When you’re sourcing natural stone for Arizona projects, you’ll quickly discover that local flagstone suppliers Arizona colors offer represents more than aesthetic choice—it’s a performance specification decision. You need to understand how Arizona Buff, Peach, Rose, and Classic Oak flagstone respond to extreme UV exposure, thermal cycling that exceeds 80°F daily swings, and soil conditions ranging from caliche-heavy substrates to expansive clays. Your material selection directly impacts project longevity, maintenance requirements, and client satisfaction over the 20-30 year service life you’re specifying.

The challenge with local flagstone suppliers Arizona colors provide goes beyond catalog browsing. You’re evaluating quarry-specific characteristics—porosity ranges from 3-9%, compressive strengths between 6,500-14,000 PSI, and thermal absorption coefficients that vary by 40% between buff and rose tones. When you specify flagstone wholesale Arizona sources, you should verify how each color responds to the state’s unique environmental stressors. Here’s what catches most specifiers off-guard: two flagstones with identical compressive strength ratings can perform completely differently in Phoenix heat versus Flagstaff freeze-thaw cycles, and the color variation you see in samples represents only 60-70% of the range you’ll encounter in full-pallet deliveries.

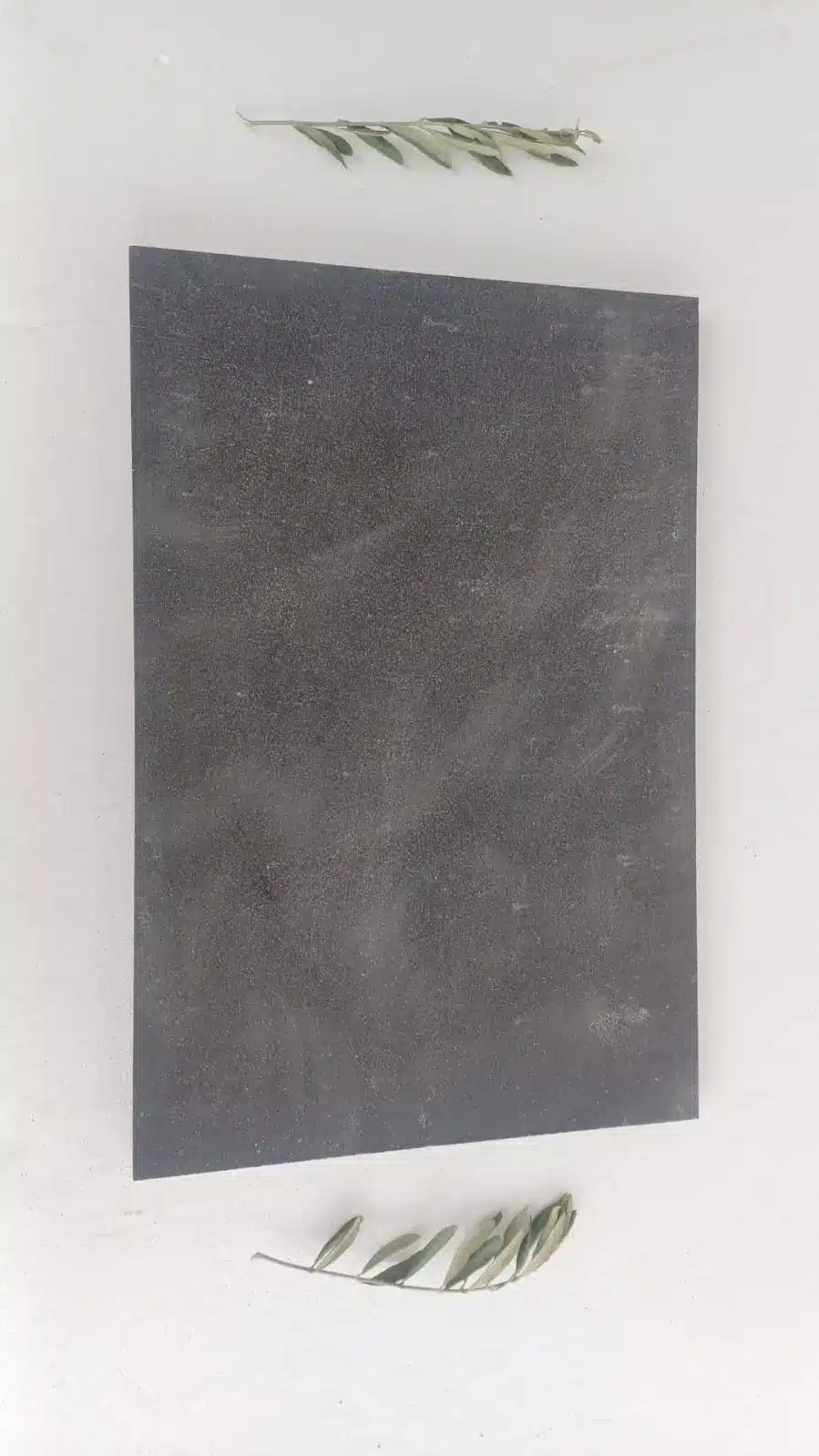

Understanding Arizona Flagstone Color Performance Characteristics

Arizona flagstone colors aren’t just visual classifications—they’re indicators of mineral composition that determine thermal behavior and weathering patterns. When you evaluate Arizona Buff flagstone, you’re looking at material with 12-18% iron oxide content that creates solar reflectance values around 0.35-0.42. Your surface temperature readings will peak at 135-148°F during June-August afternoons in direct sun exposure. Compare this to Rose flagstone, which exhibits 22-28% iron oxide concentrations and reflectance values of 0.28-0.35, resulting in surface temperatures reaching 152-165°F under identical conditions.

You need to account for these thermal differentials when you specify outdoor living spaces. The 15-20°F temperature variance between buff and rose tones directly affects barefoot comfort zones, furniture longevity, and adjacent plant material viability. For natural flagstone suppliers Arizona near me searches, you should prioritize yards that provide thermal performance data alongside color samples. Professional specifications require you to match color selection with exposure orientation—south and west-facing installations benefit from lighter buff and peach tones, while north and east exposures can accommodate the richer rose and oak colors without excessive heat retention.

The mineral composition that creates these colors also determines porosity and water absorption characteristics. Classic Oak flagstone, with its darker brown-gray tones, typically exhibits 6-9% porosity—higher than the 3-6% you’ll find in Arizona Buff. When you specify for pool decks or areas with irrigation overspray, this porosity differential becomes critical. Higher porosity materials require more aggressive sealing protocols, with reapplication intervals of 18-24 months versus 36-48 months for denser buff tones. You’ll also observe different efflorescence patterns—lighter colors show salt deposits more prominently but the deposits themselves cause less permanent staining compared to darker materials where mineral salts create contrast etching.

Evaluating Local Flagstone Suppliers Arizona Colors and Quality Consistency

Your biggest challenge with local flagstone suppliers Arizona colors isn’t finding material—it’s securing consistent quality across the volume your project requires. A residential patio might need 800-1,200 square feet of flagstone, while commercial plaza installations can demand 8,000-15,000 square feet from the same quarry run. You should verify that suppliers can provide color consistency within acceptable variation ranges: ±15% for residential projects, ±10% for high-visibility commercial work.

When you visit flagstone suppliers Arizona local yards, examine full pallets rather than individual samples. The sample pieces you see in display areas represent ideal specimens—typically the top 10-15% of quarry output. You need to inspect production-grade material to understand the actual color range, thickness variation (expect ±1/2″ to ±3/4″ on 1.5″ nominal material), and surface texture consistency. Pull random pieces from the middle and bottom of pallets to assess quality distribution. Professional procurement requires you to establish acceptance criteria before material ships: maximum percentage of off-color pieces (typically 8-12% is reasonable), minimum average thickness, and maximum thickness variation within single pieces.

Arizona flagstone suppliers locations matter more than most specifiers realize. Material trucked from Prescott quarries exhibits different weathering characteristics than stone sourced from areas near Sedona or Kingman. The geological age and formation conditions create performance variations you won’t see in technical data sheets. You’ll find that northern Arizona sources generally provide denser material with better freeze-thaw resistance—critical if your project is in Flagstaff or higher elevations. Southern quarries often produce more porous stone that excels in heat dissipation but requires different base preparation protocols to prevent subsurface moisture accumulation.

Arizona Buff Flagstone: Technical Specifications for Desert Applications

Arizona Buff flagstone represents the most versatile color option for extreme heat environments, but you need to understand its specific performance envelope. The material typically delivers:

- Compressive strength: 8,500-12,000 PSI (exceeding most specification requirements)

- Porosity range: 3-6% (lower end of flagstone spectrum)

- Water absorption: 1.8-3.2% by weight

- Thermal expansion coefficient: 5.8 × 10⁻⁶ per °F

- Solar reflectance: 0.35-0.42 (moderate heat mitigation)

When you specify Arizona Buff for commercial projects, you’re selecting material that maintains visual consistency better than darker tones. The lighter base color masks minor staining, normal weathering, and the inevitable joint sand migration that occurs in the first 18-24 months post-installation. Your clients will appreciate that maintenance requirements stay reasonable—pressure washing every 18-24 months maintains appearance without aggressive chemical treatments that darker stones often require.

The thermal expansion coefficient of 5.8 × 10⁻⁶ per °F requires you to design expansion joints every 12-15 feet in Arizona installations. This isn’t the 20-foot spacing you might use in moderate climates. When you calculate joint requirements, account for the full temperature swing: material temperature can range from 45°F on winter mornings to 145°F on summer afternoons—a 100°F delta that creates 0.07″ of linear expansion per 10 feet of stone. Your joint spacing must accommodate this movement while maintaining visual coherence. Professional details typically specify 3/8″ joints for thermal movement versus the 1/4″ joints used purely for aesthetic purposes.

For projects requiring natural flagstone suppliers Arizona near me with immediate availability, you should know that Arizona Buff maintains the most consistent warehouse stock levels. The color’s popularity means major yards keep 40,000-80,000 square feet in inventory, compared to 15,000-30,000 square feet for specialty colors. When you coordinate project timelines, this availability differential can mean the difference between 5-day lead times and 4-6 week delays waiting for quarry production runs.

Peach and Rose Flagstone: Thermal Management in High-Heat Climates

Peach and Rose flagstone occupy the middle ground in Arizona’s color spectrum, but they present specific thermal challenges you need to address in your specifications. These mid-tone colors absorb 15-25% more solar radiation than buff tones, creating surface temperatures that peak at 145-165°F in direct summer sun. You’ll need to evaluate project exposure carefully—these colors work well in partially shaded courtyards, north-facing patios, and areas with overhead structure, but require careful consideration for full-sun pool decks and walkways where barefoot traffic is expected.

The iron oxide content that creates these warm tones (18-28%) also affects long-term color stability. You should advise clients that rose and peach flagstone develops a slight patina over 3-5 years as surface minerals oxidize further. This isn’t degradation—it’s natural weathering that typically deepens color richness by 8-12%. Some clients appreciate this aging characteristic; others prefer the more stable appearance of buff tones. Your specification documents should address expected color evolution to prevent misunderstandings during warranty periods.

When you source these colors from flagstone suppliers Arizona local yards, verify the specific quarry origin. Rose flagstone from different geological formations can vary significantly in porosity. Northern sources typically provide 4-7% porosity, while some southern quarries produce material at 7-10%. This porosity differential directly impacts your sealing requirements and freeze-thaw performance. For Flagstaff and Prescott installations where you’ll see 40-60 freeze-thaw cycles annually, you must specify material at the lower porosity range. Higher elevation projects require you to verify water absorption rates below 3.5%—anything higher creates spalling risk during freeze cycles.

Classic Oak Flagstone: Performance in Transitional Climate Zones

Classic Oak flagstone delivers rich brown-gray tones that create dramatic visual impact, but you’re working with material that demands more sophisticated specification. The darker coloration comes from higher mineral content that increases density (typically 165-175 pounds per cubic foot versus 155-165 for buff tones) while paradoxically increasing porosity to 6-9%. This combination creates unique performance characteristics you need to account for in your project details.

The higher thermal mass of Classic Oak flagstone creates a 4-6 hour lag time between peak air temperature and peak surface temperature. When you’re designing outdoor spaces in Phoenix or Tucson, this thermal flywheel effect means the stone remains hot well into evening hours—surface temperatures above 120°F can persist until 9-10 PM following 110°F+ afternoon highs. You should reserve this color for areas with minimal evening use, or specify it for projects at higher elevations where the thermal mass provides beneficial heat retention during cool mornings and evenings.

Your sealing specifications for Classic Oak require more attention than lighter colors. The darker base shows water spots, efflorescence, and staining more prominently, while the higher porosity makes the material more susceptible to these issues. Professional specifications should include penetrating sealers applied at 50-75% higher coverage rates than manufacturer base recommendations. You’ll need initial application within 30 days of installation, followed by reapplication at 18-month intervals for the first 5 years, then 24-36 month intervals once the stone has fully cured and stabilized.

When you evaluate flagstone wholesale Arizona pricing, you’ll notice Classic Oak typically costs 15-25% more than buff tones. This premium reflects both lower production volumes and higher finishing costs—the dense material requires more processing time to achieve consistent thickness and surface texture. For commercial projects where budget constraints are significant, you might specify Classic Oak as accent banding or feature areas, using more economical buff tones for field areas. This approach delivers visual interest while controlling material costs.

Thickness and Grading Standards for Arizona Flagstone Colors

Thickness specifications for Arizona flagstone require you to balance structural requirements against cost and installation complexity. Standard offerings include:

- 1″ nominal (actual 3/4″ to 1-1/4″): Pedestrian pathways with stable base

- 1.5″ nominal (actual 1-1/4″ to 1-3/4″): Residential patios and commercial walkways

- 2″ nominal (actual 1-3/4″ to 2-1/4″): Vehicular applications and heavy commercial use

- 3″+ nominal: Specialty applications, steps, and architectural features

You need to understand that nominal thickness ranges create installation challenges. A pallet of 1.5″ nominal material might contain pieces ranging from 1-1/4″ to 1-3/4″—a 1/2″ variation that requires your installation crew to compensate through base adjustment or mortar bed depth changes. Professional specifications should address this reality by requiring installers to sort material by thickness ranges and install similar thicknesses in contiguous areas. This approach minimizes lippage and creates more uniform walking surfaces.

When you’re reviewing material from Arizona flagstone suppliers locations, examine the grading standards each yard uses. There’s no universal flagstone grading system, so you’ll encounter terms like “premium,” “select,” “standard,” and “rustic” that mean different things at different suppliers. You should establish specific criteria: maximum thickness variation within single pieces (±1/4″ for premium grades), minimum percentage of full-thickness pieces versus tapered edges (70%+ for quality grades), and acceptable color variation range. Document these requirements in your purchase orders to create enforceable quality standards.

The color you select affects thickness consistency. Arizona Buff flagstone, being the highest-volume production material, typically offers the most consistent thickness grading. You’ll find 75-85% of pieces within ±1/4″ of nominal thickness in premium grades. Specialty colors like Classic Oak might show 65-75% consistency in similar grades because lower production volumes make thickness sorting less economical for suppliers. When you coordinate with Citadel Stone’s natural flagstone facility, you can specify tighter thickness tolerances, but you should expect 10-15% cost premiums for enhanced sorting and grading.

Installation Base Requirements: Color-Specific Considerations

Your base preparation requirements vary slightly by flagstone color due to density and porosity differences. All Arizona flagstone installations require proper base design, but the specifics change based on material characteristics. For Arizona Buff and Peach tones (lower density, lower porosity), you can typically specify:

- Excavation to 8-10″ depth for pedestrian applications

- 6″ compacted crushed aggregate base (3/4″ minus)

- 2″ setting bed of coarse sand or fine screenings

- Minimum 95% compaction for base, 92% for setting bed

Classic Oak flagstone, with its higher density and porosity, benefits from enhanced drainage provisions. You should increase base depth to 10-12″ and incorporate a drainage layer: 4″ of 1-1/2″ drain rock, topped with filter fabric, then 4″ of crushed aggregate base, and finally the 2″ setting bed. This multi-layer approach prevents subsurface water accumulation that would exploit the higher porosity and create freeze-thaw damage or efflorescence conditions.

Arizona’s caliche layers present unique challenges you must address regardless of color choice. When you encounter caliche at 6-8″ depth during excavation, you can’t simply compact it and call it base—the material’s expansive properties create heaving conditions that destroy flagstone installations. Your specifications must require complete caliche removal to minimum 10″ depth, replaced with properly graded and compacted aggregate. In areas with deep caliche deposits (Tucson basin, Phoenix east valley), you might need to extend excavation to 14-16″ to reach stable subgrade. This adds cost, but there’s no alternative that provides acceptable performance.

For projects where truck access limits base material delivery, you’ll need to adjust specifications. Single-axle trucks can typically deliver 8-10 yards of base material; larger trucks require 12-foot access widths and 14-foot overhead clearance. When you’re working in established neighborhoods with narrow streets or gated communities with access restrictions, coordinate material delivery schedules early in the planning process. Split deliveries increase costs by 25-35% due to mobilization fees, so your project budget needs to reflect actual logistics constraints.

Joint Spacing and Sand Selection for Arizona Climate Conditions

Joint design for Arizona flagstone installations requires you to balance three competing objectives: thermal expansion accommodation, visual aesthetics, and long-term sand retention. Your specifications must address all three factors with climate-appropriate details. For thermal expansion, you need joints that accommodate the material’s 5.8-6.2 × 10⁻⁶ per °F expansion coefficient across 90-100°F daily temperature swings. This requires minimum 3/8″ joints for installations up to 12 feet in any direction, increasing to 1/2″ joints for larger areas.

The sand you specify for joint filling directly impacts long-term maintenance requirements. Standard masonry sand washes out within 18-24 months in Arizona conditions—the combination of monsoon rainfall intensity and wind exposure creates continuous sand loss. You should specify decomposed granite or crushed stone fines in the 1/16″ to 1/8″ size range. These angular materials interlock mechanically and resist washout. Your specifications should include initial filling to 100% joint depth, followed by top-off application at 3 months and 6 months post-installation. After this initial stabilization period, annual top-off maintenance keeps joints at 92-95% capacity—the optimal range for weed suppression without creating ant harvesting attractants.

Joint color selection affects the overall appearance as much as the flagstone color itself. When you specify Arizona Buff flagstone, consider contrasting joint sand in tan or light brown tones—the contrast emphasizes the stone’s natural variations. For Classic Oak flagstone, matching dark brown or gray joint sand creates a more unified appearance. You’ll find that natural flagstone suppliers Arizona near me searches yield suppliers offering pre-blended joint sands designed to complement specific stone colors. These products cost 30-40% more than generic masonry sand, but they deliver superior color coordination and better particle size distribution for long-term retention.

Sealing Requirements: Color-Specific Protocols for Arizona Flagstone

Sealer selection and application protocols vary significantly by flagstone color and porosity. You can’t apply a universal sealing specification across all Arizona flagstone colors—the material characteristics demand customized approaches. For Arizona Buff flagstone (3-6% porosity), you should specify penetrating sealers at manufacturer standard coverage rates (typically 150-200 square feet per gallon for first coat, 200-300 for second coat). The lower porosity means the material accepts sealer gradually; you’ll need 4-6 hour drying time between coats to prevent surface pooling.

Rose and Peach flagstone, with moderate porosity (5-8%), requires slightly elevated application rates—plan for 125-175 square feet per gallon for initial coats. The higher iron oxide content in these colors can create reactions with some solvent-based sealers, causing color darkening that clients often find objectionable. You should specify water-based penetrating sealers for rose and peach tones, accepting the trade-off of 20-25% shorter service life (24-30 months versus 36-48 months) in exchange for color stability.

Classic Oak flagstone demands the most aggressive sealing protocols. With 6-9% porosity, you’re working with material that accepts sealer readily but also releases it more quickly through weathering and UV exposure. Your specifications should include:

- Initial application within 30 days of installation completion

- Two-coat system at 100-150 square feet per gallon coverage

- Reapplication at 18-month intervals for first 5 years

- Annual inspection and spot treatment of high-traffic areas

- Use of sealers with minimum 8-10% solids content for adequate protection

The Arizona sun’s UV intensity degrades all sealers faster than manufacturer literature suggests. Published service life estimates assume 4-5 hours daily UV exposure; Phoenix and Tucson sites experience 8-10 hours during summer months. You should reduce expected sealer life by 30-40% when you calculate maintenance schedules for Arizona installations. This means 3-year sealers realistically provide 20-24 months of protection, and 5-year products deliver 36-42 months. Your maintenance specifications need to reflect these climate-adjusted expectations.

Cost Comparison: Flagstone Wholesale Arizona Pricing by Color and Grade

Understanding material cost structure helps you make informed specification decisions that balance aesthetics, performance, and budget. Current flagstone wholesale Arizona pricing (subject to market fluctuations and fuel surcharges) typically ranges:

- Arizona Buff, 1.5″ nominal, standard grade: $4.50-5.50 per square foot

- Arizona Buff, 1.5″ nominal, premium grade: $5.75-6.75 per square foot

- Peach/Rose, 1.5″ nominal, standard grade: $5.25-6.25 per square foot

- Peach/Rose, 1.5″ nominal, premium grade: $6.50-7.75 per square foot

- Classic Oak, 1.5″ nominal, standard grade: $6.00-7.25 per square foot

- Classic Oak, 1.5″ nominal, premium grade: $7.50-9.00 per square foot

You need to factor additional costs beyond base material pricing. Delivery charges typically add $0.35-0.65 per square foot depending on distance from supplier yard—projects more than 75 miles from source incur premium freight rates. When you coordinate with local flagstone suppliers Arizona colors from regional yards, you minimize delivery costs but might sacrifice some color selection compared to specialty suppliers willing to truck material longer distances.

Installation labor costs vary by color due to handling and cutting requirements. Classic Oak’s higher density increases cutting time by 15-20% compared to buff tones—diamond blades wear faster and cuts proceed more slowly. Your labor estimates should account for $1.50-1.85 per square foot installed for buff flagstone, increasing to $1.75-2.15 per square foot for oak tones in similar applications. Premium grades with tighter thickness tolerances actually reduce installation time by 10-15% because crews spend less time sorting material and adjusting base depths to compensate for thickness variation.

The true cost comparison must include long-term maintenance requirements. When you evaluate 20-year total cost of ownership, Arizona Buff flagstone typically delivers the lowest total cost despite premium grades costing more initially. The combination of lower sealing frequency, reduced stain treatment requirements, and minimal color stability concerns creates maintenance costs of $0.15-0.22 per square foot annually. Classic Oak flagstone, while visually striking, incurs maintenance costs of $0.28-0.38 per square foot annually due to more frequent sealing and cleaning requirements. For commercial projects with 5,000-10,000 square foot installations, this differential compounds to $7,000-12,000 additional maintenance cost over 20 years—a factor you should present to clients during material selection discussions.

Common Specification Mistakes with Arizona Flagstone Colors

Your specifications need to avoid the recurring mistakes that create project delays, cost overruns, and performance failures. The most common error involves specifying color consistency standards without understanding natural stone variation. When you require “uniform color throughout installation” for any natural flagstone, you’re creating an unachievable standard. Natural stone inherently varies by 20-35% across color, pattern, and veining characteristics. Your specifications should address acceptable variation ranges: “color variation within samples provided, with no single piece varying more than 40% from sample set median tone” creates an enforceable standard that acknowledges natural material characteristics.

Another frequent mistake involves thickness specifications that don’t account for installation method. When you specify flagstone for mortar-set applications, thickness consistency matters less because the mortar bed compensates for variation—you can accept ±3/4″ thickness range. But for sand-set installations, thickness consistency directly affects finished surface quality. You must tighten specifications to ±3/8″ for sand-set projects, and you should expect to pay 12-18% premiums for this enhanced sorting. Many specifications simply state “1.5” flagstone” without clarifying tolerance requirements, leading to disputes when material arrives with industry-standard ±1/2″ to ±3/4″ variation that’s unsuitable for the specified installation method.

Inadequate drainage specifications create long-term problems that surface 2-4 years post-installation. When you specify flagstone colors with higher porosity (rose, oak) without enhanced drainage provisions, you’re creating conditions for efflorescence, organic staining, and potential freeze-thaw damage in higher elevations. Your specifications must match base design to material characteristics—this isn’t an area where standardized details work across all applications. You should develop color-specific base details that address each material’s porosity and absorption characteristics.

Sealer specifications frequently fail to address Arizona’s extreme UV exposure. When you specify manufacturer-standard reapplication intervals (typically 3-5 years), you’re understating maintenance requirements by 30-50%. Your specifications need climate-adjusted service life estimates: reduce published intervals by 35-40% for Phoenix and Tucson projects, 25-30% for Prescott and Payson elevations. This transparency prevents maintenance budget surprises and establishes realistic owner expectations. Projects that fail to address climate-adjusted sealing requirements often experience premature weathering, staining, and client dissatisfaction that could have been avoided through proper specification language.

Citadel Stone: Premium Flagstone Suppliers Arizona Solutions for Diverse State Climate Zones

When you consider Citadel Stone’s flagstone offerings for your Arizona project, you’re evaluating premium materials specifically selected for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, from low-desert installations at 1,000 feet elevation to mountain applications above 7,000 feet. This section outlines how you would approach specification decisions for six representative cities, considering each location’s unique environmental conditions and installation requirements.

Arizona’s climate diversity requires you to modify specifications significantly across different regions. Your Phoenix project faces challenges completely different from Flagstaff installations—temperature ranges, precipitation patterns, freeze-thaw exposure, and UV intensity all vary dramatically. You need to understand these regional factors before selecting flagstone colors and developing installation details. The guidance below represents professional specification approaches for hypothetical projects, helping you understand the climate-specific considerations that affect material selection and installation protocols in each region.

Phoenix Applications

In Phoenix, you’ll encounter the most extreme heat conditions in Arizona—summer temperatures regularly exceed 110°F with direct surface exposure creating flagstone temperatures of 145-165°F. Your material selection should prioritize lighter colors: Arizona Buff performs optimally, with Peach as an acceptable alternative for partially shaded areas. You would specify 1.5″ minimum thickness for residential patios and walkways, increasing to 2″ for commercial applications experiencing heavy foot traffic. The extreme heat requires you to design expansion joints every 12 feet maximum, using 3/8″ to 1/2″ joint widths to accommodate 100°F daily temperature swings during summer months. You should recommend penetrating sealers applied at elevated coverage rates (125-150 square feet per gallon) with reapplication intervals of 24-30 months rather than manufacturer-standard 36-48 months. Your base specifications must address Phoenix’s caliche deposits—complete removal to 12″ depth minimum, replaced with crushed aggregate compacted to 95%. For warehouse logistics in Phoenix metro, you would coordinate deliveries during morning hours before surface temperatures exceed 95°F to protect material and facilitate crew handling.

Tucson Considerations

Your Tucson specifications need to account for the basin’s unique combination of extreme heat and clay-heavy soils with high expansion coefficients. You would specify Arizona Buff or Peach flagstone for most applications, reserving darker Rose tones for north-facing or substantially shaded areas. The soil conditions require you to design enhanced base systems: 12-14″ total depth with geotextile fabric separating native soil from aggregate base to prevent clay infiltration. You should specify minimum 6″ of crushed aggregate over 4″ of drain rock to manage subsurface moisture and prevent expansion-related heaving. Tucson’s lower elevation (2,400 feet) creates heat intensity similar to Phoenix, requiring similar expansion joint spacing (12-15 feet) and sealing protocols (24-30 month intervals). The area’s monsoon season delivers intense rainfall from July through September—your drainage design must handle 2-3 inch per hour rainfall intensity with positive drainage away from flagstone surfaces to prevent standing water that would exploit material porosity. You would coordinate material deliveries through local suppliers to minimize freight costs, as Tucson’s distance from northern quarries adds $0.45-0.65 per square foot in transportation charges.

Scottsdale Projects

Scottsdale projects typically involve high-end residential and resort applications where aesthetic expectations exceed standard specifications. You would specify premium grade flagstone with tighter color consistency (±20% variation versus ±35% standard) and enhanced thickness tolerances (±1/4″ versus ±1/2″ standard). Arizona Buff and Peach tones dominate Scottsdale specifications due to their refined appearance and moderate heat retention characteristics. Your installation details should address the area’s hardscape-intensive landscapes—expansive patio areas often exceed 2,000 square feet, requiring you to design multiple expansion zones with soft joints every 15-20 feet to accommodate thermal movement without creating visual disruption. You should specify decorative joint treatments using crushed stone fines in complementary colors rather than standard masonry sand. Sealing requirements follow Phoenix protocols (24-30 month reapplication), but you might specify color-enhancing sealers that deepen tone while providing protection—these products cost 25-35% more but deliver the visual richness clients in this market expect. Scottsdale’s established neighborhoods often limit truck access, requiring you to coordinate deliveries with smaller vehicles or plan material staging areas outside gated entries.

Flagstaff Requirements

Your Flagstaff specifications must address freeze-thaw cycling that reaches 50-70 events annually at 7,000 feet elevation. You would specify flagstone with proven freeze-thaw resistance: Arizona Buff with porosity below 5% and water absorption below 3% by weight. Rose and Oak colors, with their higher porosity ranges, present excessive spalling risk in Flagstaff conditions and should be avoided unless laboratory testing confirms adequate freeze-thaw durability. You need to specify 2″ minimum thickness for all applications to provide adequate structural mass for thermal cycling resistance. Your base design must include enhanced drainage: 14-16″ total depth with 6″ of drain rock, geotextile separation fabric, 6″ crushed aggregate base, and 2″ setting bed of coarse sand. This multi-layer system prevents subsurface freezing conditions that would heave flagstone surfaces. You should specify cold-weather installation protocols: no installation when ambient temperatures fall below 35°F, and protection provisions for newly installed areas if freezing temperatures are forecast within 72 hours. Joint spacing increases to 1/2″ minimum to accommodate freeze-expansion of any residual moisture in stone pores. Sealer selection requires water-based penetrating products that won’t trap moisture—solvent-based sealers that create surface films can trap water and exacerbate freeze damage. At Citadel Stone, we would recommend coordinating warehouse deliveries during summer months to ensure material availability before winter weather restricts truck access to mountain job sites.

Sedona Aesthetics

Sedona projects demand color coordination with the area’s distinctive red rock formations—your flagstone selection should complement rather than compete with the natural landscape. You would typically specify Rose and Peach flagstone tones that harmonize with Sedona’s geological palette, avoiding buff colors that create excessive contrast. The 4,500 foot elevation creates moderate climate conditions—less extreme heat than Phoenix, but 15-25 freeze-thaw cycles annually that require attention in specifications. You should specify material with 4-6% porosity and design base systems with adequate drainage: 10-12″ total depth with drainage provisions to handle Sedona’s rocky, often impermeable native soils. The area’s high-end residential and resort market demands premium grade material with enhanced color consistency and thickness tolerances. You would specify 1.5″ minimum thickness for most applications, with honed or thermal surface finishes that provide slip resistance while maintaining refined appearance. Joint design should use colored sands in warm earth tones (red-brown, terra cotta) to reinforce the regional aesthetic. Sealing protocols require UV-resistant penetrating sealers applied at 30-36 month intervals—the moderate elevation reduces UV intensity compared to low desert locations, extending sealer service life by 20-25%. Sedona’s tourism-driven economy means you need to coordinate installation schedules around peak visitor seasons, and truck access to many residential areas requires specialized knowledge of local roads and private drives.

Yuma Challenges

Yuma presents unique specification challenges due to extreme heat (average high temperatures exceed Phoenix by 2-4°F) combined with Colorado River valley soil conditions that include high alkalinity and periodic salt exposure from agricultural runoff. You would specify exclusively Arizona Buff flagstone for Yuma applications—lighter colors provide essential heat mitigation, and the lower porosity (3-5%) offers better resistance to salt infiltration that creates efflorescence in higher-porosity materials. Your base specifications must address alkaline soils with pH values often exceeding 8.5—you should require geotextile fabric separation between native soil and imported aggregate base to prevent alkali migration that accelerates efflorescence. You need to specify aggressive sealing protocols: initial two-coat application within 30 days of installation, followed by reapplication at 18-24 month intervals to maintain salt-barrier protection. Joint sand selection should avoid calcareous materials that contribute additional alkali content—specify silica-based sands or crushed granite fines instead. The extreme heat requires you to design expansion joints every 12 feet with 1/2″ minimum width to handle daily temperature swings that can reach 110°F (from 50°F winter nights to 120°F summer days, or 90°F daily swings during summer from overnight lows to afternoon peaks). Yuma’s agricultural economy means truck access is generally excellent with wide roads designed for farm equipment, but summer heat requires you to schedule deliveries before 9 AM to protect material and workers during handling. You would coordinate with Arizona flagstone suppliers locations in Phoenix or Tucson for material sourcing, as Yuma’s distance from quarry areas adds $0.55-0.75 per square foot in freight charges.

Regional Availability and Delivery Logistics Across Arizona

Your project success depends partly on understanding Arizona’s flagstone distribution network and how regional logistics affect material availability and cost. The state’s geography creates natural supply zones: northern quarries near Prescott and areas north serve Flagstaff, Sedona, and Prescott valley; central distribution through Phoenix metro serves the broader Phoenix area, Scottsdale, and east valley communities; southern supply networks from Tucson serve southern Arizona including Yuma (though distance creates cost challenges). When you specify projects, you should identify the nearest warehouse facilities and verify stock levels before committing to project timelines.

Lead times vary significantly by color and grade. Arizona Buff flagstone, being highest-volume production material, typically ships within 5-10 business days from order to delivery for standard grades in common thicknesses. Premium grades require additional sorting time—expect 10-15 business days. Specialty colors (Rose, Oak) often require 3-4 week lead times because suppliers maintain lower inventory levels and may need to coordinate quarry production runs to fulfill larger orders. When you’re working on projects requiring 5,000+ square feet of specialty colors, you should initiate procurement 8-10 weeks before needed installation date to ensure material availability.

Delivery logistics affect your installation schedule and budget. Standard truck deliveries accommodate pallets weighing 3,000-4,000 pounds—a typical pallet covers 120-150 square feet of 1.5″ flagstone. Your job site needs adequate access: minimum 12-foot width, 14-foot overhead clearance, and firm surfaces capable of supporting 40,000-pound gross vehicle weight. Many residential neighborhoods don’t meet these requirements, necessitating smaller delivery vehicles that cost 20-30% more per square foot delivered, or requiring material staging at off-site locations with transfer to smaller trucks. You should conduct site access evaluation during design phase to prevent delivery surprises that delay installation schedules.

Essential Guidelines

Your flagstone specification process for Arizona projects requires you to synthesize climate factors, material characteristics, installation protocols, and logistics constraints into comprehensive project documents. The color you select establishes the foundation for all subsequent decisions—thermal performance, sealing requirements, maintenance expectations, and cost implications all flow from this initial choice. You should evaluate each color option against specific project parameters: exposure orientation, elevation and climate zone, client maintenance expectations, and budget limitations including long-term ownership costs, not just initial material pricing.

Professional specifications demand detail beyond generic industry standards. You need to customize expansion joint spacing for Arizona’s extreme temperature swings, adjust sealer reapplication intervals for intense UV exposure, and design base systems that address regional soil conditions from caliche deposits to expansive clays. The specifications that work in moderate climates fail in Arizona conditions—you must develop climate-specific details or accept premature weathering and potential failure. Your documents should address acceptable color variation ranges, thickness tolerances matched to installation method, and quality standards that create enforceable procurement criteria.

When you coordinate with suppliers, verify specific capabilities beyond basic color availability. Can they provide enhanced sorting for tighter thickness tolerances? Do they maintain adequate inventory to support your project schedule, or will you need to build additional lead time for quarry production runs? What are delivery logistics for your specific site—standard truck access or premium charges for specialized delivery equipment? These practical considerations affect project feasibility as much as aesthetic design decisions. For comprehensive material performance data and installation best practices, review Natural flagstone material characteristics and grading standards for Arizona before you finalize your project documents. Walkway installations feature Citadel Stone, the most durable Flagstone Suppliers Arizona climate demands.