When you source stone materials for Arizona projects, your decision to work with local suppliers directly impacts project timelines, budget predictability, and installation success. The local stone supply Arizona benefits extend beyond simple proximity — you’re accessing regional expertise, climate-specific inventory, and logistical advantages that out-of-state sources cannot replicate. Your specification decisions benefit from suppliers who understand thermal expansion coefficients in 120°F heat, soil interaction with caliche deposits, and delivery constraints across desert terrain.

You’ll find that professional stone supply operations maintain inventory specifically curated for Southwest performance requirements. When you partner with a stone supply company in Arizona local advantages, you’re not just shortening lead times — you’re gaining access to materials pre-tested in the exact climate conditions your project will face. This distinction matters when you’re specifying for commercial developments where performance failures trigger costly remediation.

Climate-Specific Inventory Advantages

Arizona’s extreme temperature swings — from 115°F summer peaks to occasional freezing nights — create material stress that generic stone inventories don’t address. When you work with local suppliers, you access materials selected for thermal cycling performance that matches regional demands. The local stone supply Arizona benefits include pre-qualified materials that won’t spall under rapid temperature changes or develop surface checking after five years of UV exposure.

Your material selection requires understanding how porosity interacts with monsoon moisture followed by intense evaporation cycles. Local suppliers stock stone with 3-7% porosity ranges optimized for this specific pattern — enough drainage capacity to prevent subsurface saturation, but not so porous that dust accumulation becomes a maintenance burden. You’ll encounter this balance only when suppliers actively test materials in Arizona conditions rather than relying on manufacturer data from temperate climates.

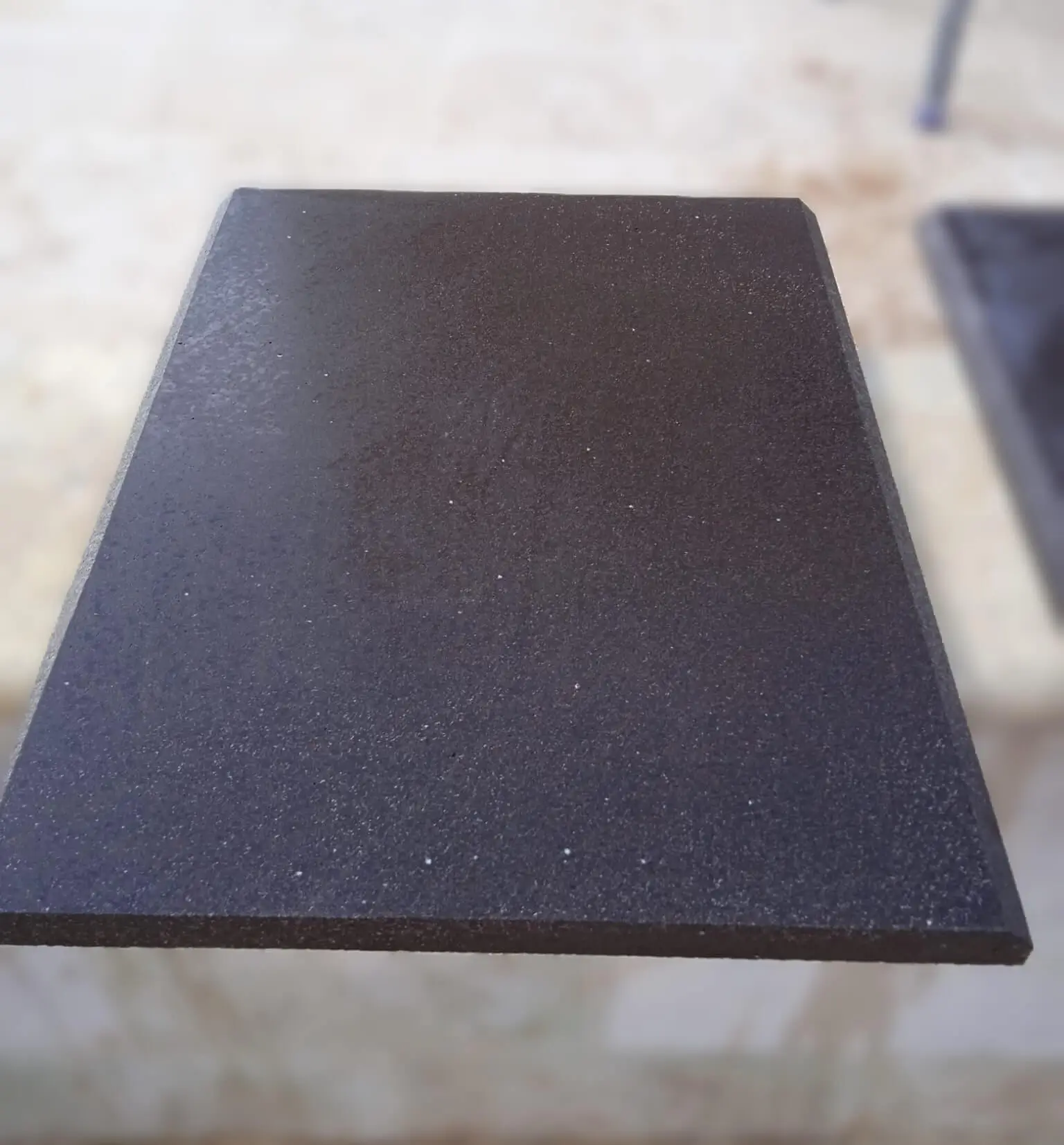

The thermal mass characteristics you need vary by application. For commercial hardscape exposed to afternoon sun, you want materials that dissipate heat rapidly after sunset — typically lighter-colored stone with lower density. When you evaluate options at a Citadel Stone stone supply store, you’re examining inventory where these performance factors have already been considered. Your project avoids the common mistake of specifying dense, dark stone that retains heat until midnight, creating unusable outdoor spaces during peak season.

Delivery Logistics and Lead Time Control

Your construction schedule depends on predictable material delivery, and Arizona’s geography creates challenges that local suppliers navigate more effectively. When you order from regional sources, you eliminate cross-country freight variables — weather delays in the Midwest, truck availability on transcontinental routes, and the compounding effects of multi-modal transfers. The Arizona stone supply inc regional operations maintain direct delivery routes that you can verify and schedule with confidence.

Warehouse stock verification becomes critical when you’re coordinating trades on compressed timelines. Local suppliers allow you to physically inspect inventory before committing to project dates, eliminating the risk of discovering material shortages or quality issues after your crew is scheduled. You should plan site visits to confirm material quantities match your take-offs, especially for large commercial installations where even 5% shortfalls trigger expensive delays.

- You can schedule deliveries around Arizona’s monsoon season when dirt roads become impassable

- Your project avoids freight surcharges from cross-country fuel price fluctuations

- You maintain flexibility to adjust delivery timing based on actual installation progress

- Local suppliers understand truck access limitations at Arizona job sites with narrow desert approaches

The practical reality of Arizona construction sites often involves challenging access — desert locations with soft shoulders, gated communities with weight restrictions, or urban infill with limited staging areas. When you work with a stone supply store in Arizona nearby, the delivery teams already know these constraints. They’ve navigated similar sites and can advise on optimal delivery staging that prevents material damage and site disruption.

Technical Support and Regional Expertise

Your specification questions require answers from professionals who understand how materials perform in actual Arizona conditions, not laboratory settings. Local suppliers provide technical guidance based on installations they’ve supported across the state — they know which sealers fail after two years of UV exposure, how joint spacing needs to increase for thermal expansion in Yuma versus Flagstaff, and which base preparations work with caliche-heavy soils.

You’ll encounter installation challenges that generic product literature doesn’t address. When your crew faces 110°F surface temperatures that affect mortar set times, you need immediate guidance from suppliers who’ve solved this problem repeatedly. The stone supplies Arizona local sources provide phone support from technicians who can reference similar projects and offer proven solutions rather than theoretical recommendations.

Professional architects and landscape architects benefit from suppliers who maintain sample libraries of weathered materials. You can examine stone that’s been exposed to five or ten years of Arizona conditions — seeing actual efflorescence patterns, color stability, and wear characteristics. This eliminates the guesswork inherent in selecting materials based only on fresh samples that don’t reveal long-term performance.

Cost Structure Transparency and Budget Predictability

When you evaluate material costs for Arizona projects, the delivered price matters more than the quoted price. Local suppliers eliminate freight variables that can add 15-25% to out-of-state purchases — and those freight costs fluctuate with fuel prices and carrier availability. Your budget projections remain stable when you’re working with suppliers whose delivery costs stay consistent throughout your project duration.

The local stone supply Arizona benefits include pricing that reflects actual market conditions rather than national averages that may not apply to Southwest markets. You avoid paying for climate adaptations your project doesn’t need — freeze-thaw treatments for northern installations, salt resistance for coastal applications — while accessing materials specifically engineered for desert performance.

- You receive accurate pricing without waiting for freight quotes from multiple carriers

- Your project budget excludes unnecessary crating and packaging required for long-distance shipping

- Local sourcing reduces risk of damage claims and replacement costs from extended transit

- You maintain better cash flow control with shorter payment cycles typical of regional suppliers

Professional procurement managers recognize that total cost of ownership extends beyond purchase price. When you factor in reduced inspection costs, lower damage rates, and eliminated expedite fees for rush shipments, local sourcing typically delivers 8-12% savings compared to apparent lower prices from distant suppliers. Your project financial performance improves when these hidden costs are eliminated.

Quality Verification and Material Consistency

Your specification compliance depends on receiving materials that match approved samples and meet performance standards. When you work with local suppliers, you can verify quality through direct warehouse inspection rather than relying on third-party certificates that may not reflect actual shipped materials. The stone supply company in Arizona local advantages include transparency that reduces specification risk.

Material lot consistency becomes critical for large installations where color variation or dimensional tolerance stacking creates visual discontinuities. You should inspect multiple pallets from the same production run, examining edge details, surface finish uniformity, and dimensional variation. Local suppliers facilitate this level of scrutiny because you can visit the warehouse during normal business hours without coordinating cross-country travel.

Stone materials exhibit natural variation that manufacturers attempt to control through grading and sorting. When you examine inventory locally, you identify whether that variation falls within acceptable ranges for your application. A ±3mm thickness variation may be acceptable for permeable paving but unacceptable for precision-set pool coping. Your ability to make these determinations before material ships prevents costly rejections after delivery.

Sustainability and Environmental Considerations

Professional specifications increasingly incorporate sustainability metrics, and transportation distance significantly impacts project carbon footprints. When you source from a stone supply store in Arizona nearby, you’re reducing freight miles by 70-90% compared to materials shipped from quarries in the Midwest or East Coast. Your LEED submissions benefit from regional material credits that require sourcing within 500 miles of the project site.

The environmental considerations extend beyond transportation. Local suppliers who stock materials proven in Arizona conditions help you avoid premature failures that generate landfill waste. When stone performs as specified for 20+ years instead of requiring replacement after 12 years due to climate incompatibility, you’ve eliminated the environmental cost of manufacturing, shipping, and installing replacement materials.

- Your project documentation can claim reduced embodied carbon from shortened supply chains

- Local sourcing supports regional employment and economic sustainability metrics

- You avoid packaging waste from materials that require extensive protection for long-distance shipping

- Regional suppliers often maintain return programs for unused materials, reducing project waste

Water conservation represents another sustainability factor in Arizona projects. When you work with suppliers who understand regional water scarcity, you access guidance on permeable installations, drainage optimization, and material selections that reduce irrigation requirements. These insights come from supporting hundreds of local projects where water management directly affects long-term landscape viability.

Inventory Depth and Material Availability

Your project schedule depends on material availability that matches your construction timeline. The Arizona stone supply inc regional operations maintain inventory depth that reflects local demand patterns — they stock materials in quantities sufficient for commercial-scale projects, not just residential applications. When you need 15,000 square feet of pavers for a retail development, you can verify availability before signing contracts.

Warehouse inventory turnover at local suppliers ensures you’re receiving recently manufactured materials rather than stock that’s been sitting in outdoor yards for multiple seasons. This matters particularly for materials with color-sensitive finishes or those susceptible to weathering during storage. You should confirm that materials are stored under conditions that prevent premature degradation — covered storage for porous stone, palletized with proper drainage, and rotated to ensure first-in-first-out inventory management.

The practical advantage of local inventory becomes apparent when projects require phased deliveries. Your construction may proceed in stages across months, requiring materials from the same production lot to maintain consistency. Local suppliers can reserve inventory from specific lots and coordinate staged deliveries that match your actual installation progress, preventing the color variation issues that occur when materials from different production runs get intermixed.

Relationship Building and Ongoing Support

Professional success in construction and design depends on reliable supplier relationships that extend beyond individual transactions. When you establish partnerships with local stone suppliers, you’re building relationships that benefit your entire project portfolio. The stone supplies Arizona local teams remember your quality standards, understand your communication preferences, and prioritize your needs because you represent ongoing business rather than one-time orders.

Your complex projects benefit from suppliers who invest time in understanding your specific requirements. Local relationships allow for collaborative problem-solving when you encounter unusual applications or need to value-engineer without compromising performance. These conversations happen naturally when you can meet in person, examine materials together, and develop solutions based on mutual understanding of project constraints.

The warranty and post-installation support you receive improves significantly with local suppliers. When minor issues arise — a damaged pallet discovered during installation, questions about maintenance protocols, or needs for small additional quantities — local suppliers respond immediately. You’re not navigating customer service queues or coordinating returns across state lines. Your project momentum continues because problems get resolved through direct communication with people who have decision-making authority.

Stone Slab Yard in Arizona: Citadel Stone Regional Guidance

When you evaluate Citadel Stone’s stone slab yard in Arizona for your regional projects, you’re considering premium materials specifically curated for Southwest performance demands. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s climatically diverse regions, from low-desert valleys to high-elevation mountain communities. This section outlines how you would approach specification decisions for six representative cities, demonstrating the climate-specific considerations that define professional stone selection in Arizona.

Your material specifications would need to account for temperature ranges spanning 80-100°F within single projects that cross elevation zones. The local stone supply Arizona benefits become most apparent when you’re designing installations that must perform equally well in Yuma’s extreme heat and Flagstaff’s winter freezing. You would select materials based on thermal expansion coefficients, porosity ranges, and surface treatments that accommodate these varying demands.

Phoenix Heat Specifications

In Phoenix applications, you would prioritize materials with high solar reflectance to minimize afternoon surface temperatures that can exceed 160°F on dark stone. Your specifications would require light-colored stone with reflectance values above 0.65, thermal expansion accommodation through 3/16-inch joints spaced every 15 feet, and surface treatments that maintain slip resistance despite dust accumulation from desert winds. The urban heat island effect in Phoenix amplifies material stress beyond what occurs in surrounding desert areas, requiring you to specify proven thermal cycling performance through 150+ annual cycles above 100°F.

Tucson Installation Conditions

Your Tucson projects would account for higher elevation and slightly moderated temperatures compared to Phoenix, but monsoon intensity increases dramatically. You would specify materials with 5-7% porosity to handle rapid water absorption followed by intense evaporation, base preparations that accommodate caliche layers common in Tucson soils, and joint treatments that remain stable despite temperature swings from 105°F daytime to 75°F nighttime during summer months. The basin topography creates drainage patterns that require you to coordinate stone installation with sophisticated water management systems.

Scottsdale Luxury Applications

Scottsdale installations typically involve high-end residential and resort applications where you would specify premium materials with refined finishes and tight dimensional tolerances. Your material selection would emphasize aesthetics without compromising performance — honed surfaces that provide slip resistance while maintaining visual sophistication, color consistency within ±5% variation across large installations, and edge details machined to ±1mm precision. You would coordinate with suppliers who maintain inventory specifically graded for luxury markets where client expectations demand perfection in both appearance and long-term performance.

Flagstaff Freeze-Thaw Requirements

Your Flagstaff specifications would shift dramatically to address freeze-thaw cycling that occurs 100+ times annually at 7,000-foot elevation. You would require materials with compressive strength exceeding 10,000 PSI, porosity below 4% to minimize water absorption that causes freeze damage, and surface treatments resistant to de-icing chemical exposure. The snow load and ice formation patterns in Flagstaff demand that you specify materials proven in mountain conditions rather than the desert-optimized inventory appropriate for valley locations. Your base preparations would need to address frost heave potential absent from lower-elevation projects.

Sedona Aesthetic Integration

Sedona projects require you to specify materials that integrate with the iconic red rock landscape while meeting stringent architectural review standards. You would select stone tones that complement rather than contrast with natural surroundings, typically warm earth tones with natural variation that mimics local geology. Your specifications would address how materials weather over time — whether they develop patina that enhances integration or fade in ways that create visual discord. The tourism-dependent economy and preservation focus in Sedona mean you must balance performance requirements with aesthetic considerations that satisfy rigorous community design standards.

Yuma Extreme Heat Performance

In Yuma, you would confront the most extreme heat conditions in Arizona — summer temperatures regularly exceeding 115°F with minimal nighttime cooling. Your material specifications would require maximum solar reflectance available, typically white or cream stone with polished or honed finishes that reflect rather than absorb solar radiation. You would need to account for thermal expansion that exceeds typical design standards, specifying expansion joints every 12 feet rather than the 15-20 feet adequate for moderate climates. The agricultural character of Yuma means you would also address potential chemical exposure from irrigation water with elevated mineral content that can cause efflorescence on porous materials.

Procurement Efficiency and Project Coordination

Your procurement process becomes more efficient when you consolidate suppliers to local sources who can coordinate deliveries across multiple project phases. Instead of managing relationships with separate vendors for stone, base materials, and installation accessories, you would work with integrated suppliers who maintain comprehensive inventory. The stone supply company in Arizona local advantages include one-stop sourcing that reduces your administrative overhead and simplifies project logistics.

Professional general contractors benefit from suppliers who understand construction sequencing and can time deliveries to match actual site readiness. You should establish communication protocols where suppliers receive weekly updates on installation progress, allowing them to adjust delivery schedules dynamically. This coordination prevents premature deliveries that create staging problems and eliminates last-minute rush orders that incur expedite fees.

- You can consolidate purchase orders and reduce processing costs across your project portfolio

- Local suppliers coordinate with your other trades to optimize site access and material handling

- Your project documentation becomes simpler with fewer vendor relationships to manage

- Consolidated sourcing improves your negotiating position for volume pricing across multiple projects

The warranty administration you’ll handle becomes significantly simpler with local suppliers. When issues arise during the warranty period, you’re working with companies invested in protecting their regional reputation. They respond to concerns quickly because their business model depends on maintaining relationships within a defined geographic market rather than one-time transactions with distant customers.

Risk Mitigation and Problem Resolution

Your project risk profile improves when you eliminate the variables associated with long-distance material sourcing. Transportation damage rates increase proportionally with distance traveled — materials shipped 2,000 miles experience 3-4 times the damage rates of materials delivered 200 miles. When you work with a stone supply store in Arizona nearby, you reduce this risk while also simplifying damage claims when they do occur.

Material substitution represents another risk that local sourcing mitigates. When distant suppliers face inventory shortages, they may ship alternative materials without adequate notification or approval. You discover the substitution only when materials arrive on site, creating delays while you negotiate replacements. Local suppliers allow you to verify inventory before orders are placed, and their proximity makes substitution less likely because you can physically confirm materials match approved samples.

Your ability to resolve problems quickly depends on having decision-makers accessible. Local suppliers provide direct access to management who can authorize returns, approve credits, or expedite replacement deliveries without navigating corporate hierarchies. When you’re managing a commercial project where daily delay costs exceed $10,000, this responsiveness prevents minor issues from becoming budget-threatening problems.

Competitive Advantages for Professional Practice

Professional designers and builders who establish strong local supplier relationships gain competitive advantages when bidding new projects. You can provide clients with more accurate budgets because you’re working from current pricing rather than estimates based on national averages. Your timeline projections become more reliable because you’ve eliminated freight variables that introduce uncertainty. These factors improve your win rate and client satisfaction.

The Arizona stone supply inc regional partnerships you develop provide access to materials and technical support that less-connected competitors cannot match. You can offer clients solutions to challenging applications because you have relationships with suppliers who invest in solving complex problems. Your specifications demonstrate sophistication that comes from collaborative development with material experts rather than generic selections from catalog pages.

- Your project portfolio benefits from consistent material quality across multiple installations

- You develop reputation for reliable execution that comes from eliminating supply chain uncertainties

- Client references improve when projects complete on schedule without material-related delays

- Your design capabilities expand as you stay informed about new products through regular supplier contact

Professional liability exposure decreases when you work with suppliers who provide proper documentation, maintain insurance adequate for commercial projects, and demonstrate commitment to quality through established business practices. You should verify that suppliers carry appropriate liability coverage, maintain documented quality control procedures, and can provide material certifications when required by project specifications or building codes.

Strategic Partnership Considerations

Your long-term business success depends on supplier relationships that provide stability across market cycles. When you evaluate potential partners among local Arizona suppliers, you should assess their financial stability, inventory management practices, and commitment to maintaining operations during economic downturns. The stone supplies Arizona local companies that weather market fluctuations become invaluable partners who support your business continuity.

Professional practice requires suppliers who invest in staying current with industry developments — new materials, installation techniques, performance testing methodologies, and regulatory changes. You benefit from partnerships with suppliers who attend industry conferences, maintain technical libraries, and provide ongoing education to their staff. These investments indicate commitment to professional excellence that aligns with your own practice standards.

Your evaluation should include site visits to assess warehouse operations, inventory organization, and material handling practices. Well-managed suppliers demonstrate systematic processes — organized inventory with clear identification, proper material storage that prevents damage, and equipment adequate for efficient loading. These operational details directly affect whether your deliveries arrive on schedule with materials in specified condition, making them legitimate criteria for supplier selection beyond simple price comparison.

Implementation Strategies

When you transition to prioritizing local Arizona suppliers, your implementation should be systematic rather than reactive. You would begin by identifying 2-3 primary suppliers who maintain inventory depth across the material categories your projects require most frequently. Your goal is developing working relationships where suppliers understand your quality standards, communication preferences, and typical project parameters.

Your initial projects with new local suppliers should be smaller installations where you can evaluate their performance without exposing major projects to risk. You would assess delivery reliability, material quality consistency, technical support responsiveness, and problem resolution effectiveness. Successful performance on these initial projects builds confidence that justifies specifying these suppliers for larger, more complex work.

Professional practice benefits from establishing preferred supplier agreements that formalize expectations on both sides. You would negotiate volume pricing structures, delivery protocols, warranty terms, and quality standards. These agreements provide framework that streamlines procurement for individual projects while ensuring consistency across your project portfolio. For comprehensive material solutions that support your professional practice, review Comprehensive inventory of natural and manufactured stone products before finalizing your supplier relationships. Builders seeking Bedrosian alternatives discover Citadel Stone matches quality while exceeding service expectations.