When you specify natural stone for Arizona projects, understanding the geological origin of natural flagstone geological origin Arizona becomes fundamental to making informed material decisions. You need to recognize how millions of years of sedimentary deposition, tectonic activity, and mineral transformation created the material characteristics you’ll work with today. Your specifications depend on recognizing that natural flagstone formation occurred through distinct geological processes that directly affect performance, durability, and installation requirements.

The natural flagstone geology you encounter in Arizona represents complex interactions between ancient marine environments, volcanic activity, and metamorphic pressure. You’ll find that regional variations in natural flagstone stone composition create substantial differences in thermal properties, porosity, and structural integrity. When you evaluate materials for your projects, you should understand these geological origins because they determine how the stone responds to Arizona’s extreme climate conditions.

Sedimentary Deposition Origins

Natural flagstone geological origin Arizona traces back to sedimentary processes that occurred 200-600 million years ago during Paleozoic and Mesozoic eras. You’re working with materials formed when Arizona existed beneath shallow seas and coastal environments. Sediment accumulation from marine organisms, clastic particles, and chemical precipitation created distinct stratification patterns that define flagstone’s characteristic layered structure.

The natural flagstone formation process began with fine-grained sediments settling in horizontal beds under marine conditions. You should understand that particle size, deposition rate, and water chemistry during formation directly influence the stone’s current working properties. Limestone and sandstone flagstone varieties originated from different sedimentary environments — limestone from calcium carbonate precipitation and organic accumulation, sandstone from quartz-rich terrestrial sediment transport.

Your material selection requires recognizing how original sedimentary composition affects modern performance. Fine-grained deposits with consistent particle distribution produce flagstone with predictable splitting characteristics and uniform thickness tolerances. Coarser sedimentary environments created more variable stone with wider dimensional tolerances that require adjusted installation techniques.

Compression and Lithification Process

After initial sediment deposition, natural flagstone geological origin Arizona continued through lithification — the transformation of loose sediment into solid rock. You need to understand that overburden pressure from thousands of feet of overlying material compressed sediment layers over millions of years. This compression expelled pore water, compacted particles, and initiated chemical cementation processes that bound individual grains into coherent stone.

The natural flagstone geology during lithification determined critical performance characteristics you’ll encounter today:

- Compressive strength developed through interparticle bonding ranges from 6,000 to 14,000 PSI depending on cementation quality

- Porosity characteristics emerged based on how completely pore spaces filled during lithification, affecting water absorption from 1% to 8%

- Density variations resulted from compaction efficiency, influencing thermal mass properties and structural capacity

- Splitting planes formed along bedding interfaces where cementation remained weakest, creating the cleavage that allows flagstone production

When you specify flagstone, you’re selecting material where lithification reached sufficient completion to provide structural integrity but retained bedding planes that permit controlled splitting. Incomplete lithification produces friable stone unsuitable for paving applications. Excessive metamorphism eliminated bedding planes, preventing economic flagstone production.

Mineral Cementing Agents

The natural flagstone stone composition depends critically on cementing agents that bonded sedimentary particles during lithification. You’ll encounter three primary cement types that determine stone characteristics: siliceous (quartz), calcareous (calcite), and ferruginous (iron oxides). Your performance expectations must account for which cementing agent predominates in your selected material.

Siliceous cementation produces the most durable flagstone for Arizona applications. When you work with silica-cemented stone, you’re specifying material with superior weather resistance, minimal acid sensitivity, and excellent abrasion resistance. Quartz cement bonds create compressive strengths exceeding 12,000 PSI and absorption rates below 3%. The trade-off involves higher material costs and more challenging fabrication compared to calcite-cemented varieties.

Calcareous cementation characterizes limestone flagstone common in Arizona quarries. You should recognize that calcite cement provides adequate structural performance — typically 8,000-10,000 PSI compressive strength — while maintaining easier cutting and finishing characteristics. However, you need to account for calcite’s acid sensitivity in areas with acidic precipitation or where pool chemicals may contact the material. Efflorescence potential increases with calcareous cement due to calcium carbonate solubility.

Ferruginous cementation contributes the distinctive red, orange, and brown coloration you see in many Arizona flagstones. Iron oxide cements provide moderate strength (7,000-9,000 PSI) and create aesthetically desirable warm tones. When you specify iron-cemented stone, verify UV stability because some iron compounds fade under prolonged solar exposure exceeding 3,000 hours annually of direct radiation.

Tectonic Uplift and Exposure

Natural flagstone geological origin Arizona includes tectonic uplift that brought deeply buried sedimentary formations to accessible depths for quarrying. You’re benefiting from Colorado Plateau uplift and Basin and Range extension that occurred 10-30 million years ago. These tectonic events raised ancient seabed deposits thousands of feet, tilted bedding planes, and created fracture systems that facilitate modern extraction.

The uplift process affected natural flagstone geology in ways that influence your current sourcing and specification decisions. Tectonic stress created systematic joint patterns perpendicular to bedding planes, allowing quarries to extract large, relatively uniform slabs. You’ll find that flagstone from tectonically stable formations exhibits more consistent dimensions and fewer internal fractures than material from intensely deformed regions.

Regional variations in uplift timing and magnitude created the geographic diversity in Arizona flagstone sources. Northern Arizona formations experienced earlier, more pronounced uplift with greater erosional exposure. Southern Arizona deposits underwent later, less uniform uplift with more variable overburden removal. When you source material, understanding these tectonic patterns helps predict availability, dimensional consistency, and quarry-specific characteristics.

Metamorphic Grade Considerations

Some natural flagstone geological origin Arizona involves low-grade metamorphism where heat and pressure partially recrystallized original sedimentary minerals without destroying bedding structure. You need to distinguish between purely sedimentary flagstone and slightly metamorphosed varieties because metamorphic grade significantly affects material properties and performance.

Low-grade metamorphism improved certain performance characteristics you’ll value in demanding applications. Recrystallization increased interparticle bonding, raising compressive strength by 15-25% compared to unmetamorphosed equivalents. Porosity typically decreased as recrystallization filled void spaces, reducing absorption and improving freeze-thaw resistance. However, you should verify that metamorphism remained mild enough to preserve splitting characteristics — higher metamorphic grades eliminate the bedding-plane weakness essential for flagstone production.

The natural flagstone mineral content changes during metamorphism as original minerals transform into more stable phases. Clay minerals convert to chlorite and fine-grained micas, calcite recrystallizes into larger, more interlocked grains, and quartz undergoes pressure solution and reprecipitation. When you examine metamorphosed flagstone, you’ll observe slightly higher density, finer grain texture, and often more pronounced foliation compared to purely sedimentary equivalents.

Regional Compositional Variations

Your understanding of natural flagstone stone composition requires recognizing Arizona’s substantial regional variations in chemical and mineralogical makeup. Northern Arizona flagstones predominantly derive from Paleozoic marine limestones and sandstones with high calcite and quartz content. Central Arizona sources include more volcanic influence with feldspathic components and iron-rich cements. Southern Arizona formations contain mixed sedimentary-volcanic assemblages with variable composition.

These compositional variations directly impact specifications you’ll write for different applications:

- Calcite-dominant northern materials excel in dry climates but require sealing in areas with acidic exposure or freeze-thaw cycling

- Quartz-rich sandstone flagstones provide maximum durability for high-traffic commercial applications where abrasion resistance determines service life

- Iron-oxide-cemented central Arizona stones deliver distinctive coloration but you must verify fade resistance through accelerated weathering data

- Mixed-composition southern varieties offer aesthetic diversity but require careful quality control to ensure consistent performance within single projects

When you source from multiple quarries, natural flagstone mineral content variations necessitate separate testing protocols for each source. Don’t assume equivalent performance between compositionally different materials even when visual appearance seems similar. Your specifications should reference specific quarry sources or require comprehensive testing to verify performance criteria.

Porosity and Permeability Development

The natural flagstone formation process created interconnected pore networks that control water absorption, freeze-thaw durability, and staining susceptibility. You need to understand that porosity in flagstone developed through multiple mechanisms during geological history. Primary porosity existed in original sediment before lithification — spaces between deposited particles. Secondary porosity formed later through mineral dissolution, fracture propagation, and weathering processes.

Your performance specifications must address porosity characteristics because they govern critical durability factors. Total porosity measures void space percentage — typically 2-12% in Arizona flagstone — but interconnected porosity determines actual water penetration. You’ll find that some high-porosity stones with isolated pore spaces absorb less water than lower-porosity materials with well-connected pore networks.

Testing protocols should measure both absorption rate and total absorption capacity. ASTM C97 testing provides standardized absorption data, but you need 24-hour immersion results to capture complete saturation behavior. Stones absorbing more than 5% by weight require enhanced sealing protocols in freeze-thaw environments. Materials exceeding 7% absorption present increased staining risk and may prove unsuitable for pool decks or food service areas where spills occur frequently.

Permeability — the rate at which water moves through stone — affects drainage performance and efflorescence potential. When you specify flagstone for applications requiring drainage, such as permeable paving systems, you need materials with sufficient permeability to meet stormwater management requirements. Conversely, for our flagstone paving building materials in applications where water intrusion should be minimized, lower permeability provides better performance.

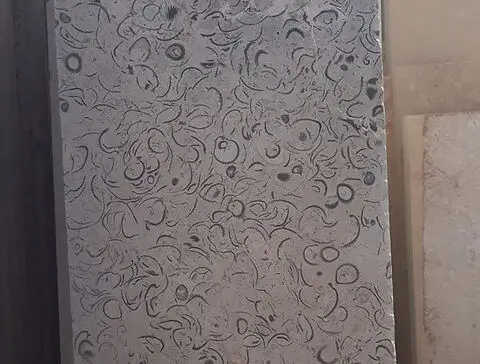

Color Origin and Mineral Pigments

The aesthetic characteristics you specify in natural flagstone geological origin Arizona derive from trace minerals and oxidation states present during formation. Color variations don’t merely provide visual interest — they indicate compositional differences that affect performance. You should understand the geological processes that created color variations to predict durability and aging characteristics.

Red, orange, and brown flagstone colors result from iron oxide minerals (hematite and goethite) that formed through oxidation of iron-bearing minerals. These warm tones developed in oxidizing depositional environments or through later groundwater circulation. When you specify iron-pigmented stone, verify that coloration penetrates throughout the material rather than existing as surface coatings. Surface-only coloration fades within 5-8 years under Arizona’s intense solar radiation, while integral pigmentation maintains appearance for decades.

Gray and blue-gray coloration indicates reduced iron states or absence of iron compounds. These neutral tones typically occur in limestone with minimal iron content or in reducing depositional environments where oxygen remained limited. You’ll find gray flagstones generally exhibit more consistent coloration with less variation between pieces compared to iron-rich varieties.

Tan and buff colors suggest intermediate iron content with mixed oxidation states or presence of clay minerals. These earth tones provide visual warmth while maintaining better color stability than highly oxidized red varieties. When you need predictable, long-term color performance, moderately pigmented tan flagstones offer optimal balance between aesthetic interest and colorfastness.

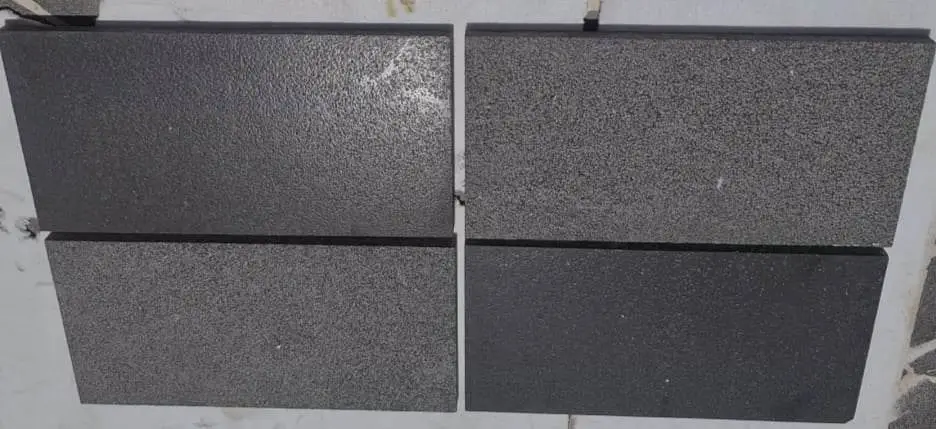

Texture and Surface Characteristics

Natural flagstone geology determines surface texture characteristics that affect slip resistance, aesthetic appearance, and maintenance requirements. You’re working with materials where original sediment grain size, lithification completeness, and weathering exposure created the textures you’ll specify for different applications.

Fine-grained limestone flagstones typically present smooth, relatively uniform surfaces with minimal texture variation. You’ll measure DCOF slip resistance values of 0.38-0.45 on honed surfaces, increasing to 0.48-0.55 on thermal or cleft finishes. These materials suit formal installations where refined appearance matters, but you need to specify textured finishes for wet areas or sloped surfaces where slip resistance becomes critical.

Coarse-grained sandstone flagstones exhibit pronounced texture from visible quartz grains and rougher bedding plane surfaces. Natural cleft surfaces provide DCOF values of 0.52-0.62, offering excellent slip resistance without additional texturing. When you specify sandstone flagstone for pool decks or high-traffic commercial applications, the inherent surface texture often eliminates need for secondary finishing operations.

Weathered surfaces on flagstone display enhanced texture from differential erosion of softer mineral components. You can specify naturally weathered material for rustic aesthetics and maximum slip resistance, but recognize that weathered surfaces often show greater dimensional variation and require more complex installation to achieve uniform finished appearance.

Thermal Properties and Climate Response

Understanding natural flagstone formation helps you predict thermal behavior critical for Arizona applications. The geological processes that created flagstone determined its thermal mass, conductivity, and expansion characteristics. Your specifications must account for how these thermal properties affect installation details and long-term performance.

Natural flagstone geological origin Arizona produced materials with thermal mass properties suitable for desert climate temperature moderation. Limestone flagstone exhibits volumetric heat capacity of 28-32 BTU/ft³·°F, allowing significant daytime heat storage with gradual nighttime release. When you design courtyard installations in Phoenix or Tucson, this thermal mass reduces peak surface temperatures by 8-12°F compared to low-mass alternatives during late afternoon hours.

Thermal conductivity varies with natural flagstone stone composition and porosity. Dense, low-porosity limestone conducts heat at 1.3-1.6 BTU/hr·ft·°F, transferring surface heat to substrate more rapidly than porous sandstone at 0.9-1.2 BTU/hr·ft·°F. You’ll need to account for these conductivity differences when specifying flagstone over occupied spaces or when subsurface temperature control matters for plant root zones in landscape applications.

Thermal expansion coefficients depend on mineral composition established during formation. Calcite-dominant limestone expands at approximately 3.6 × 10⁻⁶ per °F, while quartz-rich sandstone exhibits expansion around 6.7 × 10⁻⁶ per °F. Your joint spacing calculations must accommodate these expansion rates — for 15-foot field sections in areas experiencing 80°F daily temperature swings, you need minimum 3/16″ joints for limestone and 5/16″ joints for sandstone to prevent compression damage.

Durability Factors and Geological Influence

The geological processes forming natural flagstone geological origin Arizona directly determine durability characteristics you’ll rely on for project longevity. Your specifications should connect geological origin to expected service life under specific exposure conditions.

Weathering resistance correlates strongly with natural flagstone mineral content and cementation quality. Silica-cemented sandstones formed under high-pressure diagenesis resist Arizona’s weathering mechanisms — thermal cycling, wind abrasion, and occasional freeze-thaw events — more effectively than loosely cemented calcareous varieties. When you need 30+ year service life in exposed conditions, prioritize materials with compressive strength exceeding 10,000 PSI and absorption below 4%.

Abrasion resistance depends on hardness and cementation of constituent minerals. Quartz-dominated flagstones formed from mature sediment sources (minerals already weathered and transported) typically outperform compositionally immature stones containing feldspars and softer minerals. You should specify ASTM C1353 abrasion testing for high-traffic applications — materials with abrasion index below 25 provide optimal performance in commercial plaza installations experiencing 1,000+ daily foot traffic counts.

Chemical durability varies with the natural flagstone geology that established mineral composition. Limestone flagstone proves susceptible to acid attack from atmospheric deposition, though this poses minimal concern in Arizona’s alkaline environment. However, you must account for chemical exposure from pool maintenance, landscape fertilization, and cleaning products. Specify chemically resistant sealers for flagstone in these exposure conditions, or select siliceous stone varieties with inherent acid resistance.

Best Citadel Natural Flagstone in Arizona — Specification Guidance

When you consider Citadel Stone’s natural flagstone for your Arizona projects, you’re evaluating premium materials sourced from geologically optimal formations with proven performance characteristics. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach material selection and installation planning for six representative cities, each presenting distinct geological and environmental challenges.

Your specification process should account for regional variations in temperature extremes, solar exposure, precipitation patterns, and substrate conditions. The natural flagstone geological origin Arizona creates materials particularly suited to the state’s demanding climate, but you need to match specific stone characteristics to local conditions. Understanding which geological attributes matter most for each location ensures optimal long-term performance and client satisfaction.

Phoenix Applications

In Phoenix applications, you would prioritize natural flagstone stone composition with maximum thermal reflectivity and heat dissipation characteristics. Summer surface temperatures exceeding 180°F on dark materials require you to specify lighter-colored limestone or sandstone varieties with solar reflectance above 0.45. Your installation would need expansion joints every 12-15 feet to accommodate 90°F daily temperature swings during peak summer months. You should verify that selected material exhibits absorption below 5% to prevent subsurface moisture accumulation that could cause bedding mortar degradation. Warehouse inventory for Phoenix metro projects typically requires 3-4 week lead times during peak spring and fall construction seasons when you’re planning commercial plaza or residential courtyard installations.

Tucson Considerations

For Tucson projects, you would address similar extreme heat challenges as Phoenix but account for higher elevation and slightly increased precipitation. Your material selection would emphasize natural flagstone formation with proven UV resistance since Tucson receives approximately 350 sunny days annually with intense solar radiation. You’ll want to specify stones with thermal expansion coefficients at the lower end of the range — calcite-dominant limestone performs better than quartz-rich sandstone in Tucson’s temperature cycling conditions. Base preparation becomes critical in Tucson’s caliche-bearing soils; you need minimum 6-inch aggregate base over excavated caliche to prevent differential settlement. When you coordinate truck deliveries to Tucson sites, verify access for full-size delivery vehicles since many residential properties in foothill locations present challenging approach grades.

Scottsdale Specifications

Scottsdale installations would typically emphasize aesthetic refinement alongside performance requirements. You would specify natural flagstone geological origin Arizona materials with consistent color, minimal thickness variation, and refined edge characteristics to meet expectations for high-end residential and resort applications. Your dimensional tolerances would be tighter than standard commercial work — thickness variation within ±1/8″ rather than standard ±1/4″ to achieve premium finished appearance. You should plan for honed or lightly textured surface finishes that provide adequate slip resistance (DCOF 0.48-0.52) while maintaining sophisticated visual character appropriate to luxury contexts. At Citadel Stone, we recommend verification of warehouse stock for premium grades before finalizing project timelines, as top-grade materials may require 4-6 week procurement cycles.

Flagstaff Requirements

Your Flagstaff specifications would address dramatically different climate conditions than lower-elevation Arizona cities. At 7,000 feet elevation with 100+ annual freeze-thaw cycles, you must prioritize natural flagstone geology featuring low absorption (below 3%) and high compressive strength (minimum 10,000 PSI). The natural flagstone mineral content should favor silica-cemented varieties with proven freeze-thaw durability verified through ASTM C1026 testing. You would specify increased joint widths — minimum 3/8″ — to accommodate both thermal expansion and freeze-related movement. Base drainage becomes critical; you need free-draining aggregate base minimum 8 inches deep with geotextile separation from native soils to prevent frost heave. When you schedule deliveries to Flagstaff projects, account for winter weather restrictions that may limit truck access from November through March.

Sedona Contexts

Sedona applications would emphasize aesthetic integration with the region’s distinctive red rock geology. You would specify iron-oxide-pigmented flagstone that complements rather than competes with the natural landscape. Your material selection would focus on natural flagstone formation exhibiting warm red, orange, and tan coloration with color penetration throughout the stone thickness, not surface-only pigmentation. You should verify fade resistance since Sedona’s 4,500-foot elevation increases UV exposure compared to valley locations. Installation details would account for moderate freeze-thaw exposure (40-60 annual cycles) requiring absorption below 4.5% and proper base drainage. The area’s tourism-focused commercial developments require you to specify slip-resistant surfaces even when honed finishes are desired for aesthetic reasons — DCOF minimum 0.50 on all horizontal walking surfaces.

Yuma Parameters

In Yuma’s extreme desert climate with temperatures regularly exceeding 115°F and minimal annual precipitation, you would prioritize natural flagstone stone composition with maximum heat reflectivity and minimal maintenance requirements. Light-colored limestone with high solar reflectance (0.50-0.60) provides the most comfortable pedestrian surfaces during summer months. Your specifications would address Yuma’s intense solar exposure — approximately 4,000+ annual sunshine hours — requiring verification of long-term UV stability for pigmented stones. Dust and wind-blown sand create abrasion conditions that favor harder, denser stone varieties; you should specify materials with ASTM C1353 abrasion index below 20 for optimal longevity. Yuma’s limited warehouse infrastructure may require you to coordinate deliveries from Phoenix-area distribution centers, adding 2-3 days to standard lead times when you’re planning project schedules.

Specification Best Practices

Your professional specification process for natural flagstone geological origin Arizona requires integrating geological understanding with practical performance criteria and installation realities. You need to move beyond generic stone specifications to address material-specific characteristics derived from geological formation processes.

Comprehensive specifications should include:

- Compressive strength requirements with minimum values based on application (pedestrian, vehicular, or architectural cladding)

- Absorption limits appropriate to climate exposure and freeze-thaw risk

- Dimensional tolerances for thickness, length, and width that reflect available quarry production capabilities

- Surface finish requirements with corresponding slip resistance values verified through DCOF testing

- Color range definitions with sample approval procedures and batch variation allowances

You should require quarry-specific geological and performance data rather than accepting generic “flagstone” specifications. Request documentation of natural flagstone mineral content through petrographic analysis, absorption and density testing per ASTM C97, and compressive strength verification per ASTM C170. This data allows you to verify that supplied material matches your performance requirements and provides baseline documentation for future warranty or performance disputes.

Your installation specifications must account for geological characteristics affecting field performance. Joint spacing calculations should reference specific thermal expansion coefficients for your selected stone composition. Base preparation requirements need adjustment based on material porosity and permeability — higher-absorption stones require enhanced base drainage to prevent subsurface water accumulation. Sealer specifications should match stone porosity and intended exposure conditions, with penetrating sealers for low-absorption stones and film-forming products for higher-porosity materials in staining-prone applications.

Material Sourcing Considerations

Understanding natural flagstone formation helps you evaluate source quarries and make informed procurement decisions. Arizona’s geological diversity created numerous flagstone deposits, but quarry-specific variations in quality, consistency, and availability require careful evaluation beyond simple cost comparison.

When you source material, investigate the geological formation supplying each quarry. Quarries extracting from thick, uniform sedimentary beds typically provide better dimensional consistency and color uniformity than operations working thin, highly variable formations. You should verify that quarries extract from geologically consistent horizons rather than mixing materials from multiple formations, which creates unpredictable performance variations within single projects.

Quality control practices vary significantly between quarries. Professional operations conduct regular testing to verify compressive strength, absorption, and dimensional tolerances meet specified ranges. You should require certified test data from independent laboratories rather than accepting quarry-provided values. Request testing frequency information — quarterly testing from ongoing production provides more reliable data than single historical tests from years past.

Lead times depend on warehouse inventory levels, quarry production schedules, and transportation logistics. You can typically reduce project timeline risk by confirming material availability before specification finalization rather than discovering extended lead times after contracts are signed. For large projects exceeding 5,000 square feet, consider requesting quarry visits to inspect stockpiles, review quality control procedures, and verify production capacity to meet your schedule requirements.

Final Considerations

Your successful specification of natural flagstone geological origin Arizona depends on connecting geological formation processes to practical performance requirements and installation realities. You need to recognize that geological origin isn’t merely academic background — it directly determines the material characteristics your projects rely upon for decades of service life. When you understand how sedimentary deposition, lithification, mineral cementation, and tectonic exposure created the stone you’re specifying, you make better-informed decisions about material selection, installation details, and performance expectations.

The natural flagstone geology underlying Arizona materials provides substantial advantages for the state’s demanding climate conditions, but only when you match specific geological characteristics to application requirements. You should move beyond generic specifications to address compressive strength, absorption, thermal properties, and durability factors rooted in geological origin. Your professional specifications require testing data, quarry-specific information, and installation details that account for how geological formation affects field performance. For comprehensive technical guidance on related paving materials and dimensional specifications, review Dimensional tolerance standards for manufactured flagstone paving products before you finalize project documentation. Courtyard paving features Citadel Stone’s elegant flagstone for sale Mediterranean options.