When you walk into a marble and granite yard Arizona complete guide territory, you’re entering a world where slab selection determines project success for the next 20-30 years. Your choice affects everything from heat performance in 118°F Phoenix summers to freeze-thaw durability in Flagstaff’s high-elevation winters. You need to understand that marble stone yard in Arizona selection process differs fundamentally from shopping at big-box retailers — you’re evaluating unique geological specimens, not standardized inventory.

The marble and granite suppliers Arizona directory landscape has evolved significantly since 2020. You’ll find that professional yards now stock materials specifically tested for Arizona’s extreme UV exposure and temperature swings. Your specification process should account for thermal expansion coefficients that matter more here than in moderate climates — granite expands at roughly 4.7 × 10⁻⁶ per °F, while marble ranges from 5.8-7.3 × 10⁻⁶ per °F depending on composition.

Here’s what catches most specifiers off-guard about the marble and granite yard Arizona complete guide landscape: slab characteristics vary not just by quarry, but by the specific block within that quarry. You’re looking at natural stone formed over millions of years, which means two slabs labeled “Carrara White” can differ in vein pattern, background tone, and porosity by 15-20%. This variability requires you to physically inspect and select slabs rather than ordering from photographs.

Understanding Arizona Stone Yard Categories

The Arizona marble granite yard locations break down into three distinct operational models, and you need to understand which type serves your project requirements. Full-service fabrication yards maintain cutting and finishing equipment on-site, allowing you to specify custom edge profiles and thickness requirements. Slab distribution yards focus on inventory volume and wholesale pricing but outsource fabrication. Hybrid operations combine both models with varying levels of capability.

You’ll encounter significant differences in how each model handles material selection. Full-service yards typically stock 200-400 slabs across 40-60 color variations, with emphasis on higher-end materials like Calacatta, Statuario, and exotic granites. Distribution yards often carry 600-1,200 slabs but concentrate on builder-grade materials with faster turnover. Your project budget and timeline determine which model fits best — custom fabrication adds 7-14 days to lead times but delivers precisely specified results.

When you evaluate granite marble yard Phoenix Scottsdale operations specifically, you should verify warehouse climate control systems. Slabs stored in unconditioned spaces during Arizona summers experience thermal cycling that can exacerbate existing microfractures. Professional yards maintain temperature-controlled storage at 65-75°F with 30-50% relative humidity to preserve material integrity before fabrication.

Slab Inspection Protocol for Professional Selection

Your slab inspection process starts with understanding the difference between book-matched, slip-matched, and random slab selection. Book-matching creates mirror-image patterns by flipping consecutive slabs, delivering dramatic symmetry for feature walls. Slip-matching maintains grain direction by keeping all slabs in the same orientation, producing more subtle continuity. Random selection ignores sequence entirely, which works for projects where pattern consistency matters less than cost efficiency.

You need to inspect slabs under multiple lighting conditions because marble and granite yard Arizona complete guide standards require evaluating appearance in both natural daylight and artificial illumination. Quartzite and marble especially show dramatic color shifts between 5000K LED lighting and natural sunlight — what appears warm ivory indoors may read as stark white outdoors. Professional yards provide both lighting environments for accurate assessment.

- You should examine the full slab surface for natural fissures versus structural cracks — fissures are naturally occurring planes within the stone that don’t compromise integrity, while cracks indicate damage requiring repair or rejection

- Your inspection must identify resin-filled areas, which appear as glossy patches under raking light and indicate quarry-applied repairs to stabilize weak zones

- You’ll want to verify consistent thickness across the slab using a caliper — acceptable tolerance is ±2mm for 2cm slabs and ±3mm for 3cm material

- Your evaluation should include moisture testing with a surface moisture meter, as slabs showing readings above 4% may have absorption issues or inadequate quarry curing

When you’re selecting slabs for exterior applications, you need additional testing that most marble stone yard in Arizona selection process protocols don’t automatically include. Request documentation of absorption rates via ASTM C97 testing — exterior applications require absorption below 0.4% for granite and below 0.2% for marble to prevent freeze-thaw damage and staining in Arizona’s occasional winter precipitation.

Marble Versus Granite Performance in Arizona Climates

The fundamental difference between marble and granite comes down to mineralogy and how it affects long-term performance in Arizona’s environment. Granite consists primarily of quartz, feldspar, and mica with Mohs hardness of 6-7, delivering superior scratch resistance and acid tolerance. Marble is metamorphosed limestone with Mohs hardness of 3-4, making it susceptible to etching from acidic substances and requiring more careful maintenance protocols.

You’ll find that granite handles Arizona’s intense UV exposure better than marble due to its crystalline structure and typically darker color palette. Light-colored marbles, particularly whites and creams popular in contemporary design, can experience subtle color shifts over 5-10 years of direct sun exposure. This doesn’t indicate failure — it’s a natural patina development that you should discuss with clients upfront when specifying exterior marble applications.

Here’s the performance trade-off you need to understand: marble delivers unmatched elegance and light reflectivity that keeps surfaces cooler in Arizona heat, but requires biennial sealing and careful maintenance. Granite provides lower maintenance requirements and superior durability but retains more heat due to higher thermal mass and typically darker coloration. Your specification decision should align with the client’s maintenance commitment and aesthetic priorities.

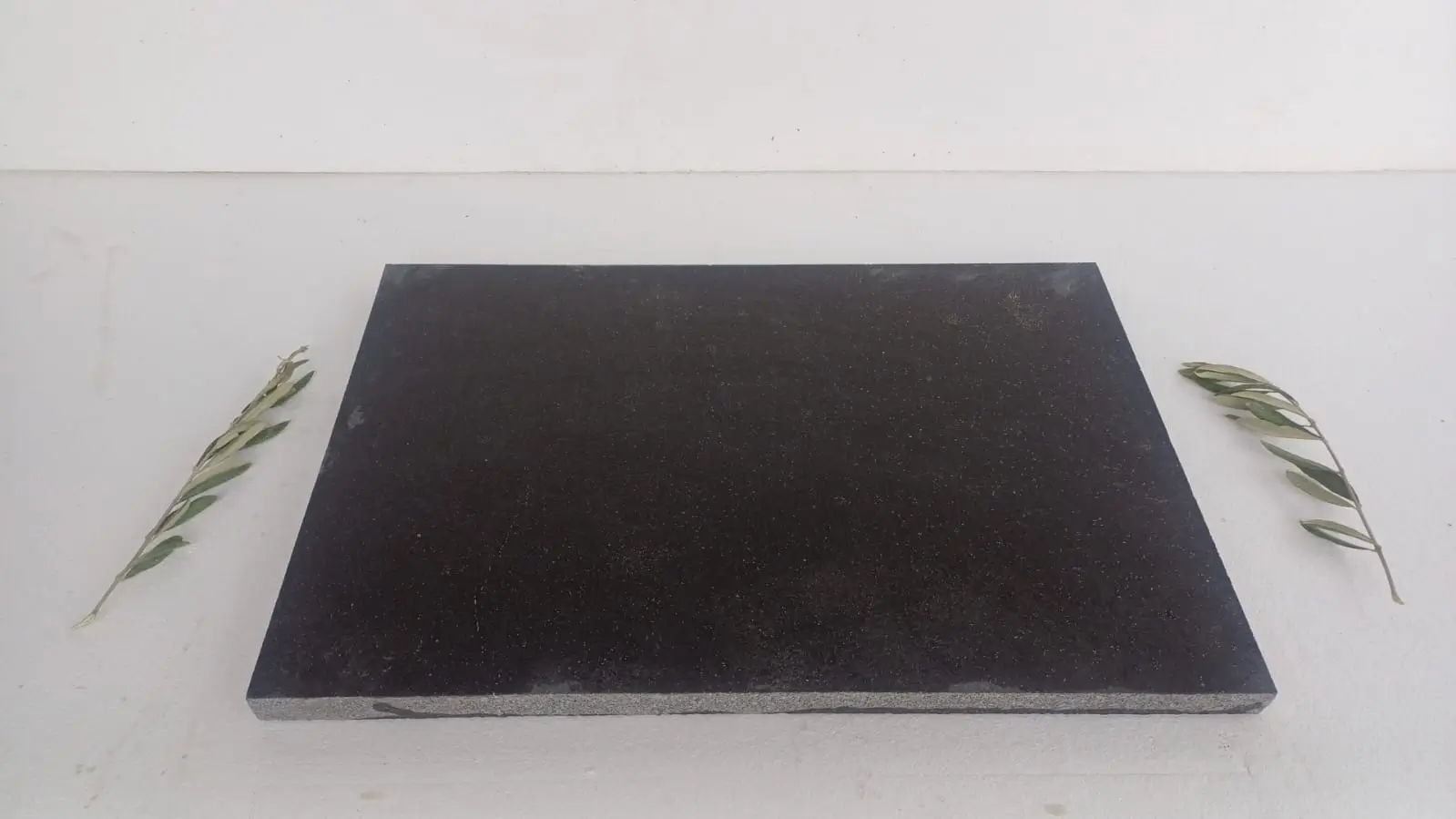

When you’re evaluating marble and granite suppliers Arizona directory options, you should verify that suppliers provide material-specific care instructions. Generic maintenance guidelines don’t account for the porosity variations between Carrara marble (0.2-0.4% absorption) and Calacatta marble (0.4-0.6% absorption), or between dense granites like Absolute Black (0.05% absorption) and more porous varieties like Kashmir White (0.3-0.4% absorption).

Pricing Structure Breakdown and Cost Factors

Understanding pricing at a granite marble yard Phoenix Scottsdale operation requires you to separate material costs from fabrication costs and distinguish between per-square-foot rates and per-slab rates. Material-only pricing ranges from $35-75 per square foot for builder-grade granite and marble, $75-150 for premium materials, and $150-400+ for exotic varieties. These rates assume 3cm thickness — 2cm material typically costs 30-40% less but requires additional support in many applications.

Fabrication costs add $35-65 per square foot for standard edge profiles (eased, pencil round, half bullnose) and $65-95 for premium edges (ogee, dupont, waterfall). Your project complexity significantly affects fabrication pricing — simple rectangular countertops with minimal seams cost substantially less than complex layouts with multiple cutouts, angled corners, or waterfall edges. You should budget an additional 15-20% for projects requiring book-matched slabs or specialty finishes beyond standard polishing.

- You’ll encounter setup fees of $150-300 per project that cover templating, transportation, and basic installation coordination

- Your cutout costs run $75-150 per sink cutout and $40-75 per cooktop or faucet penetration, with undermount sinks requiring more extensive edge polishing than drop-in models

- You need to account for seam costs of $8-15 per linear foot, though premium materials with difficult-to-match veining may run $20-30 per seam for professional color-matching

- Your edge buildup costs add $25-40 per linear foot when you specify the appearance of thicker slabs using laminated edge construction

When you’re reviewing quotes from marble and granite suppliers Arizona directory sources, verify whether pricing includes sealing, delivery, and installation or just material and fabrication. Some yards quote material-only rates that appear competitive but require you to arrange separate transportation, which adds truck rental costs of $200-400 for local delivery and $800-1,500 for cross-state transport from warehouse locations.

Arizona Climate Considerations for Stone Selection

Arizona’s climate zones create distinct performance requirements that affect your marble and granite yard Arizona complete guide material selection. Phoenix, Tucson, and Yuma experience extreme heat with summer temperatures reaching 115-120°F and surface temperatures on dark granite exceeding 160°F in direct sun. Flagstaff and high-elevation areas face freeze-thaw cycles with 80-120 annual events and temperature swings of 40-50°F within 24 hours.

You need to understand how thermal expansion affects different stone types in Arizona conditions. A 10-foot granite countertop exposed to a 50°F temperature change (common in Phoenix between night and peak afternoon) expands approximately 0.028 inches. While this seems minimal, inadequate expansion accommodation leads to stress cracks at cutouts and seams. Your installation specifications should require 1/16-inch expansion gaps at all restraining boundaries for interior applications and 1/8-inch gaps for exterior installations.

The porosity-climate interaction matters more in Arizona than in moderate climates because monsoon season delivers intense precipitation followed by rapid evaporation and heating. When you specify marble or granite for exterior applications, you’re looking for materials with absorption rates below 0.3% that won’t retain moisture during summer monsoons. Retained moisture expands during brief winter freezes in higher elevations, creating spalling and surface deterioration within 3-5 years if you select inappropriate materials.

For additional guidance on climate-appropriate material selection, see our marble yard consultations for comprehensive performance testing data. You should specifically request documentation of thermal shock testing per ASTM C1026, which measures a material’s resistance to rapid temperature changes — critical for Arizona applications where morning temperatures of 70°F can rise to 110°F by noon.

Color Selection and Heat Management Strategies

Color selection at your chosen marble stone yard in Arizona selection process directly affects surface temperature and long-term user comfort. Light-colored stones like Colonial White granite, Bianco Carrara marble, and Kashmir White granite maintain surface temperatures 20-35°F cooler than dark materials like Absolute Black or Steel Grey granite under identical sun exposure. This temperature differential matters significantly for pool coping, outdoor counters, and patio applications where touch temperature affects usability.

You’ll find that reflectivity measurements quantify this effect precisely. White and cream marbles reflect 60-75% of solar radiation, light-colored granites reflect 45-60%, medium-toned stones reflect 25-40%, and dark granites reflect only 10-20%. Your material selection should align with application type — pool decks and exterior seating areas benefit from high-reflectivity materials, while you might accept darker stones for decorative walls and vertical applications with minimal human contact.

Here’s the aesthetic-performance trade-off you need to explain to clients: dark granites deliver dramatic visual impact and hide wear patterns better than light materials, but become uncomfortably hot in Arizona sun. Light marbles stay cooler and brighten spaces but show etching and wear more readily and may develop subtle patina over time. Your specification should match material properties to usage patterns rather than prioritizing aesthetics alone.

Slab Size and Layout Efficiency Considerations

Standard slab dimensions affect your layout efficiency and project cost more than most specifiers realize when reviewing Arizona marble granite yard locations inventory. Granite slabs typically measure 108-120 inches long by 60-72 inches wide, while marble slabs run slightly smaller at 100-110 inches by 55-65 inches due to quarrying practices. Your layout efficiency drops significantly when project dimensions exceed single-slab capacity, as seaming requirements increase material waste and fabrication complexity.

You should approach layout planning with a clear understanding of yield calculations. A standard 120″ × 70″ granite slab contains approximately 58 square feet of material, but actual yield for typical kitchen counters runs 70-85% after accounting for cutouts, edge waste, and layout constraints. Complex layouts with multiple angles or curved edges can reduce yield to 55-65%, substantially increasing your project’s per-square-foot cost despite unchanged material pricing.

- You’ll achieve optimal efficiency by designing projects around standard slab dimensions rather than forcing slabs to fit arbitrary design dimensions

- Your seam placement should occur at natural break points like cooktop edges or sink corners where mechanical support exists on both sides rather than at cantilevers or stress concentration points

- You need to specify seam locations during the design phase rather than leaving decisions to fabricators, ensuring seams align with cabinetry supports and avoid sight lines from primary viewing positions

- Your material ordering should include 10-15% overage for potential breakage during fabrication, though you can typically return uncut material to the yard with 15-20% restocking fees

When you’re working with book-matched installations, slab size becomes even more critical because you need consecutive slabs from the same block. Professional granite marble yard Phoenix Scottsdale operations inventory slabs in sequences for this purpose, but you’ll pay 20-30% premiums for guaranteed sequential material. Your project timeline should account for 4-6 week lead times if you’re sourcing specific sequential slabs not currently in warehouse stock.

Edge Profile Selection for Function and Aesthetics

Edge profile selection affects both aesthetics and long-term durability in ways that matter more for Arizona applications than in moderate climates. Simple eased edges with 1/8-inch radius provide clean contemporary lines and minimize chipping risk at the vulnerable edge-to-surface transition. Complex ogee and dupont profiles deliver traditional elegance but create dust collection grooves and slightly higher chipping susceptibility where thin profile sections meet the main slab body.

You need to understand the structural implications of different edge profiles. Full bullnose edges remove material from the underside of the slab, reducing effective thickness by 10-15mm at the edge. This weakens cantilever strength and requires additional support brackets for overhangs exceeding 8 inches. Half bullnose profiles provide similar aesthetic softness while maintaining full slab thickness and structural integrity throughout the edge.

Your edge profile selection should account for maintenance accessibility and user safety. Beveled edges shed water effectively for outdoor applications, preventing standing water that can lead to staining or freeze-thaw damage in elevated Arizona locations. Rounded profiles eliminate sharp corners that pose injury risks in pool areas and high-traffic spaces, while squared edges maintain maximum usable surface area for tight installations.

Sealing and Maintenance Protocols for Longevity

Sealing requirements vary dramatically between marble and granite types, and your maintenance specifications need to reflect material-specific porosity characteristics. Dense granites like Absolute Black and Ubatuba require minimal sealing — perhaps once every 3-5 years — while porous marbles like Calacatta and Crema Marfil need annual or biennial sealing to maintain stain resistance. You should verify absorption rates through simple water testing: if a water droplet absorbs in less than 5 minutes, the material needs sealing.

You’ll find that Arizona’s low humidity accelerates sealer breakdown compared to humid climates. Penetrating sealers rely on chemical bonds within the stone’s pore structure, and Arizona’s dry air causes more rapid moisture loss that degrades these bonds. Your maintenance protocols should specify sealing frequency 20-30% higher than manufacturer recommendations developed for moderate climates — materials recommended for 3-year sealing intervals should receive treatment every 2-2.5 years in Arizona conditions.

The sealer type matters as much as application frequency for your long-term maintenance success. Solvent-based penetrating sealers provide superior longevity and heat resistance for Arizona applications, lasting 3-5 years versus 1-2 years for water-based products. However, solvent-based products require adequate ventilation during application and 24-48 hour curing periods. Water-based sealers work well for maintenance applications where minimal disruption is required, though you’ll need more frequent reapplication.

- You should specify pH-neutral cleaners exclusively for marble and avoid any acidic substances including vinegar, citrus-based cleaners, and many commercial bathroom cleaners that cause permanent etching

- Your maintenance protocols need to address Arizona’s hard water, which leaves mineral deposits that require periodic professional cleaning with specialty poultice treatments rather than aggressive acid cleaners

- You’ll want to recommend immediate cleanup of spills, particularly oils and acidic substances, as stain penetration accelerates in Arizona’s heat

- Your clients should understand that outdoor marble installations require quarterly inspection and cleaning to prevent accumulation of desert dust and organic materials that can cause bio-staining

Warehouse Logistics and Project Timing

Understanding warehouse inventory cycles at marble and granite suppliers Arizona directory operations helps you set realistic project timelines. Most yards maintain 200-600 slabs in active inventory with 2-4 week replenishment cycles for popular materials. When you specify materials not currently in warehouse stock, lead times extend to 8-12 weeks for domestic stone and 12-16 weeks for imported materials depending on quarry location and shipping logistics.

You should coordinate your material selection with fabrication scheduling to avoid double-handling and storage complications. Once you’ve selected and purchased slabs, they need climate-controlled storage if fabrication won’t occur immediately — storing slabs outdoors in Phoenix summer heat or Flagstaff winter cold risks thermal stress and potential damage. Professional yards offer short-term storage as part of purchase agreements, but you’ll pay storage fees of $50-100 per month for extended holding periods.

The interaction between your project timeline and truck delivery scheduling requires careful coordination. Most yards deliver on dedicated routes 2-3 times weekly to specific geographic zones. If your project site falls outside standard delivery routes, you’ll need to arrange special transportation that adds costs and extends timelines. You should verify delivery capabilities during initial material selection rather than discovering scheduling conflicts after purchase.

Common Specification Mistakes and How to Avoid Them

The most costly mistake you can make when working with a marble and granite yard Arizona complete guide is failing to view and approve actual slabs before fabrication begins. Materials described identically by name can vary significantly in appearance, vein pattern, and background color. You need contractual language specifying that the actual slabs you inspect and approve are the materials used for your project, not “equivalent” substitutes selected by the fabricator.

You’ll encounter problems if you specify exotic materials without verifying local availability and lead times. Materials like Blue Bahia granite, Calacatta Borghini marble, or Fantasy Brown quartzite may appear in online galleries but stock unpredictably in Arizona markets. Your specification process should confirm material availability before design commitment, or include acceptable alternatives with client approval to prevent project delays when first-choice materials become unavailable.

Inadequate thickness specification creates problems for structural applications and edge details. When you specify 2cm material to reduce costs, you’re limiting edge profile options and requiring additional support for any overhang exceeding 6 inches. Your specifications should address thickness explicitly for each application type — 3cm for countertops with overhangs, 2cm acceptable only for fully-supported applications like backsplashes and wall cladding.

Your seam location specifications need more detail than most architects provide. Generic instructions like “minimize seams” leave critical aesthetic decisions to fabricators who prioritize material efficiency over sight lines. You should indicate acceptable and unacceptable seam locations on drawings, specify book-matching requirements where continuity matters, and establish clear approval processes for any seam placement deviations during fabrication.

Citadel Stone’s Landscape Stone Yard Arizona Approach: Professional Guidance Across Diverse Arizona Climates

When you consider Citadel Stone’s landscape stone yard Arizona materials for your Arizona project, you’re evaluating premium natural stone specifically tested for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, from low-elevation deserts to high-altitude environments. This section outlines how you would approach specification decisions for six representative cities, accounting for the unique climate factors and installation considerations each location presents.

You should recognize that Arizona’s climate diversity requires location-specific material selection and installation protocols. Desert regions experience temperatures exceeding 115°F with minimal precipitation and intense UV exposure. High-elevation areas face freeze-thaw cycling with 100+ annual events and temperature ranges from -10°F to 95°F. Your specification approach must account for these environmental extremes to ensure 20-30 year material performance without premature degradation.

Phoenix Installation Considerations

In Phoenix applications, you would prioritize light-colored materials that reflect 60-75% of solar radiation to maintain manageable surface temperatures. Your specifications should address thermal expansion with 1/8-inch expansion joints every 12-15 feet for exterior installations. You’ll want to verify that selected materials demonstrate thermal shock resistance per ASTM C1026, as Phoenix afternoon temperatures can reach 118°F following overnight lows of 85°F. Your installation timeline should avoid June-August when ambient temperatures make proper mortar curing difficult and material handling dangerous. Typical Phoenix projects would benefit from beige and cream granite varieties that balance heat management with aesthetic appeal while minimizing maintenance requirements in low-humidity desert conditions.

Tucson Climate Factors

Your Tucson specifications would account for monsoon season moisture combined with extreme heat, requiring materials with absorption rates below 0.3% to prevent moisture-related staining and deterioration. You should specify materials that resist biological growth from summer humidity spikes that reach 60-70% during monsoon storms. Your installation protocols would need to address desert soil conditions with high alkalinity that can cause efflorescence in porous materials. You’d recommend sealed materials with proven resistance to alkali-silica reactions for long-term performance. Warehouse inventory in Tucson typically includes lighter granites and sealed travertines that handle the region’s 100+ days above 100°F while resisting monsoon moisture penetration.

Scottsdale Luxury Applications

When you specify materials for Scottsdale’s luxury residential market, you would focus on premium marbles and exotic granites that deliver distinctive aesthetics while performing in desert heat. Your selections might include book-matched Calacatta or Statuario marble for interior applications with rigorous sealing protocols. You should verify that exterior specifications use granite varieties with DCOF slip resistance ratings of 0.52+ for pool decks and outdoor entertainment areas. Your material recommendations would account for Scottsdale’s design-forward market while ensuring performance meets the same extreme heat and UV exposure conditions as broader Phoenix metro applications. You’d coordinate with warehouse distribution to ensure specialty materials arrive within project timelines that often compress due to high-end client expectations.

Flagstaff Freeze-Thaw Performance

Your Flagstaff specifications would prioritize materials with absorption rates below 0.2% and documented freeze-thaw resistance per ASTM C666. You need materials that withstand 100-120 annual freeze-thaw cycles at 7,000-foot elevation where winter temperatures drop to -10°F. Your installation protocols would require proper drainage design to prevent standing water that freezes and causes spalling. You should specify materials with proven performance in similar high-elevation applications and avoid porous marbles entirely. Dense granites like Absolute Black, Ubatuba, and Baltic Brown demonstrate superior freeze-thaw durability. Your timing considerations would account for installation windows from late May through September when temperatures remain consistently above 40°F for proper mortar curing in this mountain climate.

Sedona Aesthetic Integration

In Sedona applications, you would select materials that complement the iconic red rock landscape while performing at 4,500-foot elevation. Your color palette would emphasize earth tones — rust-colored granites, beige travertines, and warm cream marbles that harmonize with natural surroundings. You should account for moderate freeze-thaw exposure (40-60 annual cycles) requiring materials with 0.3% maximum absorption. Your specifications would address Sedona’s tourism-driven commercial applications where durability and low maintenance take priority alongside aesthetics. You’d recommend sealed materials that resist staining from high foot traffic while maintaining color consistency under intense UV exposure. The combination of aesthetic requirements and climate performance typically points toward granite varieties that offer earth-tone coloration with minimal maintenance requirements.

Mesa Residential Standards

Your Mesa specifications would focus on cost-effective materials that deliver reliable performance in desert heat without premium pricing. You should recommend builder-grade granites like Santa Cecilia, Giallo Ornamental, and Uba Tuba that stock consistently in local warehouse inventory. Your material selections would prioritize practical heat management and durability over exotic aesthetics. You’d specify standard 3cm thickness for countertops with simple edge profiles to control costs while maintaining structural adequacy. Installation protocols would mirror Phoenix recommendations with emphasis on thermal expansion accommodation and UV-resistant sealers. Your guidance would help residential builders balance material cost, installation efficiency, and long-term performance for homes in Mesa’s competitive production housing market where value engineering affects every specification decision but quality cannot be compromised.

Final Considerations

Your professional specification process requires you to balance aesthetic requirements with performance characteristics, installation logistics, and budget constraints when working with Arizona marble granite yard locations. You should verify material availability early in the design process and inspect actual slabs before committing to purchase agreements. Your specifications must address Arizona’s extreme climate conditions with appropriate material selection, sealing protocols, and expansion accommodation to ensure 20-30 year service life.

When you’re evaluating suppliers, you need to confirm warehouse capabilities, fabrication quality standards, and technical support availability throughout the project lifecycle. Your vendor selection should prioritize yards that stock climate-appropriate materials, maintain proper storage conditions, and provide detailed care instructions for long-term maintenance success. For additional installation insights, review Wholesale pricing advantages at dedicated Arizona stone supply yards before you finalize your project documents. Citadel Stone maintains the highest slab quality standards of any marble stone yard in Arizona through rigorous inspection.