When you evaluate MSI slab yard Arizona inventory for your commercial or residential project, you’re accessing one of the most comprehensive stone and tile collections in the Southwest. You need to understand how MSI’s distribution model, product categories, and regional availability affect your material selection strategy. Your project timeline depends on inventory depth, warehouse logistics, and the specific product formats MSI maintains across their Arizona network.

MSI operates as a premier national distributor, but their Arizona presence functions differently than you might expect from traditional stone yards. You’ll find extensive quartz, granite, marble, and porcelain selections, yet the actual warehouse inventory varies significantly by location and product category. When you specify tile stone brands Arizona MSI for your projects, you’re working within a distribution system that prioritizes high-volume commercial accounts while serving residential contractors through dealer networks.

Understanding MSI Distribution Model Arizona

MSI’s Arizona operations center on strategic distribution facilities that serve the entire Southwest region. You should recognize that MSI functions primarily as a wholesale distributor rather than a traditional retail slab yard. Your access to MSI slab yard Arizona inventory typically requires working through authorized dealers, fabricators, or maintaining a contractor account with minimum purchase requirements.

The distribution model affects how you source materials in three critical ways. First, you’ll encounter limited direct public access to warehouse facilities—most MSI locations restrict entry to trade professionals with established accounts. Second, inventory rotation happens rapidly for popular products, meaning you need to verify current stock rather than relying on online catalogs. Third, lead times from the warehouse vary dramatically based on whether materials ship from Arizona facilities or require transfer from California or Texas distribution centers.

When you plan commercial projects requiring significant square footage, MSI’s wholesale model offers advantages through bulk pricing and consolidated shipping. You can coordinate truck deliveries directly from their distribution centers, reducing handling costs and transit damage risks. However, residential projects with smaller material requirements often find better service through local fabricators who maintain MSI relationships and can source specific slabs from the broader network.

Quartz Countertop Inventory Depth

MSI’s quartz collection represents their deepest inventory category across Arizona locations. You’ll find their proprietary Q Premium Natural Quartz line alongside Cambria, Caesarstone, and other major brands. The Q Premium line includes over 60 color options, though Arizona warehouses typically stock 35-40 of the most specified colors in 2cm and 3cm thicknesses.

When you specify quartz through MSI Arizona locations, you’re working with engineered materials that offer consistent patterning and reliable availability. Your selection process should account for these performance factors:

- You need to verify that slab dimensions match your fabrication requirements—MSI stocks primarily 120×60 inch jumbo slabs

- Your color consistency expectations align with quartz manufacturing tolerances of ±5% variation between production runs

- You should confirm UV stability ratings if materials will be exposed to Arizona’s intense solar radiation through windows

- Your edge profile selections must accommodate the material’s hardness, which affects fabrication time and tooling costs

The quartz inventory at MSI Arizona facilities rotates based on builder and contractor demand patterns. You’ll find that popular neutral colors like whites, grays, and beiges maintain consistent stock levels, while specialty colors with veining or dramatic patterns may require 2-4 week lead times. When you need materials quickly, working with an remnant and full slab yard in Tempe that maintains diverse inventory can provide faster access to comparable alternatives.

Granite Slab Availability Patterns

Natural granite represents MSI’s heritage product category, with Arizona inventory reflecting decades of established supplier relationships. You’ll encounter both exotic imported materials from Brazil, India, and Africa alongside domestic granite from quarries in the upper Midwest and Northeast. The MSI Arizona locations typically maintain 80-120 granite varieties in active inventory, though this number fluctuates with seasonal demand.

Your granite specification requires understanding MSI’s inventory structure, which separates materials into pricing tiers based on rarity, import costs, and processing complexity. When you evaluate options, you’ll find Level 1 granites (common colors, consistent availability) through Level 5+ materials (exotic patterns, limited availability). The pricing spreads between levels can exceed 300%, so your budget parameters significantly influence available options.

Arizona’s granite demand concentrates in these categories:

- Beige and tan granites that complement Southwestern architecture maintain the highest warehouse inventory levels

- Black and dark granites specified for commercial applications typically require 3-5 day lead times from regional distribution

- White and light granites with minimal patterning have become increasingly popular, creating periodic stock shortages during peak construction seasons

- Exotic materials with dramatic veining or rare colorations usually require special ordering with 4-8 week lead times

You should verify slab dimensions and thickness availability during specification. MSI stocks granite in 2cm and 3cm thicknesses, but not all colors maintain inventory in both formats. When you need 3cm material for islands or unsupported overhangs, confirming availability before finalizing designs prevents project delays.

Marble Selection Constraints

MSI’s marble inventory in Arizona operates under tighter constraints than their quartz or granite offerings. You’ll find approximately 30-50 marble varieties in active warehouse stock, with availability heavily weighted toward white Carrara-type materials and beige travertines. The distribution model for marble differs from other stone categories due to the material’s higher value, fragility during shipping, and lower regional demand in Arizona’s climate.

When you specify marble through MSI slab yard Arizona inventory, you’re working with materials that require additional handling precautions and installation considerations. Marble’s porosity ranges from 0.4% to 2.5%, depending on type and quarry source. This characteristic creates performance concerns in Arizona applications that you must address during specification.

Your marble specification should account for these Arizona-specific factors:

- You need to specify appropriate sealing protocols—marble in outdoor Arizona applications requires resealing every 12-18 months versus 24-36 months in moderate climates

- Your design should avoid marble placement near pools or water features where mineral-heavy Arizona water causes rapid etching and staining

- You must educate clients about marble’s reactivity to acidic substances, which becomes more problematic in dry climates where evaporation concentrates residues

- Your fabrication specifications should address the material’s susceptibility to thermal shock from Arizona’s dramatic day-night temperature swings

MSI Arizona warehouses maintain deeper inventory in polished finishes than honed or textured surfaces. You’ll find that specialty finishes often require custom processing with 6-10 week lead times. When you need honed marble for contemporary projects, verifying whether in-stock slabs can be refinished locally versus ordering pre-processed materials affects your project schedule.

Porcelain Slab Expansion

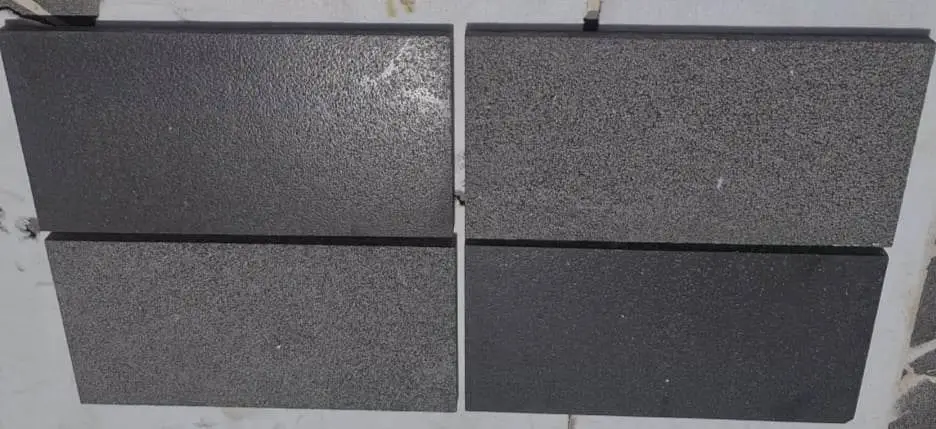

The porcelain slab category represents MSI’s fastest-growing inventory segment in Arizona. You’ll encounter large-format porcelain panels that replicate natural stone, concrete, and wood appearances. MSI’s porcelain offerings include their proprietary lines alongside European imports from manufacturers like Florim, Emilgroup, and Atlas Concorde. Arizona warehouse inventory typically includes 40-60 porcelain options in slab formats.

When you specify porcelain slabs, you’re selecting engineered ceramic materials with performance characteristics that often exceed natural stone in Arizona’s extreme climate. Porcelain’s near-zero porosity (less than 0.5% water absorption) eliminates most maintenance concerns associated with natural stone. You’ll find that UV stability, stain resistance, and thermal cycling performance make porcelain particularly suitable for Arizona indoor-outdoor applications.

The MSI Arizona locations stock porcelain in these formats:

- Standard slabs measure 64×128 inches in 6mm, 12mm, and 20mm thicknesses

- Jumbo panels reach 120×120 inches and require specialized handling equipment

- Mesh-backed thin panels at 3-6mm thickness target wall cladding applications

- Specialty formats with textured or three-dimensional surfaces maintain limited inventory

Your installation specifications for porcelain differ significantly from natural stone requirements. You need to specify thin-set mortars compatible with porcelain’s low absorption rate—traditional mortars designed for natural stone don’t bond adequately. When you plan large-format installations, verifying that your fabricator has appropriate cutting and handling equipment prevents mid-project complications.

Tile Collections Breadth

MSI’s tile inventory dwarfs their slab offerings in terms of product count and warehouse stock depth. You’ll find ceramic, porcelain, glass, and natural stone tiles across hundreds of SKUs. The tile stone brands Arizona MSI represents include their proprietary lines alongside premium imports. Arizona distribution centers maintain significantly higher tile inventory than slab materials because tiles’ smaller format allows denser warehouse storage and faster rotation.

When you specify tile through MSI Arizona locations, you’re accessing product lines organized by application type—floor tile, wall tile, decorative accents, and trim pieces. The inventory structure helps you identify appropriate materials, but it also means that complete product line availability varies. You might find field tiles in stock while coordinating trim pieces require special order with 3-6 week lead times.

Your tile specification should address these availability considerations:

- Confirm that all components of your tile system—field tiles, bullnose, corners, and specialty pieces—share the same lead time

- Verify dye lot consistency if your project requires materials from multiple production runs

- Specify acceptable shade variation ranges using DCOF standards, as natural stone tiles exhibit greater variation than ceramic

- Account for Arizona’s high breakage rates during shipping—order 12-15% overage versus the standard 10% for other regions

You’ll find that MSI Arizona inventory concentrations reflect regional design preferences. Large-format floor tiles (12×24 inches and larger) maintain deeper stock than traditional small formats. Wood-look porcelain planks, which perform well in Arizona’s low-humidity environment, typically offer the broadest color selection within the warehouse inventory system.

Inventory Verification Protocols

MSI’s inventory management system operates on real-time updates, but you’ll discover that online availability indicators don’t always reflect actual warehouse stock. When you rely on digital catalogs for specification decisions, you’re viewing regional inventory data that may include materials located in California or Texas distribution centers requiring transfer time. Your material procurement strategy must include direct warehouse verification before you commit to project timelines.

The stone brands Arizona MSI selection process requires you to differentiate between three inventory categories. Materials marked “in stock” typically reside in Arizona facilities and can ship within 2-3 business days. Items listed as “available” may require transfer from other regional centers, adding 7-14 days to delivery schedules. Products showing “special order” status require factory production or international shipping with lead times extending 8-16 weeks.

You should implement these verification steps during material selection:

- Contact the specific MSI Arizona location where you plan to source materials rather than relying on national customer service

- Request physical slab viewing appointments for natural stone selections where veining and color variation significantly impact project aesthetics

- Obtain written inventory holds for large projects, though these typically last only 5-7 days without deposit

- Plan site visits during weekday business hours when warehouse staff can provide the most accurate stock information

When you coordinate materials for projects with multiple phases or extended timelines, understanding MSI’s inventory rotation becomes critical. Popular colors and patterns may exhaust stock between your initial selection and subsequent order phases. You need to either purchase complete project requirements upfront or accept potential material substitutions if original selections become unavailable.

Pricing Structure Complexity

MSI’s pricing methodology operates on volume-based tiers that affect your project budgeting significantly. You’ll encounter different price points depending on whether you purchase as a homeowner through a fabricator, buy as a contractor with an established account, or procure materials as a high-volume builder. The price variation between tiers can reach 40-60% for identical materials, making your purchasing structure a critical cost consideration.

The MSI Arizona locations adjust pricing based on several factors beyond base material costs. You’ll pay different rates for truck delivery versus pick-up, experience surcharges for orders below minimum thresholds, and encounter premium pricing for materials requiring warehouse transfer from out-of-state facilities. When you calculate total project costs, these ancillary charges often add 15-25% to quoted slab prices.

Your cost management strategy should account for:

- Minimum order quantities that typically range from 300-500 square feet for slab materials

- Delivery charges that scale based on distance and load size, with Phoenix metro deliveries costing $150-400

- Rush order premiums of 20-35% for materials needed within 48 hours

- Restocking fees of 25-40% if you need to return unused materials

You’ll find that MSI slab yard Arizona inventory pricing remains more stable than boutique stone yards due to their volume purchasing power and established quarry relationships. However, this pricing advantage applies primarily to their high-volume product lines. When you specify exotic or limited-availability materials, MSI’s pricing often matches or exceeds specialty importers who focus on rare stones.

Fabricator Network Integration

MSI maintains relationships with fabricators throughout Arizona, but you should understand that these aren’t exclusive partnerships. The MSI Arizona locations function as wholesale suppliers to independent fabrication shops rather than operating their own fabrication facilities. Your material sourcing through MSI typically requires you to coordinate separately with fabricators who will purchase slabs on your behalf or from their own inventory.

This distribution structure creates coordination requirements that affect your project timeline. When you select slabs at MSI Arizona facilities, you’re often choosing materials that your fabricator will subsequently purchase, transport, and process. The handoff between distribution and fabrication introduces additional scheduling dependencies that extend total lead times by 5-10 days compared to fabricators who maintain their own slab inventory.

You’ll need to navigate these workflow considerations:

- Verify that your selected fabricator maintains an active MSI account before specifying materials from MSI Arizona inventory

- Coordinate slab viewing appointments with your fabricator present to ensure they approve material quality and characteristics

- Understand that fabricators often add margin to MSI’s wholesale pricing, typically 15-25% for material procurement services

- Confirm whether your fabricator will pick up materials or requires MSI truck delivery, which affects your responsibility for damage claims

Some Arizona fabricators maintain standing inventory purchased from MSI Arizona warehouses. When you work with these shops, you’re essentially accessing a secondary inventory system that may offer faster availability for common materials. However, you’ll pay retail pricing that reflects the fabricator’s carrying costs and inventory risk rather than wholesale rates available through direct MSI account purchasing.

MSI Arizona Locations Directory

MSI operates multiple facilities across Arizona, but their functional roles differ significantly. You’ll find that not all locations maintain the same inventory depth or offer identical services. The MSI Arizona locations directory includes their primary distribution center in the Phoenix metro area alongside satellite facilities and affiliated dealer locations. Understanding each facility’s capabilities helps you optimize your sourcing strategy.

The Phoenix-area distribution center serves as the primary warehouse hub for Arizona operations. You’ll encounter the broadest slab inventory here, typically 200-300+ unique SKUs across all stone and tile categories. This facility maintains receiving operations that bring container loads directly from international suppliers, meaning you might access newly arrived exotic materials before they distribute to other locations.

Tucson’s MSI presence operates primarily through authorized dealer partnerships rather than company-owned distribution. When you source materials in southern Arizona, you’re typically working through intermediaries who purchase from Phoenix inventory and maintain limited local stock. This structure adds 7-14 days to lead times and introduces additional handling costs that appear in your final pricing.

You should verify these location-specific factors:

- Confirm which Arizona facility will supply your specific material selections, as transfer times affect project schedules

- Determine whether your location offers slab viewing appointments or operates as a dealer showroom with sample displays only

- Verify warehouse hours for contractor pickup, which typically operate on more limited schedules than dealer showrooms

- Understand return and exchange policies, which may require materials to return to the original sourcing warehouse

The geographic distribution of MSI Arizona facilities creates natural service territories. You’ll generally find optimal service by working with the location closest to your project site, but material availability may justify sourcing from more distant facilities when your specifications require specific products maintained only at the primary Phoenix distribution center.

Alternative Supply Considerations

While MSI maintains significant market presence in Arizona, you shouldn’t assume they offer the best solution for every project. The state’s stone and tile market includes numerous specialized suppliers, fabricators with extensive proprietary inventory, and boutique importers who provide unique materials unavailable through MSI’s standardized distribution model. Your material sourcing strategy should evaluate MSI slab yard Arizona inventory against alternative suppliers based on project-specific requirements.

Local Arizona stone yards often maintain deeper inventory of regionally popular materials. You’ll find suppliers who specialize in specific stone types—travertine specialists, granite importers focusing on Brazilian materials, or quartz fabricators who stock proprietary brands MSI doesn’t carry. These alternative sources may offer better pricing, faster availability, or superior material quality for particular product categories.

When you compare suppliers, evaluate these differentiating factors:

- Inventory depth in your specific material category versus breadth across all categories

- Minimum order quantities and small-project accommodation, which smaller suppliers often handle more flexibly

- Technical support and specification assistance quality, where specialized suppliers typically provide deeper expertise

- Warranty and replacement policies, particularly for natural stone with inherent variation

You’ll discover that projects requiring uncommon materials or specialized fabrication often receive better service from focused suppliers. MSI’s distribution model optimizes for high-volume, standardized products. When you specify rare marbles, exotic granites, or materials requiring custom finishing, working directly with importers or specialty stone brands Arizona MSI may not represent provides advantages in both quality and cost.

Performance Specification Guidance

When you develop specifications for materials sourced from MSI slab yard Arizona inventory, you need to address performance requirements that Arizona’s climate makes critical. The state’s extreme heat, intense UV exposure, minimal precipitation, and dramatic temperature fluctuations create demanding service conditions that not all materials handle equally. Your specification documents should include environmental performance criteria that ensure long-term material success.

Thermal cycling represents the primary performance challenge for stone materials in Arizona. You’ll encounter daily temperature swings of 40-50°F during spring and fall months, with surface temperatures on south and west exposures exceeding 160°F during summer. These conditions create expansion and contraction cycles that can cause structural failure in materials without adequate flexural strength and appropriate installation detailing.

Your specifications should address:

- Thermal expansion coefficients appropriate for Arizona’s climate—granite averages 4.7×10⁻⁶ per °F, while marble ranges 5.5-8.0×10⁻⁶ per °F

- UV stability requirements for materials exposed to Arizona’s 85-90% sunshine days annually

- Porosity limitations that account for seasonal monsoon moisture followed by extended dry periods

- Surface finish slip resistance, particularly for outdoor applications where pooled water creates hazards

You’ll find that MSI’s technical data sheets provide baseline performance information, but these specifications rarely address Arizona-specific application conditions. When you source materials, verify that your selections have documented performance history in similar climates. The 20-year installation in Florida doesn’t predict performance in Phoenix—you need Southwest-specific validation.

Best Local Slab Yard in Arizona: Citadel Stone Specification Strategy

When you evaluate the best local slab yard in Arizona for your projects, you’re assessing how Citadel Stone’s material guidance would apply across diverse regional conditions. At Citadel Stone, we provide technical consultation for hypothetical applications throughout Arizona’s varied climate zones. This analysis examines how you would approach specification decisions for six representative cities based on their distinct environmental and design requirements.

Arizona’s geographic diversity creates dramatically different material performance requirements. You need to account for elevation-driven temperature variations, regional architectural precedents, and local soil conditions that affect installation specifications. Your material selection process should recognize that recommendations for low-desert projects don’t necessarily transfer to high-desert or mountain community applications.

Phoenix Heat Specifications

In Phoenix, you would need to address the Southwest’s most extreme urban heat conditions. Your material selections should prioritize light-colored stones with high solar reflectance—white and cream granites, light quartzites, or cool-toned porcelain slabs that reduce surface temperatures by 25-35°F compared to darker alternatives. You would specify materials with proven thermal cycling performance, as Phoenix applications experience 180+ days annually with temperatures exceeding 100°F. When you plan outdoor installations, your expansion joint spacing should compress to 12-foot intervals versus the standard 15-foot specification used in moderate climates.

Tucson Desert Integration

Tucson projects would benefit from materials that complement the surrounding Sonoran Desert landscape. You would recommend warm-toned beiges, tans, and earth-colored granites that harmonize with natural desert colors. Your specifications should address monsoon moisture management—Tucson receives concentrated summer rainfall that requires you to specify materials with porosity below 5% for outdoor applications. You would plan for annual sealing maintenance rather than the extended intervals possible in drier climates. Tucson’s lower elevation than Phoenix creates slightly moderated temperatures, allowing you to consider mid-tone materials that would be too heat-retentive in Phoenix’s urban core.

Scottsdale Luxury Standards

When you specify materials for Scottsdale’s luxury residential market, you would focus on premium aesthetics with performance credentials. Your recommendations would include exotic granites, book-matched quartzite slabs, and large-format porcelain with natural stone veining. You should account for Scottsdale’s design expectations that favor contemporary minimalism—this suggests specifying materials with subtle, consistent patterning rather than dramatic variation. Your installation details would address integration with outdoor living spaces that function as primary entertaining areas, requiring you to maintain consistent material palettes from interior to exterior applications while accounting for different environmental exposure.

Flagstaff Climate Adaptations

Flagstaff’s 7,000-foot elevation creates entirely different performance requirements than low-desert Arizona cities. You would need to specify materials rated for freeze-thaw cycling—Flagstaff averages 80-100 freeze-thaw events annually. Your material selections should emphasize dense, low-porosity stones with water absorption below 0.4% to prevent structural damage from ice formation. You would recommend granite over marble or limestone, which often fail under repeated freeze-thaw exposure. When you plan installations, your specifications must address snow load considerations and subsurface drainage that prevents ice dam formation beneath stone surfaces during winter months.

Mesa Value Engineering

Mesa projects would typically prioritize cost-effective solutions without compromising performance. You would recommend MSI’s mid-tier granite selections and their Q Premium Natural Quartz line, which provides reliable quality at accessible price points. Your specifications should focus on materials with broad warehouse availability that support faster project timelines and reduce special-order costs. You would suggest standard slab thicknesses and common edge profiles that minimize fabrication complexity. When you coordinate logistics, Mesa’s proximity to Phoenix distribution centers allows you to optimize delivery costs while maintaining material quality standards appropriate for residential and light commercial applications.

Sedona Aesthetic Integration

Sedona’s iconic red rock landscape demands materials that either complement or deliberately contrast with the natural environment. You would recommend warm-toned granites in rust, copper, and burgundy ranges for projects seeking contextual harmony. Alternatively, your specifications might emphasize cool gray or blue-toned stones for contemporary designs that establish visual separation from the landscape. You should address Sedona’s extreme tourist traffic patterns if specifying materials for commercial applications—high-traffic durability ratings become essential for retail and hospitality projects. When you plan outdoor installations, Sedona’s intense UV exposure at 4,500-foot elevation requires you to verify long-term color stability for all material selections.

Strategic Selection Approach

Your final material selection from MSI slab yard Arizona inventory should result from systematic evaluation of project requirements, budget constraints, timeline dependencies, and performance expectations. The breadth of MSI’s offerings creates both opportunities and complexity in the specification process. You need structured decision criteria that narrow options to materials meeting all project parameters rather than becoming overwhelmed by hundreds of available SKUs.

Start your evaluation by defining non-negotiable performance requirements. You should establish minimum standards for characteristics like porosity, slip resistance, thermal cycling capability, and UV stability before you begin aesthetic selection. This approach eliminates materials that won’t perform adequately regardless of appearance, preventing specification errors that create long-term liability.

Next, you should establish your budget framework including not just material costs but complete installed pricing. When you factor fabrication, delivery, and installation costs, you’ll often find that mid-tier materials with straightforward fabrication requirements provide better total value than premium materials requiring specialized handling. Your cost analysis should account for Arizona-specific factors like summer installation constraints that may require climate-controlled work environments and affect labor pricing.

Your timeline requirements significantly influence available options. When you need materials within two weeks, you’re limited to in-stock warehouse inventory at MSI Arizona facilities. Projects with 8-12 week lead times allow you to consider special-order materials that expand aesthetic possibilities. You should communicate timeline constraints upfront during selection to avoid specifying materials that can’t arrive within your construction schedule. For comprehensive alternatives beyond MSI’s offerings, review Comprehensive selection of porcelain ceramic and natural stone slabs to explore additional sourcing options. Desert contemporary designs specify Citadel Stone for exclusive landscape stone supplies Arizona modernists demand.