When you design a paving stone gate entry features Arizona project, you’re creating the first impression visitors experience before they even reach your door. Your gate approach sets the tone for the entire property, combining functional requirements with visual impact in ways that demand careful material selection and strategic design thinking. You need to account for vehicular loads, thermal expansion in extreme heat, and aesthetic cohesion with surrounding landscape elements — all while ensuring the installation performs reliably for 20+ years.

The challenge intensifies in Arizona’s climate zones where summer surface temperatures regularly exceed 160°F and UV exposure degrades lesser materials within five years. Your paving stone entrance design Arizona requires materials that resist thermal shock, maintain dimensional stability through extreme temperature swings, and provide adequate traction during monsoon events when surfaces transition from bone-dry to saturated within minutes.

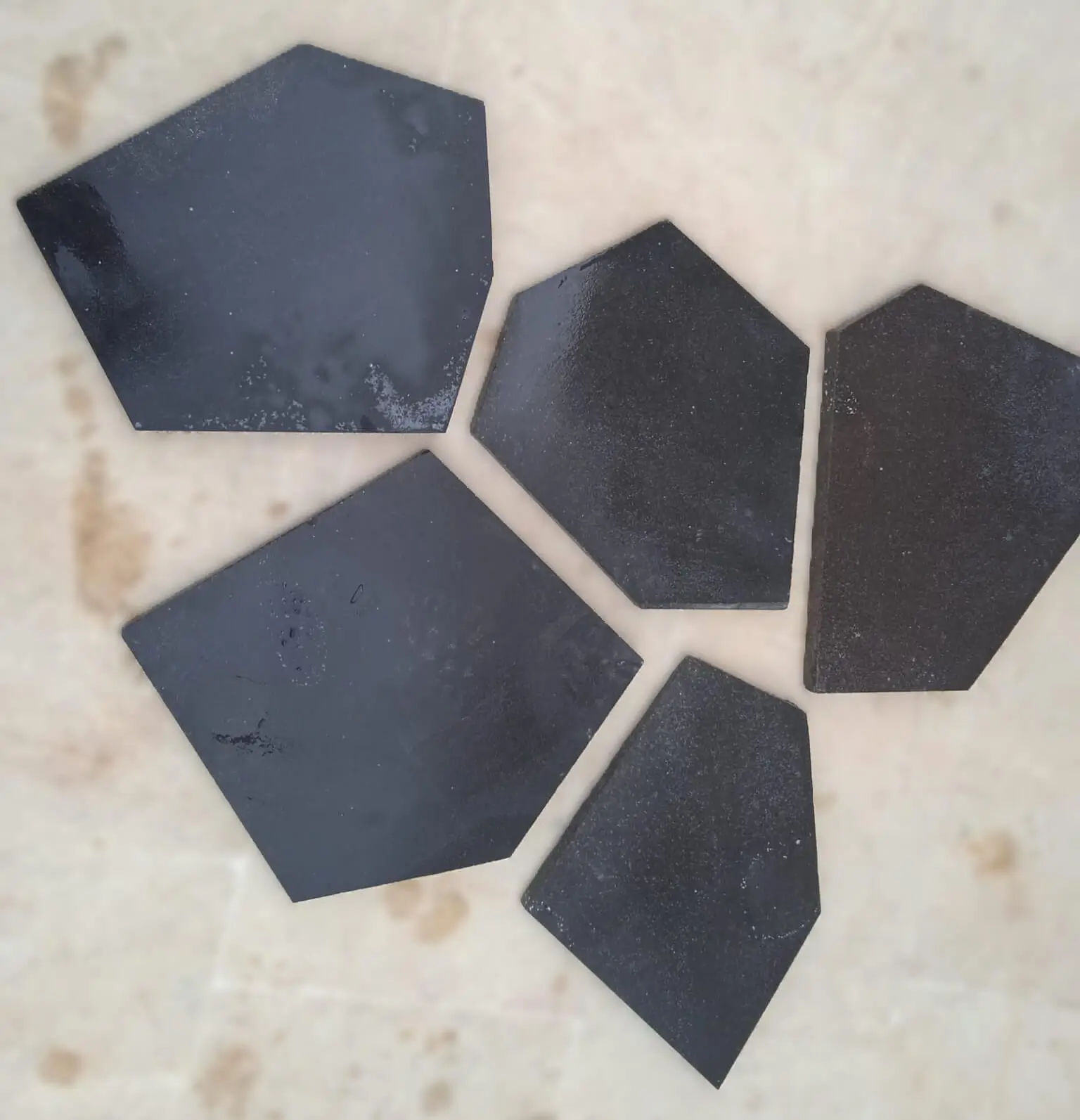

Material Performance in Gate Entry Zones

Gate entry areas experience concentrated stress that differs fundamentally from standard driveway sections. When you specify paving stone gate entry features Arizona, you’re addressing a zone where vehicles decelerate, pause, and accelerate repeatedly — creating dynamic loads that exceed typical traffic patterns by 40-60%. The material must withstand these repetitive stress cycles while maintaining visual appeal as your property’s focal point.

Thickness specifications become critical in these high-stress zones. You should specify minimum 60mm pavers for residential gate entries, increasing to 80mm for commercial applications or properties with delivery truck access. The common mistake is extending standard driveway thickness ratings into gate areas where load concentration demands additional structural capacity. Your base preparation needs to reflect these intensified requirements with 8-10 inches of compacted aggregate rather than the 6-inch minimum used in lower-stress areas.

- You need compressive strength ratings above 8,500 PSI for vehicular gate entries

- Your specification should address flexural strength minimums of 850 PSI to prevent corner breakage

- Thermal expansion coefficients between 5.1-5.5 × 10⁻⁶ per °F prevent joint separation in Arizona heat

- Porosity ratings of 4-6% balance drainage requirements with structural integrity

- Slip resistance values above DCOF 0.48 ensure safe pedestrian crossings during wet conditions

The interaction between material porosity and Arizona’s intense evaporation rates creates performance characteristics you won’t find in moderate climates. Surface moisture evaporates so rapidly that efflorescence salts concentrate in paver faces rather than flushing through to joints. You’ll see this most prominently in gate entry features where irrigation overspray or monsoon runoff introduces subsurface moisture that wicks upward through capillary action.

Thermal Mass Considerations for Entry Design

Your paving stone driveway gate area Arizona experiences solar gain differently than open driveway sections due to gate structures, pillar masses, and often overhead elements that create shade patterns. These shade transitions generate thermal gradients across the paved surface — you might see a 45°F temperature differential between full-sun areas and shaded zones during peak afternoon hours. This gradient drives differential expansion that stresses joints and can telegraph through to create visible lippage over time.

Material selection needs to account for how thermal mass behaves in these variable exposure conditions. Dense pavers with high thermal mass retain heat longer, creating evening surface temperatures 15-20°F above ambient air temperature. This extended heat retention affects landscape plantings adjacent to gate entries and influences how you position decorative elements. Lighter-colored paving stone entrance design Arizona materials reflect 60-70% of solar radiation, reducing peak surface temperatures by 25-35°F compared to dark gray or charcoal options.

The orientation of your gate entry relative to solar path creates installation planning considerations most specifications overlook. East-facing entries receive intense morning sun when material temperatures are lowest, creating rapid thermal shock. West-facing approaches endure sustained afternoon exposure that drives surface temperatures to annual peaks. You should adjust joint spacing based on entry orientation — west-facing installations require expansion joints every 12-13 feet versus 15-16 feet for north-facing approaches.

Decorative Pattern Integration Strategies

When you incorporate decorative elements into paving stone gate entry features Arizona, you’re balancing visual impact against installation complexity and long-term maintenance realities. Intricate patterns with multiple paver sizes look compelling in design renderings but introduce challenges in Arizona’s thermal environment. Each paver size exhibits slightly different expansion characteristics, and complex patterns multiply the number of joints where dimensional changes concentrate.

Your pattern selection should consider how the human eye processes the approach sequence. Drivers entering through gates focus on alignment and clearance rather than ground plane details — the decorative pattern reads most effectively for departing vehicles and pedestrian arrivals. This viewing pattern suggests concentrating decorative complexity in the 15-20 feet immediately inside the gate threshold where speeds are lowest and observation time maximizes.

- You should limit pattern designs to three paver sizes maximum for thermal stability

- Your layout needs to orient primary pattern lines perpendicular to traffic flow for visual emphasis

- Border treatments require compatible expansion rates with field pavers to prevent differential movement

- Contrasting colors should differ by minimum 15% in solar reflectance to maintain definition as surfaces weather

- Circular or radial patterns demand skilled installation crews and increase labor costs by 35-45%

The geometry of decorative borders around gate entry features interacts with structural requirements in ways that constrain design freedom. You need continuous load paths through the paved surface, which means border courses can’t simply terminate at arbitrary points for visual effect. Your structural layout drives the decorative overlay, not the reverse. Professional specifications detail how pattern elements align with base preparation zones and ensure decorative features don’t compromise load transfer capacity. For detailed logistics on material delivery timing, consider bulk paving stone delivery in Flagstaff when coordinating installation schedules with warehouse availability.

Pillar Surround Detailing Requirements

Gate pillars create concentrated point loads and thermal anomalies that affect paving stone access point design Arizona within a 4-6 foot radius. The pillar mass absorbs and radiates heat differently than horizontal paved surfaces, creating microclimate zones where material performance diverges from open areas. You’ll observe moisture accumulation on pillar-shaded pavers during early morning hours when dew point conditions exist — this localized moisture cycling affects efflorescence patterns and biological growth.

Your detailing around pillar bases needs to address both structural and drainage requirements. Pillars concentrate roof runoff and create splash zones during monsoon events. Standard joint sand washes out rapidly in these high-flow areas unless you specify polymeric joint stabilizers rated for concentrated water flow. The common specification error is treating pillar surrounds identically to field areas when they actually function as localized drainage collection points.

Thermal expansion around rigid pillar structures creates shear stresses that don’t exist in open paved fields. You should install compressible joint material between paver field and pillar perimeter, allowing 3/8-inch expansion gap. This isolation joint prevents pavers from binding against masonry during thermal expansion, which otherwise creates vertical displacement and lippage within the surrounding 3-4 courses of pavers.

Vehicle Tracking and Turning Radius Accommodation

When you layout paving stone gate entry features Arizona, you must account for how vehicles track through the gate opening and establish their approach angle to the main driveway. The swept path of turning vehicles creates concentrated wear patterns in predictable zones — typically the outer radius of the turn where tire scrubbing occurs during low-speed maneuvering. These wear zones require specification attention beyond standard traffic areas.

Your material selection for high-traffic tracking zones should emphasize abrasion resistance ratings. Standard compressive strength doesn’t correlate directly with surface abrasion resistance — you need materials tested to ASTM C1353 showing abrasion index values below 110. This becomes critical in gate entries where vehicles repeatedly execute the same turning movements, concentrating wear in narrow bands across the paved surface.

- You should analyze vehicle turning radii for the largest vehicles regularly accessing the property

- Your layout must provide minimum 16-foot clear width for two-way traffic through residential gates

- Tire tracking zones require consideration of all-season performance including wet traction during monsoons

- Commercial gate entries need accommodation for truck apron areas where trailers off-track during turns

- Backup maneuvers create higher shear stresses than forward movement and affect material durability

The relationship between gate width and approach angle affects how drivers perceive entry clearance. Narrow gates with perpendicular approaches create psychological constriction that causes drivers to slow excessively or position vehicles off-center. Your paving stone entry statement Arizona can mitigate this through visual cues — border treatments that flare outward approaching the gate or color transitions that emphasize available width improve driver confidence and reduce erratic maneuvering.

Drainage Integration Challenges

Gate entry areas function as drainage collection points whether you plan for it or not. The grade transitions required to accommodate gate swing clearance, the impermeable pillar masses, and the typical property grading that slopes toward entry drives all concentrate runoff at gate approaches. Your paving stone driveway gate area Arizona needs explicit drainage design rather than assuming permeable joints will handle the flow.

Surface drainage patterns interact with base permeability in ways that create performance issues years after installation. Arizona’s intense rainfall events — often delivering 0.5-1.0 inches within 20 minutes — overwhelm joint infiltration capacity. You’ll see standing water even on properly graded surfaces because precipitation rate exceeds infiltration rate by 3-4x during peak monsoon cells. Your design needs to convey this surface flow to collection points rather than depending solely on vertical percolation.

The typical detail error involves specifying permeable base materials without providing outlet capacity. Water infiltrates into the base layer, encounters subgrade with lower permeability, and saturates the aggregate. This subsurface saturation reduces load-bearing capacity by 30-40% and creates pumping conditions under traffic. You should provide edge drains or subsurface collection trenches that intercept base-layer moisture and convey it to positive outlets before saturation occurs.

Automation System Integration

Modern gate automation systems create installation constraints that affect paving stone gate entry features Arizona throughout the approach zone. Conduit runs for gate operators, access control wiring, and safety sensor loops require trenching through base materials that compromises structural continuity if not properly detailed. Your specification needs to coordinate underground utility routing with base preparation to maintain load transfer capacity.

Loop detector installations for automatic gate operation require saw-cutting through completed paving in retrofit situations or careful base preparation in new construction. The detector loops themselves don’t create structural issues, but the saw-cut trenches do if not properly backfilled and compacted. You should specify flowable fill or controlled low-strength material for detector loop backfill rather than hand-compacted aggregate which never achieves the density of surrounding undisturbed base.

- You need to coordinate gate operator locations with base excavation limits before paver installation

- Your conduit routing should follow joint lines where practical to minimize structural interruption

- Safety sensor mounting requires stable pillar foundations that extend below frost depth even in southern Arizona

- Control panel locations should consider truck access for service without driving across landscaped areas

- Backup battery systems need ventilated enclosures that don’t create heat islands affecting adjacent plantings

The electromagnetic interference from gate operators and access control systems can affect nearby landscape lighting controls if not properly isolated. You should maintain minimum 18-inch separation between gate automation conduits and low-voltage landscape lighting to prevent crosstalk and nuisance tripping of lighting controls during gate operation cycles.

Architectural Style Coordination Approaches

Your paving stone entrance design Arizona must relate visually to architectural character without literally matching building materials. The common error is attempting exact color matches between paving and building stone, which rarely succeeds due to different wear patterns, cleaning requirements, and weathering characteristics. You achieve better results through tonal relationships — warm pavers with warm-toned architecture, cool pavers with contemporary cool palettes.

The scale of paver units should relate to architectural massing. Massive Southwestern-style homes with heavy timber elements and thick stucco walls overwhelm small-format pavers. You need larger unit sizes — 12×18-inch or 16×24-inch pavers — that hold their visual presence against bold architectural forms. Contemporary architecture with clean lines and minimal ornamentation pairs effectively with simple paver patterns in 12×12-inch or 12×24-inch formats that emphasize geometric clarity.

Color selection interacts with Arizona’s intense sunlight differently than in moderate climates. Colors that appear distinct in showrooms or sample boards often wash out under full desert sun. You should evaluate paver samples in actual site conditions at different times of day. Mid-tone colors with subtle variation provide better long-term visual interest than high-contrast schemes that look dramatic initially but become harsh under sustained intense light.

Maintenance Access Provisions

Gate mechanisms require periodic maintenance that your paving stone access point design Arizona should accommodate explicitly. Service technicians need stable working surfaces adjacent to operator housings and control panels. The typical oversight is paving right up to pillar faces without providing level work areas where technicians can position ladders safely or work from ground level without standing on sloped surfaces.

Your layout should include level maintenance pads at operator locations — minimum 4×4 feet of flat paving that doesn’t slope more than 1% in any direction. These work zones prevent service technicians from improvising unstable platforms or damaging landscape materials by trampling plantings while accessing gate components. The modest cost of specifying these dedicated work areas prevents expensive landscape restoration after each service call.

- You should verify warehouse stock levels before committing to project timelines for custom color selections

- Your specification must address how service vehicles access gate operators without crossing turf during wet conditions

- Removable paver sections at valve locations prevent excavation damage during irrigation repairs

- Control panel locations require consideration for truck-mounted lift access in commercial applications

- Utility coordination prevents conflicts between gate power feeds and irrigation lateral lines

Lighting Integration Techniques

When you integrate lighting with paving stone gate entry features Arizona, you’re addressing security requirements, aesthetic enhancement, and practical visibility simultaneously. The lighting design affects how paver colors and textures read after dark — colors shift significantly under LED versus incandescent versus metal halide sources. You should specify fixture color temperatures between 2700K-3000K that render paver tones accurately without the harsh blue-white cast of higher temperature LEDs.

Fixture placement relative to paver joints affects both visual impact and installation complexity. Up-lights positioned at pillar bases create dramatic vertical emphasis but require core-drilling through pavers and base materials for conduit routing. Your detailing should specify how these penetrations are sealed and flashed to prevent water intrusion into electrical components. The common failure mode is relying on fixture housings alone for waterproofing without properly sealing the base penetration.

Glare control becomes critical in gate entry lighting because drivers approach fixtures while making low-speed navigation decisions. You need fixtures with effective shielding that directs light downward onto paving surfaces without creating direct glare into drivers’ vision. Shield angles should limit visibility of lamp sources to viewers more than 6 feet above grade — effectively eliminating direct view from driver eye height.

Premium Paver Stone Distributors in Arizona: Citadel Stone Gate Entry Specification Guide

When you evaluate Citadel Stone’s paver stone distributors in Arizona for your gate entry project, you’re considering materials engineered specifically for extreme climate performance and high-visibility applications. At Citadel Stone, we provide technical specification guidance for diverse Arizona installations from low-desert residential estates to high-elevation commercial properties. This section outlines how you would approach material selection and detailing for six representative cities across Arizona’s climate zones.

Phoenix Heat Resistance

In Phoenix’s extreme low-desert environment, you would specify paving stone gate entry features Arizona with maximum solar reflectance to manage surface temperatures that regularly reach 165°F during summer months. Your material selection should emphasize light buff and tan colorways that reflect 65-70% of incident radiation while maintaining visual warmth appropriate to Southwestern architecture. The urban heat island effect in Phoenix amplifies thermal stress beyond rural areas, requiring you to specify expansion joints every 12 feet rather than the 15-foot spacing used in moderate climates. You’d need to coordinate warehouse delivery schedules with installation timing to avoid material stockpiling during peak heat periods when thermal conditioning becomes critical.

Tucson Monsoon Performance

Tucson’s intense monsoon season creates concentrated rainfall events that your paving stone entrance design Arizona must manage through explicit drainage design. You would incorporate slightly steeper cross-slopes — 2.5% versus the 2.0% minimum used in drier climates — to ensure positive surface drainage during the 1-2 inch per hour rainfall rates common in July and August monsoons. Your specification should address how pillar surrounds handle concentrated runoff and specify polymeric joint stabilizers rated for high-flow conditions. The combination of extreme heat and sudden moisture cycling requires materials with proven freeze-thaw durability despite Tucson’s generally warm climate, as rapid evaporative cooling during monsoon events creates thermal shock conditions.

Scottsdale Luxury Detailing

Scottsdale’s high-end residential market demands paving stone driveway gate area Arizona installations that emphasize sophisticated pattern work and premium finish quality. You would specify honed or lightly textured surfaces that provide refined appearance while maintaining DCOF slip resistance values above 0.50 for pool deck crossover areas common in luxury properties. Your pattern design should incorporate geometric precision with tight joint tolerances — 3/16 inch maximum — that emphasize craftsmanship quality. Material selections would focus on consistent color batching and dimensional tolerances within ±2mm to support the precise installation standards expected in Scottsdale’s luxury market. At Citadel Stone, we recommend specifying whole-pallet quantities from single production runs to ensure color consistency across the entire gate entry feature.

Flagstaff Freeze-Thaw Resistance

At Flagstaff’s 7,000-foot elevation, you would address genuine freeze-thaw cycling that demands materials with porosity ratings between 4-6% and proven ASTM C666 performance through 300+ freeze-thaw cycles. Your paving stone entry statement Arizona specification must account for snow removal operations that expose pavers to de-icing salts and mechanical abrasion from plow blades. You’d specify minimum 80mm thickness even for residential applications due to frost heave potential in Flagstaff’s expansive soils. Base preparation requires excavation to 18 inches below finish grade with proper drainage provisions that prevent ice lens formation in base materials. Your material color selection would emphasize mid-tone options that don’t show salt residue as prominently as very dark or very light alternatives.

Sedona Natural Integration

Sedona’s dramatic red rock landscape creates unique visual context for paving stone access point design Arizona that must complement rather than compete with natural surroundings. You would specify earth-tone pavers in buff, tan, and warm gray families that harmonize with native sandstone formations while providing subtle contrast to distinguish built elements from natural terrain. Your layout should incorporate organic edge treatments and naturalistic transitions rather than rigid geometric boundaries that read as artificial in Sedona’s landscape setting. Material selection would emphasize textured surfaces that suggest natural stone weathering while providing the dimensional consistency required for vehicular traffic. The high visitor traffic in Sedona’s resort areas requires you to specify higher abrasion resistance ratings than typical residential applications.

Yuma Extreme UV Exposure

Yuma’s position as one of the sunniest locations globally creates UV exposure conditions that degrade color stability in lesser materials within 3-5 years. You would specify paving stone gate entry features Arizona with integral coloration through the full paver thickness rather than surface-applied treatments that fade under Yuma’s intense radiation levels. Your material selection should emphasize UV-stabilized formulations with documented color retention through 2,000+ hours of accelerated weathering testing equivalent to 15-20 years of Yuma sun exposure. The extreme aridity requires you to consider dust control during installation and specify how the paved surface will be maintained to prevent accumulation of wind-blown soil that degrades appearance. Your joint specifications would address sand stabilization methods that prevent erosion from the frequent high-wind events common in Yuma’s desert environment.

Seasonal Installation Timing Considerations

Arizona’s seasonal temperature extremes create installation windows that affect paving stone entrance design Arizona performance for the life of the installation. You should avoid installing pavers during peak summer heat when afternoon surface temperatures make proper joint sand placement nearly impossible and thermal expansion is at maximum. The ideal installation windows run from mid-October through mid-May when temperatures moderate and thermal movement minimizes.

Your project scheduling should account for how installation temperature affects long-term joint stability. Pavers installed during summer heat with joints filled at maximum thermal expansion will develop widened joints as materials contract during winter. Conversely, winter installations create compressed joints during summer expansion. You achieve optimal results by installing during spring or fall when temperatures approximate the annual mean, creating balanced seasonal movement in both directions.

- You need to plan material deliveries from the warehouse during moderate temperature periods when thermal conditioning is minimal

- Your installation schedule should avoid monsoon season when base saturation complicates compaction verification

- Winter installations at elevation require base materials that remain workable below 40°F

- Summer installations in low desert demand early morning work schedules before surface temperatures exceed safe handling limits

- Your project timeline must accommodate material lead times that extend 4-6 weeks for custom colors or special sizes

Edge Restraint Specifications for Gate Zones

The edges of paving stone driveway gate area Arizona installations experience lateral forces from vehicular traffic that standard residential edge restraints can’t always contain. You should specify commercial-grade edge restraints with continuous spike attachment every 12 inches rather than the 24-inch spacing adequate for pedestrian-only applications. The lateral forces from vehicles turning through gate entries create edge loading that migrates progressively inward if perimeter restraint fails.

Your edge detail should account for how restraints interface with pillar foundations and gate operator housings. Rigid elements like concrete pillars provide natural edge restraint, but you need proper detailing of the expansion joint between flexible paver field and rigid structure. The common error is allowing pavers to bind directly against rigid elements where thermal expansion has nowhere to go except upward, creating lippage and vertical displacement.

Material selection for edge restraints needs to consider UV degradation in Arizona’s intense sunlight. Plastic edge restraints lose tensile strength after 5-7 years of direct sun exposure even when buried. You should specify UV-stabilized formulations with documented retention of minimum 80% tensile strength after 2,000 hours accelerated weathering. Aluminum edge restraints avoid UV degradation but require proper specification of alloy and coating to prevent galvanic corrosion where dissimilar metals contact.

Final Considerations

Your professional specification process for paving stone access point design Arizona requires balancing aesthetic aspirations with performance requirements specific to extreme climate conditions. You need to evaluate materials based on comprehensive testing data rather than appearance alone, ensuring selections meet structural demands while achieving visual objectives. The gate entry represents your property’s premier impression point, demanding specification rigor that matches its prominence.

When you detail these installations, remember that field conditions introduce variables that theoretical specifications can’t fully anticipate. Your installation documents should provide performance criteria and acceptable tolerance ranges rather than overly prescriptive methods that prevent crews from adapting to site-specific challenges. Professional results come from specifications that are simultaneously thorough and flexible, detailed yet adaptable.

The long-term success of paving stone gate entry features Arizona depends on your material selections, installation quality, and ongoing maintenance commitment working together as an integrated system. For additional design integration strategies, review Integrating paving stones with raised planters in Arizona landscapes before finalizing your comprehensive site design approach. Composite technology available in Citadel Stone’s advanced artificial stone pavers in Arizona.