Sedona Color Coordination

Sedona’s red rock landscape creates unique aesthetic requirements where you would coordinate paver colors with natural surroundings. Your specifications should address iron oxide staining from local soils, requiring either stain-resistant materials or acceptance of patina development. Elevation at 4,500 feet creates moderate freeze-thaw exposure requiring materials rated for 20-30 annual cycles. Professional paving stone fixing techniques Arizona experts would apply in this environment would emphasize natural appearance retention while addressing weathering that affects color uniformity over time.

Yuma Alkali Soils

Your Yuma installations would contend with highly alkaline soils and minimal freeze exposure. You should specify materials with demonstrated alkali resistance and expect efflorescence management as ongoing maintenance requirement. Surface temperatures approach Phoenix levels but with lower elevation UV exposure. Base design would address expansive clay soils common in this region, potentially requiring soil stabilization or increased base thickness to 8-10 inches. Repair services would focus on efflorescence control through improved drainage and vapor barrier installation during base reconstruction projects.

Long Term Maintenance Planning

You should develop comprehensive maintenance programs that prevent major repairs through systematic intervention. Your planning needs to account for material service life expectations, climate-specific deterioration rates, and cost-effective intervention timing.

Joint material maintenance represents the highest frequency requirement. You’ll need to plan for polymeric sand inspection every 6 months with anticipated replenishment every 24-36 months in most Arizona locations. Your maintenance specifications should include joint cleaning, weed removal, sand installation, and proper activation. Deferring this maintenance accelerates base degradation as water infiltration and soil pumping occur through open joints.

Sealer reapplication intervals depend on product type and exposure conditions. You should establish 24-month cycles for acrylic sealers, 36-month cycles for polyurethanes, and 60-month cycles for advanced fluoropolymer systems. Your application timing should avoid extreme temperatures — apply when ambient conditions range between 60-80°F for optimal curing. Surface preparation before resealing requires cleaning to remove all contaminants that prevent adhesion.

Comprehensive condition assessment every 36-48 months allows you to identify developing problems before they require major repairs. Your assessment should document joint condition, individual unit integrity, overall surface planarity, drainage function, and edge restraint security. Systematic documentation with photography creates baseline records that reveal deterioration trends requiring proactive intervention.

Final Considerations

Your approach to paving stone repair services Arizona requires understanding how climate extremes, soil conditions, and installation quality interact to create specific failure modes. You’ll achieve successful repairs by accurately diagnosing root causes rather than treating surface symptoms, selecting materials appropriate for identified exposure conditions, and following proven protocols that account for regional performance factors. Professional paving stone crack repair Arizona techniques demand precision in execution whether you’re addressing individual unit damage or system-level failures affecting entire installations. When you evaluate repair versus replacement decisions, you need honest assessment of whether interventions will provide lasting solutions or merely postpone inevitable reconstruction. For additional installation insights, review Polymeric sand stabilization methods for Arizona paver joints before you finalize your project documents. Project quantities available through Citadel Stone’s flexible bulk paver stones in Arizona sales.