When you search for local slab yard Arizona locations, you’re navigating a fragmented market where material quality, inventory depth, and technical support vary dramatically. You need reliable access to granite, marble, and quartzite slabs that meet professional specification standards while ensuring your project timelines align with actual warehouse availability. The reality of slab procurement in Arizona’s competitive construction market requires you to evaluate suppliers based on material sourcing, fabrication capabilities, and logistical coordination—not just proximity to your job site.

Finding the right stone slab yard Arizona local guide starts with understanding how regional suppliers manage inventory for diverse applications. You’ll encounter significant differences in slab selection processes, quality control protocols, and delivery coordination across Phoenix, Scottsdale, Tucson, and Mesa. Your specification decisions depend on verified material performance data, not generic product descriptions that fail to address Arizona’s extreme thermal cycling and UV exposure conditions.

Material Sourcing Verification Protocols

You should investigate how local slab yard Arizona locations source their granite, marble, and quartzite inventory before committing to material selections. Reputable suppliers maintain relationships with quarries that provide certified geological data, including mineral composition analysis and structural integrity testing. When you evaluate marble slab yard nearby options, you’re assessing more than surface aesthetics—you need documentation of Mohs hardness ratings, acid sensitivity factors, and porosity measurements that determine long-term performance in Arizona’s alkaline soil conditions.

Your due diligence process must verify whether suppliers conduct independent material testing or rely exclusively on quarry-provided data. The distinction matters significantly when you specify materials for high-value commercial installations or custom residential projects. Professional-grade slab yard in Arizona near me finder tools should provide access to material certifications that include compressive strength values (typically 19,000-25,000 PSI for quality granite), flexural strength measurements, and absorption rate documentation. You’ll find that suppliers who warehouse-test random slab samples demonstrate higher consistency in material performance compared to operations that accept shipments without verification protocols.

- You need to confirm that granite slabs meet ASTM C615 standards with compressive strength exceeding 19,000 PSI for structural applications

- Your marble specifications should verify calcite content and acid resistance factors if you’re planning exterior installations in areas with monsoon precipitation patterns

- You should request absorption testing documentation showing porosity below 0.4% for freeze-thaw resistant applications in northern Arizona elevations

- Your quality standards must include dimensional tolerance verification within ±1/16 inch for slabs destined for precision fabrication

Inventory Depth and Project Coordination

When you evaluate the slab yard Arizona city locations, inventory breadth directly affects your ability to match book-matched slabs or maintain color consistency across large-format installations. You’ll discover that suppliers maintaining 5,000+ square feet of warehouse space can provide sequential slab numbering from the same quarry block—a critical factor when you’re specifying materials for continuous wall cladding or expansive countertop layouts. The difference between adequate and exceptional inventory management becomes apparent when you need to source replacement slabs 18-24 months after initial installation due to fabrication errors or damage during construction.

Your project timeline depends on understanding the distinction between in-stock inventory and special-order lead times. For detailed material procurement strategies, review Citadel Stone slab yard in Phoenix to understand how warehouse inventory management affects project scheduling. You should confirm whether local slab yard Arizona locations maintain safety stock of popular materials or operate on just-in-time inventory models that introduce 6-12 week lead times for non-standard selections. Professional specifications require you to identify backup material options when your first-choice slabs aren’t available in sufficient quantities to complete your project scope.

Truck delivery coordination becomes critical when you’re managing multi-phase projects requiring staged material releases. You need suppliers who can accommodate partial shipments without penalty charges while maintaining slab sequence integrity. The logistical complexity increases significantly when you’re coordinating deliveries to sites with restricted access hours or limited truck maneuvering space—common constraints in established Scottsdale neighborhoods and historic Tucson districts.

Slab Selection and Inspection Standards

You must physically inspect slabs before fabrication authorization, regardless of digital catalog representations or sales team assurances. Stone slab yard Arizona local guide resources emphasize the importance of viewing materials under consistent lighting conditions that replicate your installation environment. What appears as subtle veining variation in warehouse fluorescent lighting can manifest as dramatic color shifts under Arizona’s intense natural sunlight. Your inspection protocol should include viewing slabs both horizontally (as stored) and vertically (as installed) because gravitational effects on mineral deposits create different visual presentations in each orientation.

Professional specifiers evaluate slab quality using systematic assessment criteria that go beyond aesthetic preferences. You should examine surface finish consistency across the entire slab face, checking for fabrication irregularities that indicate improper gang-saw operation or resin fill applications that weren’t disclosed. The presence of micro-fissures requires careful evaluation—naturally occurring fissures in materials like Calacatta marble represent authentic geological characteristics, while stress fractures from improper handling indicate compromised structural integrity. Your acceptance criteria must distinguish between these conditions to avoid rejecting premium materials unnecessarily or accepting damaged inventory that will fail prematurely.

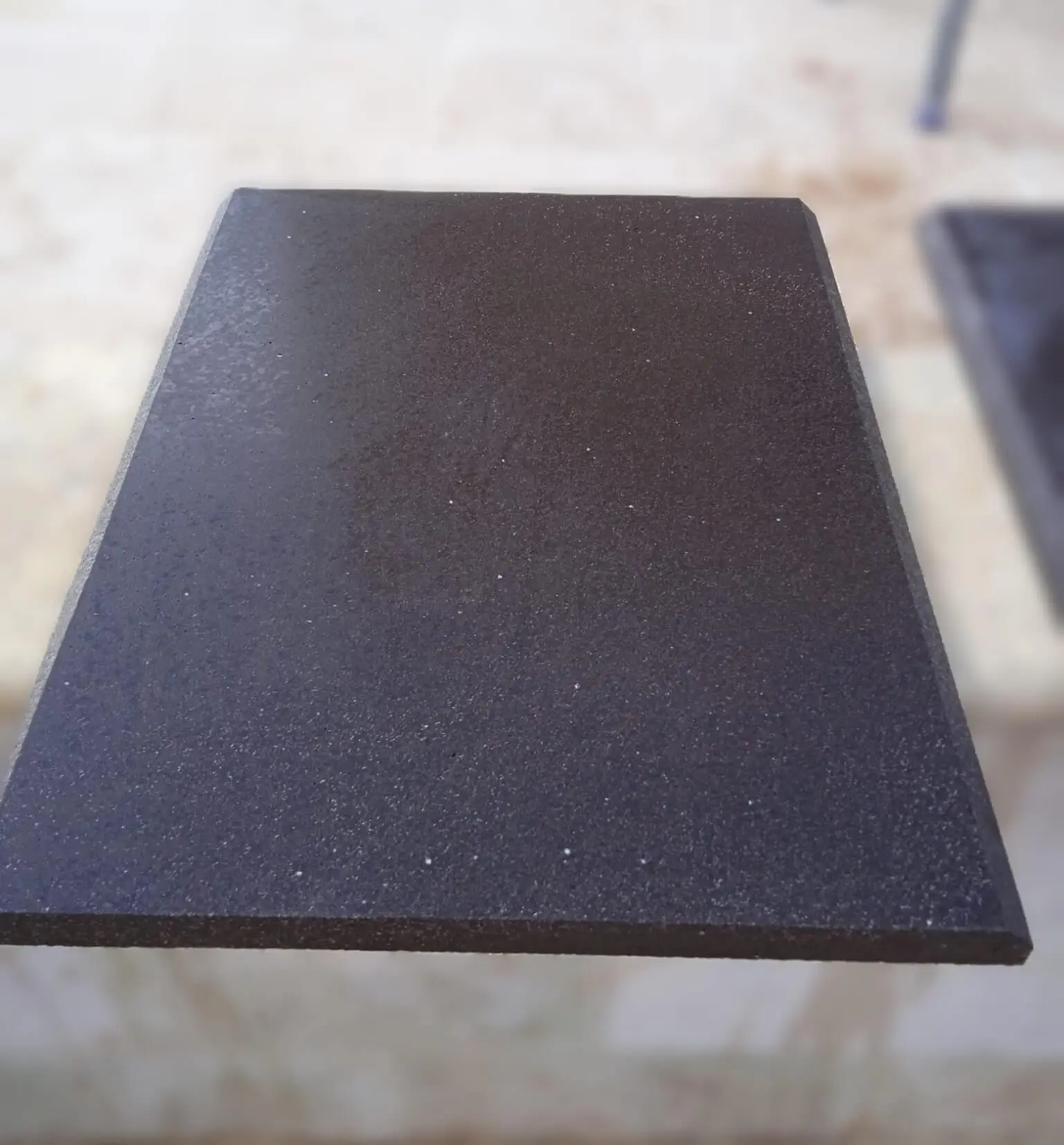

- You need to verify surface finish specifications match your design intent, whether polished (90+ gloss units), honed (20-30 gloss units), or leathered finishes that affect maintenance requirements

- Your inspection should identify any epoxy resin fills or mesh backing reinforcements that affect material performance and require disclosure in your specifications

- You must document natural fissure patterns and mineral deposits to establish baseline conditions that prevent false warranty claims after installation

- Your quality verification includes edge inspection for potential delamination risks in materials with pronounced bedding planes or mineral stratification

Fabrication Capabilities and Equipment Standards

When you work with local slab yard Arizona locations that offer integrated fabrication services, you’re evaluating both material quality and processing capabilities. Modern CNC bridge saws with laser-guided cutting systems maintain tolerances within ±0.5mm across 10-foot slab lengths—precision that manual cutting operations cannot replicate consistently. You should verify whether fabricators utilize waterjet cutting technology for intricate edge profiles and cutout details, as this method eliminates the micro-fracture risks associated with traditional blade cutting in brittle materials like quartzite.

Your fabrication specifications must address edge profile options and their structural implications. A simple eased edge provides maximum strength retention by preserving full material thickness at vulnerable corners, while decorative ogee profiles remove 30-40% of edge material and create stress concentration points that increase chipping risk. You’ll need to balance aesthetic preferences against functional performance requirements when you specify edge treatments for high-impact areas like kitchen islands or commercial reception desks. Professional fabricators understand these trade-offs and can recommend edge profiles that maintain design intent while optimizing durability for your specific application.

Seam placement strategy represents another critical fabrication consideration that affects both appearance and structural performance. You want fabricators who plan seam locations based on your space layout and material movement patterns, not arbitrary shop drawing conveniences. Optimal seam placement avoids high-stress areas like cooktop cutouts and dishwasher openings while positioning joints in visually inconspicuous locations. The quality of seam execution—measured by joint tightness (typically 1/32 inch maximum) and color-matched epoxy application—distinguishes skilled fabricators from operations that prioritize production speed over installation quality.

Thermal Performance in Arizona Climate Conditions

You must account for Arizona’s extreme temperature variations when you select stone materials from any slab yard in Arizona near me finder results. Summer surface temperatures on south-facing exterior installations regularly exceed 160°F in Phoenix metro areas, creating thermal expansion stresses that materials must accommodate without structural failure. Granite’s thermal expansion coefficient of 4.7 × 10⁻⁶ per °F means a 10-foot horizontal surface expands approximately 1/16 inch during a 100°F temperature swing—movement that requires properly designed expansion joints or results in buckling failure within 18-24 months.

Your material selection decisions should consider thermal conductivity variations across stone types. Marble exhibits lower thermal conductivity (1.3-2.5 W/m·K) compared to granite (2.0-3.0 W/m·K), affecting surface comfort temperatures in outdoor living spaces and pool deck applications. When you specify materials for these applications, you’re balancing heat retention characteristics against slip resistance requirements and maintenance considerations. Honed finishes provide superior slip resistance but absorb more heat than polished surfaces, while textured finishes like flamed or brushed granite offer optimal traction with moderate heat retention properties.

- You should specify expansion joint placement every 12-15 feet for exterior granite installations exposed to full sun exposure exceeding 6 hours daily

- Your material selection needs to account for thermal shock resistance if installations include areas with dramatic temperature transitions like poolside surfaces adjacent to air-conditioned interior spaces

- You need to verify that sealant products maintain flexibility across Arizona’s 80-120°F temperature range to prevent joint failure during seasonal expansion cycles

- Your installation specifications must address substrate preparation that accommodates differential expansion between stone surfaces and concrete bases

Moisture Management and Porosity Considerations

When you evaluate stone materials at local slab yard Arizona locations, porosity characteristics determine maintenance requirements and long-term appearance retention. Dense granite with absorption rates below 0.2% resists staining and requires minimal sealing maintenance, while more porous marbles (0.4-1.2% absorption) need professional-grade penetrating sealers reapplied every 12-18 months to maintain stain resistance. You’ll encounter significant performance differences even within the same stone category—Carrara marble exhibits higher porosity than Calacatta marble due to calcite crystal size variations, affecting your sealer selection and maintenance protocol specifications.

Your understanding of capillary action in porous stone becomes critical when you specify materials for applications with moisture exposure risks. The same porosity that creates aesthetic depth in honed marble surfaces also enables water infiltration that carries dissolved minerals from substrate materials. You’ve likely seen the yellowish-brown discoloration that appears on marble shower walls 24-36 months after installation—this occurs when iron compounds from mortar beds migrate through capillary pathways and oxidize at the stone surface. Professional specifications prevent this condition by specifying appropriate waterproofing membranes and iron-free setting materials, not just premium stone selection.

Arizona’s alkaline soil conditions and hard water chemistry create additional moisture-related challenges you need to address in your specifications. When capillary moisture draws calcium carbonate and magnesium sulfate from concrete substrates through porous stone, you see white efflorescence deposits that require acid-based removal treatments. These treatments work on granite but damage acid-sensitive marble and limestone, creating a maintenance dilemma that proper substrate preparation and moisture barrier installation prevent. Your specification process must address these systemic issues rather than relying on post-installation remediation attempts.

Color Consistency and Vein Matching Protocols

You need realistic expectations about color variation when you select natural stone materials from the slab yard Arizona city locations inventory. Professional-grade stone suppliers provide range samples showing minimum and maximum color variation within specific material lots, helping you establish acceptance criteria that reflect geological reality rather than idealized catalog photography. When you specify book-matched or sequence-matched slabs for feature walls or large-format applications, you’re requesting materials cut from adjacent positions in the same quarry block—a requirement that demands adequate inventory depth and sophisticated warehouse management.

Your vein matching strategy affects both aesthetic outcomes and material costs. Book-matching creates mirror-image symmetry by opening consecutive slabs like pages in a book, producing dramatic visual effects that work well for vertical applications like fireplace surrounds and accent walls. Sequence-matching maintains natural vein flow across multiple slabs without mirroring, creating continuous patterns suitable for horizontal surfaces like large island tops. You should understand that these matching requirements can increase material costs by 30-45% because they limit usable yield from quarry blocks and require skilled layout planning that extends fabrication time.

- You must approve all slabs in person before fabrication begins, particularly for materials with significant natural variation like Calacatta Gold or Blue Bahia granite

- Your specification should establish clear acceptance criteria for color variation using range samples that define acceptable minimum and maximum values

- You need to document vein orientation preferences and communicate these requirements clearly to fabricators who may default to layouts that optimize material yield rather than aesthetic intent

- Your project timeline must accommodate the 2-3 week lead time required for locating and reserving sequence-matched slabs from warehouse inventory

Pricing Structures and Value Analysis

When you compare pricing across different marble slab yard nearby locations, you’re evaluating more than per-square-foot material costs. Professional procurement requires you to analyze total installed cost including fabrication quality, delivery coordination, and post-installation support. A supplier offering granite at $45 per square foot with substandard fabrication creates higher total project costs than a $55 per square foot supplier providing precision CNC fabrication and experienced installation coordination. You should request itemized pricing that separates material costs from fabrication charges, allowing you to compare value propositions accurately across competing suppliers.

Your cost analysis must account for waste factors that vary significantly based on project complexity and material characteristics. Standard countertop layouts typically generate 15-20% waste in materials without pronounced vein patterns, while book-matched feature walls can produce 35-40% waste due to precise matching requirements. You need suppliers who calculate material quantities based on actual project layouts rather than simple square footage multiplication, providing accurate estimates that prevent mid-project cost overruns when additional material becomes necessary to complete installations.

Minimum order quantities and cutting fees represent hidden cost factors you should clarify during supplier evaluation. Some stone slab yard Arizona local guide directories connect you with suppliers who require full-slab purchases even for small projects, while others accommodate partial slab sales with cutting fees of $75-150 per cut. Your small project economics change dramatically based on these policies—a simple vanity top requiring 8 square feet of material becomes financially impractical if it necessitates purchasing a full 45-square-foot slab with no secondary use for remnant material.

Delivery Logistics and Site Coordination Requirements

You must coordinate delivery scheduling with fabrication completion timelines and installer availability to prevent costly delays or material storage complications. Stone slabs delivered to job sites before installation crews are ready face damage risks from construction traffic, weather exposure, and improper storage conditions. Professional project management requires you to sequence deliveries within 24-48 hours of scheduled installation dates while building contingency time for unexpected site preparation delays that commonly occur in renovation projects.

Your site access evaluation should identify potential delivery obstacles before materials leave the warehouse. Standard material delivery trucks require 14-foot clearance height for overhead obstacles and 35-foot turning radius for maneuvering into residential driveways. You’ll encounter access constraints in established neighborhoods with mature tree canopies, narrow street widths, and overhead utility lines that prevent direct truck access to properties. Alternative delivery methods using smaller trucks or manual material transfer increase costs by $200-500 per delivery and extend unloading time from 30 minutes to 2-3 hours, affecting installer scheduling and labor costs.

- You need to verify site access dimensions including overhead clearance, street width, and driveway slope before confirming delivery dates with suppliers

- Your delivery coordination should specify exact placement locations that minimize material handling distance for installation crews while protecting slabs from construction activity

- You must ensure adequate storage space with level surfaces, protection from direct weather exposure, and separation from high-traffic construction zones

- Your project timeline should include buffer time for delivery rescheduling when weather conditions or site preparation delays affect original delivery dates

Warranty Coverage and Performance Guarantees

When you evaluate local slab yard Arizona locations, warranty terms reveal supplier confidence in material quality and fabrication standards. Comprehensive warranties cover material defects, fabrication errors, and installation failures for 12-24 months post-installation, while limited warranties exclude natural stone characteristics like fissures, color variation, and mineral deposits that represent inherent geological features rather than quality defects. You should obtain written warranty documentation before project commencement, clearly understanding which conditions trigger warranty coverage and which fall outside protected parameters.

Your warranty analysis must distinguish between material warranties from quarries and workmanship warranties from fabricators and installers. A material warranty covering stone defects provides no protection against poor fabrication resulting in visible seams, lippage between adjacent surfaces, or inadequate edge profile execution. You need comprehensive coverage addressing the complete installation system, not fragmented warranties that create disputes about responsibility when performance issues emerge. Professional suppliers coordinate warranty coverage across material sourcing, fabrication, and installation services, providing single-source accountability that simplifies resolution processes when problems occur.

Exclusions in warranty coverage often prove more significant than covered items. Most warranties exclude damage from improper maintenance, including etching from acidic cleaners on marble surfaces, scratching from abrasive cleaning methods, and staining from failure to maintain recommended sealer applications. You should review these exclusions carefully and provide clients with written maintenance guidelines that preserve warranty validity while establishing realistic performance expectations for different stone types under Arizona’s challenging environmental conditions.

Sealer Selection and Maintenance Protocols

You need material-specific sealer recommendations from suppliers who understand performance differences between impregnating sealers, topical coatings, and enhancement products. Impregnating sealers penetrate below the stone surface, providing stain resistance without altering appearance or creating surface films that wear away under traffic. These products work best for dense granite and quartzite with low porosity, requiring reapplication every 3-5 years in residential applications. More porous materials like honed marble need specialized sealers formulated for calcium carbonate chemistry, with reapplication intervals of 12-18 months to maintain protection against oil-based staining and etching from acidic exposure.

Your maintenance protocol specifications should address Arizona-specific environmental challenges including hard water deposits, dust accumulation, and UV degradation of organic stain protection compounds. The calcium carbonate in Arizona’s municipal water supplies creates persistent white scale deposits on stone surfaces, particularly noticeable on dark-colored granite in shower enclosures and around sink fixtures. You’ll need maintenance programs incorporating pH-neutral cleaners and periodic professional restoration services that remove accumulated deposits without damaging stone surfaces or sealer protection layers.

- You should specify impregnating sealers with fluoropolymer chemistry for maximum stain resistance in kitchen applications where oil-based cooking residue creates persistent staining risks

- Your maintenance guidelines need to prohibit acidic cleaners including vinegar, lemon juice, and many commercial bathroom cleaners that etch marble and limestone surfaces

- You must establish realistic resealing intervals based on material porosity and application intensity rather than generic manufacturer recommendations

- Your client education should address the distinction between staining (treatable) and etching (permanent surface damage) to set appropriate expectations for marble performance

Premium Stone Slab Yard in Arizona Installations—Citadel Stone’s Arizona Specification Approach

When you consider Citadel Stone’s stone slab yard in Arizona materials for your project, you’re evaluating premium granite, marble, and quartzite slabs selected specifically for Arizona’s extreme climate challenges. At Citadel Stone, we provide technical guidance for hypothetical applications across diverse Arizona regions, from low-desert heat zones to high-elevation freeze-thaw environments. This section outlines how you would approach specification decisions for six representative cities where material performance requirements vary significantly based on local climate conditions and architectural design preferences.

Your material selection process with stone slab yard in Arizona options should account for regional temperature extremes, UV exposure intensity, and precipitation patterns that affect long-term stone performance. You’ll encounter different specification priorities when you compare Phoenix’s 120°F summer heat against Flagstaff’s winter freeze-thaw cycles and monsoon moisture management requirements throughout central Arizona. Professional specifications require you to evaluate thermal expansion characteristics, moisture absorption rates, and surface finish durability under the specific environmental stresses present in each installation location.

Phoenix Specifications

In Phoenix applications, you would specify dense granite materials with thermal expansion coefficients below 5.0 × 10⁻⁶ per °F to minimize expansion joint requirements in large-format installations. Your material selection should prioritize light-colored stones with solar reflectance values exceeding 0.60 to reduce surface temperatures in outdoor living spaces where materials routinely reach 150-165°F during peak summer months. You’ll want to verify that selected materials maintain structural integrity through 90+ days of consecutive temperatures exceeding 105°F—thermal stress conditions that reveal quality differences between premium and standard-grade stone. Typical installations in Phoenix’s urban heat island require you to account for accelerated sealer degradation from UV exposure, reducing standard 3-year resealing intervals to 18-24 months for exposed exterior applications. Your specifications would include penetrating sealers with UV inhibitors formulated specifically for desert climate conditions where solar radiation intensity exceeds most manufacturer testing parameters.

Scottsdale Considerations

Scottsdale projects typically involve high-end residential applications where you would recommend book-matched marble or quartzite for dramatic interior feature walls and kitchen islands. Your material selection process should emphasize consistent color grading and vein pattern continuity across multiple slabs, requiring warehouse inventory depth of 15-20 sequential slabs from the same quarry block. You’ll need to coordinate with suppliers maintaining adequate stock levels to support these aesthetic requirements while meeting compressed project timelines common in luxury custom home construction. At Citadel Stone, we would advise specifying materials with documented Mohs hardness ratings above 6.0 for countertop applications to resist scratching from food preparation activities and daily use patterns in high-performance kitchens. Your fabrication specifications would require CNC-cut edges with tolerances within ±0.5mm to achieve the seamless appearance expected in premium residential installations where quality standards often exceed commercial project requirements.

Tucson Requirements

When you specify materials for Tucson installations, you would account for the region’s higher elevation (2,400 feet) and greater precipitation variability compared to Phoenix metro areas. Your stone selection should verify absorption rates below 0.5% for materials exposed to monsoon rainfall patterns that deliver 2-3 inches of precipitation in concentrated summer storm events. You need materials that resist moisture-induced staining when alkaline desert soils become saturated and capillary action draws dissolved minerals toward stone surfaces. Professional specifications for Tucson projects would include enhanced substrate waterproofing and drainage provisions that prevent moisture accumulation beneath stone installations where freeze-thaw cycling occurs 10-15 times annually at higher elevation properties. Your maintenance protocols would address seasonal sealer inspection following monsoon periods when concentrated moisture exposure tests the durability of protection systems in ways that normal conditions don’t replicate.

Mesa Applications

Mesa installations share Phoenix’s extreme heat challenges while serving a broader range of residential market segments from entry-level to luxury custom homes. You would recommend material selections balancing performance requirements with budget parameters that vary significantly across this diverse market. Your specification approach should identify granite options providing reliable thermal performance and stain resistance at moderate price points of $45-60 per square foot installed, compared to premium materials at $85-120 per square foot common in Scottsdale applications. You’ll want to emphasize materials with proven track records in Arizona climate conditions rather than newly introduced exotic stones lacking long-term performance data in desert environments. At Citadel Stone, we maintain warehouse inventory focused on materials with demonstrated 15-20 year performance histories in Arizona installations, helping you avoid specification risks associated with unproven materials that may exhibit unexpected behavior under sustained thermal stress exposure.

Flagstaff Specifications

Your Flagstaff material specifications would prioritize freeze-thaw resistance over heat management requirements that dominate low-desert specifications. At 7,000 feet elevation, you need materials with absorption rates below 0.4% and documented ASTM C666 testing showing minimal strength degradation after 300 freeze-thaw cycles. You should specify materials with appropriate porosity characteristics that allow moisture to escape during freeze events rather than creating internal expansion pressures that cause spalling and delamination failures. Professional installations at this elevation require you to account for snow load considerations and ice-melt chemical exposure that don’t factor into specifications for lower elevation Arizona projects. Your sealer selection would emphasize products maintaining flexibility across temperature ranges from -10°F to 95°F rather than the 40°F to 120°F range appropriate for Phoenix installations.

Sedona Considerations

Sedona projects typically emphasize natural aesthetic integration with the region’s distinctive red rock landscape, requiring you to select stone materials complementing rather than competing with surrounding geological features. Your material recommendations would include warm-toned granites and quartzites that harmonize with the area’s iron-oxide-rich sandstone formations while providing superior performance compared to locally sourced sedimentary stone. You’ll need to balance clients’ desires for regional aesthetic consistency with the practical reality that local sandstone lacks the density and durability required for high-performance countertop and flooring applications. At Citadel Stone, we would guide you toward materials like Golden Riviera granite or Brazilian Fantasy quartzite that offer warm earth tones and natural variation patterns echoing Sedona’s landscape while delivering compressive strength exceeding 20,000 PSI and absorption rates below 0.3%. Your specifications would address the area’s tourist-driven economy with commercial applications requiring exceptional durability under high-traffic conditions in restaurant and hospitality environments where material replacement costs far exceed initial installation premiums for superior quality stone.

Specification Documentation and Communication Standards

You need comprehensive written specifications that eliminate ambiguity in material selection, fabrication requirements, and installation standards. Professional specification documents include material identification by quarry name and block number, surface finish specifications with measurable gloss unit targets, edge profile details with cross-section drawings, and seam location plans coordinated with architectural drawings. Your specifications should establish acceptance criteria for natural stone characteristics including fissures, mineral deposits, and color variation—defining what constitutes acceptable material versus grounds for rejection before fabrication begins.

Your communication protocols with suppliers, fabricators, and installers must include formal approval processes at critical project milestones. You should require photographic documentation of selected slabs with dimensional measurements and orientation markings before fabrication authorization. Template verification represents another critical control point where you confirm that field measurements translate accurately to shop drawings before cutting begins on expensive stone materials. These verification steps add 3-5 days to project timelines but prevent costly errors that result in unusable materials and project delays measuring weeks rather than days. For comprehensive guidance on stone quality assessment, refer to Evaluating granite marble and quartzite slab quality standards before you finalize your specifications.

Professional Procurement Strategies

Your supplier selection process should evaluate technical capabilities beyond material availability and competitive pricing. You need partners who understand building code requirements, maintain fabrication equipment to precision standards, and employ experienced installers who recognize field conditions requiring specification adjustments. Professional suppliers provide value through problem-solving capabilities when you encounter unexpected substrate conditions, design modifications, or material performance concerns during construction—situations where expertise matters more than low pricing. You’ll find that suppliers offering comprehensive project support from material selection through post-installation service deliver superior outcomes compared to operations focused exclusively on transaction completion. Your long-term professional relationships with quality suppliers create competitive advantages through priority access to premium materials, flexible scheduling coordination, and technical support that helps you avoid specification errors before they become expensive field corrections. Projects requiring Bedrosian-equivalent quality benefit from Citadel Stone’s relationship-focused business model.