When you design paving stone fire pit surrounds Arizona projects, you’re working with one of the most thermally demanding applications in residential and commercial hardscaping. You need materials that won’t crack under extreme heat cycling, won’t retain dangerous surface temperatures, and can handle the unique combination of radiant heat from below and intense solar gain from above. Your material selection determines whether the installation performs safely for 20+ years or fails within three seasons.

The desert Southwest presents challenges that don’t exist in other regions. You’ll encounter ambient temperatures exceeding 115°F combined with fire pit temperatures reaching 800-1,200°F at the source. This creates thermal gradients that stress paving materials in ways standard specifications don’t address. Your paving stone fire feature areas Arizona installations require you to understand coefficient of thermal expansion, heat retention characteristics, and how different stone compositions respond to rapid temperature fluctuations.

Thermal Performance Requirements for Fire Zone Applications

You need to specify materials with thermal properties that prevent catastrophic failure under fire pit conditions. The critical metric isn’t just heat resistance—it’s thermal shock resistance, which measures how materials handle rapid temperature changes. When you select paving stone fire pit surrounds Arizona materials, you’re looking for low thermal expansion coefficients combined with high thermal mass that moderates temperature swings.

Your specification should address three distinct thermal zones around fire features. The immediate surround (within 18 inches of the fire source) experiences the most severe conditions. You’ll see temperatures ranging from 400-600°F in this zone during active use. The transition zone (18-36 inches) sees 200-350°F, while the peripheral zone (36-60 inches) operates at 150-200°F. Each zone requires different material considerations.

- You should verify compressive strength exceeds 12,000 PSI for immediate surround zones

- Your material must maintain structural integrity through 500+ thermal cycles annually

- You need porosity levels between 2-5% to prevent moisture-related spalling during heating

- Your selected stone should exhibit thermal conductivity below 2.5 W/mK to minimize surface temperature retention

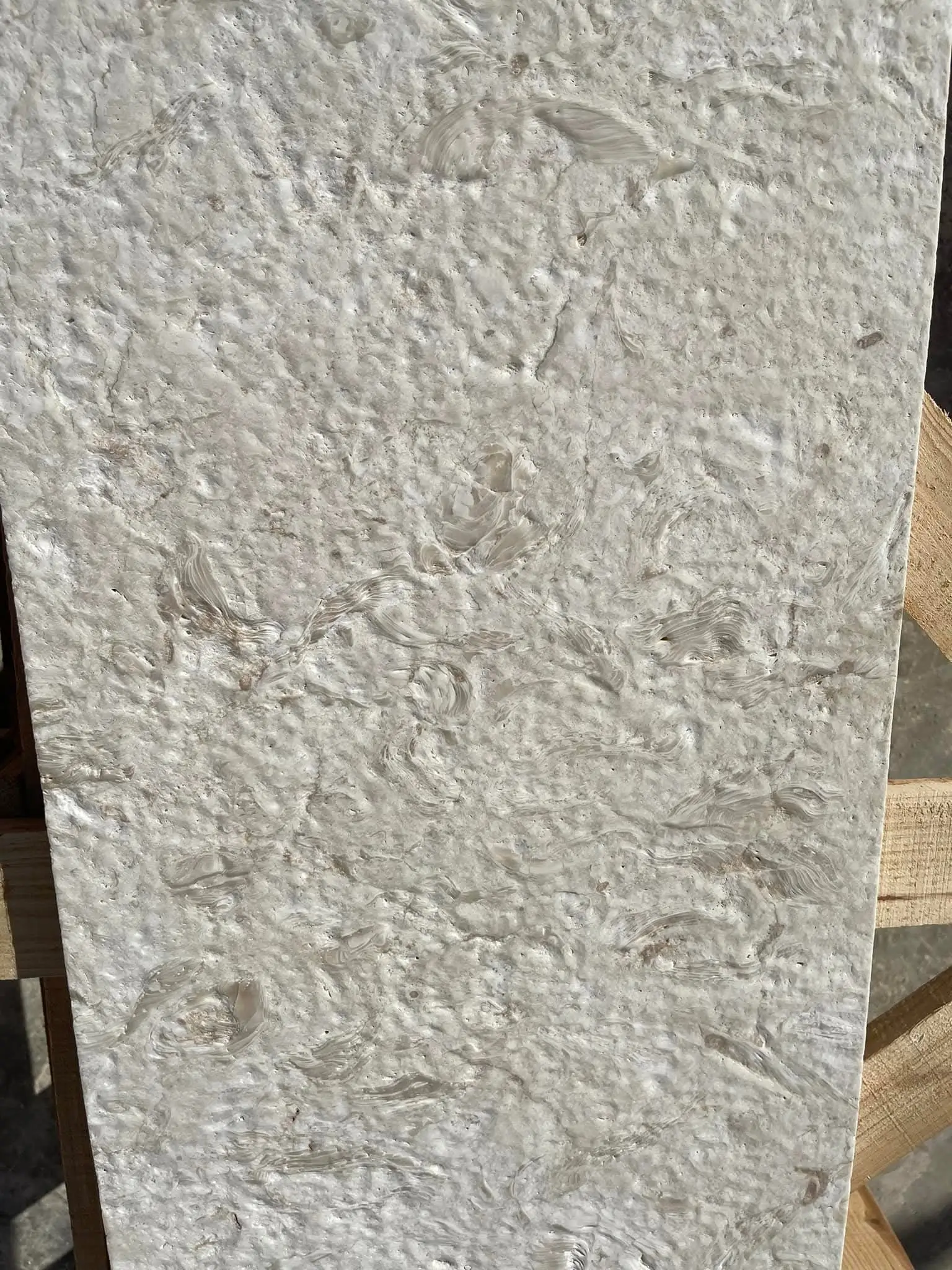

Natural stone outperforms concrete pavers in fire applications because crystalline structures dissipate heat more effectively than cementitious matrices. When you evaluate paving stone heat resistant zones Arizona options, limestone and travertine demonstrate superior performance due to their calcite composition and interconnected pore structures that allow thermal expansion without surface cracking.

Material Selection Criteria for Desert Fire Features

Your paving stone fireplace surrounds Arizona material choices come down to understanding how different stone types respond to combined thermal stress. The mistake most specifiers make is focusing solely on heat resistance without considering thermal mass behavior. You need materials that absorb heat slowly and release it gradually—this prevents dangerous surface temperatures that create liability concerns.

Limestone pavers offer the best balance of thermal performance and aesthetic versatility for fire pit applications. The material’s calcium carbonate composition provides natural fire resistance while maintaining workable surface temperatures. You’ll find that honed or brushed finish limestone stays 15-20°F cooler than polished surfaces under identical conditions because textured finishes increase surface area for convective cooling.

Here’s what catches specifiers off-guard about material thickness in fire zones. Standard 1.25-inch pavers work adequately for peripheral zones, but you need 2-inch minimum thickness for transition zones and 2.5-3 inches for immediate surrounds. The additional mass doesn’t just add structural capacity—it fundamentally changes thermal behavior by increasing the time constant for heat penetration. Your thicker pavers create a thermal buffer that protects the base layer from heat damage. For comprehensive options across all applications, see our paver distribution facility which maintains specialized inventory for high-performance installations.

Color and Surface Temperature Dynamics

When you select paving stone fire pit surrounds Arizona colors, you’re making a decision that affects both safety and user comfort. Light-colored limestone in white, cream, and beige tones reflects 60-70% of solar radiation, while darker grays and browns absorb 70-85%. This 30-40°F surface temperature difference becomes critical in fire feature areas where you’re already managing heat from the combustion source.

Your paving stone outdoor fire areas Arizona projects should prioritize reflective surfaces in the transition and peripheral zones. The immediate surround experiences such intense radiant heat from the fire that solar gain becomes secondary, but the surrounding areas where people sit and walk need to remain below 135°F for safe bare-foot contact. Light limestone achieves this threshold even on 110°F afternoons.

- White limestone surfaces measure 115-125°F at 3:00 PM in July Phoenix conditions

- Medium gray limestone reaches 140-155°F under identical exposure

- Dark charcoal pavers exceed 160°F, creating burn hazard conditions

You should also consider how fire pit usage patterns align with solar exposure timing. Most fire features operate during evening hours when solar gain diminishes, but peripheral paving remains hot from afternoon exposure. Your color selection determines whether the area becomes comfortable by 7:00 PM or retains excess heat until 10:00 PM.

Base Preparation for Thermal Stability

Your paving stone fire pit surrounds Arizona installations fail more often from inadequate base preparation than from material selection errors. The combination of thermal cycling and structural loading requires you to engineer bases that accommodate expansion while maintaining dimensional stability. Standard paver base specifications don’t address the thermal movement you’ll encounter in fire feature applications.

You need to specify a three-layer base system for fire pit surrounds. The subgrade must be compacted to 95% modified Proctor density, then overlaid with 6 inches of crushed aggregate base (3/4-inch minus) compacted in 2-inch lifts. Your critical innovation comes in the setting bed—instead of standard concrete sand, you should use 1.5 inches of high-temperature refractory sand designed for thermal expansion accommodation.

The refractory sand layer allows lateral movement during thermal expansion without compromising interlock. When you install paving stone fire pit surrounds Arizona projects with conventional sand, you’ll see joint opening and paver displacement within two seasons as repeated thermal cycling compacts the setting bed unevenly. Refractory sand maintains consistent compaction through 500+ thermal cycles.

- Your base must extend 24 inches beyond the paved perimeter for edge restraint stability

- You should install fiber-reinforced concrete edge restraint rated to 180°F minimum

- Your aggregate base requires thermal expansion joints every 12 feet in fire feature areas

- You need 4-6 inches of clearance between the fire pit structure and paver edge

Joint Spacing and Thermal Expansion Management

When you detail paving stone fire feature areas Arizona projects, joint spacing becomes your primary tool for managing thermal expansion. Limestone exhibits a thermal expansion coefficient of 4.5-5.5 × 10⁻⁶ per °F. In fire pit applications where you’re seeing 400°F temperature swings from ambient to peak heat, this translates to 0.020-0.025 inches of expansion per linear foot of paving.

Your standard 1/8-inch joint spacing that works for pool decks and patios becomes inadequate for fire features. You need 3/16-inch minimum joints in the immediate surround zone, increasing to 1/4-inch for pavers larger than 18×18 inches. The additional joint width accommodates thermal expansion without creating compression stress that leads to edge spalling and corner breakage.

Here’s the specification detail that prevents long-term joint failure. You should use polymeric sand rated to 350°F minimum for fire feature applications. Standard polymeric sand breaks down at 180-200°F, losing binding capacity and allowing joint erosion. High-temperature polymeric sand maintains structural integrity through repeated heating cycles while accommodating the expansion movement your joints experience.

Your paving stone heat resistant zones Arizona installations require you to create thermal breaks between the fire pit structure and surrounding pavement. Install a 1-inch expansion joint filled with high-temperature ceramic fiber rope or calcium silicate board around the pit perimeter. This detail isolates thermal movement and prevents stress transfer from the fire structure to your paving field.

Edge Detail Specifications for Fire Zone Stability

You’ll find that edge restraint failures cause 40% of paving stone fire pit surrounds Arizona installation problems. The thermal cycling creates expansion forces that standard edge restraints can’t accommodate. Your specification must address both the structural requirements of edge containment and the thermal movement you’re managing in fire feature areas.

Fiber-reinforced concrete edge restraint works best for fire pit applications because it provides mass and thermal stability that plastic or aluminum systems can’t match. You should detail a 4×8-inch concrete edge with 1% fiber reinforcement by volume, placed 1 inch below finished paver height. The concrete must be rated to 180°F minimum to prevent deterioration from radiant heat exposure in the transition zone.

- Your edge restraint must extend 6 inches below the base layer for frost protection in Flagstaff installations

- You need to install expansion joints in the edge restraint every 10 feet aligned with paving field joints

- Your concrete edge should be placed 2 inches from the paver edge with compacted aggregate fill

- You should specify non-shrink grout for the void between edge restraint and pavers in immediate surround zones

Surface Finish Impact on Heat Management

When you specify surface finishes for paving stone fireplace surrounds Arizona applications, you’re affecting both thermal performance and slip resistance under diverse conditions. Honed and brushed finishes provide superior heat dissipation compared to polished surfaces because increased texture creates more surface area for convective cooling. You’ll measure 8-12°F lower surface temperatures on textured limestone versus polished stone under identical fire pit operation.

Your finish selection also determines slip resistance when ash and moisture combine during fire pit use. Polished finishes that measure 0.42 DCOF when clean can drop to 0.28 when contaminated with fine ash particles. Honed finishes maintain 0.50-0.55 DCOF even when ash is present because the texture provides mechanical interlock that wet polished surfaces lack.

Flamed finishes offer maximum slip resistance (0.58-0.65 DCOF) but create surface irregularities that accumulate ash and debris. You should reserve flamed finishes for peripheral zones where cleaning access is easy and thermal exposure is moderate. The immediate surround performs better with honed finishes that balance cleaning ease with adequate slip resistance.

Installation Timing and Environmental Conditions

Your paving stone outdoor fire areas Arizona installation success depends heavily on timing and ambient conditions during construction. The challenge isn’t just worker comfort—it’s how temperature affects material handling, base compaction, and jointing compound curing. You need to plan installations around thermal conditions that allow proper material placement.

Avoid installing paving stone fire pit surrounds Arizona projects when ambient temperatures exceed 95°F or fall below 50°F. High temperatures cause premature setting of jointing materials and make accurate base compaction difficult to verify. Low temperatures prevent polymeric sand activation and can cause micro-cracking in freshly placed pavers due to thermal shock.

- You should schedule base preparation during morning hours when temperatures allow optimal compaction moisture retention

- Your paver placement should occur when surface temperatures remain below 90°F to prevent thermal expansion during installation

- You need to protect polymeric sand installations from moisture for 48 hours minimum in Arizona’s low-humidity environment

- Your crew should maintain consistent joint spacing using 3/16-inch spacers throughout fire feature zones

Morning installations in Phoenix and Tucson provide the most stable conditions. You’ll get 4-5 hours of moderate temperatures between 7:00 AM and noon during summer months, allowing base work and paver placement before excessive heat creates problems. Your jointing operations should wait until late afternoon when temperatures drop below 85°F but humidity remains low enough for proper polymeric sand curing.

Common Specification Errors and Field Corrections

When you review failed paving stone fire feature areas Arizona installations, you’ll see recurring specification mistakes that create predictable problems. The most common error is treating fire pit surrounds like standard paving applications without accounting for thermal stress. Your specification must explicitly address the unique requirements of high-heat environments.

Undersized joint spacing causes 35% of fire pit surround failures. Specifiers use standard 1/8-inch joints appropriate for pool decks, then discover edge spalling and corner breakage within two heating seasons. You can correct this in existing installations by routing joints to 3/16-inch width and refilling with high-temperature polymeric sand, but the correction costs 3-4 times more than proper initial specification.

Inadequate base thickness under immediate surround zones creates settlement and lippage as thermal cycling degrades the compacted base. You’ll see this manifest as 1/8-inch or greater vertical displacement between adjacent pavers. The correction requires removing pavers, excavating an additional 2-3 inches of base depth, and reinstalling with proper refractory sand bedding.

- You should specify paver thickness based on thermal zone, not just structural loading requirements

- Your base specification must include refractory sand for setting bed in all fire feature applications

- You need to detail high-temperature polymeric sand explicitly—don’t allow substitution with standard products

- Your edge restraint specification should prohibit plastic systems in favor of concrete or steel

Maintenance Requirements for Sustained Performance

Your paving stone fire pit surrounds Arizona installations require maintenance protocols that address both normal weathering and thermal degradation. You should advise owners that fire feature pavers need different care than standard paving due to the accumulation of combustion byproducts and accelerated joint sand erosion from thermal cycling.

Annual joint sand inspection and replenishment prevents the cascading failures that occur when joints drop below 80% fill capacity. You’ll see accelerated edge deterioration once joints open because thermal expansion forces concentrate at paver edges rather than distributing across joint spaces. Your maintenance specification should include joint evaluation every 12 months with refilling as needed to maintain 90-95% capacity.

Ash and soot accumulation affects both appearance and surface temperature. The carbon deposits create a darker surface that increases solar absorption by 15-20%, raising surface temperatures above design expectations. You should recommend quarterly cleaning with pH-neutral stone cleaner and pressure washing at 1,200-1,500 PSI to remove combustion deposits without damaging limestone surfaces.

Sealer application provides additional thermal protection and simplifies cleaning. You need penetrating sealers rated to 250°F minimum that won’t film or discolor under heat exposure. Your sealer specification should call for application every 24-36 months, with surface preparation including thorough cleaning and 48-hour drying time before sealer placement.

Citadel Stone: Premier Paving Wholesalers in Arizona — Fire Feature Specification Guidance

When you consider Citadel Stone’s paving wholesalers in Arizona capabilities for your fire feature projects, you’re evaluating materials specifically selected for extreme thermal performance. At Citadel Stone, we provide technical specification guidance for hypothetical fire pit surround applications across Arizona’s diverse climate zones. This section outlines how you would approach material selection and installation planning for six representative cities, each presenting unique environmental challenges that affect paving stone fire pit surrounds Arizona performance requirements.

Phoenix Heat Island

In Phoenix installations, you would specify light-colored limestone with maximum solar reflectance to counteract the extreme urban heat island effect. Your material selection should account for ambient temperatures reaching 118°F combined with fire pit radiant heat. You’d need 3/16-inch joint spacing minimum with high-temperature polymeric sand rated to 350°F. Base preparation would require refractory sand setting beds to accommodate the 450°F temperature differentials between winter morning lows and summer fire pit operation. Your warehouse coordination should verify summer inventory availability, as Phoenix demand peaks during spring installation season before temperatures become prohibitive for construction activity.

Tucson Monsoon Considerations

Tucson projects would require you to address the unique combination of thermal stress and monsoon moisture cycling. Your specification should include enhanced drainage provisions in the base layer because summer moisture can combine with heat to create steam pressure that damages pavers from below. You’d detail 8-inch aggregate base depth with 2% slope away from fire features. The material you select must handle rapid temperature changes when monsoon storms drop surface temperatures 40°F in 20 minutes during active fire pit use. Your edge restraint specification would need to accommodate both thermal expansion and moisture-induced soil movement in Tucson’s expansive clay soils.

Scottsdale Luxury Standards

When you specify for Scottsdale applications, you’d be working with clients who expect premium aesthetics combined with technical performance. Your material recommendation would focus on consistent color selection from warehouse inventory to ensure the visual uniformity high-end projects demand. You’d specify honed finish limestone in cream and beige tones that complement Scottsdale’s desert contemporary architecture. Joint spacing would follow the same thermal expansion protocols as Phoenix, but your installation details would include precision edge alignment and laser-verified level tolerance of ±1/16 inch across the entire fire feature area. The typical Scottsdale fire pit surround extends 6-8 feet from the fire source, requiring you to coordinate thermal zones with aesthetic paver layout patterns.

Flagstaff Freeze-Thaw Cycling

Flagstaff installations would require you to address freeze-thaw cycling combined with fire pit thermal stress—a combination that doesn’t exist in lower-elevation Arizona cities. Your material specification must verify absorption rates below 3% to prevent winter ice formation within the stone structure. You’d need to detail 8-inch minimum base depth extending below the 24-inch frost line, with edge restraint foundations at 30 inches to prevent frost heave. The paving stone heat resistant zones Arizona materials you select for Flagstaff would handle temperature ranges from -10°F winter ambient to 600°F fire pit surround temperatures. Your installation timing would be restricted to May through September when ground conditions allow proper base compaction and polymeric sand curing.

Sedona Aesthetic Integration

Sedona projects would emphasize how your paving stone fireplace surrounds Arizona material selection integrates with the distinctive red rock landscape. You’d recommend warm-toned limestone in terra cotta and beige ranges that complement rather than compete with the natural environment. Your specification would address the moderate climate that allows year-round fire pit use, requiring materials that perform through 200+ annual heating cycles. Base preparation would be complicated by Sedona’s rocky substrate, requiring you to detail excavation procedures that work with limited soil depth over bedrock. Truck access limitations in Sedona’s hillside locations would affect your delivery planning and material staging requirements.

Yuma Extreme Conditions

Yuma installations would test material performance limits with the highest sustained temperatures in Arizona. You’d be specifying for locations where ambient temperatures exceed 110°F for 90+ days annually, combined with intense solar radiation that creates surface temperatures approaching 170°F before fire pit operation begins. Your paving stone fire feature areas Arizona material selection would prioritize maximum solar reflectance and thermal mass properties that moderate temperature extremes. You’d detail 2.5-inch minimum paver thickness in immediate surround zones to provide adequate thermal buffering. Joint spacing would increase to 1/4-inch for pavers larger than 16×16 inches to accommodate the extreme thermal expansion Yuma conditions create. Your installation timing would be restricted to November through March when temperatures allow safe working conditions and proper material placement.

Performance Verification and Quality Control

When you implement paving stone fire pit surrounds Arizona projects, your quality control protocols determine whether the installation achieves design performance. You need field verification procedures that confirm material properties, base preparation, and installation details match specifications before, during, and after construction.

Your pre-installation verification should include material testing for compressive strength, absorption rate, and thermal expansion coefficient. You can’t rely solely on manufacturer data—you need batch-specific testing for projects where thermal performance is critical. Request certification that materials meet ASTM C1528 slip resistance standards and verify absorption rates below 5% through ASTM C97 water absorption testing.

- You should verify base compaction at 95% modified Proctor density using nuclear density gauge testing

- Your quality control must include joint spacing verification at 10% of paver locations minimum

- You need to confirm polymeric sand installation follows manufacturer protocols for temperature and moisture conditions

- Your final inspection should document surface flatness within ±1/8 inch over 10 feet

Post-installation performance monitoring helps you identify problems before they become failures. You should conduct 30-day, 6-month, and 12-month inspections that evaluate joint sand retention, edge stability, and paver condition. This documentation proves valuable for warranty administration and provides feedback that improves future specifications.

Cost-Performance Analysis for Material Selection

Your paving stone outdoor fire areas Arizona budget planning requires you to evaluate lifecycle costs, not just initial material expense. The installed cost differential between standard pavers and thermally-rated limestone for fire pit applications runs 18-25%, but the performance difference justifies the investment when you factor replacement costs and liability exposure.

Standard concrete pavers in fire pit applications fail within 5-8 years through edge spalling, surface scaling, and joint deterioration. Your replacement cost includes demolition, disposal, new materials, and reinstallation—typically 140-160% of original installation cost due to the complexity of working around existing fire pit infrastructure. When you specify appropriate limestone pavers initially, you achieve 20+ year performance with routine maintenance only.

The cost comparison shifts further when you account for safety and liability considerations. Fire pit surrounds that retain excessive heat or develop trip hazards from thermal displacement create premises liability exposure that far exceeds the modest upfront investment in proper materials. Your specification decision should weight risk mitigation alongside material costs.

Final Considerations

Your professional specification process for paving stone fire pit surrounds Arizona installations requires you to integrate thermal performance requirements with aesthetic goals and budget constraints. You’ve learned that material selection extends beyond standard paver criteria to encompass thermal expansion coefficients, heat retention characteristics, and resistance to thermal shock. Your base preparation must address thermal movement through refractory sand setting beds and properly sized expansion joints. The edge restraint systems you specify need thermal rating compatibility with the extreme conditions fire features create.

When you detail these installations, remember that surface finish affects both temperature management and slip resistance. Your color selection influences solar gain and user comfort in ways that become critical when combined with radiant fire pit heat. Joint spacing and polymeric sand specification determine whether your installation accommodates thermal expansion or fails through compression stress and edge deterioration. The maintenance protocols you recommend affect long-term performance as much as initial installation quality.

You should verify that your specifications explicitly address the unique requirements of fire feature applications rather than defaulting to standard paving details. The thermal zones around fire pits require different material thicknesses, joint widths, and base preparations than surrounding paving areas. Your quality control procedures need to confirm that field conditions match design intent through material testing and installation verification. For related installation guidance, review Comparing cement epoxy and polyurethane paving stone joint fillers before you finalize your project documents. Container-direct imports make Citadel Stone efficient bulk stone pavers in Arizona value leader.