When you see white powdery deposits emerging on your Arizona paving stone surfaces, you’re witnessing efflorescence — a crystallization process that affects nearly 40% of hardscape installations within the first 18 months. Understanding paving stone efflorescence treatment Arizona protocols requires you to recognize the difference between surface-level cosmetic issues and deeper structural moisture problems. You’ll need to diagnose the root cause before selecting removal methods, since aggressive treatments on the wrong efflorescence type can permanently damage your investment.

The white residue you’re seeing represents soluble salts migrating through the paving stone’s interconnected pore structure. These salts originate from three primary sources: the stone material itself, the setting bed and base layers, or groundwater infiltration carrying dissolved minerals. Your treatment approach must address the moisture pathway, not just the visible symptom, or you’ll see recurring deposits within 3-6 months of initial cleaning.

Understanding Efflorescence Formation in Desert Climates

Arizona’s unique climate conditions create an ideal environment for paving stone efflorescence treatment Arizona challenges. You’re dealing with alkaline soils (pH 7.8-8.5), sporadic intense rainfall, rapid evaporation rates, and extreme temperature fluctuations. This combination drives moisture upward through capillary action, depositing salts as water evaporates at the surface. Desert regions experience this phenomenon more intensely than humid climates because the quick evaporation concentrates mineral deposits rather than washing them away.

The chemical composition of efflorescence determines your treatment strategy. Primary efflorescence appears during initial curing and typically resolves within 6-12 months as residual construction moisture dissipates. Secondary efflorescence indicates ongoing moisture infiltration and requires you to address subsurface drainage before surface treatment. You’ll encounter calcium carbonate (white, powdery), sodium sulfate (crystalline, can cause surface spalling), and calcium sulfate deposits most commonly in Arizona installations.

- You need to test pH levels of the white deposits before selecting cleaning solutions — acidic cleaners work on calcium-based salts but can worsen sodium sulfate conditions

- Your base layer permeability should exceed surface material absorption by 3-4x to prevent moisture accumulation at the interface

- Temperature differentials between day and night in Arizona desert climates can reach 40-50°F, accelerating the capillary moisture movement that causes paving stone salt buildup Arizona

- Groundwater table depths below 8 feet typically eliminate efflorescence concerns unless irrigation systems introduce additional moisture sources

Diagnostic Assessment Protocols Before Treatment

Before you implement any paving stone efflorescence treatment Arizona methodology, you must conduct a proper diagnostic assessment. Start by determining whether moisture is evaporating upward through the stone or if surface water is penetrating downward. The plastic sheet test provides immediate answers: tape a 2×2 foot plastic sheet over the affected area for 24 hours. If moisture accumulates on the underside of the plastic, you’re seeing rising damp from below. Moisture on the top surface indicates poor surface drainage or seal failure.

Your inspection should document the efflorescence pattern distribution. Uniform coverage across the entire installation suggests base layer moisture issues or material-inherent salts. Localized deposits near joints or edges indicate lateral water infiltration. Concentrations around specific pavers point to individual stones with higher porosity or salt content. You’ll want to photograph these patterns for comparison after treatment to verify effectiveness.

Testing the white deposits tells you which cleaning chemistry will work. Calcium carbonate efflorescence fizzes when you apply white vinegar (dilute acetic acid). Sodium sulfate doesn’t react to acid and requires mechanical removal or specialty cleaners. When you encounter paving stone white deposits Arizona that resist both acid testing and standard cleaning, you may be dealing with calcium hydroxide, which requires professional-grade treatment solutions. Professional testing services can provide detailed mineral composition analysis when you’re specifying treatments for large commercial projects.

Mechanical Removal Methods for Light to Moderate Deposits

For recently appeared paving stone white deposits Arizona, mechanical removal provides the safest initial approach. Dry brushing with stiff nylon or natural bristle brushes removes loose surface deposits without introducing additional moisture. You should work in circular patterns, applying moderate pressure, then vacuum or blow away loosened material. This method works effectively on calcium carbonate efflorescence that hasn’t deeply penetrated the stone’s pore structure.

Pressure washing requires careful technique to avoid making paving stone efflorescence treatment Arizona problems worse. You must use low pressure (800-1200 PSI maximum) with wide fan tips to prevent surface erosion. The critical factor: you need to allow complete drying (72-96 hours in Arizona’s dry climate) before assessing results, because wet stone temporarily hides efflorescence. When moisture introduced by washing evaporates, it often brings additional salts to the surface, temporarily worsening the visible condition before improvement occurs.

- Your pressure washing angle should remain at 45 degrees to the surface, never perpendicular, which can drive water deeper into joints and exacerbate paving stone mineral staining Arizona

- Water temperature between 140-160°F improves salt dissolution without the risks associated with true hot water systems above 180°F

- You’ll achieve better results by working in sections, allowing each area to dry completely before treating adjacent zones

- Rinse water runoff needs to drain away from untreated areas to prevent salt migration to clean sections

Abrasive methods like light sandblasting provide options when you’re dealing with stubborn paving stone crystallization issues Arizona that resist other approaches. You must use fine media (80-120 grit) at reduced pressures (40-60 PSI) to avoid surface texture changes. This technique works best on textured or tumbled finishes where slight surface alteration won’t be noticeable. Smooth or honed finishes show visible dulling from abrasive treatment, requiring you to consider chemical approaches instead.

Chemical Treatment Solutions for Persistent Efflorescence

When mechanical methods don’t fully resolve paving stone efflorescence treatment Arizona challenges, you’ll need to evaluate chemical cleaning options. Dilute acidic cleaners (muriatic acid at 10:1 or 20:1 water-to-acid ratios) effectively dissolve calcium-based deposits. You must pre-wet the stone surface, apply the diluted acid solution, allow 5-10 minutes of dwell time, then thoroughly rinse. The pre-wetting step is critical — it prevents the acid from penetrating too deeply into the porous stone structure.

Safety protocols for acid-based paving stone efflorescence treatment Arizona require proper personal protective equipment and environmental controls. You need chemical-resistant gloves, eye protection, and respiratory protection in enclosed areas. Neutralize acid runoff with baking soda or lime before it enters drainage systems. Test your dilution ratio on an inconspicuous area first, since overly concentrated solutions can etch stone surfaces or alter coloration. For commercial projects, consult Citadel Stone paver stone inventory in Phoenix for material-specific treatment recommendations.

Proprietary efflorescence removers formulated for paving stone white deposits Arizona offer safer alternatives to straight acids. These products typically combine organic acids, surfactants, and inhibitors that target salt deposits while minimizing stone damage risk. You’ll pay 3-5x more than hardware store muriatic acid, but the formulations provide more controlled cleaning action and reduce the risk of installation damage. Application methods follow similar protocols: pre-wet, apply, dwell, scrub if needed, and rinse thoroughly.

- Your chemical selection must consider the specific stone type — limestone and travertine require gentler treatments than granite or engineered pavers

- pH monitoring during treatment helps you avoid over-application that could damage the stone matrix or joint sand stability

- You should schedule chemical treatments during moderate temperature periods (65-85°F) when solutions won’t evaporate before working

- Secondary rinses 48 hours after initial treatment remove residual salts that migrate to the surface during the first drying cycle

Moisture Barrier Solutions to Prevent Recurrence

Treating visible paving stone efflorescence treatment Arizona symptoms provides only temporary relief unless you address the underlying moisture pathways. Penetrating sealers create a chemical bond within the stone’s pore structure, reducing water absorption while allowing vapor transmission. You need to select breathable sealers specifically formulated for exterior horizontal surfaces — non-breathable sealers trap moisture beneath the surface, causing spalling and accelerated deterioration.

Application timing determines sealer effectiveness. You must wait until efflorescence has been fully removed and the installation has dried completely (typically 7-14 days after treatment in Arizona conditions). Applying sealer over damp stone or remaining salt deposits locks moisture and minerals into the system, guaranteeing future paving stone salt buildup Arizona problems. Moisture meters help you verify the stone has reached acceptable levels (typically below 4% moisture content) before sealing.

Your sealer selection should balance protection with maintenance requirements. Silane/siloxane blends penetrate deeply (2-4mm) and last 3-5 years but require professional application equipment. Acrylic sealers provide surface-level protection, enhance color, but need reapplication every 18-24 months. Fluoropolymer treatments offer superior water and oil resistance for 5-7 years but cost significantly more. For high-traffic commercial installations, the longer service life of premium sealers justifies the initial investment compared to frequent reapplication of economy products.

Subsurface Drainage Improvements for Chronic Issues

When you encounter recurring paving stone mineral staining Arizona despite surface treatments, the problem originates below the installation. Inadequate base drainage allows water to accumulate, creating a reservoir that feeds continuous efflorescence through capillary action. You’ll need to evaluate the entire drainage system: base layer permeability, edge drainage provisions, and site grading that directs water toward rather than away from the paved area.

Retrofitting drainage improvements requires partial installation removal in affected areas. You should extend corrections at least 3 feet beyond visible efflorescence zones, since moisture spreads laterally through base materials. Base reconstruction typically involves removing existing aggregate, installing geotextile fabric, adding 4-6 inches of clean, angular drainage aggregate (3/4″ crushed stone works well), and incorporating edge drains that outlet to daylight or collection systems. This level of intervention costs $15-25 per square foot but provides permanent resolution for chronic paving stone crystallization issues Arizona.

- Your drainage aggregate must meet minimum permeability standards of 50 inches per hour to prevent water accumulation at the setting bed interface

- Edge restraints require weep holes or permeable sections every 10-15 feet to allow lateral drainage rather than trapping water within the installation

- You need to verify that site grading maintains minimum 2% slope away from the paved area to prevent surface water infiltration

- French drains positioned along the upslope edge of installations intercept groundwater before it reaches the paving system

Irrigation system modifications eliminate a common moisture source. Overspray from sprinkler heads, leaking joints, or excessive watering schedules introduce more water than Arizona’s arid climate can evaporate quickly. You should redirect heads to avoid paved surfaces, convert to drip irrigation in planter areas adjacent to hardscape, and reduce watering frequency. Even minor irrigation contact can cause localized paving stone efflorescence treatment Arizona requirements in otherwise problem-free installations.

Joint Material Considerations in Efflorescence Control

The material filling joints between pavers significantly influences efflorescence patterns. Traditional silica sand contains minimal soluble salts but allows water to penetrate freely to the base layer. Polymeric sands create water-resistant barriers when properly activated but can contribute their own salt content during curing. When you see paving stone white deposits Arizona concentrated along joint lines, the joint material itself may be the source.

Joint sand selection requires you to balance drainage needs with stability. Clean, washed silica sand free of fines allows maximum permeability but requires periodic replacement as it migrates or washes away. Polymeric sand reduces maintenance and weed growth but needs careful installation to avoid surface hazing (polymer residue on paver faces) that resembles efflorescence. You must follow activation protocols precisely: sweep thoroughly before misting, use fine fog spray rather than heavy water streams, and allow proper curing time before subjecting the surface to traffic or additional moisture.

When you’re addressing paving stone salt buildup Arizona in existing installations, joint material replacement often proves necessary. Contaminated sand harbors salt deposits that continuously reintroduce minerals as moisture cycles through the system. Removing old joint sand (using specialized vacuum tools or pressure washing with immediate extraction), allowing complete drying, then refilling with clean material eliminates this source. Budget 10-15% of the original installation cost for comprehensive joint sand replacement on typical residential projects.

Material Selection for Efflorescence-Resistant Installations

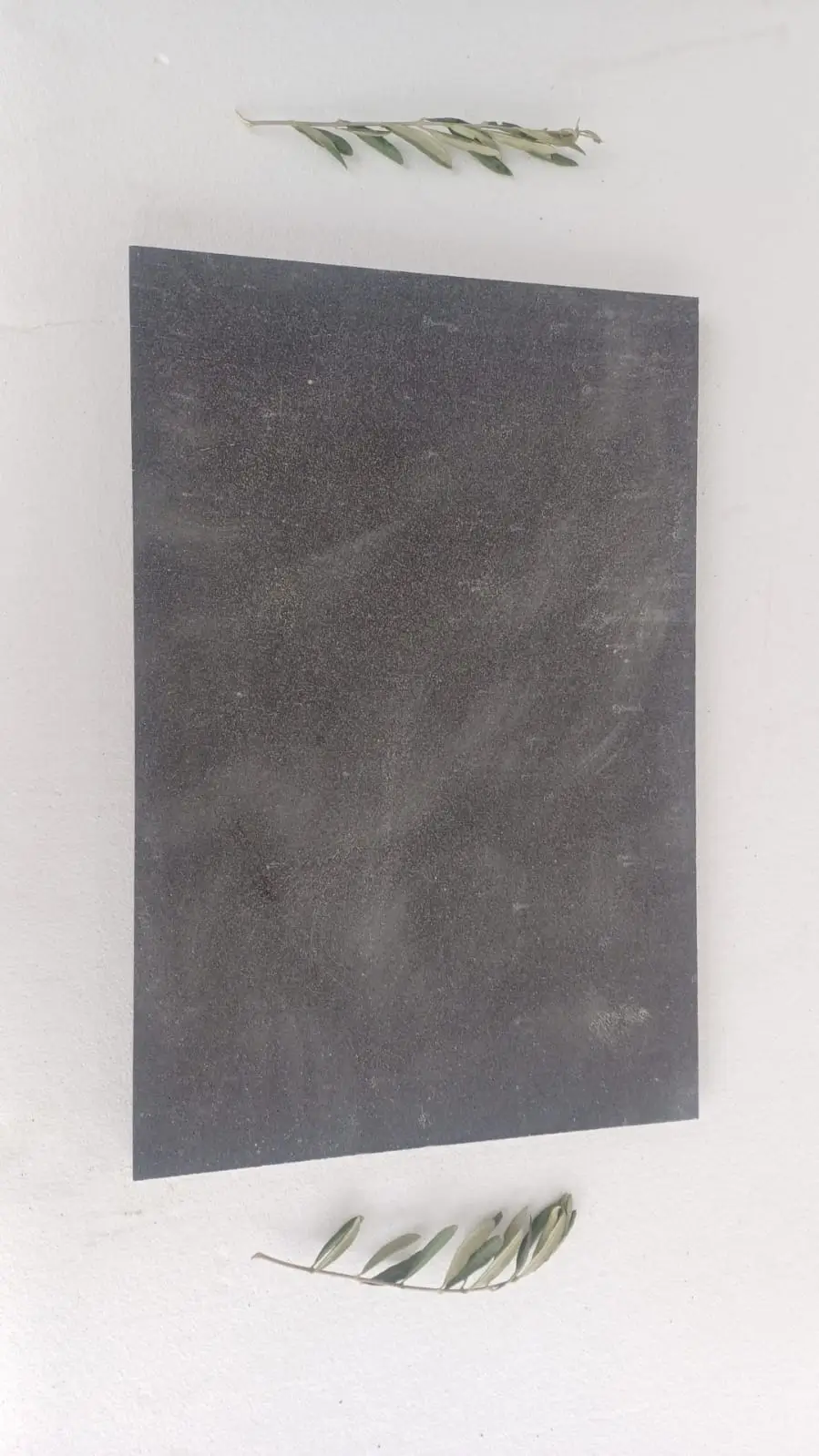

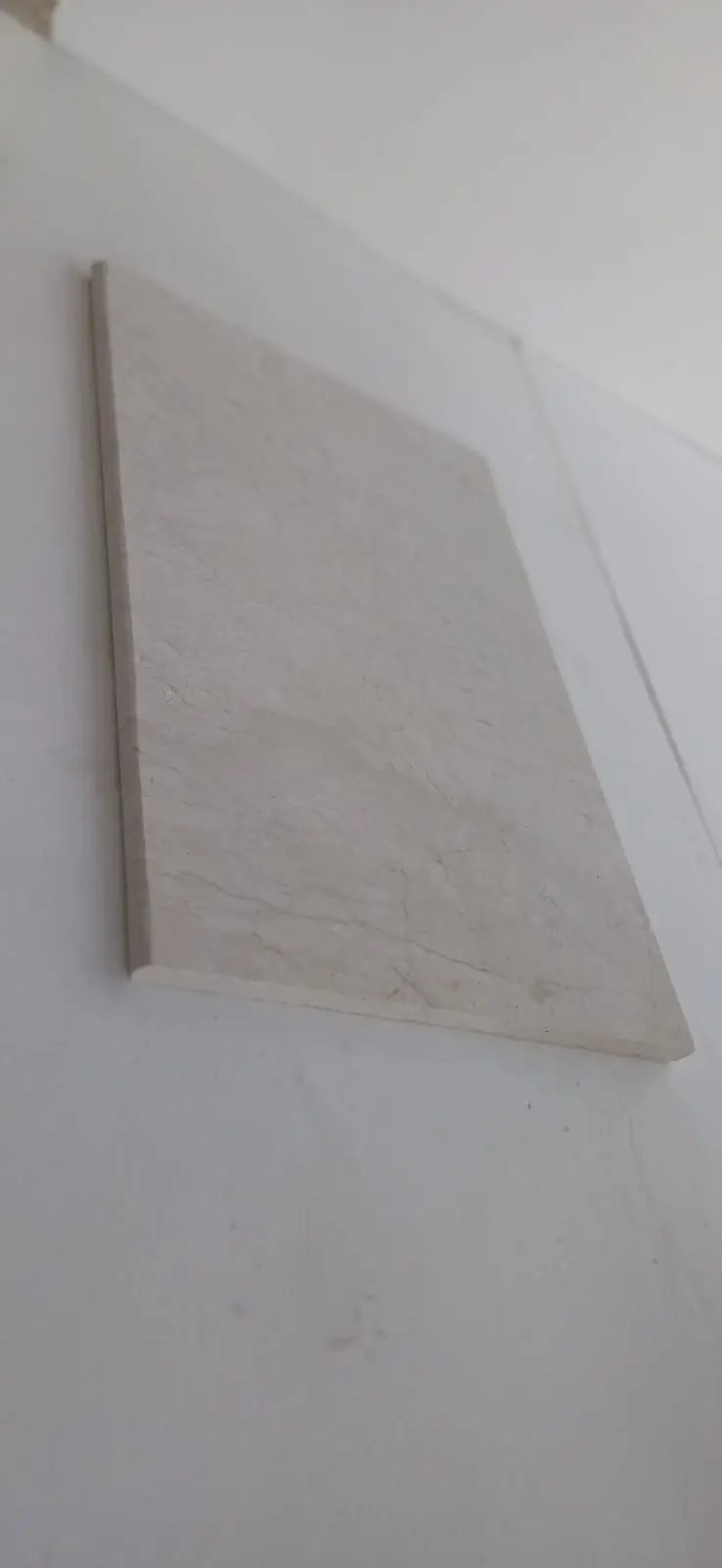

Your material choices at the specification stage dramatically affect long-term paving stone efflorescence treatment Arizona requirements. Dense, low-porosity materials (granite, some engineered concrete pavers) resist moisture penetration and salt migration more effectively than highly porous natural stones. However, material density must be balanced against other performance factors like slip resistance, thermal properties, and aesthetic requirements specific to Arizona applications.

Concrete paver manufacturing quality directly correlates with efflorescence propensity. Pavers produced with low water-to-cement ratios, proper curing protocols, and minimal calcium chloride accelerators exhibit significantly less efflorescence. You should verify that specified products meet ASTM C936 standards and request manufacturer documentation about water absorption rates (target below 5% for Arizona installations) and salt content testing. Premium manufacturers often provide efflorescence warranties that indicate confidence in their production quality control.

Natural stone selection requires you to understand geological composition. Limestone, travertine, and sandstone contain inherent calcium carbonate that contributes to paving stone mineral staining Arizona through normal weathering processes. Granite, quartzite, and some basalts have much lower soluble mineral content. However, even resistant stone types can exhibit efflorescence if set in mortar or grout with high salt content. Your specification should address the complete assembly — stone, setting materials, base, and joints — as an integrated system.

Citadel Stone — manufactured paving stones in Arizona Efflorescence Solutions

When you evaluate manufactured paving stones in Arizona through Citadel Stone’s technical lens, you’re examining materials engineered specifically for desert climate performance. At Citadel Stone, we emphasize the importance of understanding regional moisture dynamics before material selection. This case study section provides hypothetical specification guidance for six representative Arizona cities, illustrating how you would adapt paving stone efflorescence treatment Arizona protocols to local conditions.

Phoenix Urban Heat

In Phoenix’s urban core, you face temperatures exceeding 115°F combined with alkaline soils (pH 8.0-8.5) and occasional monsoon deluges. Your material specification would prioritize dense pavers with absorption rates below 4% to minimize moisture penetration. You’d need to account for rapid surface temperature changes that accelerate salt crystallization during morning dew periods. Efflorescence prevention here requires you to emphasize subsurface drainage capacity capable of handling 2-inch-per-hour monsoon intensity while preventing upward capillary action during Phoenix’s 200+ days of zero precipitation. Base layer specifications would call for minimum 6-inch clean aggregate depth with edge drainage provisions every 12 linear feet.

Tucson Soil Chemistry

Tucson’s caliche soil layers create unique challenges for addressing paving stone crystallization issues Arizona. You would need to specify excavation depths that penetrate below caliche horizons (typically 18-30 inches) to prevent the calcium carbonate-rich hardpan from contributing to efflorescence. Your installation protocol would include geotextile separation between native soil and base aggregate to prevent caliche migration. When you specify treatments for existing Tucson installations, you’d focus on calcium-based deposit removal using diluted acidic cleaners, since the geological chemistry strongly favors calcium carbonate efflorescence. Warehouse staging in Tucson requires covered storage to prevent pre-installation moisture absorption during summer monsoon humidity spikes.

Scottsdale Premium Standards

Scottsdale’s high-end residential and commercial projects demand you balance efflorescence resistance with aesthetic sophistication. You would specify premium manufactured paving stones in Arizona with integral color (rather than surface-applied pigments) to minimize color variation if chemical treatments become necessary. Your design specifications would incorporate architectural details like recessed joints with polymeric sand engineered for minimal salt contribution. When addressing paving stone white deposits Arizona in luxury Scottsdale installations, you’d recommend professional treatment services rather than DIY approaches to protect property values. Material selection would favor proven low-efflorescence products even at 20-30% cost premiums, since the total project investment justifies minimizing maintenance requirements over the 25-year design life.

Flagstaff Freeze Considerations

At Flagstaff’s 7,000-foot elevation, you encounter freeze-thaw cycles that compound paving stone efflorescence treatment Arizona challenges. Your material specifications would require freeze-thaw durability testing per ASTM C1645 in addition to efflorescence resistance. You’d need to address the interaction between salt deposits and freeze damage — efflorescence in joints can cause ice lens formation that displaces pavers. Treatment timing becomes critical since you can’t apply water-based cleaners when overnight temperatures drop below 40°F. Your installation specifications would emphasize even more rigorous drainage standards, since trapped moisture creates both efflorescence and structural damage through freeze expansion. Truck delivery scheduling requires you to account for winter road closures and summer wildfire risks that affect material availability.

Sedona Red Rock

Sedona’s iconic red rock geology influences soil chemistry and aesthetic requirements for manufactured paving stones in Arizona applications. You would specify warm earth-tone materials that complement the natural environment while resisting the iron oxide-rich soil’s contribution to staining and efflorescence. Your treatment protocols would need to distinguish between true efflorescence (white salt deposits) and reddish staining from iron-bearing groundwater. When you address paving stone mineral staining Arizona in Sedona contexts, standard acidic cleaners may intensify iron staining while removing calcium deposits. You’d recommend oxalic acid-based treatments for iron staining and standard efflorescence removers for white deposits, applied in sequence. The tourist-focused economy requires you to schedule major treatments during shoulder seasons to avoid disrupting business operations.

Yuma Extreme Aridity

Yuma’s position as one of the driest cities in North America creates paradoxical efflorescence risks. The Colorado River’s agricultural influence introduces elevated groundwater salinity that you must account for in specification documents. Your drainage designs would need to prevent capillary rise from saline groundwater tables (often 6-10 feet deep in developed areas). When you encounter paving stone salt buildup Arizona in Yuma installations, the deposits often contain sodium sulfate rather than the calcium carbonate common elsewhere. This requires you to specify mechanical removal or specialty cleaners rather than standard acid treatments. Material selection favors impermeable surfaces with minimal absorption, even at the cost of reduced slip resistance, since moisture barrier properties outweigh other factors. At Citadel Stone, we maintain warehouse inventory considerations for Yuma’s remote location, where truck transport from Phoenix distribution centers requires 3-4 day lead times for specialty treatment products and replacement materials.

Preventive Maintenance Programs to Minimize Treatment Needs

Establishing routine maintenance protocols significantly reduces the frequency and severity of paving stone efflorescence treatment Arizona interventions. You should implement quarterly inspections that document efflorescence emergence patterns, drainage system performance, and joint material condition. Early detection allows you to address localized issues before they spread across entire installations. Photographic documentation provides baseline comparisons that help distinguish normal weathering from progressive efflorescence.

Regular cleaning removes surface contaminants before they contribute to efflorescence. You need to sweep or blow debris weekly in high-traffic areas, since organic matter decomposition introduces additional salts and retains moisture against paver surfaces. Monthly rinsing with clear water during Arizona’s dry seasons helps remove atmospheric dust and minor salt deposits before they accumulate. Your maintenance schedule should account for seasonal variations — increase frequency during and immediately after monsoon season when moisture infiltration peaks.

- You should verify joint sand levels annually and replenish to within 1/8 inch of paver chamfers to maintain drainage function and prevent lateral moisture migration

- Your sealer maintenance includes reapplication at manufacturer-specified intervals, typically every 2-4 years depending on product type and exposure conditions

- Drainage system inspections need to confirm that edge outlets remain clear and base permeability hasn’t been compromised by soil infiltration

- When you identify areas with recurring paving stone white deposits Arizona despite treatment, consider those locations for subsurface drainage retrofits rather than repeated surface interventions

Documentation creates institutional knowledge essential for large properties with multiple installations. Your maintenance records should log treatment methods, products used, application dates, and effectiveness observations. This data helps you refine protocols, identify problematic areas requiring capital improvements, and provide accurate cost forecasting for annual budgets. Professional property managers typically allocate $0.15-0.35 per square foot annually for comprehensive paving stone maintenance that prevents major efflorescence problems.

Professional Services Versus Owner Treatment Decisions

Determining whether to engage professional contractors or pursue DIY paving stone efflorescence treatment Arizona depends on several factors. For installations under 500 square feet with light, recent efflorescence, you can typically achieve satisfactory results using retail cleaning products and mechanical methods. Projects exceeding 1,000 square feet, installations with chronic recurring deposits, or situations requiring subsurface drainage modifications warrant professional evaluation and treatment.

Professional services provide expertise in proper chemical selection and application techniques that prevent stone damage. You’re paying for knowledge about material-specific reactions, proper dilution ratios, safety protocols, and disposal compliance. Contractors maintain commercial-grade equipment (adjustable pressure washers, professional-grade cleaners, moisture meters) that achieves results difficult to replicate with consumer tools. Insurance coverage protects you from liability if treatment damages the installation — a critical consideration for commercial properties or homeowner association common areas.

Cost analysis helps you evaluate the trade-off between professional services and owner treatment. DIY approaches using retail products typically cost $0.25-0.75 per square foot for materials and equipment rental. Professional treatment ranges from $1.50-4.00 per square foot depending on severity and required methods. However, improper DIY treatment that damages stone surfaces can necessitate replacement costing $15-30 per square foot. For valuable installations or uncertain situations, professional evaluation (typically $200-400) provides diagnosis and treatment recommendations that allow informed decisions about proceeding independently or hiring full-service remediation.

Environmental and Regulatory Considerations for Treatment Methods

Arizona’s environmental regulations affect how you conduct paving stone efflorescence treatment Arizona, particularly regarding chemical usage and wastewater disposal. Acidic cleaning solutions, if not properly neutralized, can harm desert vegetation and alter soil chemistry in ways that persist for years. You must contain and neutralize runoff rather than allowing it to flow into landscape areas, storm drains, or natural drainage channels. Most municipal codes prohibit discharge of acidic or high-pH cleaning solutions into stormwater systems without prior neutralization.

Your treatment planning should include containment methods appropriate to project scale. Small residential applications might use sand berms and absorbent materials to capture runoff for proper disposal. Larger commercial projects require pump-and-haul systems that collect all wastewater for off-site treatment or neutralization tanks that adjust pH to 6.5-8.5 before controlled release. Professional contractors typically include these provisions in their scopes, while DIY treatments often overlook environmental compliance, creating potential liability exposure.

Material safety data sheets (MSDS) for cleaning products specify proper handling, storage, and disposal requirements. You’re legally responsible for compliance even on residential properties. Concentrated acids require specific storage conditions, spill containment provisions, and emergency response equipment. When you’re comparing paving stone efflorescence treatment Arizona product options, factor in disposal costs for hazardous materials versus more environmentally friendly alternatives that may cost more initially but eliminate special handling requirements.

Technical Specifications for New Installations That Minimize Efflorescence

Prevention through proper initial installation far exceeds treatment costs for addressing paving stone crystallization issues Arizona after completion. Your specifications should mandate materials testing for soluble salt content in pavers, setting bed sand, and base aggregate. ASTM C1580 provides standardized methodology for measuring water-soluble sulfate content in concrete materials. Specifying maximum thresholds (typically below 0.03% by weight) eliminates high-risk materials before installation.

Base preparation specifications determine long-term efflorescence resistance. You need to require compaction testing at 95% modified Proctor density for the subgrade and 92-95% for aggregate base layers. Overcompaction (above 96%) can reduce permeability and create impermeable layers that trap moisture. Your specifications should detail aggregate gradation (avoid excessive fines that inhibit drainage), depth requirements based on soil conditions and intended use, and geotextile placement between native soil and aggregate base to prevent contamination.

- You should specify that setting bed sand must be clean, angular, and meet ASTM C33 gradation requirements with less than 3% passing the No. 200 sieve to ensure proper drainage

- Your edge restraint details need to include provisions for moisture escape rather than creating impermeable barriers that trap water within the installation

- Joint sand specifications should address both immediate installation requirements and long-term performance, balancing stability with permeability

- When you specify sealers as part of new construction, require minimum 30-day curing period before application to allow residual construction moisture to dissipate and avoid trapping salts

Construction sequencing specifications prevent contamination that leads to efflorescence. You should prohibit installation during rain events or when precipitation is forecast within 48 hours. Require covering of stored materials to prevent moisture absorption before installation. Specify that concrete flatwork (pool decks, patios adjacent to pavers) be completed and fully cured before paver installation to prevent cement contamination. These provisions add minimal cost but dramatically reduce paving stone mineral staining Arizona risks that require expensive post-installation remediation.

Long-Term Performance Expectations and Warranty Considerations

Understanding realistic outcomes helps you set appropriate expectations for paving stone efflorescence treatment Arizona. Primary efflorescence (from initial installation moisture and material curing) typically resolves within 12-18 months without intervention beyond basic cleaning. Secondary efflorescence from ongoing moisture infiltration requires addressing root causes; surface treatment alone provides only temporary 3-6 month relief before recurrence. You should communicate these distinctions clearly when discussing projects with clients or property owners.

Treatment effectiveness varies by deposit type and installation conditions. Calcium carbonate efflorescence responds well to acidic cleaning, often showing 90-95% removal after single treatment. Sodium sulfate proves more resistant, typically requiring multiple interventions to achieve 70-80% reduction. When subsurface drainage improvements accompany surface treatment, you can expect 5-7 years minimum before significant efflorescence reappears. Without drainage correction, recurring deposits often emerge within one season, requiring you to reset expectations or recommend comprehensive remediation.

Warranty implications require careful consideration when you’re specifying paving stone efflorescence treatment Arizona methods for commercial projects. Aggressive treatments, particularly strong acids or abrasive techniques, may void manufacturer warranties on certain materials. You should review warranty terms before proceeding and document that recommended treatments won’t compromise coverage. Professional installation warranties typically exclude efflorescence unless installation defects contributed to the condition. Material warranties generally cover manufacturing defects but not normal efflorescence from environmental factors. For additional surface maintenance insights, review Professional pressure washing methods for Arizona paving stone surfaces before you finalize long-term maintenance protocols. Hardscape installations feature Citadel Stone’s diverse paver stones in Arizona material selection.