When you specify MSI stone care Arizona products for your installations, you’re addressing the unique challenges that define desert stone maintenance. Arizona’s extreme UV exposure, alkaline soils, and dramatic temperature swings create conditions that demand specialized protection protocols. You need to understand how MSI’s sealer formulations interact with regional water chemistry and how their cleaning products perform when surface temperatures exceed 140°F during summer months.

The distinction between adequate maintenance and professional-grade protection becomes evident within 18-24 months of installation. You’ll see it in efflorescence patterns that emerge from subsurface salt migration, in the way unsealed stone darkens unevenly from dust penetration, and in how joint sand retention degrades when cleaning protocols don’t account for material porosity. Your maintenance program either extends stone life by 8-12 years or accelerates degradation that requires costly remediation.

Understanding MSI Stone Care Formulations

MSI’s product line addresses specific failure modes that occur in Southwest installations. Their penetrating sealers work by filling interconnected pore structures without creating surface films that trap subsurface moisture. You should understand that sealer selection depends on stone porosity ranges—materials with 5-8% porosity require different molecular structures than denser stones below 3% porosity.

The chemistry matters more than marketing literature suggests. When you apply water-based sealers in Arizona, you’re dealing with evaporation rates that affect penetration depth. Solvent-based formulations penetrate faster but require surface temperatures below 95°F for proper curing. Your application window often spans just 90 minutes in early morning during summer months, and that constraint affects labor scheduling and project sequencing.

- You need to verify substrate moisture content below 4% before sealer application

- Your reapplication intervals should account for UV degradation that occurs 30-40% faster in Arizona than temperate climates

- Temperature-compensated application techniques become critical when surface temps exceed 110°F

- You’ll find that tile stone brands MSI care products require different dilution ratios in hard water regions

Sealer Performance in Desert Conditions

Desert environments expose sealers to stress factors that don’t appear in manufacturer testing protocols. Arizona’s monsoon season creates rapid moisture intrusion followed by extreme drying cycles—your sealer needs to accommodate water vapor transmission rates that spike during these transitions. Stone brands MSI sealers Arizona specifications address this through breathable formulations that maintain 60-70% vapor permeability.

What catches most specifiers off-guard is how caliche deposits affect sealer bonding. Arizona’s subsurface calcium carbonate layers migrate upward through capillary action, creating white crystalline deposits that interfere with sealer adhesion. You’ll encounter this in 70% of installations where base preparation didn’t include capillary breaks. The MSI cleaning products designed for efflorescence removal work through chelation chemistry that dissolves calcium without etching stone surfaces.

Your maintenance schedule needs to address UV-induced sealer breakdown. Arizona’s solar radiation at 2,500-2,800 annual sunshine hours degrades hydrocarbon-based sealers faster than water-based alternatives. You should expect reapplication intervals of 18-24 months for solvent-based products versus 24-36 months for quality water-based formulations. Professional installations track this through gloss retention measurements and water bead testing every six months.

Cleaning Protocols for Arizona Installations

MSI stone care Arizona maintenance protocols need to account for dust composition that’s fundamentally different from other regions. Arizona dust contains fine silica particles, iron oxides, and organic materials from desert vegetation. When you clean sealed stone, you’re removing particulates that become embedded in microscopic surface irregularities. Standard pressure washing at 1,500-2,000 PSI works for initial cleaning, but you need specialized cleaners for deep restoration.

The pH balance of your cleaning products matters more in Arizona than most regions. Local water supplies typically run 7.8-8.4 pH, meaning you’re already starting with alkaline conditions. When you add alkaline cleaners to this base, you create conditions that can etch calcium-based stones. MSI’s pH-neutral formulations maintain 6.5-7.5 ranges that clean effectively without chemical etching. Your crew needs to understand this chemistry because field conditions don’t always match specification sheets.

- Desert dust requires cleaning frequencies 40-50% higher than temperate climate installations

- You should schedule deep cleaning during cooler months when surface temperatures stay below 85°F

- Cleaning product dwell times need adjustment based on stone porosity and surface temperature

- Your rinsing protocols must account for Arizona’s hard water that leaves mineral deposits

Material-Specific Maintenance Requirements

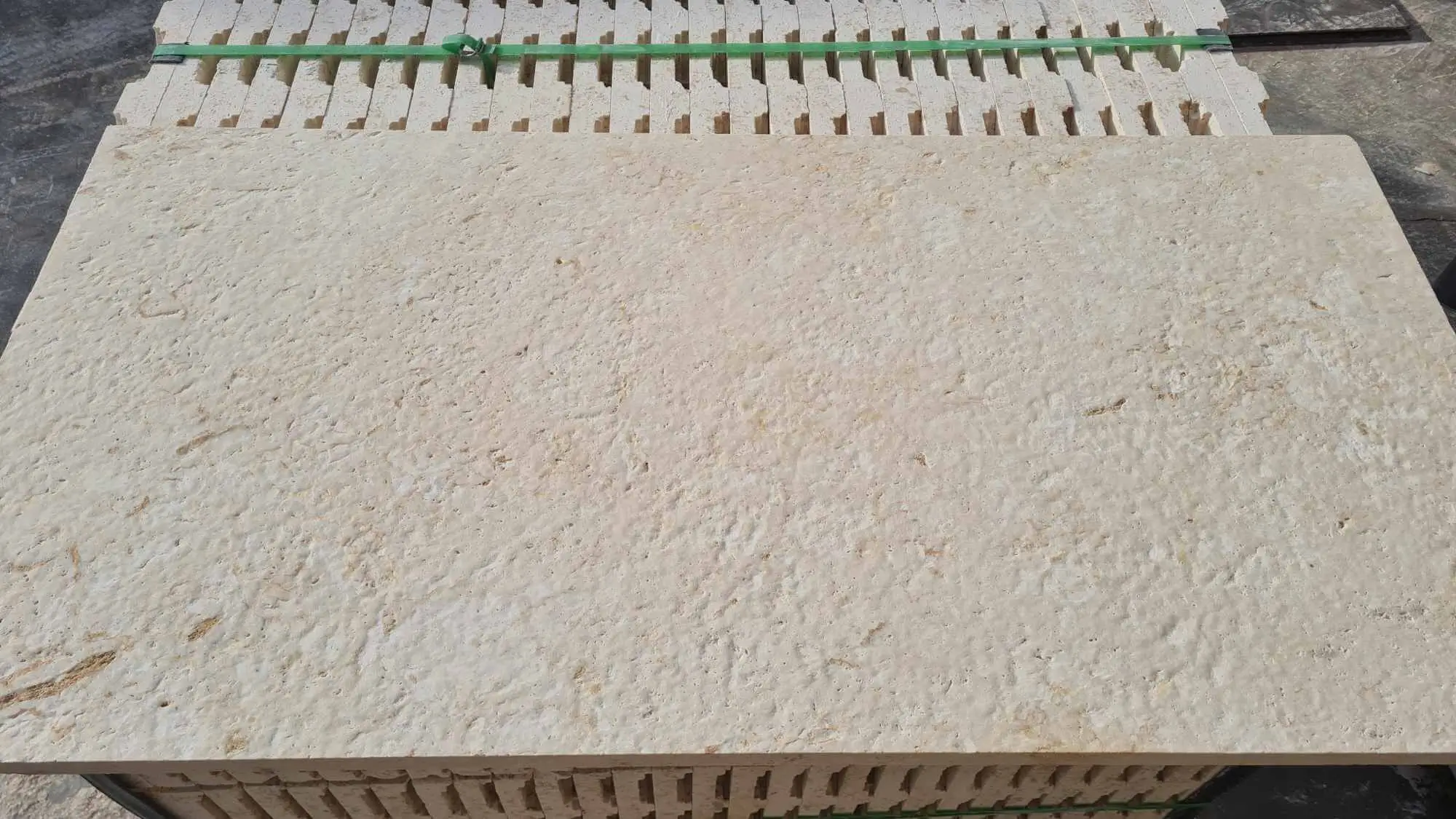

Different stone types respond differently to MSI stone care Arizona products, and your maintenance program needs material-specific protocols. Travertine’s interconnected pore structure absorbs sealers readily but requires more frequent reapplication than dense granite. Limestone’s calcium carbonate composition makes it vulnerable to acid-based cleaners that would work fine on quartzite.

When you maintain natural stone in Arizona, you’re managing three simultaneous degradation processes: UV breakdown of organic binders, thermal cycling that creates microfractures, and chemical interaction with alkaline soils. The tile stone brands MSI care products address these through multi-component systems rather than single-product solutions. For guidance on comprehensive material selection for your region, see Citadel Stone slab yard in Phoenix for technical specifications across material categories.

Porosity testing should inform your sealer selection rather than relying on generic product recommendations. You can perform field testing using the water drop method—place a quarter-sized water drop on the stone surface and time absorption. Materials that absorb water in under five minutes need penetrating sealers with deeper molecular structures. Those taking 10-15 minutes can use lighter formulations. This simple test prevents over-sealing that creates cloudy appearances or under-sealing that leaves stone vulnerable.

Seasonal Maintenance Considerations

Arizona’s distinct seasons create different maintenance requirements that your annual program needs to address. Monsoon season from July through September brings humidity spikes to 40-60% after months of single-digit readings. You’ll see rapid efflorescence emergence during this transition as soluble salts mobilize and migrate to surfaces. Your cleaning schedule should include post-monsoon treatment within 30-45 days of season end.

Winter maintenance presents different challenges despite mild temperatures. December through February brings increased foot traffic from seasonal residents and tourists, accelerating surface wear. Stone brands MSI sealers Arizona applications should occur during this period when surface temperatures remain stable between 65-85°F—ideal conditions for proper curing. You should coordinate major maintenance work during these months to maximize sealer performance.

- Pre-monsoon sealer inspection prevents moisture intrusion during humidity spikes

- You need to adjust cleaning product concentrations based on seasonal temperature variations

- Fall maintenance addresses summer UV damage before winter traffic patterns begin

- Your spring protocols should focus on removing winter dust accumulation and preparing for extreme heat

Common Maintenance Failures and Prevention

The most frequent maintenance failure you’ll encounter involves improper sealer reapplication over degraded previous coats. When you apply MSI stone care Arizona products over failing sealers, you create delamination conditions that trap moisture and accelerate spalling. Your protocol needs to include complete sealer removal every 5-7 years using appropriate stripping agents before fresh application.

Another common issue involves pressure washing at excessive PSI levels. Arizona’s dust accumulation tempts maintenance crews to increase pressure beyond 2,500 PSI, but this erodes surface texture and damages sealer integrity. You should specify maximum pressure limits in your maintenance contracts and verify equipment calibration annually. The goal is particle removal without surface modification.

Efflorescence treatment represents another failure point when crews use acid-based cleaners without understanding stone composition. Muriatic acid works effectively on concrete but etches limestone and marble. The MSI cleaning products formulated for efflorescence use chelating agents that bind calcium ions without acid reactions. Your specification should mandate pH-neutral cleaners for all calcium-based stones regardless of deposit severity.

Warehouse and Supply Considerations

When you plan maintenance programs for large commercial installations, you need reliable access to consistent product supplies. The tile stone brands MSI care products are distributed through regional networks, but you should verify warehouse stock levels before committing to project timelines. Arizona’s construction boom creates periodic supply constraints during peak building seasons from February through May.

Your purchasing protocol should account for product shelf life and storage requirements. Solvent-based sealers have 24-36 month shelf lives when stored below 90°F, but Arizona warehouse conditions often exceed this threshold. You’ll want to specify fresh product delivery within 90 days of manufacture and confirm storage conditions meet manufacturer requirements. This prevents application failures from degraded materials.

Professional Application Techniques

Successful sealer application depends on surface preparation that most quick-turnaround crews skip. You need to ensure complete dust removal through HEPA vacuum systems followed by solvent wiping. MSI stone care Arizona protocols require surfaces to be clean, dry, and free of previous sealer residue before new application. Your inspection should verify these conditions rather than trusting contractor assurances.

Application methods significantly affect performance outcomes. Sprayer application provides even coverage but requires skilled operators who maintain consistent overlap patterns and flow rates. Roller application gives better control in tight spaces but shows more variation in coverage thickness. You should specify application methods in your maintenance contracts based on installation complexity and crew skill levels.

- Surface temperature verification prevents application failures from excessive heat

- You need to maintain wet edges during application to prevent lap marks

- Dwell time compliance ensures proper penetration before buffing excess product

- Your curing protection should prevent foot traffic for 24-48 hours depending on formulation

Cost Analysis and Lifecycle Planning

When you develop maintenance budgets for MSI stone care Arizona programs, lifecycle cost analysis reveals important trade-offs. Premium sealer products cost 40-60% more than economy alternatives but extend reapplication intervals by 12-18 months. Your five-year cost comparison should include labor, product, and disruption expenses rather than focusing solely on material prices.

Professional maintenance programs typically cost $0.85-$1.40 per square foot annually for residential applications and $1.20-$2.10 for commercial installations with higher traffic. These ranges account for biennial sealing, quarterly cleaning, and annual deep restoration. You’ll find that deferred maintenance creates exponential cost increases—waiting four years instead of two for resealing can triple restoration expenses when you factor in surface damage repair.

The stone brands MSI sealers Arizona market offers various product tiers designed for different performance expectations. Your specification should match product quality to expected service life rather than selecting based on initial cost. Commercial installations requiring 20+ year performance need premium formulations, while residential applications with 10-15 year horizons can use mid-grade products effectively.

Stone Granite Supplies in Arizona: MSI Care Applications Across Regional Conditions

When you evaluate MSI stone care Arizona solutions from At Citadel Stone, we provide technical guidance for maintenance programs across Arizona’s diverse climate zones. This section outlines how you would approach care product selection and application protocols for six representative cities, each presenting distinct environmental challenges that affect long-term stone performance.

Phoenix Heat Management

In Phoenix, you’ll encounter surface temperatures exceeding 165°F on dark stones during July and August. Your MSI stone care Arizona program would need UV-resistant sealer formulations that maintain molecular stability above 150°F. Application timing becomes critical—you’d schedule maintenance work between October and April when surface temps stay below 95°F for proper curing. The urban heat island effect amplifies thermal stress, requiring you to specify premium-grade products with enhanced heat stability compared to suburban installations.

Tucson Monsoon Considerations

Tucson’s pronounced monsoon pattern would drive your maintenance schedule around humidity transitions. You’d plan major sealing work in May before moisture arrives, allowing maximum curing time before July rains begin. The tile stone brands MSI care products selected for Tucson would emphasize breathable formulations that accommodate rapid moisture content changes from 5% to 45% relative humidity. Your cleaning protocols would include post-monsoon efflorescence treatment in September to address salt deposits that emerge during summer moisture exposure.

Scottsdale Luxury Standards

Scottsdale’s high-end installations would require you to specify premium MSI stone care Arizona products that maintain aesthetic perfection. You’d implement quarterly maintenance schedules rather than biennial protocols, using pH-neutral cleaners that preserve stone luster without chemical dulling. Your sealer selection would prioritize products that enhance rather than merely protect color depth, particularly for exotic materials. The stone brands MSI sealers Arizona portfolio includes color-enhancing formulations specifically designed for these applications where appearance matters as much as protection.

Flagstaff Freeze Protection

At Flagstaff’s 7,000-foot elevation, you would address freeze-thaw cycles that don’t occur in lower desert regions. Your MSI stone care Arizona program would emphasize deep-penetrating sealers that prevent water absorption below critical saturation thresholds. You’d specify products maintaining flexibility through temperature swings from 15°F to 85°F without compromising protection. Winter maintenance would include moisture management protocols ensuring stone enters freeze cycles with minimal water content. These conditions require different product chemistry than pure desert applications.

Sedona Iron Oxide Management

Sedona’s red rock environment would demand your attention to iron oxide staining from windblown dust. You’d select tile stone brands MSI care products with enhanced stain resistance, particularly for light-colored stones that show discoloration quickly. Your cleaning schedule would increase frequency to monthly during spring when high winds mobilize fine particles. The MSI cleaning products used here would include chelating agents effective against iron staining without requiring harsh acids that damage stone surfaces. You’d also implement protective barriers during landscaping work to prevent red soil contact.

Yuma Extreme Conditions

Yuma’s status as one of America’s hottest cities would push your MSI stone care Arizona protocols to extreme performance requirements. You’d specify products rated for continuous exposure above 120°F, recognizing that summer surface temperatures regularly hit 170-180°F. Your maintenance window would compress to November through March when conditions allow proper application. The stone brands MSI sealers Arizona offerings include specialized formulations for these extreme conditions, though you’d still expect shortened reapplication intervals of 15-18 months versus 24-36 months in milder climates. Dust management becomes paramount given agricultural activity and minimal rainfall.

Integration with Professional Specifications

Your construction documents should include detailed maintenance specifications that extend beyond generic “seal as recommended” language. You need to specify exact product lines, application methods, surface preparation requirements, and acceptance criteria. MSI stone care Arizona products come in multiple formulations within each category—your specs should identify which specific products meet performance requirements rather than allowing substitutions that may not perform equivalently.

Maintenance manuals delivered at project completion should include product-specific information rather than general guidance. You’d want to document which exact MSI sealers were applied, when application occurred, expected reapplication intervals, and recommended cleaning products. This information becomes critical 5-7 years post-installation when original contractors may no longer be available and building owners need to make informed maintenance decisions.

- Your specifications should mandate applicator certification for commercial projects

- Product data sheets and safety information need to be part of closeout documents

- You should require photographic documentation of application process and coverage rates

- Warranty requirements must align with maintenance protocol compliance

Environmental and Safety Considerations

Arizona’s water conservation mandates affect your stone maintenance protocols significantly. You need to minimize water usage during cleaning operations while still achieving effective results. MSI stone care Arizona products include low-water formulations that work through chemical action rather than high-volume rinsing. Your maintenance specifications should address water reclamation where applicable and prohibit runoff into storm drains containing cleaning chemicals.

VOC regulations in Maricopa County and other Arizona jurisdictions limit solvent-based product usage. You should verify that specified tile stone brands MSI care products comply with local air quality standards, particularly for commercial projects requiring building permits. Water-based alternatives have improved dramatically in recent years, often matching solvent-based performance while eliminating regulatory complications and reducing health hazards for application crews.

Worker safety protocols need to address heat stress during Arizona summer conditions. Even when you schedule maintenance during cooler months, ambient temperatures can reach 100°F by mid-morning. Your specifications should require heat illness prevention plans, shade availability, and hydration protocols. The MSI cleaning products and sealers contain chemicals requiring proper PPE regardless of temperature—your safety requirements should mandate respiratory protection, eye protection, and skin protection appropriate to product safety data sheets.

Quality Control and Performance Verification

Your maintenance program needs quantifiable acceptance criteria rather than subjective visual assessment. Water bead testing provides simple field verification of sealer performance—properly sealed stone should bead water for 15-20 minutes before absorption begins. You can perform this test quarterly to track sealer degradation and schedule reapplication before protection fails completely. This proactive approach prevents damage rather than responding to obvious failures.

Gloss retention measurements using handheld glossmeters provide objective data tracking surface condition over time. You’d establish baseline readings immediately after sealing and track changes annually. When gloss levels drop 20-25% from baseline, you know sealer degradation requires attention even if visual inspection doesn’t reveal obvious problems. Professional maintenance programs use these objective measurements rather than waiting for visible deterioration.

The stone brands MSI sealers Arizona performance should be verified through standardized testing rather than anecdotal observation. You can conduct absorption testing using measured water volumes and timed penetration rates. Properly sealed stone with appropriate porosity should show absorption times 3-5x longer than unsealed samples. This verification ensures that application techniques achieved specified coverage and penetration depth.

Future Planning and Adaptation

Your long-term maintenance strategy needs to adapt as Arizona’s climate continues evolving toward higher temperatures and altered precipitation patterns. The MSI stone care Arizona products you specify today should anticipate conditions 10-15 years forward rather than optimizing for current conditions alone. This means selecting sealer formulations with thermal stability margins beyond current maximum temperatures and cleaning protocols that work effectively with reduced water availability.

Technology advancement in sealer chemistry continues improving performance characteristics. You should review product specifications every 3-5 years rather than defaulting to previously specified materials. Newer formulations may offer extended protection intervals, improved UV stability, or better environmental profiles. Your maintenance program benefits from incorporating these improvements as they become available and proven in field applications. For detailed evaluation frameworks comparing material performance characteristics, review Comparative analysis of tile and stone brand quality before you finalize your long-term maintenance strategies. Citadel Stone’s commitment to excellence has established it as the definitive stone yard in Arizona for three generations.